Professional Documents

Culture Documents

WPS-PQR - Sanitary

WPS-PQR - Sanitary

Uploaded by

AnhNtCao0 ratings0% found this document useful (0 votes)

25 views4 pagesOriginal Title

WPS-PQR- SANITARY

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

25 views4 pagesWPS-PQR - Sanitary

WPS-PQR - Sanitary

Uploaded by

AnhNtCaoCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

‘TRUONG THUAN SERVICE TRADING INVESTMENT COMPANY LIMITED.

~ Add: 260B/2 KP 4B, An Phu, Thuan An, Binh Duong.

~Tell : 0978 069 586

WELDING PROCEDURE SPECIFICATION (WPS)

jelding Procedure Specification No.:CN.GTAW.1.2 Date: 17-02-2022 Revision No. 0

ISupporting POR No. CNGTAW-1.2 Date: 08-02-2022

elaing Process(es) GTAW. Type: Manual

[Applicable Code: ASME SECTION IX

Prepare by: DINH CAO TUNG.

DOINTS (aW-402)

Joint cesign:

[Backing /gouging (Yes). (No)

[Backing Material (Type): NA

0 Metal 1D Non fusing Metal

1D Nonmetallic 0 Other

BASE METALS (QW-403)

IP -No. 8 Group No. 4 To P No. 08 Group Now! 4

[Specification Type & Grade: ASTM 240 Type 304L. To: ASTM A 240 Type 304L.

[Thickness Range:

[Base Metal Groove: 1.2-2.4mm.... Filet: NIA

PPine Dia. Range: Groove: ALL. Fillet N/A

lotner:

[FILLER METAL (QW 404)

ISpec. No. (SFA): NA,

JAWS No. (Class) NA

IF -No NIA

lA- No. NA

[size of Fiter meta: Nia

[Thickness Range:

Groove NA

Filet: NIA.

lElectode - Flux (Class):

IFiux Trade Name: NA

IConsumable Insert. NA

lother

[POSITIONS (QW - 05) PREHEAT (QW - 408)

IPosition (2) Groove: a Proheet Temp/ Min

felding Progression UP @....DOWN a, Interpass Temp/ Max

[Position (s) Fillet

Al Preheat Maintemance:

‘TRUONG THUAN SERVICE TRADING INVESTMENT COMPANY LIMITED.

= Add: 2608/2 KP 18, An Phu, Thuan An, Binh Duong.

= Tell : 0978 069 586

WELDING PROCEDURE SPECIFICATION (WPS)

POST WELD HEAT TREAMENT (QW - 407) Jas (aw - 408)

[Temperature Range: NIA Percent Composition

[Time Range: NA Gas (es) Mixture Flow Rate

18+30LPM

18+60LPM

ELECTICAL CHARACTERISTIC (QW - 409)

Icurrent AC or Dc: oc Polarity See Table

impe (Range): See Table Votts (Range). See Table,

[Tungsten Electrode Size and Type: 24mm

[Mode of Metal Transfer for GMAW: NA

[Electrode Wire Feed Speed Range NA

TECHNIQUE (QW - 410)

|stnng or weave ead: ‘Sting or Weaving

rifice or Gas Cup Size: No.6

initial and interpass Cleaning (Brushing, Grinding, etc, ..): Brushing,

[Method of Rack Gouging NA

lOscilation NA

IMuttpie or Single Pass (per side) Single Pass.

IMuttipte or Single Electrodes: Single

[Travel Speed (Range): See Table,

Peening NA

lotner. NA

Wed | prcase Filter Metal Current (A) Vo [Travel Speed] Remarks

Layers) Class _[ Dia. (mim)| Type Polarity Amp. Range| Rangge (V)| (m/min)

1

NA WA | DCEN | 0760 | 6-16 | 6-12

'APAVE VIETNAM & S.E.A

Name: TONG VAN TRON,

signature

Wt

\Name

[siananure

17/02/2022

‘TRUONG THUAN SERVICE TRADING

= Tell : 0978 069 586

- Add: 2608/2 KP 18, An Phu, Thuan An, Binh Duong.

INVESTMENT COMPANY LIMITED

[Procedure Qualification Record No, CN-GTAW-1 2

/PS support No, cN-GTAW.2

leding Process(es): GTAW

Applicable Code. ASME SECTION IX

[Prepare by: DINH CAO TUNG

JOINTS (QW-402)

IBASE METALS (QW-403)

[PREHEAT (QW - 406)

lPreneating Temp: Ais

lterpass Temp: max 120°C

IMetarial Spec... 260 temperature:

[Type & Grade: ...Type Sos.

PLN. nn ToP.No... &

lor. No. ToGrNo:..1 Percent Composition

[Thickness of Test Coupon... 1.2 Jcas(es) Mature FlowRate

lDiamater of test Coupon...05° shieding: Arg 29.90%. 18uPM

other. Backing: Avg 09.005 25L2M

FILLER METAL (QW - 404) [ELECTRICAL CHARACTERISTICS (QW - 408)

ISFA Speciicaton: NA Jcurent oe

[AWS Classification: NA Polarity: EN

Filer Meta F. No: NA lamps: See Table

fal Matal Analysis A Nov Na [Tungsten Electrode Size: 2.4 mm

[size of Filler metat NA Jotner:

[Trace Name:

JDeposited weld metal thickness: (N/A [TECHNIQUE (aw - 410)

jotner [Travel Speed: See Table

[Pwr (QW -407): NA

string or Weave Bead: Weave

Josciation: WA

Muttinass or Single Pass (per size) Single pass

[cas cup Size: No.6

Method of cleaning: Brushing

Method of Back Gouging: N/A

lotner:

fotner:

Filer Metal Current Vor | Travel

Wels Heat input

We | Process THe] Are] Range | Specs tinput | Remarks

Layer(s) ciass[oiatmm) | poten | mange | | cemveany | mn)

7 [eran | NA [NA | DceN | 35 10 8 02626

‘TRUONG THUAN SERVICE TRADING INVESTMENT COMPANY LIMITED

- Add: 260B/2 KP 1B, An Phu, Thuan An, Binh Duong.

- Tell : 0978 069 586

PROCEDURE QUALIFICATION RECORD

(POR)

TEST RESULTS

[TENSILE TEST (QW - 150)

Specimen] _Omanton mm) [Area | utim. Tensiewoad | Utim Unt Stress |Characiorof] pay

bos Width [Thickness | (mm?) (KN) (Mpa) Failture

7 12 | 1502 703 32 Wedmetal| Pass

z ize) 16738 708 358) Haz | Pass

[SUIDED BEND TEST (QW - 160)

SeE="] Type ana Faure No | WEF [RSS] cenangaroe [OER] caracer | _Resut

1 Face bend 19 12 180 6 | Nocrack | Pass

2 Root bend 19 [12 7180 | NoCrack | Pass

3 Face bend 19 [12 180 | NoCrack | Pass

4 Root bend 19 [| 12 7180 | Nocrack | Pass

[TOUGHNESS TEST (QW 170): WA

Specimen] yo . Specimen Test Impact Values ‘Drop weight

No. | _ Neteh Locator Size(mm) _|temp.(c)| Fume] Shear [Mis | Break YIN)

[FILLET -WELD TEST (QW- 180): NIA

Resut-satstacioy Yess Noo Penetration info ParentMetal Yess (Nc

IMacro- Resuts

joTHER Test

[Type of Testing VISUAL Date oftesting 8122022 Resut —_Aczeptabie

RADIOGRAPHIC TestReportNo:APSIHLUWPS-RT-01 eau Acceptable

Deposit Anais Date of shootin 8722022

joner

[Welders name: VOOUY LIN Stamp no: WE-17

[Tests conducted by: NGUYEN THANH LE - SGS Laboratory Test No: INL12/0043 Testing date: Feb 13, 2022

[We certty that the staterments in this record are correct and the test weld were prepared, welded, and tested in

laccordance withthe requirement of Section IX ofthe ASME code.

‘APAVE VIETNAM & S.E.A

[Signature

Tr

Rise

1722022

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- WPS-PQR 1 SSDocument4 pagesWPS-PQR 1 SSAnhNtCaoNo ratings yet

- WPS - PQR SusDocument4 pagesWPS - PQR SusAnhNtCaoNo ratings yet

- CN 3Document1 pageCN 3AnhNtCaoNo ratings yet

- 010 4Document1 page010 4AnhNtCaoNo ratings yet

- 010 3Document1 page010 3AnhNtCaoNo ratings yet

- 010 1Document1 page010 1AnhNtCaoNo ratings yet

- CN 4Document1 pageCN 4AnhNtCaoNo ratings yet

- A&A Green Phoenix Group Joint Stock Company (Phenikaa) : Mechanical Datasheet For Reactor Vacuum Pump Vp-601/701Document3 pagesA&A Green Phoenix Group Joint Stock Company (Phenikaa) : Mechanical Datasheet For Reactor Vacuum Pump Vp-601/701AnhNtCaoNo ratings yet

- J2018-18-CWR-001: Test PackageDocument4 pagesJ2018-18-CWR-001: Test PackageAnhNtCaoNo ratings yet

- Test Package: Cooling Water 5.0 42.0 3.5 Water 7.5Document4 pagesTest Package: Cooling Water 5.0 42.0 3.5 Water 7.5AnhNtCaoNo ratings yet

- List of Isometric Drawing For Test Package: No. Area Iso Dwg. No. Sht. Line No. Rev. RemarkDocument5 pagesList of Isometric Drawing For Test Package: No. Area Iso Dwg. No. Sht. Line No. Rev. RemarkAnhNtCaoNo ratings yet

- Gas Disperser DPS-A 160 For InstallationDocument3 pagesGas Disperser DPS-A 160 For InstallationAnhNtCaoNo ratings yet

- 1360621-0001 A-0 Steam Piping, TEP Pre-HeaterDocument4 pages1360621-0001 A-0 Steam Piping, TEP Pre-HeaterAnhNtCaoNo ratings yet

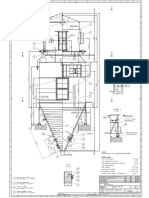

- Bagfilter, TRH A 45 132 280 For InstallationDocument11 pagesBagfilter, TRH A 45 132 280 For InstallationAnhNtCaoNo ratings yet

- A&A Green Phoenix Group Joint Stock Company (Phenikaa) : Mechanical Datasheet For Cooling Water Pump P-101A/BDocument3 pagesA&A Green Phoenix Group Joint Stock Company (Phenikaa) : Mechanical Datasheet For Cooling Water Pump P-101A/BAnhNtCaoNo ratings yet

- A&A Green Phoenix Group Joint Stock Company (Phenikaa) : Mechanical Datasheet For Air Compressor C-201A/BDocument3 pagesA&A Green Phoenix Group Joint Stock Company (Phenikaa) : Mechanical Datasheet For Air Compressor C-201A/BAnhNtCaoNo ratings yet

- T-501 - Glycol 1 Strorage TankDocument9 pagesT-501 - Glycol 1 Strorage TankAnhNtCaoNo ratings yet

- A&A Green Phoenix Group Joint Stock Company (Phenikaa) : Mechanical Datasheet For Filling Station U-605, U-705Document4 pagesA&A Green Phoenix Group Joint Stock Company (Phenikaa) : Mechanical Datasheet For Filling Station U-605, U-705AnhNtCaoNo ratings yet

- D A42 1362 0001J 17 Isometric ExtractedDocument3 pagesD A42 1362 0001J 17 Isometric ExtractedAnhNtCaoNo ratings yet