Professional Documents

Culture Documents

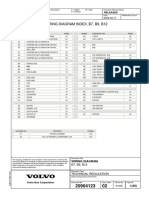

Volvo FH 16 Electrical

Volvo FH 16 Electrical

Uploaded by

fetrian IvabOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Volvo FH 16 Electrical

Volvo FH 16 Electrical

Uploaded by

fetrian IvabCopyright:

Available Formats

New Volvo FM and FH Truck Electrical Harnesses

Technical Data-Design and Compliance

General

The latest generation Volvo FM and FH trucks have an electrical system based on TEA2+ Data Bus

technology. This design is significantly different to the previous generation FM and FH trucks.

Located in the chassis is a Front Input/Output Module (FCIOM), a Central Chassis Input/Output

Module (CCIOM) and a Rear Chassis Input/Output Module (RCIOM). These modules control the

various chassis mounted electrical components located in their region.

A new high integrity corrugated harness cover (Monoflex) has been introduced with the new

electronic architecture.

The new electrical harnesses have been determined by Volvo to comply with the requirements of

Australian Standard AS 2809.1-2008.

Identifying New FM and FH Truck Chassis

The simplest method of identification is by chassis number. The new models use a “20000” series

chassis number and retain the original “D” prefix. Eg. D 201501.

Chassis VIN number is stamped into the right front chassis rail adjacent to the right front wheel. It

also appears on the vehicle ID and manufacturer’s plate located in the door aperture.

Harness Design

The new Monoflex harness material uses a 2 piece self-locking self-sealing corrugated outer

covering that allows greater harness filling for a given diameter. It uses the same snap lock branch

connecters as the previous generation tubular corrugated harness material.

PO Box Address Telephone Volvo Group Australia

916 Summer Park 36 Viking Dr +61 7 3258 7500 Pty Ltd

Qld Wacol ABN 27 000 761 259

Australia Qld 4076

IP67 rated cam lock connectors with double lip seals and wire entry grommet seals are used at

Input/Output modules. Other connectors use double lip seals and wire entry grommet seals.

The harness cover is taped with aerospace grade tape at close intervals. Close attention is paid to

cable support and routing in the chassis to maximise harness integrity.

Monoflex is a 2 piece self-locking, self-sealing cover material. It is totally different to “Split

Conduit” which is widely used in the Automotive Industry. “Split Conduit” has no sealing properties

at all and should not be used in reference to the new generation Volvo harness cover material.

Compliance

The previous model Volvo FM and FH truck corrugated harness material met both the International

Carriage of Dangerous Goods by Road (European ADR) and Australian Standard ASA2809.1-2008

requirements as referred to in Safe Load Pass (SLP) program. The new Monoflex material harnesses

have been designed to meet the same standards as the previous generation harnesses and have the

same functional requirements. The European ADR regulation covers vehicles intended to carry

explosives, low flash point liquids, flammable gases and mobile explosive mixing units (MEMU).

No change has been made to the harness material specification so the new harnesses will meet the

same technical demands as the previous tubular corrugated hose material.

The new harness material reduces bundle sizes giving safer more reliably packaged harness

installations. The risk of chafing is reduced.

The reduced harness bundle sizes improve access for bodybuilder electrical installation and

contribute to the reliability of secondary installations. The new harness material has been fully tested

by Volvo to meet the same high demands as the previous harness material by endurance testing, field

testing and rig testing.

Compliance Summary:

Complies with AS 2809.1

Complies with ASNZS 61386.1:2012 Part1 and Part23

Meets property requirements for:

o Bending

o Flexing

o Collapse

o Bonding

o Thermal properties

o Electromagnetic compatibility

o Fire

o Ingress of water

o Ingress of foreign solid objects (dust etc.)

Bev Gray Moffatt

Application Engineer - Volvo Group Australia

PO Box Address Telephone Volvo Group Australia

916 Summer Park 36 Viking Dr +61 7 3258 7500 Pty Ltd

Qld Wacol ABN 27 000 761 259

Australia Qld 4076

You might also like

- Engine D13a-1Document55 pagesEngine D13a-1Nandu kumarNo ratings yet

- Autocom 2020 Installation InstructionsDocument12 pagesAutocom 2020 Installation InstructionsRemigiusz GolanowskiNo ratings yet

- Spare Parts Catalog: 16 S 151 IT Material Number: 1315.041.719 Current Date: 29.10.2013Document94 pagesSpare Parts Catalog: 16 S 151 IT Material Number: 1315.041.719 Current Date: 29.10.2013Муслим КадралиевNo ratings yet

- NOx Exceedance - Root Cause Unknown First Level P11609BDocument1 pageNOx Exceedance - Root Cause Unknown First Level P11609BlibertyplusNo ratings yet

- 59344-3 MID 136 SID 66 Modulator Trailer CheckDocument5 pages59344-3 MID 136 SID 66 Modulator Trailer CheckTun Tun Win KseNo ratings yet

- WLAN Setup Instructions VOCOM II ToughDocument18 pagesWLAN Setup Instructions VOCOM II Toughyasernaji100% (1)

- Volvo fh4 Apm CodesDocument3 pagesVolvo fh4 Apm CodesRajNo ratings yet

- 21-129 Exhaust Pressure Sensor, Closed Loop Butterfly-23-08-2010Document2 pages21-129 Exhaust Pressure Sensor, Closed Loop Butterfly-23-08-2010yazeed naiban100% (2)

- Volvo Fh4 Euro 6: Installation Manual Emulator U1Document5 pagesVolvo Fh4 Euro 6: Installation Manual Emulator U1Luisyxime Luisyxime100% (1)

- Location, EBS-3 ECU (D376)Document1 pageLocation, EBS-3 ECU (D376)Daniel PricopNo ratings yet

- 89079502-Wiring Diagram VM EM-EU5.PDF 12121Document96 pages89079502-Wiring Diagram VM EM-EU5.PDF 12121willanNo ratings yet

- Ebs PDF Vacuum Tube Steering PDFDocument2 pagesEbs PDF Vacuum Tube Steering PDFGabriel Cayetano MurilloNo ratings yet

- Diagnostico Motor B8RDocument13 pagesDiagnostico Motor B8Rfrancisco soto madariaga100% (3)

- Truck Adblue Emulator For SCANIA INSTRUCTIONS PDFDocument4 pagesTruck Adblue Emulator For SCANIA INSTRUCTIONS PDFobd2works100% (1)

- Scania Pseries Workshop Manual - Removing Front SpringDocument1 pageScania Pseries Workshop Manual - Removing Front SpringocnogueiraNo ratings yet

- FH (4) - April2014 1 (100 200)Document101 pagesFH (4) - April2014 1 (100 200)Paulo canassaNo ratings yet

- Instruction XCOM On 4 SeriesDocument3 pagesInstruction XCOM On 4 SeriesscaniaNo ratings yet

- ICDocument2 pagesICsengottaiyanNo ratings yet

- Deciphering The Volvo Chassis Number: - Prior To 2004, It Has With Separate Series For Each Chassis ProducedDocument3 pagesDeciphering The Volvo Chassis Number: - Prior To 2004, It Has With Separate Series For Each Chassis ProducedJohn Gabriel IbayNo ratings yet

- PDF Produtos Frenodiag Icones ClicaveisDocument17 pagesPDF Produtos Frenodiag Icones Clicaveisrafael pena100% (1)

- Speed Sensor and Cable Harness, Replace PDFDocument8 pagesSpeed Sensor and Cable Harness, Replace PDFEsam Phlipe0% (1)

- Volvo Fh4 Fm4 Renault K T C Euro5 Euro6Document11 pagesVolvo Fh4 Fm4 Renault K T C Euro5 Euro6Xair3No ratings yet

- Diagrama B7, B9, B12 BEA II PDFDocument98 pagesDiagrama B7, B9, B12 BEA II PDFjoseNo ratings yet

- Install Volvo EURO 6 AdBlue Emulator With RetarderDocument7 pagesInstall Volvo EURO 6 AdBlue Emulator With RetarderMasmas MasNo ratings yet

- Location: Volvo Construction Equipment Customer SupportDocument13 pagesLocation: Volvo Construction Equipment Customer SupportLeopoldo Del Campo100% (1)

- PowertronicDocument4 pagesPowertronicsherzad100% (2)

- 15-Pole Trailerconnection ADRDocument18 pages15-Pole Trailerconnection ADRЕвгений Аксёнов100% (1)

- Fault Codes: STO U AndriivDocument14 pagesFault Codes: STO U AndriivAtochkavNo ratings yet

- FH 4 Multiplicação Interna QTS PDF - PDF - Steering - Anti Lock Braking SystemDocument183 pagesFH 4 Multiplicação Interna QTS PDF - PDF - Steering - Anti Lock Braking Systembouchaib crouch100% (1)

- 89595948-Wiring Diagram VM EM-EU5 - EU6Document124 pages89595948-Wiring Diagram VM EM-EU5 - EU6Rhuan FavorettiNo ratings yet

- Renault enDocument180 pagesRenault enMATIASNo ratings yet

- 04 PDFDocument146 pages04 PDFEli RochaNo ratings yet

- Planos Electricos Bus Articulado B12M VolvoDocument61 pagesPlanos Electricos Bus Articulado B12M VolvoAlejandro LenisNo ratings yet

- Power TronicDocument16 pagesPower TronicSherzad Chem100% (1)

- 1a Catálogo CompletoDocument77 pages1a Catálogo CompletoSuyla Cabral100% (1)

- Safari - 31-Oct-2018 at 11:23Document1 pageSafari - 31-Oct-2018 at 11:23petrishiaNo ratings yet

- Station 3 Ngs Support, I&m Engines TPM Uk 2017.01Document65 pagesStation 3 Ngs Support, I&m Engines TPM Uk 2017.01jose breno vieira silva100% (2)

- MID 150 Electronically Controlled Suspension, Fault CodesDocument7 pagesMID 150 Electronically Controlled Suspension, Fault CodesOscar VargasNo ratings yet

- Ebs PDF Vacuum Tube SteeringDocument1 pageEbs PDF Vacuum Tube Steeringᠡᠷᠳᠡᠨᠢ ᠡᠷᠳᠡᠨᠢNo ratings yet

- Sops ListDocument64 pagesSops ListPaul Galvez100% (1)

- Renault Truck C, D, K, T описаниеDocument259 pagesRenault Truck C, D, K, T описаниеAnatoliiNo ratings yet

- Mid 185 - Sid 254 - Fmi 9Document3 pagesMid 185 - Sid 254 - Fmi 9AkbarNo ratings yet

- Qdoc - Tips Codigo de Falhas IvecopdfDocument16 pagesQdoc - Tips Codigo de Falhas IvecopdfJackson Da Silva100% (2)

- RTH2610B - RT3210HV Carrier Catalogue PDFDocument16 pagesRTH2610B - RT3210HV Carrier Catalogue PDFasdNo ratings yet

- GMS - Gearbox Management System: Tms2 GR/S/O 875/895/905/925/926/935/R Manual Gearbox or OPC 2016-08Document1 pageGMS - Gearbox Management System: Tms2 GR/S/O 875/895/905/925/926/935/R Manual Gearbox or OPC 2016-08Abner Souza Dos SantosNo ratings yet

- XCOM User Guide PDFDocument39 pagesXCOM User Guide PDFaleman100% (1)

- Volvo B11LDocument3 pagesVolvo B11LGerman Vera Vera100% (1)

- 4 6023786718920967112Document88 pages4 6023786718920967112ali roozbahaniNo ratings yet

- Scania Radio Premium ManualDocument83 pagesScania Radio Premium ManualAlex Renne ChambiNo ratings yet

- Davie Xdcii 530 Eng DafDocument8 pagesDavie Xdcii 530 Eng Dafjose breno vieira silvaNo ratings yet

- MS.93. MID 249. BBM. Codigo de Averias. Edicion 5Document36 pagesMS.93. MID 249. BBM. Codigo de Averias. Edicion 5Benjamin Miranda Flores0% (1)

- Special Tools 3Document20 pagesSpecial Tools 3p_jankoNo ratings yet

- Spec 1 Vt2009bDocument5 pagesSpec 1 Vt2009bYasin Noer Huda PNo ratings yet

- MID 140 Instrument Cluster Signal Description (Spesifications 381)Document20 pagesMID 140 Instrument Cluster Signal Description (Spesifications 381)Lazuardhitya oktanandaNo ratings yet

- CAN RawDocument386 pagesCAN RawhubacskaNo ratings yet

- Scania CatalogDocument54 pagesScania Catalogkhaledshekh133No ratings yet