Professional Documents

Culture Documents

010 3

010 3

Uploaded by

AnhNtCao0 ratings0% found this document useful (0 votes)

4 views1 pageOriginal Title

010-3

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views1 page010 3

010 3

Uploaded by

AnhNtCaoCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

L_

Company Nae

Procedure Qualification Record No.:

|supporting WPS No.

|Welding Process(es): GTAW

Types:

JOINTS (QW-402)

PROCEDURE QUALIFICATION RECORDS (PQR)

(According to: ASME Section IX: 2019 _ Boller and Pressure Vessel Code)

‘TRUONG THUAN SERVICE TRADING INVESTMENT COMPANY LIMITED

Np-vD174-enR.010 Revision: Date: 04/22/2022

ND-VD174-pwS.010 Revision: 0 Date: 27/10/2022

Manual [] Semi-Automatic L] Mechanized L] ‘Automatic C]

+

|wela Metal Analysis A-No,

554mm

F Sequence of weld beads

sme

‘BASE METALS (QW-403) POSTWELD HEAT TREATMENT (QW-407):

Material Spe. AST AS3 Gr Temperature: None

[Tvpe/Grade or UNS No. “6B Time: a None =

IP-No.1 Group No. 1 to Po. GroupNo.i Other: == None

pee of Test Coupon: 554mm -

Diameter of Test Coupon: (00 114mm GAS (QW-408)

Max. Pass Thickness 13mm Percent Composition

jot None 7 Gas(es) Mixture Flow Rate |

Shielding 99.99% 30-15 L/min

FILLER METAL (QW-404) 1 Trailing: None We

Process: -

SFA Specification: 5

laws ciassification -

Filler Metal F-N See below Table

See below Table

{size of Filler Metal: 24 Amps. See below Table Volts: See below Table

Fiter Trade name: oRECO | Weld bead length

rit Mota Product Form: Seid | Tungsten Clectrode Size/Type: 2.4 / 2% Thoriated (WT20)

[Electrode Flux Class.: None : | Mode of Metal Transfer for GMAW (FCAW): N/A

[riux Type: None Heat Input: See below Table

[Flux Trade name: None : Other: None

[Weld Metal Thickness 554mm = =

'POSmION (@w-405) TECHNIQUE (QW-#30)

Position of Groove: 66 Travel Speed: See below Table

|Weld Progression (Up/Downhill) “Uphill String or Weave Bead: Both

ther: None Oscillation: —10-14mm

[PREHEAT (QW-406) E Multipass or Single Pass (per side}: Multipass

[Preheat Temperature ‘Ambient (29°C) Single or Multiple Electrodes: single

Interpass Temperature See below Table Other: None

[Method of Checkin Infrared Thermometer

ee

Page Lof2

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- WPS - PQR SusDocument4 pagesWPS - PQR SusAnhNtCaoNo ratings yet

- WPS-PQR - SanitaryDocument4 pagesWPS-PQR - SanitaryAnhNtCaoNo ratings yet

- WPS-PQR 1 SSDocument4 pagesWPS-PQR 1 SSAnhNtCaoNo ratings yet

- 010 1Document1 page010 1AnhNtCaoNo ratings yet

- 010 4Document1 page010 4AnhNtCaoNo ratings yet

- CN 4Document1 pageCN 4AnhNtCaoNo ratings yet

- CN 3Document1 pageCN 3AnhNtCaoNo ratings yet

- A&A Green Phoenix Group Joint Stock Company (Phenikaa) : Mechanical Datasheet For Reactor Vacuum Pump Vp-601/701Document3 pagesA&A Green Phoenix Group Joint Stock Company (Phenikaa) : Mechanical Datasheet For Reactor Vacuum Pump Vp-601/701AnhNtCaoNo ratings yet

- J2018-18-CWR-001: Test PackageDocument4 pagesJ2018-18-CWR-001: Test PackageAnhNtCaoNo ratings yet

- Test Package: Cooling Water 5.0 42.0 3.5 Water 7.5Document4 pagesTest Package: Cooling Water 5.0 42.0 3.5 Water 7.5AnhNtCaoNo ratings yet

- List of Isometric Drawing For Test Package: No. Area Iso Dwg. No. Sht. Line No. Rev. RemarkDocument5 pagesList of Isometric Drawing For Test Package: No. Area Iso Dwg. No. Sht. Line No. Rev. RemarkAnhNtCaoNo ratings yet

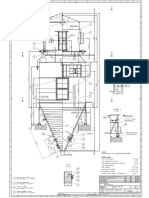

- Gas Disperser DPS-A 160 For InstallationDocument3 pagesGas Disperser DPS-A 160 For InstallationAnhNtCaoNo ratings yet

- 1360621-0001 A-0 Steam Piping, TEP Pre-HeaterDocument4 pages1360621-0001 A-0 Steam Piping, TEP Pre-HeaterAnhNtCaoNo ratings yet

- Bagfilter, TRH A 45 132 280 For InstallationDocument11 pagesBagfilter, TRH A 45 132 280 For InstallationAnhNtCaoNo ratings yet

- A&A Green Phoenix Group Joint Stock Company (Phenikaa) : Mechanical Datasheet For Cooling Water Pump P-101A/BDocument3 pagesA&A Green Phoenix Group Joint Stock Company (Phenikaa) : Mechanical Datasheet For Cooling Water Pump P-101A/BAnhNtCaoNo ratings yet

- A&A Green Phoenix Group Joint Stock Company (Phenikaa) : Mechanical Datasheet For Air Compressor C-201A/BDocument3 pagesA&A Green Phoenix Group Joint Stock Company (Phenikaa) : Mechanical Datasheet For Air Compressor C-201A/BAnhNtCaoNo ratings yet

- T-501 - Glycol 1 Strorage TankDocument9 pagesT-501 - Glycol 1 Strorage TankAnhNtCaoNo ratings yet

- A&A Green Phoenix Group Joint Stock Company (Phenikaa) : Mechanical Datasheet For Filling Station U-605, U-705Document4 pagesA&A Green Phoenix Group Joint Stock Company (Phenikaa) : Mechanical Datasheet For Filling Station U-605, U-705AnhNtCaoNo ratings yet

- D A42 1362 0001J 17 Isometric ExtractedDocument3 pagesD A42 1362 0001J 17 Isometric ExtractedAnhNtCaoNo ratings yet