Professional Documents

Culture Documents

Om Grup Assignment

Uploaded by

Nor Saadiah Mat DaliOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Om Grup Assignment

Uploaded by

Nor Saadiah Mat DaliCopyright:

Available Formats

Best practices for improving warehouse picking productivity

Order picking is one of the essential functions of a warehouse operation. Utilizing the right picking

methodologies, leveraging technology to streamline processes and following sound hiring practices will

go a long way in optimizing your workflows and contributing to the bottom line.

To help you further optimize order fulfillment workflows, let’s take a look at best practices for improving

warehouse picking productivity.

Design your warehouse for optimal flow

Each functional area of your warehouse should be designed and positioned to flow from one activity to

the next. This design is based on how inventory flows through each area, from receiving to outbound

shipment. For instance, goods flow through a typical warehouse this way: Receiving – Storage –

Replenishment – Order picking – Sorting – Packing – Shipping.

Such a logical flow of inventory eliminates scenarios in which associates have to double back across

areas to perform an order fulfillment activity. Also, each area should be designed to accommodate the

expected amount of traffic. Aisles should be wide enough to facilitate the smooth flow of associates and

equipment without causing congestion — even during periods of high-volume traffic.

How to prevent excess and obsolete inventory?

4 steps to reduce excess and obsolete inventory

Identify your excess and obsolete inventory.

Evaluate whether the excess inventory is 'risky' (could become obsolete)

Understand the causes of your excess and obsolete inventory.

Use these rules as proactive strategies to help prevent excess and obsolete inventory.

Customizing at delivery Customizing vans at delivery rather than at production

Postponemen

t

1. Identify your excess and obsolete inventory

Try to categories your stock into three categories:

Healthy inventory: Also called cycle stock. This is the inventory you plan to sell, based on demand

forecasts.

Excess inventory: When stock levels for a product plus buffer stock exceed forecasted demand.

Obsolete inventory: When stock remains in the warehouse and there is no demand for it over a

prolonged period of time (typically for at least 12 months).

This information is a great starting point to understand if you have a problem with excess and obsolete

inventory.

2. Evaluate whether the excess inventory is ‘risky’ (could become obsolete)

Sometimes it’s OK to have higher levels of stock than demand requires. For example, if you have high

volumes of fast-moving items that continuously sell well, no problem! You can easily lower current stock

levels by reordering less and using up the surplus.

However, excess stock becomes a risk when you have high volumes of items sat in your warehouse that

are slow moving or have volatile demand e.g periods of low or no sales, or have declining demand i.e

they are coming to the end of their product life cycle. You therefore need to identify these items and put

a plan together to reduce their stock levels and prevent obsolescence.

3. Understand the causes of your excess and obsolete inventory

There can be many reasons why you have excess inventory. Most often it’s down to:

1. Poor demand forecasting capabilities

2. Needing to mitigate supply risks e.g the consequences of a no-deal Brexit or regularly inconsistent

supplier lead times

3. A desire to ensure 100% stock availability (service levels)

4. A complex supply chain (this could be multi-tier (echelon) or multi-site)

5. Purely bad decisions

4. Use these rules as proactive strategies to help prevent excess and obsolete inventory

Rule one: Prevent excess inventory with better demand forecasting

If your demand forecasting regularly leads to over or under stocking, it’s time to look at ways to improve

it. For starters, forecasting based on number of stock days is an over-simplistic and inadequate method

for predicting demand. Instead you need to consider moving to demand forecasting techniques that will

take into account demand trends, seasonality and promotional activity.

Statistical demand forecasting carried out by inventory optimization software, such as EazyStock, will

analyses every product in your portfolio and assign a demand type according to its position in the

product life cycle. This means that as a product moves through the growth, maturity and decline stages,

and its demand patterns change as a consequence, the algorithms used to calculate demand will also

dynamically update to make forecasts as accurate as possible.

Read more on demand forecasting accuracy or EazyStock’s demand forecasting software.

Rule two: Don’t use excess stock to mitigate supply risks

Carrying excess stock is not the answer to alleviating issues with your supplier lead times. Instead you

need to address this problem by:

Planning for supplier holidays in advance: If you know when your suppliers shut down e.g for annual

holidays, Chinese New Year etc, add these periods of closure to your lead times and adjust reordering

points accordingly.

Monitoring supplier lead times: Keep track of your suppliers’ lead times – are they sticking to their

service level agreements, or are they often late? If it’s the latter, get the issue sorted at source. In the

meantime, add adequate safety stock, (buffer stock) to your inventory to cover delays.

Read our post on effective inventory replenishment for more information on managing supply and

demand variables to reduce excess inventory.

Rule three: Stop carrying excess inventory to prevent stockouts

It’s a massive misconception to think that holding lots of stock is the only way to ensure product

availability – this is simply not the case!!! Of all the tips in this post, this is the biggest takeaway. It’s

possible to have high service levels and achieve excellent stock availability without carrying high

volumes of every item in your warehouse. The key is to use inventory optimisation techniques when

setting your stocking policies.

This means going beyond simple ABC analysis. Instead, you need to priorities which inventory items to

carry based on multi-dimensional criteria, such as demand types, pick frequency, demand volatility and

cost to sell (or profitability). This allows you to set the stock levels of every item in your warehouse

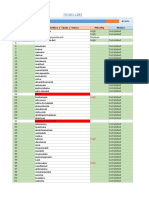

according to how well it sells and how much it costs the business. A typical inventory policy matrix may

look something like this:

Here, the items in the light orange, bottom right categories are picked most frequently and are cheap

the sell, so are usually stocked in greater quantities than those dark orange, that are picked less and are

more expensive to the business.

Every company’s inventory matrix will look different (and you can have more than one for different

product categories), for example, a catalogue business may wish to stock all items and would therefore

have all boxes shaded in to some degree.

For each category, you should set a service level (stock availability) target. Typically, these would be

higher for products that are picked more frequently and have a lower cost to sell. The aim is to find a

balance between the capital you invest in stock, versus your ideal availability targets.

With stocking policies in place for every SKU that define individual stock levels and associated fulfilment

targets, the risk of excess and obsolete inventory is dramatically reduced.

Obviously, creating an inventory matrix with this much detail could be very challenging without

inventory optimisation software. A tool such as EazyStock will undertake all the hard work for you and,

as demand, pick frequency and costs change, will automatically move inventory from box to box,

dynamically adjusting recommended stocking levels.

Rule 4: Optimise inventory levels along your supply chain

If you have a multi-tier (echelon) supply chain or carry stock across multiple locations it can be difficult

to prevent excess inventory from building up. For example, if you have decentralized ordering its very

common for inventory planners to order ‘a little extra’ and inflate their forecasts to cover the risk of run-

out. But do this across each stock location and these ‘little extras will amount to high levels of surplus

stock.

The answer is to plan and manage inventory with one centralized view. Systems, such as EazyStock,

allow forecasting and reordering to be based on point-of-sale demand data, not demand at each stage

of the supply chain. In addition, with a view of stock levels across all locations, inventory can be

balanced out. This means excess stock at one location can be redistributed to other sites, where levels

of the same item are low, before needing to order more from the supplier.

By managing your inventory across all echelons, or locations you’ll quickly remove surplus stock from

your supply chain and the risk of obsolete items appearing on warehouse shelves.

Rule 5: Buy stock wisely

It’s easy to be tempted to buy in bulk to get the best price on an order. And, if the items will move

quickly off the shelves, it may not be a bad idea. But, if it the goods are slower-moving with erratic or

declining demand, you should think again. It’s no good getting a cheap price for inventory that’s going to

tie up capital and even worse, be at risk of becoming obsolete and sold at a discounted rate.

Excess inventory may also be a result of setting your minimum order quantities too high. If this is the

case, renegotiate! Do the math’s: it may be better to pay a higher unit rate for smaller order quantities,

than have cash tied up in stock that isn’t moving fast enough through the warehouse.

Summary

Excess and obsolete inventory can be very problematic to businesses, and finding proactive ways to

prevent stock build up can bring major benefits. Improved cash flow, more working capital, a better

inventory turnover ratio and lower storage costs will all help ensure a healthy profit margin.

You might also like

- Supply Chain ManagementDocument8 pagesSupply Chain ManagementEr Shammi KumarNo ratings yet

- Pros of Bulk ShipmentsDocument16 pagesPros of Bulk ShipmentsGraceCayabyabNiduazaNo ratings yet

- Inventory ControlDocument7 pagesInventory ControlTamene GeletuNo ratings yet

- Inventory MAnagement TechniquesDocument12 pagesInventory MAnagement TechniquesMarlon ReyesNo ratings yet

- Receiving and Managing New StocksDocument17 pagesReceiving and Managing New StocksSatish Reddy Karri (PGDM 17-19chn)No ratings yet

- Term Paper On Inventory Management W.R.T. Retail IndustryDocument17 pagesTerm Paper On Inventory Management W.R.T. Retail IndustryAbbas Ansari100% (4)

- What Is Inventory ManagementDocument28 pagesWhat Is Inventory ManagementArfe Lanhac RaganasNo ratings yet

- Stock Control and InventoryDocument8 pagesStock Control and Inventoryadede2009No ratings yet

- Functions of InventoryDocument22 pagesFunctions of InventoryAshiqul Islam100% (4)

- Inventory ManagementDocument5 pagesInventory ManagementVarshaNo ratings yet

- Inventory ManagementDocument28 pagesInventory ManagementLaica PentuanNo ratings yet

- Inventory Management: Organization's Policies, Procedures and Practices May IncludeDocument6 pagesInventory Management: Organization's Policies, Procedures and Practices May IncludenigusNo ratings yet

- Material ControlDocument4 pagesMaterial ControlNor Saadiah Mat DaliNo ratings yet

- Introduction of Inventory Management SelectedDocument26 pagesIntroduction of Inventory Management Selectedsradavadkar1973No ratings yet

- Inventory Finals ReportDocument42 pagesInventory Finals ReportMazey AustriaNo ratings yet

- Retail InvontryDocument47 pagesRetail InvontryManoj Kumar.SNo ratings yet

- Inventory Final 97-03Document62 pagesInventory Final 97-03navneet9702No ratings yet

- Project On Inventory MangementDocument16 pagesProject On Inventory MangementJYOTI VERMA100% (1)

- Inventory LossDocument8 pagesInventory LosselizarNo ratings yet

- Inventroy ControlDocument28 pagesInventroy ControlSathya BharathiNo ratings yet

- Inventory Goods and MaterialsDocument3 pagesInventory Goods and MaterialsJeevan ChoudharyNo ratings yet

- Inventory and Working Capital ManagementDocument61 pagesInventory and Working Capital ManagementRomuell BanaresNo ratings yet

- Untitled DocumentDocument12 pagesUntitled DocumentBaishali RoyNo ratings yet

- What Is Inventory 1Document17 pagesWhat Is Inventory 1sriramimNo ratings yet

- PSM 104 Lesson FourDocument6 pagesPSM 104 Lesson FourgregNo ratings yet

- Warehouse Management Semis1 Warehouse Process From Replenishment To DispatchDocument9 pagesWarehouse Management Semis1 Warehouse Process From Replenishment To DispatchJay GalleroNo ratings yet

- Payal PPT RetailDocument16 pagesPayal PPT Retailvinit PatidarNo ratings yet

- 5272833396Document3 pages5272833396pranalibhote471No ratings yet

- Difficulty: Easy Time Required: 5 Min. Here's How:: What Is Inventory?Document14 pagesDifficulty: Easy Time Required: 5 Min. Here's How:: What Is Inventory?Gunasekar ManickamNo ratings yet

- Best Inventory Management Techniques You Need To KnowDocument5 pagesBest Inventory Management Techniques You Need To KnowManoj Kumar MannepalliNo ratings yet

- Warehouse Process From Replenishment To DispatchDocument9 pagesWarehouse Process From Replenishment To DispatchErika ApitaNo ratings yet

- Or 2011Document2 pagesOr 2011stabrezhassanNo ratings yet

- 6 Inventory Control TechniquesDocument8 pages6 Inventory Control TechniquesAngel TagudNo ratings yet

- Inventory Refers To Idle Goods or Materials That Are Held by An Organization For Use Sometime in The FutureDocument14 pagesInventory Refers To Idle Goods or Materials That Are Held by An Organization For Use Sometime in The FutureASM NASIMNo ratings yet

- Inventory Management TechniquesDocument6 pagesInventory Management TechniquessankasturkarNo ratings yet

- Advantages and Disadvantages of InventoryDocument3 pagesAdvantages and Disadvantages of InventoryAditi Rajvanshi79% (14)

- Activity - Chapter 9Document9 pagesActivity - Chapter 9Michael CruzcabreraNo ratings yet

- LM Imp TopicsDocument17 pagesLM Imp TopicsPallavi SinhaNo ratings yet

- Min Max LevelsDocument7 pagesMin Max LevelsUday JoshiNo ratings yet

- Inventory ModelsDocument3 pagesInventory ModelsRaihan RakibNo ratings yet

- What Is Inventory ManagementDocument9 pagesWhat Is Inventory ManagementmartgetaliaNo ratings yet

- Retail Analytics Unit 3Document19 pagesRetail Analytics Unit 3Adarsh DashNo ratings yet

- Manjunath ProjectDocument32 pagesManjunath ProjectGanesh SravistaNo ratings yet

- Wareshouse and InventoryDocument8 pagesWareshouse and InventoryAnooshaNo ratings yet

- Setting Up and Designing Your Warehouse LayoutDocument13 pagesSetting Up and Designing Your Warehouse LayoutSiew Ming SooNo ratings yet

- Risk PoolingDocument3 pagesRisk PoolingÄyušheë TŸagïNo ratings yet

- Ten Ways To Reduce InvDocument4 pagesTen Ways To Reduce InvMurat GüventürkNo ratings yet

- Inventory AssDocument3 pagesInventory AssJudd Ralph SamaniegoNo ratings yet

- Deciding Timely Replenishment of StocksDocument2 pagesDeciding Timely Replenishment of StocksDaniella Mae ElipNo ratings yet

- Operations Management Answer 1Document8 pagesOperations Management Answer 1shiv panjnaniNo ratings yet

- Warehousing Fundamentals, Inventory ManagementDocument18 pagesWarehousing Fundamentals, Inventory ManagementNayan NagmotiNo ratings yet

- Activity ProfilingDocument9 pagesActivity ProfilingSafijo AlphonsNo ratings yet

- Contemporary Logistics 11th Edition Murphy Test BankDocument19 pagesContemporary Logistics 11th Edition Murphy Test Bankdieulienheipgo100% (31)

- Week - 2 LAQ - Operations ManagementDocument6 pagesWeek - 2 LAQ - Operations Managementbabitha76260No ratings yet

- MODULE 7 - Inventory ManagementDocument31 pagesMODULE 7 - Inventory ManagementBelle BeautyNo ratings yet

- Chapter Three Inventory ControlDocument18 pagesChapter Three Inventory Controlkidanemariam HabtemariamNo ratings yet

- Internal Assignment Applicable For June 2022 Examination: Operations ManagementDocument12 pagesInternal Assignment Applicable For June 2022 Examination: Operations ManagementShruti MakwanaNo ratings yet

- FIN AC 1 - Module 5Document17 pagesFIN AC 1 - Module 5Jackie Lyn Bulatao Dela PasionNo ratings yet

- UNIT IV Inventory ControlDocument7 pagesUNIT IV Inventory ControlMuchaelNo ratings yet

- Dropshipping: Unleashing the Power of E-commerce and Dropshipping (The Ultimate Guide to Building an Ecommerce Business and Earning Passive Income)From EverandDropshipping: Unleashing the Power of E-commerce and Dropshipping (The Ultimate Guide to Building an Ecommerce Business and Earning Passive Income)No ratings yet

- Principles of Business Handout # 17 Grade 10.Document3 pagesPrinciples of Business Handout # 17 Grade 10.Da bertNo ratings yet

- Bus 5114 Discussion Assignment 01 - 07Document3 pagesBus 5114 Discussion Assignment 01 - 07Sheu BasharuNo ratings yet

- Path-Goal Theory PPT (Hibba)Document11 pagesPath-Goal Theory PPT (Hibba)Capt. Sohail AhmadNo ratings yet

- You Exec - Key Account Management FreeDocument11 pagesYou Exec - Key Account Management FreeEnrique ArinNo ratings yet

- Bc210426441 (MGT501)Document2 pagesBc210426441 (MGT501)shahbaz shahidNo ratings yet

- CIPS L4M6 V5.0 Mock TestDocument10 pagesCIPS L4M6 V5.0 Mock TestAbdallah100% (2)

- Rekap Excel To Do List Template Drop Down List - v1Document3 pagesRekap Excel To Do List Template Drop Down List - v1roziyayanNo ratings yet

- Chhaya Resume (1) - 1Document1 pageChhaya Resume (1) - 1chhayaNo ratings yet

- Corporate Governance AssignmentDocument6 pagesCorporate Governance AssignmentAshika PrasadNo ratings yet

- GROUP 1 BA 316 DocumentDocument11 pagesGROUP 1 BA 316 DocumentKhim NaulNo ratings yet

- Purpose of The ReportDocument2 pagesPurpose of The ReportDomnic OnyangoNo ratings yet

- Chap Leo 2013Document12 pagesChap Leo 2013Teodora Maria DeseagaNo ratings yet

- School Directory: SeoniDocument202 pagesSchool Directory: SeoniUnknown PersonNo ratings yet

- Submission: Subject: To Offer New Course "Logistics and Supply Chain Management" at IITRAMDocument2 pagesSubmission: Subject: To Offer New Course "Logistics and Supply Chain Management" at IITRAMDileep GuptaNo ratings yet

- Performance Apprails Answer KeyDocument3 pagesPerformance Apprails Answer KeyblockettNo ratings yet

- Marketing Management: Developing Marketing Strategies & PlansDocument40 pagesMarketing Management: Developing Marketing Strategies & PlansHiba KhanNo ratings yet

- Together We LeadDocument8 pagesTogether We LeadBurjuman JumeirahNo ratings yet

- Pmi DassmDocument68 pagesPmi DassmErik BRENA LORANo ratings yet

- CourseraDocument12 pagesCourseraRODOLFO ENRIQUE PEREZ SALAZARNo ratings yet

- Business-To-Business-Marketing-How-To-Understand-1 - Annas-Archive-1Document100 pagesBusiness-To-Business-Marketing-How-To-Understand-1 - Annas-Archive-1Caian MoreiraNo ratings yet

- Importance of Human Resource Management in An Organization: By: Amulya PDocument7 pagesImportance of Human Resource Management in An Organization: By: Amulya PVarshini NagarajuNo ratings yet

- Eds Chapter 2 MsmeDocument27 pagesEds Chapter 2 MsmeharshuNo ratings yet

- CVSyed HassanDocument4 pagesCVSyed HassanAliya HussainNo ratings yet

- Nur Fakhira Muhamad Ia1Document14 pagesNur Fakhira Muhamad Ia1MUHAMMAD ZARIF IQMAL ZOLKIFLYNo ratings yet

- Integrated: 29 March 2020 - 3 April 2021Document133 pagesIntegrated: 29 March 2020 - 3 April 2021Henry Sicelo NabelaNo ratings yet

- Practice Career ProfessionalismDocument21 pagesPractice Career ProfessionalismIvy Macairan - RodriguezNo ratings yet

- Recap Slides - Agile LeadershipDocument46 pagesRecap Slides - Agile LeadershipLisario Conde100% (2)

- Tsinukal BezabihDocument190 pagesTsinukal BezabihSirgut TesfayeNo ratings yet

- Chapter 2 Operation StrategyDocument11 pagesChapter 2 Operation StrategyBiraj GhimireNo ratings yet

- Module 6 - SMDocument7 pagesModule 6 - SMFaiz RautNo ratings yet