Professional Documents

Culture Documents

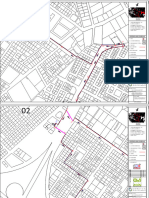

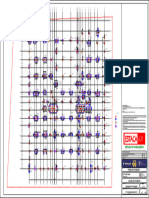

A A B B: Top View

Uploaded by

Dario CisnerosOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A A B B: Top View

Uploaded by

Dario CisnerosCopyright:

Available Formats

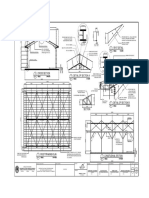

12 11 10 9 8 7 6 5 4 3 2 1

450224

J J

181.32mm

616.90mm

562.32mm

435.32mm

308.32mm

24.288in

22.139in

17.139in

12.139in

54.32mm

7.139in

2.139in

0mm

0in

13.49mm

2682.62mm .53in

R105.62in TYP.

CUTTING RADIUS 0mm

0in

I

I

63.98mm

568.96mm 2.519in

22.40in

SQ.

15.88mm

2832.10mm 5/8" 190.98mm

C (20) HOLES

R111.50in 7.519in

SILO RADIUS

H H

643.89mm

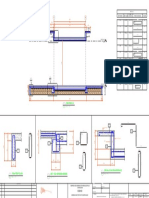

TOP VIEW 25.35in 317.98mm

SQ. 12.519in

444.98mm

17.519in

G C 5664.20mm G

18'-7.00" 149.48mm

SILO 5.88in

C 571.98mm

SILO WALL

22.519in

CLEARANCE

616.92mm

24.288in

SECTION B-B

DISCHARGE FLANGE

NOT TO SCALE

F F

600.08mm

23.63in .44in 11.11mm THRU

(20) HOLES

E E

RECLAIMER

AND SILO CL 7.5HP [5.59KW] TEFC 1800 RPM 460V B

RECLAIM MOTOR

45°

A A 511.18mm

20.13in 561.98mm

22.13in

508mm 554.05mm

D 20.00in 21.81in D

B B

TRANSITION

1778mm TAKEAWAY CONVEYOR (BY OTHERS)

C (BY OTHERS)

70.00in

1270mm

50.00in 327.03mm 1222.93mm

12.88in 48.15in

C C

TOP OF FOUNDATION

SECTION A-A

ELEVATION VIEW MOUNTING FLANGE

NOT TO SCALE

MATERIAL NOTES:

1. MATERIAL CONSISTS OF WHEAT BRAN:

SILO DESIGN NOTES: DENSITY 40 LBS/FT³ [640.74 KG/M³], PARTICLE SIZE 1/4"- [6.35MM-]

12% MOISTURE CONTENT, AMBIENT TEMPERATURE

SILO DESIGN IS PROVIDED BY OTHERS AND

B LAIDIG ASSUMES NO LIABILITY FOR THE SILO DESIGN. 2. RECLAIM AUGER IS INTENDED TO STIMULATE MATERIAL FLOW AND IS DESIGNED B

SILO DESIGN MUST ACCOUNT FOR--BUT IS NOT LIMITED TO-- EQUIPMENT NOTES: TO DELIVER 4 FT³/MIN [0.11 M³/MIN] AT 100% AUGER EFFICIENCY. BALANCE OF RATE

THE FOLLOWING: EXPECTED FROM FREE FLOW PER MATERIAL SPECIFICATION.

1. INSPECTION DIMENSIONS X.XX AND CIRCLED TEXT REQUIRE 3. WHEN MATERIAL IS ACTIVELY FLOWING, THE POTENTIAL FLOW RATE INTO REF. 445160

1. MASS FLOW CONDITIONS.

2. SIDE LOADING CONDITIONS. CUSTOMER CONFIRMATION. THE HOPPER OF THE RECLAIMER WILL BE IN EXCESS OF PROJECT

J22012

LAIDIG SYSTEMS, INC.-14535 DRAGOON TRAIL, MISHAWAKA, IN 46544 PH(574) 256-0204, EMAIL SALES@LAIDIG.COM NO:

3. SHIFTING LOAD CONDITIONS. 40 FT³/MIN [1.13 M³/MIN]. UNIT OF MEASURE: INCHES

MATERIAL:

2. BOXED TEXT XXXXX DENOTE ELECTRICAL CONNECTIONS. SEE MATERIAL NOTES: ()

4. CENTER FILLED CONDITIONS. **** C SILO DIA. WAS 18', MOUNTING FLANGE HEIGHT WAS 96" 05/18/22 TJM GENERAL TOLERANCES: WEIGHT:

BY DATE

5. SUFFICIENT SILO ROOF VENTS. 4. DURING MAXIMUM FLOW, THE CUSTOMERS TAKEAWAY X.XX 0.50

6. LAIDIG'S SPECIFICATION FOR OVERALL SILO HEIGHT 3. NOT DESIGNED FOR HAZARDOUS EXPLOSIVE ENVIRONMENTS. CONVEYOR WILL CONTROL THE ACTUAL DELIVERY RATE OF THE MATERIAL. **** B WAS 1500RPM, 380VAC, & 50HZ 05/02/22 TJM

X.XXX 0.03 SIZE MODELED JJJ 04/27/22

AND ELEVATED FLOOR HEIGHT. LAIDIG RECOMMENDS ENVIRONMENT CLASSIFICATION IS CUSTOMER’S RESPONSIBILITY. **** A FOR APPROVAL 04/28/22 TJM X'-X" REFERENCE ONLY D DRAWN TJM 04/28/22

A STORAGE HEIGHT TO DIAMETER RATIO WITHIN 3:1. 5. EQUIPMENT DAMAGE MAY RESULT IF THE RATE OF THE CUTOMERS TAKEAWAY DESCRIPTION PER ASME Y14.5M – 1994 TITLE SHEET 1 OF 2 REV: C

ECN REV DATE BY

LAYOUT 3445-18' MODERNA A

7. LAIDIG'S SPECIFICATION FOR ACCESS OPENINGS. 4. ALL ELECTRIC MOTORS TO OPERATE ON 3PH/60HZ/460VAC POWER B CONVEYOR IS LESS THAN 140% OF THE RECLAIM AUGER RATE LISTED IN MATERIAL DWG NO.:

ALIMENTOS-ECUDOR- 450224

Neither this drawing nor any portion of this drawing may be reproduced without written permission of Laidig Systems, Inc.. This drawing contains

NOTE 2. Laidig Systems, Inc. proprietary information. By viewing this drawing the viewer agrees to maintain the confidentiality of the information contained DO NOT

herein and not to use the information in any way or disclose the information to anyone else without written permission of Laidig Systems, Inc.

SN2023445 SCALE

12 11 10 9 8 7 6 5 4 3 2 1

12 11 10 9 8 7 6 5 4 3 2 1

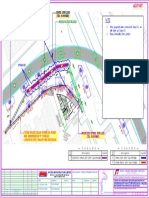

450224 MACHINE LOADS IMPOSED ON STRUCTURE (UNFACTORED)

J J

ITEM NO. DESCRIPTION VALUE

4 1 RECLAIMER WEIGHT ON CONE FLANGE 1,130 LBM [513 KG]

2 OVERTURNING MOMENT AT SILO CENTER LINE DUE TO AUGER WEIGHT 2,950 FT-LB [4,000 NM]

3 MAX AUGER THRUST 2,000 LBF [8.90 KN]

4 MAX ADVANCE MOMENT 4,000 FT-LB [5,432 NM]

I

I 5 MAX AUGER TORQUE 1,200 FT-LB [1,627 NM]

6 EXPOSED SURFACE AREA AUGER 6.02 FT² [0.56 M²]

PICK WEIGHTS OF CRITICAL COMPONENTS

ITEM NO. DESCRIPTION VALUE

6 7 RECLAIM AUGER ASSEMBLY 180 LBM [82 KG]

H H

8 DISCHARGE ASSEMBLY 950 LBM [431 KG]

G

G

F F

E E

2 3

1

D D

C C

B

B

REF. 445160

LAIDIG SYSTEMS, INC.-14535 DRAGOON TRAIL, MISHAWAKA, IN 46544 PH(574) 256-0204, EMAIL SALES@LAIDIG.COM

PROJECT

NO: J22012

MATERIAL:

UNIT OF MEASURE: INCHES SEE MATERIAL NOTES: ()

**** C SILO DIA. WAS 18', MOUNTING FLANGE HEIGHT WAS 96" 05/18/22 TJM GENERAL TOLERANCES: WEIGHT:

BY DATE

X.XX 0.50

**** B WAS 1500RPM, 380VAC, & 50HZ 05/02/22 TJM

X.XXX 0.03 SIZE MODELED JJJ 04/27/22

**** A FOR APPROVAL 04/28/22 TJM X'-X" REFERENCE ONLY D DRAWN TJM 04/28/22

A DESCRIPTION PER ASME Y14.5M – 1994 TITLE SHEET 2 OF 2 REV: C

ECN REV DATE BY

LAYOUT 3445-18' MODERNA A

DWG NO.:

ALIMENTOS-ECUDOR- 450224

Neither this drawing nor any portion of this drawing may be reproduced without written permission of Laidig Systems, Inc.. This drawing contains

Laidig Systems, Inc. proprietary information. By viewing this drawing the viewer agrees to maintain the confidentiality of the information contained DO NOT

herein and not to use the information in any way or disclose the information to anyone else without written permission of Laidig Systems, Inc.

SN2023445 SCALE

12 11 10 9 8 7 6 5 4 3 2 1

You might also like

- Evgeny Grinko - Valse PDFDocument2 pagesEvgeny Grinko - Valse PDFAntony Petrushko44% (9)

- BC Rich Stealth Full RockarDocument1 pageBC Rich Stealth Full RockarPablo FerrariNo ratings yet

- Buckthorpe Etal 23 Optimising Early Stage ACL Rehab ProcessDocument24 pagesBuckthorpe Etal 23 Optimising Early Stage ACL Rehab ProcessCole VincentNo ratings yet

- Roof Beam 1 Side Elevation: Existing TrussDocument1 pageRoof Beam 1 Side Elevation: Existing TrussJun NarvaezNo ratings yet

- 01 Locação de Pilares e Blocos de CoroamentoDocument1 page01 Locação de Pilares e Blocos de Coroamentoperfect engenhariaNo ratings yet

- Balcony Detail-EVEN PLANDocument1 pageBalcony Detail-EVEN PLANAyushi GuptaNo ratings yet

- Es-1 - Detalles de Sec - 1-1Document1 pageEs-1 - Detalles de Sec - 1-1RAFAEL LLANEZANo ratings yet

- El PalmarrDocument1 pageEl PalmarrRUSSHSoftNo ratings yet

- NRL Network Study 23 - 12 - 22 ModelDocument1 pageNRL Network Study 23 - 12 - 22 Modelsameed bhaiNo ratings yet

- PRE COM PLAN - SG BULOH-ModelDocument1 pagePRE COM PLAN - SG BULOH-ModelThashnee BalaNo ratings yet

- TSJ Transportation Frame Item Detail DrawingDocument1 pageTSJ Transportation Frame Item Detail DrawingBhuvan GanesanNo ratings yet

- Losa A 2DDocument2 pagesLosa A 2DWilfredo Poma RojasNo ratings yet

- Mil CD IlDocument1 pageMil CD IlGerardo KaijuNo ratings yet

- Piso 4 N 17-50 Corte 2Document1 pagePiso 4 N 17-50 Corte 2Carlos CastilloNo ratings yet

- Primer PisoDocument1 pagePrimer PisoMANUEL SANTIAGO BARRERA RIVERANo ratings yet

- LG959 LG958L Wheel Loader BrochureDocument4 pagesLG959 LG958L Wheel Loader BrochureAntonyNo ratings yet

- MOD-DESPIECE Sec 2-2 (2) Las BariasDocument1 pageMOD-DESPIECE Sec 2-2 (2) Las BariasRAFAEL LLANEZANo ratings yet

- SECCIONESDocument1 pageSECCIONESJosé Rodrigo MoralesNo ratings yet

- Existing Layout PlanDocument1 pageExisting Layout PlancinchmakNo ratings yet

- Bur0021 To Arb Qassim-01 & Bur0062 To Abr Qassim-02 (Design) R-1Document4 pagesBur0021 To Arb Qassim-01 & Bur0062 To Abr Qassim-02 (Design) R-1hf8476237No ratings yet

- Tendon 21 Developed ElevationDocument1 pageTendon 21 Developed ElevationYoussef TakateNo ratings yet

- Left Hand Console: Electrical System 313 and 313 GC ExcavatorDocument6 pagesLeft Hand Console: Electrical System 313 and 313 GC ExcavatorHenry Sergio HuayhuaNo ratings yet

- E 1e LeganzaDocument1 pageE 1e Leganzasebastian bautistaNo ratings yet

- Block-E: Phase # 1 & 2Document1 pageBlock-E: Phase # 1 & 2Jawad HaiderNo ratings yet

- 9129-4S OtfordDocument1 page9129-4S OtfordWarren RogersNo ratings yet

- Spot DetailDocument1 pageSpot Detailzab04148114No ratings yet

- 2010 CENSUS - CENSUS BLOCK MAP (INDEX) : Baldwin County, AL: MILFORD 47500 Davis 18100Document1 page2010 CENSUS - CENSUS BLOCK MAP (INDEX) : Baldwin County, AL: MILFORD 47500 Davis 18100Igor SemenovNo ratings yet

- Sewer Pipe Line (DIA: Ø1800MM)Document1 pageSewer Pipe Line (DIA: Ø1800MM)ashis maityNo ratings yet

- DepositoDocument1 pageDepositosanchitha RNo ratings yet

- As Proposed Caffee1659536163409Document10 pagesAs Proposed Caffee1659536163409dubai eyeNo ratings yet

- La Polca Del Barril TubaDocument1 pageLa Polca Del Barril TubaMaxwell RodriguezNo ratings yet

- E-D-07-01 - Fire Detection - 0-0m PDFDocument1 pageE-D-07-01 - Fire Detection - 0-0m PDFspeaker_john-1No ratings yet

- Acad Lotes Cristian 03-Model-A1Document1 pageAcad Lotes Cristian 03-Model-A1Diana Yuleysi Benavidez RubioNo ratings yet

- 1234yf Tanks HCL Tanks: Shipping & Receiving AreaDocument1 page1234yf Tanks HCL Tanks: Shipping & Receiving AreaGraciaVelitarioNo ratings yet

- Pandolfini - Endgame Course - 239 Chess Endgame Positions You Have To Know How To Play Instantly TO SOLVE - BWC PDFDocument40 pagesPandolfini - Endgame Course - 239 Chess Endgame Positions You Have To Know How To Play Instantly TO SOLVE - BWC PDFpablomatus100% (2)

- Gsquare Arakonam Industrial Estate-Schematic Plan-Plan 02Document1 pageGsquare Arakonam Industrial Estate-Schematic Plan-Plan 02BharatNo ratings yet

- Navi Mumbai International Airport Site Plan: SCALE - 1:10,000 All Dimensions in Meters Sheet Size - A1Document1 pageNavi Mumbai International Airport Site Plan: SCALE - 1:10,000 All Dimensions in Meters Sheet Size - A1Meenakshi RajNo ratings yet

- Sewer Pipe Line (DIA: Ø1800MM)Document1 pageSewer Pipe Line (DIA: Ø1800MM)ashis maityNo ratings yet

- 01 PROJECT LAYOUT-ModelDocument1 page01 PROJECT LAYOUT-ModelsatpuraNo ratings yet

- C201010 - 2020-A30lm30-Da-Pg 3 04 00Document1 pageC201010 - 2020-A30lm30-Da-Pg 3 04 00nicu1212No ratings yet

- Planos Arq - fincaCana.A03Document1 pagePlanos Arq - fincaCana.A03Cristian Nuñez RamirezNo ratings yet

- HANWHA - Q - PEAK - DUO - BLK ML - G10 - Plus - 400Document1 pageHANWHA - Q - PEAK - DUO - BLK ML - G10 - Plus - 400said.med.islam.1991No ratings yet

- Contracts 2 Mind MapDocument1 pageContracts 2 Mind MapjadeftjdbNo ratings yet

- Detail Emotion 1Document1 pageDetail Emotion 1pradito ala perdanaNo ratings yet

- (Cota +4,42) : LegendaDocument1 page(Cota +4,42) : LegendaCorneliu DobreNo ratings yet

- Queenston BLVD CUARTAS BUSINESS PARKDocument2 pagesQueenston BLVD CUARTAS BUSINESS PARKElmer HabloNo ratings yet

- Untitled 1 DDocument1 pageUntitled 1 DMargraf EditoraNo ratings yet

- Municipalidad Provincial de Cajamarca: Longitud Y PendienteDocument1 pageMunicipalidad Provincial de Cajamarca: Longitud Y PendienteJosé A. Moscol VizcondeNo ratings yet

- Situasi Bor Main DamDocument1 pageSituasi Bor Main Damdedy falloNo ratings yet

- Bm.2 Bang - Sadap ModelDocument1 pageBm.2 Bang - Sadap ModelsumarlinNo ratings yet

- Site Plan With Tiered Retaining WallsDocument1 pageSite Plan With Tiered Retaining WallsMohsin RazaNo ratings yet

- Corte y Elevacion EstructurasDocument1 pageCorte y Elevacion Estructurasfrancisca campos cartesNo ratings yet

- 2104Document1 page2104zaheerNo ratings yet

- 2INCHES UPVC PIPE (73.47%) : (1,484 / 2,020 Meters)Document1 page2INCHES UPVC PIPE (73.47%) : (1,484 / 2,020 Meters)Jhn Cbllr BqngNo ratings yet

- Sewer Pipe Line (DIA: Ø1800MM)Document1 pageSewer Pipe Line (DIA: Ø1800MM)ashis maityNo ratings yet

- Site PlanDocument1 pageSite PlanNishant DetwalNo ratings yet

- Left Hand Console: Electrical System 313 and 313 GC ExcavatorDocument6 pagesLeft Hand Console: Electrical System 313 and 313 GC ExcavatorHenry Sergio HuayhuaNo ratings yet

- Fun 01 Locação Estacas Monte Solaro Rev01Document1 pageFun 01 Locação Estacas Monte Solaro Rev01ian.dias.carloNo ratings yet

- Gon SNR K09Document1 pageGon SNR K09BNG GondomarNo ratings yet

- ENTREGACIMENTACION3010Document1 pageENTREGACIMENTACION3010Osvaldo VCNo ratings yet

- Mono 108Document438 pagesMono 108pasaricaNo ratings yet

- Safety Procedures For Vertical Formwork PDFDocument17 pagesSafety Procedures For Vertical Formwork PDFbalya7No ratings yet

- Bahasa Inggris PATDocument10 pagesBahasa Inggris PATNilla SumbuasihNo ratings yet

- Conceptual FrameworkDocument3 pagesConceptual Frameworkprodiejigs36No ratings yet

- 2019 - High Levels of Polypharmacy in RheumatoidDocument7 pages2019 - High Levels of Polypharmacy in RheumatoidGustavo ResendeNo ratings yet

- Assignment 1 - Statistics ProbabilityDocument3 pagesAssignment 1 - Statistics ProbabilityAzel Fume100% (1)

- 1943 Dentures Consent FormDocument2 pages1943 Dentures Consent FormJitender ReddyNo ratings yet

- Chapter 4 Occupational Safety Hazards in Food Service OperationsDocument14 pagesChapter 4 Occupational Safety Hazards in Food Service OperationsStraichea Mae TabanaoNo ratings yet

- Introduction: Science and Environment: Brgy - Pampang, Angeles City, PhilippinesDocument65 pagesIntroduction: Science and Environment: Brgy - Pampang, Angeles City, PhilippinesLance AustriaNo ratings yet

- Osce05ans 110918053819 Phpapp01Document20 pagesOsce05ans 110918053819 Phpapp01masood alamNo ratings yet

- Exploded View & Parts Listing Air Operated Double Diaphragm PumpDocument2 pagesExploded View & Parts Listing Air Operated Double Diaphragm PumpCarlos AvalosNo ratings yet

- Magical ExercisesDocument5 pagesMagical ExercisesAnonymous ytxGqZNo ratings yet

- Advanced Aesthetics: The Definitive Guide For Building A Ripped and Muscular PhysiqueDocument73 pagesAdvanced Aesthetics: The Definitive Guide For Building A Ripped and Muscular PhysiqueRoger murilloNo ratings yet

- Notice - Appeal Process List of Appeal Panel (Final 12.1.24)Document13 pagesNotice - Appeal Process List of Appeal Panel (Final 12.1.24)FyBerri InkNo ratings yet

- Introduction To Kalman FilterDocument4 pagesIntroduction To Kalman FilterArghya MukherjeeNo ratings yet

- Legend Of Symbols: Chú Thích Các Ký HiệuDocument9 pagesLegend Of Symbols: Chú Thích Các Ký HiệuKiet TruongNo ratings yet

- Famous Bombers of The Second World War - 1st SeriesDocument142 pagesFamous Bombers of The Second World War - 1st Seriesgunfighter29100% (1)

- BRASS Introduction 2012Document23 pagesBRASS Introduction 20121234scr5678No ratings yet

- Course On Quantum ComputingDocument235 pagesCourse On Quantum ComputingAram ShojaeiNo ratings yet

- Muharem Bazdulj - The Second Book (Writings From An Unbound Europe) - Northwestern University Press (2005) PDFDocument154 pagesMuharem Bazdulj - The Second Book (Writings From An Unbound Europe) - Northwestern University Press (2005) PDFjeff tehNo ratings yet

- American Pile Driving Equipment Equipment CatalogDocument25 pagesAmerican Pile Driving Equipment Equipment CatalogW Morales100% (1)

- OLFACTIVE TRAINING 101 by SozioDocument36 pagesOLFACTIVE TRAINING 101 by SoziojaviercdeaeNo ratings yet

- EU - Guidance On GMP For Food Contact Plastic Materials and Articles (60p)Document60 pagesEU - Guidance On GMP For Food Contact Plastic Materials and Articles (60p)Kram NawkNo ratings yet

- Design of Cycle Rickshaw For School ChildrenDocument23 pagesDesign of Cycle Rickshaw For School ChildrenAditya GuptaNo ratings yet

- IDRW MagazineDocument10 pagesIDRW MagazineVirarya100% (1)

- International Travel Insurance Policy: PreambleDocument20 pagesInternational Travel Insurance Policy: Preamblethakurankit212No ratings yet

- No Client Too Far: Flexible Antenna Options TDMA GPS Sync ClientDocument2 pagesNo Client Too Far: Flexible Antenna Options TDMA GPS Sync ClientFelix MartinezNo ratings yet

- T 1246784488 17108574 Street Lighting Control Based On LonWorks Power Line CommunicationDocument3 pagesT 1246784488 17108574 Street Lighting Control Based On LonWorks Power Line CommunicationsryogaaNo ratings yet

- DLL - Mapeh 6 - Q2 - W8Document6 pagesDLL - Mapeh 6 - Q2 - W8Joe Marie FloresNo ratings yet