Professional Documents

Culture Documents

Albany GA Style Brochure

Albany GA Style Brochure

Uploaded by

saifOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Albany GA Style Brochure

Albany GA Style Brochure

Uploaded by

saifCopyright:

Available Formats

GENERAL & CHEMICAL

Albany Pumps

A N E M P LOY E E O W N E D CO M PA N Y

BITUMEN

G: Gear type pump range

G: A Style:

Materials: CI | CS

FIRE

General purpose pumps

The GA range is Albany’s general purpose

DISPENSER MACHINES

pump, the origins of which can be traced back

to 1901 when the company first started. It

is capable of handling the widest variety of

liquids, including extremely viscous. These

pumps offer a durable, robust design ensuring

ease of use and maintenance.

With a large choice of pump sizes, materials

and sealing options to suit all applications, the

FOOD

GA range can be adapted to suit any customer

or OEM application. Bespoke mountings and

additional components and pipework allow

simplified fitment to the final application.

LUBRICATION

Use CEFG pumps for 3.1 certification.

Albany’s 24-page brochure is

available as a download at

MARINE

www.albany-pumps.co.uk

Maximum working pressure 25 barg Pump size range 1∕2" - 4" Maximum temperature 200°C Flow rate 9.5-2273 L/min

AL Aluminium | CS Cast Steel | CI Cast Iron | GM Gunmetal | HY Hastelloy | NR Ni-resist | NY Nylon | PP Polypropylene | SD Super Duplex | SS Stainless Steel

General and Chemical Bitumen Fire Dispenser Machines Food Industry Lubrication Marine Oil & Gas Refrigeration Sugar

OIL & GAS

www.albany-pumps.co.uk +44 (0) 1594 842 275

Head Office and Manufacturing Centre Service and Repair Centre

Albany Engineering Company Ltd Albany Engineering Company Ltd

Church Road, Lydney Richter Works, Garnett Street

REFRIGERATION

Gloucestershire, GL15 5EQ Bradford BD3 9HB

United Kingdom United Kingdom

t: +44 (0) 1594 842 275 t: +44 (0) 1594 842 275

Head Office Option 1 Service and Repair (Option 2).

e: salesdept@albany-pumps.co.uk e: servicedept@albany-pumps.co.uk

SUGAR

E&OE: Errors and omissions excepted. All content contained herein

is subject to change at the Company’s discretion without notice.

GENERAL & CHEMICAL

Albany Pumps

G: A Style:

BITUMEN

Versatile general purpose pump capable of handling the widest variety of viscous liquids together with

simple robust design ensuring ease of maintenance

Plain internal bearings cater for self lubricating liquids, external lubrication being available when

required.

Available with double helical rotors for quiet pulse-free running

Simple design with two moving parts

FIRE

Temperature 200°C max. (320°C with steel casing)

Pressures to 25 barg (350 psig)

Capacity range 9.5 L/min – 2273 L/min

DISPENSER MACHINES

Can be supplied without integral safety relief valve

Leaflet shows standard sizes, but special capacities can often be catered for

Some of the many liquids handled by Albany Pumps

refined tar viscose silicate of soda bitumen

glucose glue paints, resins varnish

FOOD

Size, wax molasses fats soap

chocolate all oils asphalt printing ink

cocoa butter grease petrol paraffin

wines & spirits foodstuffs acids, alkalis polYMERS

LUBRICATION

The Albany Engineering Company Limited, Lydney, GLOS GL15 5EQ

U.K

SPECIFICATION

Tel: +44 (0) 1594 842275 Email: sales@albany-pumps.co.uk

Certificate No. FM 20986 as standard carbon steel to ASTM A216 WCB or cast iron to BS452 as standard with

Pump Casing: R1/15

option of steel

Rotors: as standard cast iron or carbon steel

Options for nitrided steel, phosphor bronze, stainless steel, or ni-resist

MARINE

Spur gears are standard up to AP090 with double helical optional for AP060 to AP090.

Double helical rotors are standard for AP100 to HD140

Shafts: usually hardened and ground steel, can also be supplied in stainless steel AISI 316 for

Internal Bearings: for most liquids a PTFE based bearing is used

bushes can also be supplied in cast iron, phosphor bronze or carbon

Sealing: packed with PTFE based packing, or mechanical seals.

Mounting: foot mounted or flange mounted pumps are supplied as standard

OIL & GAS

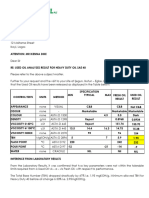

PERFORMANCE – powers and flows typical for 3.5 BARg

REFRIGERATION

Pump 95% of Maximum viscosity Maximum viscosity Maximum viscosity Maximum viscosity

Frame Theoretical 3,000 centistokes 2,000 centistokes 1,200 centistokes 750 centistokes

Size output 500 RPM 720 RPM 960 RPM 1420 RPM

Litres/rev

L/min kW L/min kW L/min kW L/min kW

AP040 .0194 9.5 .37 13.9 .37 18.6 .37 27.7 .56

AP050

Maximum .031 25 barg15.5 Pump size

working pressure .37range 1∕2" - 22.3

4" .56

Maximum 30.0

temperature 200°C .55 Flow44.0

rate 9.5-2273 .75

L/min

AP060 .0434 21.4 .56 32.3 .75 42.7 75 63.6 1.1

SUGAR

www.albany-pumps.co.uk

AP070 .0687 35.5 +44 .75

(0) 1594 842

50.0 275 1.1 65.9 1.5 97.7 2.2

AP080 .108 54.1 1.5 80.9 1.5 107.7 2.2 159 3

Internal Bearings: for most liquids a PTFE based bearing is used

GENERAL & CHEMICAL

bushes can also be supplied in cast iron, phosphor bronze or carbon

Sealing: packed with PTFE based packing, or mechanical seals.

Albany Pumps

Mounting: foot mounted or flange mounted pumps are supplied as standard

G: A Style:

PERFORMANCE – powers and flows typical for 3.5 BARg

BITUMEN

Pump 95% of Maximum viscosity Maximum viscosity Maximum viscosity Maximum viscosity

Frame Theoretical 3,000 centistokes 2,000 centistokes 1,200 centistokes 750 centistokes

Size output 500 RPM 720 RPM 960 RPM 1420 RPM

Litres/rev

L/min kW L/min kW L/min kW L/min kW

AP040 .0194 9.5 .37 13.9 .37 18.6 .37 27.7 .56

AP050 .031 15.5 .37 22.3 .56 30.0 .55 44.0 .75

FIRE

AP060 .0434 21.4 .56 32.3 .75 42.7 75 63.6 1.1

AP070 .0687 35.5 .75 50.0 1.1 65.9 1.5 97.7 2.2

AP080 .108 54.1 1.5 80.9 1.5 107.7 2.2 159 3

DISPENSER MACHINES

AP090 .162 80.9 1.5 117 1.5 156 2.2 230 4

AP09W .213 104 3.0 154 3.5 208 4.0 313 6.5

AP100 .195 100.5 2.2 145 3.0 187 4.0 277 5.5

HD030 .273 136 4.0 197 4.0 264 5.5 390 7.5

HD040 0.386 195 4.1 277 5.6 368 7.5 520 8.5

HD050 0.491 245 5.6 350 7.5 473 7.5 650 9.5

FOOD

HD060 0.62 310 7.5 445 7.5 600 11.2 880 14.0

HD070 0.805 405 7.5 582 11.2 773 11.2 REFER TO WORKS

HD080 1.00 509 11.2 718 11.2 955 14 REFER TO WORKS

HD100 1.32 618 11.2 950 15.0 1273 22.4

LUBRICATION

HD110 2.09 1045 16.0E 1500 22.0E 2000 31.0E

HD120 3.0 1364 18.6

Maximum speed

HD140 5.0 2273 37.3 600 rpm

1 Gland

2 Front Cover

PARTS LIST

MARINE

3* Gland Packing

4* Driving Shaft

Valve

5* Bushes (4 per set)

6* Gaskets Adjusting screw

7 Relief Valve comprises… Locknut

Spring -

8 Back Cover

9* Rotors (2) (AP11 & over)

10 Body Spring Header

OIL & GAS

Fibre Washer

11* Key (2)

12* Following Shaft

SPARES

Items we recommend as spares are indicated*

When ordering spares please quote pump size and the

pump serial number usually stamped in position ‘X’.

REFRIGERATION

Maximum working pressure 25 barg Pump size range 1∕2" - 4" Maximum temperature 200°C Flow rate 9.5-2273 L/min

SUGAR

www.albany-pumps.co.uk +44 (0) 1594 842 275

You might also like

- Goulds IC Pump BulletinDocument24 pagesGoulds IC Pump BulletinSergio E. Marchetti Newco S. A.100% (1)

- Piled-Raft Tc18 Report July 2001Document46 pagesPiled-Raft Tc18 Report July 2001pperic13No ratings yet

- Catalogo Goulds PumpsDocument1,249 pagesCatalogo Goulds Pumpsleslie83% (6)

- Module 01 - Small and Large Deflection Plate TheoryDocument9 pagesModule 01 - Small and Large Deflection Plate TheorySameera JayaratneNo ratings yet

- Rotan Internal Gear Pumps: Desmi IncDocument14 pagesRotan Internal Gear Pumps: Desmi IncVijay BhureNo ratings yet

- DSR 2016 (Vol.2) PDFDocument258 pagesDSR 2016 (Vol.2) PDFJoe87% (38)

- Cargo Oil Pump PDFDocument17 pagesCargo Oil Pump PDFa03041998No ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Taxable Invoice: To: Saif Hammad: Saif HammadDocument1 pageTaxable Invoice: To: Saif Hammad: Saif HammadsaifNo ratings yet

- ABEL For Mining: Positive Displacement Pumps For Sludge, Slurry and Solids HandlingDocument6 pagesABEL For Mining: Positive Displacement Pumps For Sludge, Slurry and Solids HandlingPete PompesNo ratings yet

- Astm C20Document3 pagesAstm C20nee2790100% (1)

- IB DP Prescribed PracticalsDocument24 pagesIB DP Prescribed PracticalsMitul HariyaniNo ratings yet

- Failure Avoidance Brief: Estimating Heater Tube Life: FeatureDocument3 pagesFailure Avoidance Brief: Estimating Heater Tube Life: Featureriza9847No ratings yet

- 10-Low Alloy Steel PDFDocument32 pages10-Low Alloy Steel PDFIdes Trian100% (1)

- Pumped ConcreteDocument7 pagesPumped ConcreteSa ReddiNo ratings yet

- Fornovo Gas Presentation RNG 2020 03Document39 pagesFornovo Gas Presentation RNG 2020 03RODIS ECHEVARRIA SALDAÑANo ratings yet

- Compressor Roto InjectDocument2 pagesCompressor Roto InjectJeremias UtreraNo ratings yet

- 1 - Albany Twin Screw BrochureDocument4 pages1 - Albany Twin Screw BrochureDurrani SonsNo ratings yet

- A G IIP: Mine Uard RocessDocument2 pagesA G IIP: Mine Uard Rocessmehul10941No ratings yet

- Sundyne Compressor Brochure - USDocument16 pagesSundyne Compressor Brochure - USluca.valenti.1971No ratings yet

- Ebara Gs DatasheetDocument132 pagesEbara Gs DatasheetWalter PerezNo ratings yet

- SIL 23701 (International)Document4 pagesSIL 23701 (International)EleazarNo ratings yet

- Rocky Mount Vacuum TechnologyDocument18 pagesRocky Mount Vacuum TechnologyPraveen GolharNo ratings yet

- Bendix BA-922 Sae Universal Flange Air Compressor: CompressorsDocument2 pagesBendix BA-922 Sae Universal Flange Air Compressor: Compressorscarlos maradiagaNo ratings yet

- Installation and Operation Manual: KP1 and KP2 Vehicle Mounted Fire PumpDocument42 pagesInstallation and Operation Manual: KP1 and KP2 Vehicle Mounted Fire PumpZacke EsmaNo ratings yet

- ALS InglésDocument26 pagesALS Inglésjose belloNo ratings yet

- Multi-Stage, Water-Cooled Compressors: Series TVX 900Document2 pagesMulti-Stage, Water-Cooled Compressors: Series TVX 900Mohamed Nagim Cheikh AhmedNo ratings yet

- Eni Grease AC 2 PDFDocument1 pageEni Grease AC 2 PDFranjanguptNo ratings yet

- English Full Catalouge Facing UpDocument96 pagesEnglish Full Catalouge Facing Updaboo sanatNo ratings yet

- Oil Free. Disrupted: Your Always Better Choice Is HereDocument24 pagesOil Free. Disrupted: Your Always Better Choice Is Herevuongdt1995No ratings yet

- 24 02 Brochure OCTGDocument8 pages24 02 Brochure OCTGAryanto YogaNo ratings yet

- Automatic Transmission Fluid III-HDocument2 pagesAutomatic Transmission Fluid III-HQuy NguyenNo ratings yet

- ALMIG TOTAL RZ Web GB 01 - Compresor Belt 45Document16 pagesALMIG TOTAL RZ Web GB 01 - Compresor Belt 45breNo ratings yet

- LMI Metering Pumps BrochureDocument8 pagesLMI Metering Pumps BrochureRoberto MejiaNo ratings yet

- Fiche Technique Surpresseur PDFDocument25 pagesFiche Technique Surpresseur PDFsalif saadNo ratings yet

- Grundfos CMBE Booster DB LDocument27 pagesGrundfos CMBE Booster DB LAish MohammedNo ratings yet

- Fiche Technique Surpresseur PDFDocument25 pagesFiche Technique Surpresseur PDFsalif saadNo ratings yet

- BF1212 - Baldwin - Spin-On Fuel Filters - BaldwinDocument4 pagesBF1212 - Baldwin - Spin-On Fuel Filters - BaldwinJulioNo ratings yet

- PG 475 1500cf Rig Compressor IndiaDocument6 pagesPG 475 1500cf Rig Compressor IndiaKumar Nishant100% (1)

- Blackmer LPG PumpsDocument8 pagesBlackmer LPG PumpsDarshan PatelNo ratings yet

- EagleBurgmann - BTE - E3 - PDF3 - EagleBurgmann BT Mechanical Seals - EN - 18.10.2018Document30 pagesEagleBurgmann - BTE - E3 - PDF3 - EagleBurgmann BT Mechanical Seals - EN - 18.10.2018Augusto RezendeNo ratings yet

- Goulds Pumps - IC I-FrameDocument20 pagesGoulds Pumps - IC I-FrameJodi MitchellNo ratings yet

- Portables NewDocument16 pagesPortables Newالتقني للكهرباءNo ratings yet

- C SeriesDocument19 pagesC SeriesLuis DominguezNo ratings yet

- Armfield Rising Film EvaporatorDocument2 pagesArmfield Rising Film EvaporatorEvy Citra Ayu NegariNo ratings yet

- Broschüre Environmental - 28 05 16Document16 pagesBroschüre Environmental - 28 05 16gheantikaNo ratings yet

- Compair Serie CDocument16 pagesCompair Serie CJulio VolcanNo ratings yet

- Pompa Albin Pompe Pompe Peristaltice Apa Industrie Alimentara 1Document8 pagesPompa Albin Pompe Pompe Peristaltice Apa Industrie Alimentara 1Diana GoriNo ratings yet

- TVX 900 Sprężarka Tłokowa MehrerDocument2 pagesTVX 900 Sprężarka Tłokowa MehrerZamriNo ratings yet

- P004283 Molygen New Generation 5W 30 DPF 21 en - GBDocument1 pageP004283 Molygen New Generation 5W 30 DPF 21 en - GBshadow.line.contracting.bhNo ratings yet

- World Lubricants Brochure-2021-LRDocument18 pagesWorld Lubricants Brochure-2021-LRAung Myat ThuNo ratings yet

- Hydraulic 10WDocument2 pagesHydraulic 10WCarlos Molina TorradoNo ratings yet

- AlgasSDI BlendaireII BrochDocument4 pagesAlgasSDI BlendaireII BrochDanny SanchezNo ratings yet

- Engine Oil Test Results and Recommendations To Interkels - 07082019Document2 pagesEngine Oil Test Results and Recommendations To Interkels - 07082019Georgina SuleNo ratings yet

- Ethylene Plant Processes and Solutions Bro PDFDocument6 pagesEthylene Plant Processes and Solutions Bro PDFBarath KumarNo ratings yet

- Evomax 2 30kW Spec Sheet 2020Document4 pagesEvomax 2 30kW Spec Sheet 2020SupyNo ratings yet

- Folder-Small L & B-EnGDocument16 pagesFolder-Small L & B-EnGRodrigo GonçalvesNo ratings yet

- Fire Ball PumpsDocument16 pagesFire Ball PumpsalancortestecnicoNo ratings yet

- Dana Lubricants Factory L.L.C Dana Lubricants Factory L.L.CDocument2 pagesDana Lubricants Factory L.L.C Dana Lubricants Factory L.L.CChemilomNo ratings yet

- Rubia Fleet HD 500 20W-50: Key DataDocument2 pagesRubia Fleet HD 500 20W-50: Key DataAdnanNo ratings yet

- CSB CatalogDocument8 pagesCSB Catalogdebsaikat00No ratings yet

- Ó Chi PDFDocument16 pagesÓ Chi PDFGỗ MộcNo ratings yet

- Truck-Mounted Two-Stage Gas Driven Reciprocating Air Compressor 13-14 HPDocument3 pagesTruck-Mounted Two-Stage Gas Driven Reciprocating Air Compressor 13-14 HPKrist San QNo ratings yet

- Shell Gas Compressor Oil S4 PV 190 (En) TDSDocument2 pagesShell Gas Compressor Oil S4 PV 190 (En) TDSrehan7777No ratings yet

- BVG - UVG Series: Compressors & Gas Treatment Systems For Wet Gases ApplicationsDocument8 pagesBVG - UVG Series: Compressors & Gas Treatment Systems For Wet Gases ApplicationsSteven TurnerNo ratings yet

- Hill Catalogue 2010Document17 pagesHill Catalogue 2010hillpumpsNo ratings yet

- RMB 22 - 37 KW RMB IVR 22 - 37 KW: Solid, Simple, Smart: Advanced Reliability in Compressed AirDocument6 pagesRMB 22 - 37 KW RMB IVR 22 - 37 KW: Solid, Simple, Smart: Advanced Reliability in Compressed AirRUDRA MORENo ratings yet

- Mobilgrease XHP 222 PdsDocument2 pagesMobilgrease XHP 222 PdsmuhammadNo ratings yet

- LPG Design and Installation For Commercial and Industrial FacilitiesDocument171 pagesLPG Design and Installation For Commercial and Industrial Facilitiesnathanielvillanueva093086No ratings yet

- Tgo Charges - 2021 12 24Document1 pageTgo Charges - 2021 12 24saifNo ratings yet

- Ksagreasesamplingrev1 240131235124 9908b48bDocument16 pagesKsagreasesamplingrev1 240131235124 9908b48bsaifNo ratings yet

- 10.32-Monorail BeamDocument1 page10.32-Monorail BeamsaifNo ratings yet

- EydhdfghsgjDocument1 pageEydhdfghsgjsaifNo ratings yet

- General Features: Diesel Generating Set Powered byDocument4 pagesGeneral Features: Diesel Generating Set Powered bysaifNo ratings yet

- AghsisweDocument2 pagesAghsiswesaifNo ratings yet

- Foam Pump Operating and Maintenance ManualDocument16 pagesFoam Pump Operating and Maintenance ManualsaifNo ratings yet

- Hazard Identification - Technical - Version 09 - FinalDocument21 pagesHazard Identification - Technical - Version 09 - FinalsaifNo ratings yet

- Close Coupled Pumps Operating and Maintenance ManualDocument16 pagesClose Coupled Pumps Operating and Maintenance ManualsaifNo ratings yet

- Wet Layup Price ItemDocument1 pageWet Layup Price ItemMuhammad ZulfamiNo ratings yet

- TocDocument11 pagesTocKwok Fai ChanNo ratings yet

- Solvent Based 3D Printing of Biopolymer and Bioactive Glass Composite and Hydrogel For Tissue Engineering Applicattions.Document6 pagesSolvent Based 3D Printing of Biopolymer and Bioactive Glass Composite and Hydrogel For Tissue Engineering Applicattions.Celia Miranda OportaNo ratings yet

- Introduction To MEMSDocument29 pagesIntroduction To MEMSjaimon_cletusNo ratings yet

- Chapter 4 Transport PhenomenaDocument89 pagesChapter 4 Transport PhenomenaaasattiNo ratings yet

- Failure Analysis of An Onshore Pipeline in Petroleum IndustryDocument9 pagesFailure Analysis of An Onshore Pipeline in Petroleum Industrypesanpesta IDNo ratings yet

- Roof WaterproofingDocument10 pagesRoof WaterproofingNazir MobasharNo ratings yet

- Chemistry Chapter 2 Form 4Document121 pagesChemistry Chapter 2 Form 4Angie Kong Su MeiNo ratings yet

- Ac1 Ac3 Temperatures p1, p2Document2 pagesAc1 Ac3 Temperatures p1, p2jlplazaola0% (1)

- Instalacion GeogrillasDocument2 pagesInstalacion GeogrillasChris Muñoz CardozaNo ratings yet

- Sem 1 ElectronicsDocument867 pagesSem 1 Electronicsjlincy2010No ratings yet

- Concrete Technolgy PDFDocument31 pagesConcrete Technolgy PDFSaqib imranNo ratings yet

- Reaseach Paper For Powder CoatingDocument10 pagesReaseach Paper For Powder CoatingAkshay DhakanNo ratings yet

- FOS/TAC Introduction of New Digester MetricsDocument18 pagesFOS/TAC Introduction of New Digester MetricsCédric RochatNo ratings yet

- Sand 2Document21 pagesSand 2Pavan MNo ratings yet

- SheetDocument2 pagesSheetKhaled Gamal EL-SaftawyNo ratings yet

- Compare D2 and D3Document2 pagesCompare D2 and D3GANESHNo ratings yet

- Molecule Shapes Student HandoutDocument7 pagesMolecule Shapes Student HandoutmrschnellteacherNo ratings yet

- Mohs Scale of Mineral HardnessDocument3 pagesMohs Scale of Mineral HardnessDeep JoshiNo ratings yet

- Renderoc LA Xtra: Shrinkage Controlled, Fluid Micro-Concrete For Structural Repairs of All TypesDocument2 pagesRenderoc LA Xtra: Shrinkage Controlled, Fluid Micro-Concrete For Structural Repairs of All TypesBassam ElsayedNo ratings yet

- MSDS HypoDocument4 pagesMSDS HypoRoderick TevesNo ratings yet