Professional Documents

Culture Documents

ASC Pressure Ratings Tech Data v05

Uploaded by

pt presisi engineering indonesiaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASC Pressure Ratings Tech Data v05

Uploaded by

pt presisi engineering indonesiaCopyright:

Available Formats

Technical Data Sheets

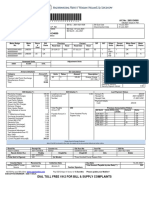

Coupling Working Pressure Rating

on Light Wall Roll Grooved Steel Pipe

Gruvlok Coupling Working Pressure Rating (PSI) On Light Wall Roll Grooved Steel Pipe

Maximum Working Pressure (PSI*)

Nominal Nom. Wall Pipe

O.D. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig.7 Fig.

Size Thickness Schedule Fig.70

7000 7001 7003 7004 7005 7010* 7012 7013 7400 401 74/7402

In./DN In./mm In. Number Lightweight Standard Hingelok® High Roughneck® Reducing Flange Flange Rigidlite® Rigidlok® SlideLOK® SlideFLEX™

(mm) Pressure

0.065 5 300 500 – – – – – – 175 – – –

1 1.315

0.085 XL 300 300 – – – – – – 300 – – –

25 33.4

0.109 10 600 750 – – – – – – 300 – – –

0.065 5 300 500 – – – – – – 175 – – –

1¼ 1.660

0.085 XL 300 300 – – – – – – 300 – – –

32 42.2

0.109 10 600 750 – – – – – – 300 – – –

0.065 5 300 500 200 – – – – – 175 500 – –

1½ 1.900

0.090 XL 300 300 250 – – – – – 300 300 – –

40 48.3

0.109 10 600 750 300 – – – – – 300 750 – –

0.065 5 300 500 200 500 – 250 200 500 175 500 – –

2 2.375

0.090 XL 300 300 250 300 – 300 300 300 300 300 – –

50 60.3

0.109 10 600 750 300 800 500 350 300 720 300 750 600 750

0.083 5 300 500 200 500 – 250 200 500 175 500 – –

2½ 2.875

0.130 XL 300 300 250 300 – 300 300 300 300 300 – –

65 73.0

0.120 10 600 750 300 800 500 350 300 720 300 750 600 750

0.083 5 300 500 200 500 – 250 200 500 175 500 – –

3 3.500

0.130 XL 300 300 250 300 – 300 300 300 300 300 – –

80 88.9

0.120 10 600 750 300 800 500 350 300 720 300 750 600 750

3½ 4.000 0.083 5 300 500 – – – – – – – – – –

90 101.6 0.120 10 600 750 – – – – – – – – – –

4 4.500 0.083 5 300 500 200 400 – 200 200 500 175 500 – –

100 114.3 0.120 10 600 750 300 600 400 300 300 720 300 750 500 750

5 5.563 0.109 5 250 400 200 400 – 200 200 400 175 400 – –

125 141.3 0.134 10 500 500 250 600 400 300 300 500 300 500 500 –

0.109 5 250 350 150 400 – 200 200 350 175 350 – –

6 6.625

0.134 10 400 500 200 500 300 300 300 500 300 500 500 500

150 168.3

0.188 – 400 500 200 700 – 350 300 500 300 500 – –

0.109 5 250 300 150 300 – 150 200 300 175 300 – –

8 8.625 0.148 10 350 400 200 400 300 250 300 400 175 400 300 400

200 219.1 0.188 – 350 400 200 500 – 300 300 400 300 400 – –

0.250 20 350 500 250 600 – 300 300 500 300 500 – –

0.134 5 – 250 – 300 – – 200 250 – 250 – –

10 10.750 0.165 10 – 350 – 400 – – 200 350 – 350 – –

250 273.1 0.188 – – 350 – 400 – – 300 350 – 350 – –

0.250 20 – 400 – 500 – – 300 400 – 400 – –

0.156 5 – 200 – 200 – – 200 200 – 200 – –

12 12.750 0.180 10 – 350 – 300 – – 200 350 – 350 – –

300 323.9 0.188 – – 350 – 300 – – 300 350 – 350 – –

0.250 20 – 400 – 400 – – 300 400 – 400 – –

0.156 5 – 125 – – – – 125 – – 125 – –

14 14.000

0.250 10 – 250 – – – – 250 – – 250 – –

350 355.6

0.312 20 – 275 – – – – 250 – – 275 – –

0.165 5 – 125 – – – – 100 – – 100 – –

16 16.000

0.250 10 – 175 – – – – 175 – – 175 – –

400 406.4

0.312 20 – 275 – – – – 250 – – 275 – –

18 18.000 0.250 10 – 100 – – – – 100 – – 100 – –

450 457.2 0.312 20 – 175 – – – – 175 – – 175 – –

20 20.000 0.250 10 – 100 – – – – 100 – – 100 – –

500 508.0 0.375 20 – 300 – – – – 250 – – 250 – –

24 24.000 0.250 10 – 75 – – – – 75 – – 75 – –

600 609.6 0.375 20 – 300 – – – – 250 – – 250 – –

Maximum line pressure, including surge, to which a joint should be subjected on pipe roll grooved to standard roll grooving specification with coupling properly assembled.

For coupling performance on standard wall steel pipe, refer to individual Gruvlok Coupling performance listing.

* Rating based on larger pipe size.

asc-es.com

06.22 page 1 ASC-Pressure-Ratings-Tech-Data-v05 20221107

Technical Data Sheets

Coupling Working Pressure Rating

on Roll Grooved ISO Size Steel Pipe

Gruvlok Coupling Working Pressure Rating (Bar) On Roll Grooved ISO Size Steel Pipe

Nominal Nom. Wall Maximum Working Pressure (bar)

O.D.

Size Thickness Fig. 7000 Fig. 7001 Fig. 7003 Fig. 7004 Fig. 7010* Fig. 7012 Fig. 7013 Fig. 7400 Fig. 7401 Fig. 74/7402

In./DN(mm) In./mm mm Lightweight Standard Hingelok® High Pressure Reducing Flange Flange Rigidlite® Rigidlok® SlideLOK®

1 1.315 1.8 20.7 34.5 – – – – – 12.1 – –

25 33.4 2.9 41.4 51.7 – – – – – 20.7 – –

3.2 41.4 69.0 – – – – – 20.7 – –

1¼ 1.660 1.8 20.7 34.5 – – – – – 12.1 – –

32 42.2 2.9 41.4 51.7 – – – – – 20.7 – –

3.6 41.4 69.0 – – – – – 20.7 – –

1½ 1.900 1.8 20.7 34.5 13.8 – – – – 12.1 34.5 –

40 48.3 2.9 41.4 51.7 17.2 – – – – 20.7 51.7 –

3.6 41.4 69.0 20.7 – – – – 20.7 51.7 –

2 2.375 1.8 20.7 34.5 13.8 34.5 17.2 13.8 34.5 12.1 34.5 –

50 60.3 2.9 41.4 51.7 17.2 55.2 24.1 20.7 51.7 20.7 51.7 41.1

3.6 41.4 69.0 20.7 82.3 24.1 20.7 69.0 20.7 51.7 51.7

2½ 2.875 2.0 20.7 34.5 13.8 34.5 17.2 13.8 34.5 12.1 34.5 –

65 73.0 3.2 41.4 51.7 17.2 55.2 24.1 20.7 51.7 20.7 51.7 41.1

5.0 41.4 69.0 20.7 82.3 24.1 20.7 69.0 20.7 51.7 51.7

3 O.D. 2.996 2.0 20.7 34.5 – – – 13.8 – 12.1 34.5 –

76.1 76.1 3.2 41.4 51.7 – – – 20.7 – 20.7 51.7 –

5.0 41.4 69.0 – – – 20.7 – 20.7 51.7 –

3 3.500 2.0 20.7 34.5 13.8 34.5 17.2 13.8 34.5 12.1 34.5 –

80 88.9 3.2 41.4 51.7 17.2 55.2 24.1 20.7 51.7 20.7 51.7 41.1

5.6 41.4 69.0 20.7 82.3 24.1 20.7 69.0 20.7 51.7 51.7

3½ 4.000 2.0 20.7 34.5 – – – – – – – –

90 101.6 3.2 41.4 51.7 – – – – – – – –

5.6 41.4 69.0 – – – – – – – –

4 4.500 2.0 20.7 34.5 13.8 27.6 13.8 13.8 34.5 12.1 34.5 –

100 114.3 3.2 41.4 51.7 17.2 41.4 20.7 20.7 51.7 20.7 51.7 34.5

5.6 41.4 69.0 20.7 82.3 24.1 20.7 69.0 20.7 51.7 51.7

4¼ O.D. 4.250 2.0 20.7 – – – – – – – – –

108.0 108.0 3.2 41.4 – – – – – – – – –

5.6 41.4 – – – – – – – – –

5 5.563 2.9 17.2 27.6 10.3 27.6 13.8 13.8 27.6 12.1 27.6 –

125 141.3 3.6 34.5 34.5 13.8 41.4 20.7 20.7 34.5 20.7 34.5 34.5

6.3 34.5 69.0 20.7 82.3 24.1 20.7 69.0 20.7 51.7 51.7

5¼ O.D. 5.236 2.9 17.2 – – – – – – – – –

133.0 133.0 3.6 34.5 – – – – – – – – –

6.3 34.5 – – – – – – – – –

5½ O.D. 5.500 2.9 17.2 – – – – 13.8 – 12.1 – –

139.7 139.7 3.6 34.5 – – – – 20.7 – 20.7 – –

6.3 34.5 – – – – 20.7 – 20.7 – –

6 6.625 2.9 17.2 24.1 10.3 27.6 13.8 13.8 24.1 12.1 24.1 –

150 168.3 3.6 27.6 34.5 13.8 34.5 20.7 20.7 34.5 20.7 34.5 34.5

7.1 27.6 69.0 20.7 82.3 24.1 20.7 69 20.7 51.7 48.3

6¼ O.D. 6.259 2.9 17.2 – – – – – – – – –

159.0 159.0 3.6 27.6 – – – – – – – – –

7.1 27.6 – – – – – – – – –

6½ O.D. 6.500 2.9 17.2 24.1 – – – 13.8 – 12.1 24.1 –

165.1 165.1 3.6 27.6 34.5 – – – 20.7 – 20.7 34.5 –

7.1 27.6 69.0 – – – 20.7 – 20.7 51.7 –

8 8.625 2.9 17.2 20.7 10.3 20.7 10.3 13.8 20.7 12.1 20.7 –

200 219.1 5.0 24.1 34.5 13.8 35.4 24.1 20.7 34.5 20.7 34.5 20.7

8.0 24.1 55.2 20.7 69 24.1 20.7 55.2 20.7 51.7 41.4

10 10.750 3.6 – 17.2 – 20.7 – 13.8 17.2 – 17.2 –

250 273.1 5.0 – 24.1 – 27.6 – 20.7 24.1 – 24.1 –

8.0 – 55.2 – 55.2 – 20.7 55.2 – 51.7 –

12 12.750 4.0 – 17.2 – 13.8 – 13.8 17.2 – 17.2 –

300 323.9 5.0 – 24.1 – 20.7 – 20.7 24.1 – 24.1 –

8.0 – 55.2 – 55.2 – 20.7 55.2 – 51.7 –

14 14.000 4.0 – 8.6 – – – 8.6 – – 8.6 –

350 355.6 6.3 – 17.2 – – – 17.2 – – 17.2 –

8.8 – 20.7 – – – 20.7 – – 20.7 –

16 16.000 4.0 – 6.9 – – – 6.9 – – 6.9 –

400 406.4 6.3 – 12.1 – – – 12.1 – – 12.1 –

8.8 – 20.7 – – – 20.7 – – 20.7 –

18 18.000 5.0 – 5.2 – – – 5.2 – – 5.2 –

450 457.2 6.3 – 6.9 – – – 6.9 – – 6.9 –

8.8 – 17.2 – – – 17.2 – – 17.2 –

20 20.000 5.0 – 3.4 – – – 3.4 – – 3.4 –

500 508.0 6.3 – 6.9 – – – 6.9 – – 6.9 –

8.8 – 17.2 – – – 17.2 – – 17.2 –

24 24.000 5.0 – 1.7 – – – 1.7 – – 1.7 –

600 609.6 6.3 – 5.2 – – – 5.2 – – 5.2 –

8.8 – 17.2 – – – 17.2 – – 17.2 –

Maximum line pressure, including surge, to which a joint should be subjected on pipe roll grooved to standard roll grooving specification with coupling properly assembled. For coupling performance on

standard wall steel pipe, refer to individual Gruvlok Coupling performance listing.

* Rating based on larger pipe size.

asc-es.com

07.16 page 2 ASC-Pressure-Ratings-Tech-Data-v05 20221107

Technical Data Sheets

Coupling & Flange Working Pressure Rating

on 304 and 316 Stainless Steel Roll Grooved Pipe

The following are pressure ratings for Gruvlok Stainless Steel Piping Systems. The ratings for Schedule 10S pipe are based upon the use of roll-groover roll sets that

have been specifically designed for use on Schedule 10 Stainless Steel pipe. Using roll sets that were designed for roll grooving standard wall pipe may significantly

reduce the pressure ratings that can be obtained. The Model 1007/3007 roll groovers require the use of the optional Schedule 10 roll set to groove Schedule 5S and

10S. For grooving Schedule 40S on the Model 1007/3007 roll groovers, the standard steel roll grooving set should be used.

Gruvlok Coupling & Flange Working Pressure Ratings (PSI) On 304 And 316 Stainless Steel Roll Grooved Pipe

Coupling and Flanges

Nominal Nominal Pipe Fig. Fig. Fig. Fig. Fig.

Pipe Fig. Fig.

Pipe Wall Sch. 7000 Fig. 7001 Fig. 7003 7004 Fig. 7010* Fig. 7012 Fig. 7400 7001SS 7400SS 7401SS Fig. 74 Fig. 770 Fig.70

O.D. 7013 7401

Size Thickness Number Light- Standard Hingelok® High Reducing Flange Rigidlite® Flexible Rigidlite Rigid SlideLOK® Coupling SlideFLEX™

Flange Rigidlok®

weight Pressure Coupling Coupling Coupling

In./DN(mm) In./mm Inches – PSI

0.065 5S 400 400 – – – – – 300 – 325 – – – – –

1 1.315

0.109 10S 400 500 – – – – – 300 – 500 – – – – –

25 33.4

0.133 40 500 750 – – – – – 300 – 500 – – – – –

0.065 5S 400 400 – – – – – 300 – 325 275 200 – – –

1¼ 1.660

0.109 10S 500 500 – – – – – 300 – 500 300 300 – – –

32 42.4

0.140 40 500 750 – – – – – 300 – 750 300 600 – – –

0.065 5S 400 400 275 – – – – 300 400 325 275 200 – – –

1½ 1.900

0.109 10S 500 500 300 – – – – 300 500 500 300 300 – – –

40 48.3

0.145 40 500 750 300 – – – – 300 750 750 300 600 – – –

0.065 5S 250 325 250 325 250 250 275 250 325 225 275 200 – – –

2 2.375

0.109 10S 500 500 300 500 500 300 300 300 500 350 300 300 500 500 500

50 60.3

0.154 40 500 750 300 750 500 300 300 300 750 500 300 600 750 750 750

0.083 5S 250 325 250 325 250 250 275 250 325 225 200 200 – – –

2½ 2.875

0.120 10S 500 500 300 500 500 300 300 300 500 350 300 300 500 500 500

65 73.0

0.203 40 500 750 300 750 500 300 300 300 750 500 300 600 750 750 750

0.083 5S 250 325 250 325 250 250 275 250 325 225 200 200 – – –

3 3.500 400 500 500

0.120 10S 500 500 300 500 500 300 300 300 500 350 300 300

80 88.9 500 750 750

0.216 40 500 750 300 750 500 300 300 300 750 500 300 600

0.083 5S 200 250 200 250 200 200 250 200 250 200 200 200 – – –

4 4.500

0.120 10S 300 400 300 400 300 300 300 300 400 300 300 300 350 500 250

100 114.3

0.237 40 500 750 300 750 500 300 300 300 750 325 300 600 400 750 325

0.109 5S 125 200 125 200 125 125 200 125 200 125 – 200 – – –

5 5.563

0.134 10S 200 300 200 300 200 200 300 200 300 200 – 300 300 – –

125 141.3

0.258 40 300 500 300 500 300 300 300 300 500 200 – 600 400 – –

0.109 5S 75 125 75 125 75 75 125 75 125 125 125 200 – – –

6 6.625

0.134 10S 200 200 200 200 200 200 200 200 200 200 250 300 300 350 200

150 168.3

0.280 40 300 500 300 500 300 300 300 300 500 200 275 600 400 750 200

0.109 5S 50 75 50 75 50 50 75 50 75 50 75 200 – – –

8 8.625

0.148 10S 150 200 150 200 150 150 200 150 200 75 150 300 300 350 150

200 219.1

0.322 40 300 400 300 400 300 300 300 300 400 200 275 600 400 650 200

0.134 5S – 50 – 50 – 50 50 – 50 – – N/R – – –

10 10.750

0.165 10S – 100 – 100 – 100 100 – 100 – – 300 – – –

250 273.0

0.365 40 – 400 – 400 – 300 300 – 400 – – 600 – – –

0.156 5S – 75 – 75 – 50 75 – 75 – – N/R – – –

12 12.750

0.180 10S – 125 – 125 – 100 125 – 125 – – 125 – – –

300 323.9

0.375 40 – 400 – 400 – 300 300 – 400 – – 300 – – –

Notes:

1) Pressure ratings based on ASTM A312 Type 304 stainless steel pipe or equivalent.

2) Failure to use Rollers specifically designed for Stainless Steel Pipe may significantly reduce pressure retention capabilities.

3) Pressure ratings on cut grooved pipe meet or exceed the schedule 40 pressure ratings listed above. For information regarding higher ratings contact Anvil.

4) *For pressure ratings on Figure 7010 Reducing Couplings use larger pipe size.

5) For pressure ratings for the reducing tees, concentric reducers and eccentric reducers, use the rating of the weakest end.

6) Pressure ratings on schedule 10 stainless steel pipe may be decreased by not using ASC's 1007/3007 roll groovers with the schedule 10 roller set. Contact ASC for details.

For pressure tests exceeding the published load, please contact an ASC Representative.

asc-es.com

07.20 page 3 ASC-Pressure-Ratings-Tech-Data-v05 20221107

Technical Data Sheets

Coupling & Flange Working Pressure Rating

on Aluminum Pipe

Gruvlok Coupling & Flange Working Pressure Ratings (PSI) On Aluminum Pipe

Coupling and Flanges

Nominal Wall

Pipe O.D. Schedule R/C Fig. 7401 Fig. 7001 Fig. 7400 Fig. 7000 Fig. 7012 Fig. 74 Fig. 70

Pipe Size Thickness

Rigidlok® Standard Rigidlite® Light Weight Flange SlideLOK® Slideflex™

In./DN(mm) In./mm Inches – – PSI

0.179 80 C – 1000 500 500 – – –

1 1.315 0.133 40 R/C – 800 500 500 – – –

25 33.4 0.109 10 R – 600 500 500 – – –

0.065 5 R – 500 500 500 – – –

0.191 80 C – 1000 500 500 – – –

1¼ 1.660 0.140 40 R/C – 800 500 500 – – –

32 42.4 0.109 10 R – 600 500 500 – – –

0.065 5 R – 500 500 500 – – –

0.200 80 C 750 1000 500 500 – – –

1½ 1.900 0.145 40 R/C 750 800 500 500 – – –

40 48.3 0.109 10 R 600 600 500 500 – – –

0.065 5 R 500 500 500 500 – – –

0.218 80 C 750 1000 500 500 – – –

2 2.375 0.154 40 R/C 750 800 500 500 250 – –

50 60.3 0.109 10 R 600 600 500 500 250 600 600

0.065 5 R 500 500 500 500 150 – –

0.276 80 C 750 1000 500 500 250 – –

2½ 2.875 0.203 40 R/C 750 800 500 500 250 – –

65 73.0 0.120 10 R 600 600 500 500 150 – –

0.083 5 R 500 500 500 500 250 – –

0.300 80 C 750 1000 500 500 250 – –

3 3.500 0.216 40 R/C 750 800 500 500 150 – –

80 88.9 0.120 10 R 500 600 500 500 150 500 600

0.083 5 R 400 400 500 500 250 – –

0.337 80 C 750 800 500 500 250 – –

4 4.500 0.237 40 R/C 600 600 500 500 150 600 600

100 114.3 0.121 10 R 350 350 350 350 250 – –

0.083 5 R 250 250 250 250 250 – –

0.375 80 C 750 800 450 450 150 – –

5 5.563 0.258 40 R/C 600 600 450 450 150 – –

125 141.3 0.134 10 R 350 300 300 300 250 – –

0.109 5 R 250 250 250 250 250 – –

0.432 80 C 600 600 450 450 150 – –

6 6.625 0.280 40 R/C 600 600 450 450 250 400 500

150 168.3 0.134 10 R 200 200 200 200 250 – –

0.109 5 R 200 200 200 200 150 – –

0.500 80 C 400 400 300 300 150 – –

8 8.625 0.322 40 R/C 300 300 150 150 250 500 400

200 219.1 0.148 10 R – – 100 100 250 – –

0.109 5 R – – 100 100 100 – –

10 10.750 0.594 80 C 300 300 – – 250 – –

250 273.0 0.365 40 R/C 200 200 – – 250 – –

12 12.750 0.688 80 C 300 300 – – 250 – –

300 323.9 0.406 40 R/C 200 200 – – 250 – –

Notes:

Field roll grooving is recommended for 6061-T4/6063-T4, 6063 T-5 aluminum pipe. Field cut grooving is recommended for 6061-T6/6063-T6 aluminum pipe. Field roll grooving may result in stress cracking.

ASC recommends reviewing roll/cut groove recommendations with the aluminum pipe manufacturer’s as mechanical properties may vary from pipe to pipe.

asc-es.com

11.22 page 4 ASC-Pressure-Ratings-Tech-Data-v05 20221107

Technical Data Sheets

Coupling Working Pressure Rating

on CPVC Pipe

Gruvlok Coupling Working Pressure Ratings (PSI) On CPVC Pipe

Wall R (Roll)/C (Cut) Coupling

Nominal Pipe Size Pipe O.D. Schedule

Thickness Groove Fig. 7001 Standard

In./DN(mm) In./mm Inches – – PSI

2 2.375

0.218 80 C 400

50 60.3

2½ 2.875

0.276 80 C 420

65 73.0

3 3.500

0.300 80 C 370

80 88.9

4 4.500

0.337 80 C 320

100 114.3

6 6.625

0.432 80 C 280

150 168.3

8 8.625

0.500 80 C 250

200 219.1

Temperature Derating Factors on CPVC Pipe

Working Temperature Pipe De-rating Factor(multiply by pressure rating from chart above)

°F °C Cell Class: CPVC 4120-05 Cell Class: CPVC 4120-06

73-80 23.0-26.7 1.00 1.00

90 32.2 0.91 0.91

100 37.8 0.82 0.83

120 48.9 0.65 0.70

140 60.0 0.50 0.57

160 71.1 0.40 0.44

180 82.2 0.25 0.41

Notes:

1. Cut groove per ASC's CPVC Cut Groove Specification.

2. ASC Recommended Groover: Rex Wheeler 6950 Plastic Cut Groover

3. Pressure ratings based upon Corzan Schedule 80 CPVC Pipe produced to ASTM F441 standards

4. Gruvlok Standard Lubricant is FBC Compatible

5. FBC compliant lubricants are required for use with CPVC Pipe.

6. CPVC pipe manufactured per ASTM F441. Minimum cell class “23447” per ASTM D1784.

asc-es.com

04.21 page 5 ASC-Pressure-Ratings-Tech-Data-v05 20221107

You might also like

- Unit Weight Standard Hook 135 Deg. BAR Diameter Anchorage LengthDocument14 pagesUnit Weight Standard Hook 135 Deg. BAR Diameter Anchorage LengthMarvin BeatoNo ratings yet

- CAD Sales Request 72530-0 Scope of Supply Preview: TCD 2.2 L3Document4 pagesCAD Sales Request 72530-0 Scope of Supply Preview: TCD 2.2 L3emrah kucukakcaNo ratings yet

- Ejector A-Type - EllehammerDocument3 pagesEjector A-Type - EllehammerlucasNo ratings yet

- 7-12-0013 Rev. 6 Nozzle Reinforcement & ProjectionDocument2 pages7-12-0013 Rev. 6 Nozzle Reinforcement & ProjectionJitender Kumar GuptaNo ratings yet

- CAD Sales Request 16053-0 Scope of Supply Preview: DEUTZ Engine DocumentationDocument4 pagesCAD Sales Request 16053-0 Scope of Supply Preview: DEUTZ Engine DocumentationEric ChuNo ratings yet

- Hollow SectionDocument1 pageHollow Sectiondhiny.andrianiNo ratings yet

- IS 1538 Table 7 Flanged Sockets (Clause 9.1 and 11.1)Document1 pageIS 1538 Table 7 Flanged Sockets (Clause 9.1 and 11.1)Akshat JainNo ratings yet

- BF4M 2012 C - Engine-ViewsDocument4 pagesBF4M 2012 C - Engine-ViewsKevinCollenNo ratings yet

- Futures Contracts: Filter By: Expiry DateDocument6 pagesFutures Contracts: Filter By: Expiry DateDheeraj KumarNo ratings yet

- Quiz 2Document2 pagesQuiz 2ImjusttryingtohelpNo ratings yet

- Conversion Tables: 12.1 Metric To English Conductor SizeDocument16 pagesConversion Tables: 12.1 Metric To English Conductor SizeGerardo Muñoz UrbinaNo ratings yet

- IEC 60071-1 Page 30Document1 pageIEC 60071-1 Page 30omid fathiNo ratings yet

- Inertia Base: Feature and BenefitsDocument1 pageInertia Base: Feature and BenefitsKABIR CHOPRANo ratings yet

- BEAMDocument3 pagesBEAMTano BahabobaNo ratings yet

- Pre Plan Semana 34Document6 pagesPre Plan Semana 34rpumacayovNo ratings yet

- Reinforcement Calculation of Abutment (2) : A B A BDocument12 pagesReinforcement Calculation of Abutment (2) : A B A Bshashi rajhansNo ratings yet

- Kalyanpur AFR Shed BOQ-Column and TrussDocument38 pagesKalyanpur AFR Shed BOQ-Column and TrussPinak ProjectsNo ratings yet

- TolerânciasDocument1 pageTolerânciasJose Do Carmo SilvaNo ratings yet

- MST-Manual 19121735 PDFDocument101 pagesMST-Manual 19121735 PDFKároly VighNo ratings yet

- Mesh (Scale) : Mesh Series Have Been EstablishedDocument4 pagesMesh (Scale) : Mesh Series Have Been EstablishedKewell LimNo ratings yet

- Bba-6 Szabist: Submitted: TODocument7 pagesBba-6 Szabist: Submitted: TOshahidbhuttNo ratings yet

- Engine Performance Data - OM 473.: R6 - 380 KW (517 HP)Document3 pagesEngine Performance Data - OM 473.: R6 - 380 KW (517 HP)Osman SomuncuNo ratings yet

- CAD Sales Request 52692-0 Scope of Supply Preview: TCD 914 L06 MDocument4 pagesCAD Sales Request 52692-0 Scope of Supply Preview: TCD 914 L06 Mjordan navarroNo ratings yet

- Rocksledger Crusher: TABLE 3 Equivalent Jaw SettingsDocument1 pageRocksledger Crusher: TABLE 3 Equivalent Jaw SettingsMechanical departmentNo ratings yet

- CPWD 2016 Vol 2Document1 pageCPWD 2016 Vol 2Nizar AhamedNo ratings yet

- Distribution Network ProblemDocument12 pagesDistribution Network ProblemLALIT MOHAN PATNAIK Jaipuria JaipurNo ratings yet

- Book1 PDFDocument1 pageBook1 PDFbryanNo ratings yet

- Prysmian EU 11kV 1core ArmourDocument5 pagesPrysmian EU 11kV 1core ArmourBhagoo HatheyNo ratings yet

- Scale Factor Drawing Limits / Plot ScaleDocument2 pagesScale Factor Drawing Limits / Plot ScaleReymond IgayaNo ratings yet

- Pressure Capacity Table Homogenizers 110114Document1 pagePressure Capacity Table Homogenizers 110114Xuân Hòa NguyễnNo ratings yet

- Reade Particle Size Conversion AnsiDocument1 pageReade Particle Size Conversion AnsijhscribdaccNo ratings yet

- Compact Enclosures Ax: Technical DetailsDocument24 pagesCompact Enclosures Ax: Technical DetailsJorge OsorioNo ratings yet

- Revised Cutoff Report M Tech M DesDocument5 pagesRevised Cutoff Report M Tech M Desaustin00012No ratings yet

- Molded-Case Circuit Breaker Design: Frame Size A Interrupting Capacity A Continuous Current Ratings, ADocument16 pagesMolded-Case Circuit Breaker Design: Frame Size A Interrupting Capacity A Continuous Current Ratings, AGlenn GregorioNo ratings yet

- RUBIRU Irrigation Scheme Measurement Sheet Vol 2 - Final 23 - 06 - 2022-Ednah FinalDocument39 pagesRUBIRU Irrigation Scheme Measurement Sheet Vol 2 - Final 23 - 06 - 2022-Ednah FinalWangai MichaelNo ratings yet

- Cable ScunDocument8 pagesCable ScunPoppy IrawanNo ratings yet

- Cyclotec SalesDocument11 pagesCyclotec SalesRama BugarinNo ratings yet

- 2 X 7.6 Skew 31Document48 pages2 X 7.6 Skew 31Sheik MohamedNo ratings yet

- Pipe Schedule Chart InchDocument1 pagePipe Schedule Chart InchLeroy Ambrosio GabineteNo ratings yet

- Charts & Tables Charts & Tables: Socomec Busbar Support Fault LevelsDocument1 pageCharts & Tables Charts & Tables: Socomec Busbar Support Fault Levelsmuqtar4uNo ratings yet

- 2023Document4 pages2023VJ CalanogaNo ratings yet

- TP, MP, MC CurvesDocument13 pagesTP, MP, MC Curvesnihma100% (2)

- BRAY s40 PDFDocument26 pagesBRAY s40 PDFCristina Mayumi InoueNo ratings yet

- Pipe Thickness Sizes PDFDocument1 pagePipe Thickness Sizes PDFSualp EsenliNo ratings yet

- (In) (In) : Schedule 10 20 30 STD 40 60 XS 80 100 120 140 160 XXS Nominal Pipe Size Outside Diameter Wall Thickness (In)Document1 page(In) (In) : Schedule 10 20 30 STD 40 60 XS 80 100 120 140 160 XXS Nominal Pipe Size Outside Diameter Wall Thickness (In)dimaszrizkiNo ratings yet

- Monocrystalline Silicon Solar Cells: 275Wp (6x10) 330Wp (6x 12)Document2 pagesMonocrystalline Silicon Solar Cells: 275Wp (6x10) 330Wp (6x 12)Foe AungNo ratings yet

- JMS Mochia Fab Aug-19Document14 pagesJMS Mochia Fab Aug-19SAMEERNo ratings yet

- Drawing Built New Room at Maintenance ApprovalDocument12 pagesDrawing Built New Room at Maintenance ApprovalPardana MardiyanaNo ratings yet

- Engine Performance Data - OM 936.: R6 - 175 KW (238 HP)Document5 pagesEngine Performance Data - OM 936.: R6 - 175 KW (238 HP)Osman SomuncuNo ratings yet

- Ware HouseDocument8 pagesWare Houseshun cheeNo ratings yet

- Lampiran Minggu 12 ADocument1 pageLampiran Minggu 12 ABekti NurpambudiNo ratings yet

- Bondek Plus: User & Installation GuideDocument6 pagesBondek Plus: User & Installation Guidevishnumani3011No ratings yet

- SA AbsorberDocument3 pagesSA AbsorberMOHSENNo ratings yet

- CS Bridge ApproachesDocument20 pagesCS Bridge ApproachesvenkyNo ratings yet

- Inventory Review: S.No. Item Code Item Name Monthly Schedule Raw MaterialDocument30 pagesInventory Review: S.No. Item Code Item Name Monthly Schedule Raw MaterialHarsh KachhawaNo ratings yet

- Existing Computer Lab and Class Room: W W W WDocument1 pageExisting Computer Lab and Class Room: W W W WvijaykrishnaasacivilNo ratings yet

- Tabel Nominal Wall THK - Small 4xDocument5 pagesTabel Nominal Wall THK - Small 4xdioalfanandaNo ratings yet

- Lowara z8 z10 z12 Technical Datasheet PDFDocument108 pagesLowara z8 z10 z12 Technical Datasheet PDFArif MahendraNo ratings yet

- Piling NormsDocument2 pagesPiling Normsdaman bistaNo ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- Flair Catalogue FullDocument12 pagesFlair Catalogue FullEl Houcine KabdaNo ratings yet

- 현대물리학6판Document40 pages현대물리학6판rlaxksrua123No ratings yet

- Ee0065 Module3 PDFDocument36 pagesEe0065 Module3 PDFMV5 ChannelNo ratings yet

- Analytical Method For Recalibration of Incore and Excore Nuclear Instrumentation System of PWRsDocument7 pagesAnalytical Method For Recalibration of Incore and Excore Nuclear Instrumentation System of PWRshgffdkhjgcasdgNo ratings yet

- An Ideal Gas Mixture Consists of 2kmol of N2 and 6 Kmol of CO2. The Mass Fraction of CO2 IsDocument9 pagesAn Ideal Gas Mixture Consists of 2kmol of N2 and 6 Kmol of CO2. The Mass Fraction of CO2 IsLance Andrew LagmanNo ratings yet

- Vacuum Contactor: Addendum To VSC Installation and Service Instructions 7.2/12 KV - 400 ADocument16 pagesVacuum Contactor: Addendum To VSC Installation and Service Instructions 7.2/12 KV - 400 ANISHANNo ratings yet

- Project Reference SCIS PDFDocument1 pageProject Reference SCIS PDFAgus RiyanaNo ratings yet

- Computation For VOCDocument3 pagesComputation For VOCBROADFIELD ENGINEERINGNo ratings yet

- PSX Power Solutions: Single Voltage Power SystemsDocument2 pagesPSX Power Solutions: Single Voltage Power SystemsMaria Paulina Hoyos BurgosNo ratings yet

- Oil Investor RiskDocument18 pagesOil Investor RiskBehrang BaghernejadNo ratings yet

- STANLEY 45HW Electrified Mortise LockDocument6 pagesSTANLEY 45HW Electrified Mortise LocksacdawoodNo ratings yet

- Battery Specs UnboxDocument2 pagesBattery Specs UnboxEuro VoltaNo ratings yet

- TAD 4, 5, 6 - 7 Series WM-Technical DataDocument92 pagesTAD 4, 5, 6 - 7 Series WM-Technical DataTrong Pham100% (2)

- We Wlsk3012a Wlsk6012a Wlsk8012a SolderDocument2 pagesWe Wlsk3012a Wlsk6012a Wlsk8012a Solderzeroescobar9No ratings yet

- Printed by SYSUSER: Dial Toll Free 1912 For Bill & Supply ComplaintsDocument1 pagePrinted by SYSUSER: Dial Toll Free 1912 For Bill & Supply Complaintsvinay seemuNo ratings yet

- Fuaadi 1991Document19 pagesFuaadi 1991jalestNo ratings yet

- York High Wall Split Cooling OnlyDocument2 pagesYork High Wall Split Cooling OnlyLuqman MohammadNo ratings yet

- Inst Sheet L2461Document44 pagesInst Sheet L2461RonaldNo ratings yet

- Cambridge Assessment International Education: Combined Science 0653/32 March 2019Document9 pagesCambridge Assessment International Education: Combined Science 0653/32 March 2019equakeroatsNo ratings yet

- 028-Dehaco Water Distribution Skid - 3 (030408)Document3 pages028-Dehaco Water Distribution Skid - 3 (030408)brat.jose2023No ratings yet

- Manual Oper Manut Gerador KATO - 350 01001 00Document48 pagesManual Oper Manut Gerador KATO - 350 01001 00Damiao PereiraNo ratings yet

- Tech FRTDocument8 pagesTech FRTNaveen BosNo ratings yet

- Workshop 29: Accessing, Reading & Erasing Engine Trouble Codes 2.7tdiDocument3 pagesWorkshop 29: Accessing, Reading & Erasing Engine Trouble Codes 2.7tdimorusNo ratings yet

- CapacitanceDocument23 pagesCapacitanceChristianNo ratings yet

- Go Green - Print - QuizizzDocument4 pagesGo Green - Print - QuizizzNUR WAHEDAH BINTI ABD RAHMAN MoeNo ratings yet

- Bio CNG From City WasteDocument12 pagesBio CNG From City WastenehareshailNo ratings yet

- SSED - Solved Problems For Chapter 3Document7 pagesSSED - Solved Problems For Chapter 3MINH NGUYỄN THẾNo ratings yet

- Automate Pentru Arzatoare Brahma CM - SM - MMDocument6 pagesAutomate Pentru Arzatoare Brahma CM - SM - MMrtsNo ratings yet

- Carta de FiltrosDocument47 pagesCarta de FiltrosJesús AraizaNo ratings yet

- Electric Power SwitchesDocument11 pagesElectric Power Switchesautomation vguardNo ratings yet