Professional Documents

Culture Documents

Rocksledger Crusher: TABLE 3 Equivalent Jaw Settings

Uploaded by

Mechanical departmentOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rocksledger Crusher: TABLE 3 Equivalent Jaw Settings

Uploaded by

Mechanical departmentCopyright:

Available Formats

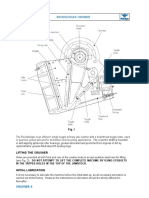

ROCKSLEDGER CRUSHER

Actual capacities can vary considerably from those given due to the following application and

operational factors: Material - Friability & Toughness. Feed Conditions - Grading of feed size,

presence of clay or sticky material. Moisture content. Installation - Method of Feeding, Removal of

undersize.

Our policy of continuous development may necessitate changes to Specification/Data without notice.

MACHINE T.D.C. CLOSED SIDE JAW SETTING (MM)

SIZE

mm x mm 50 65 75 100 125 150 175 200 250 300

1100 x 760 -------- ---------- 110 138 166 195 224 253 ---------- ----------

1100 x 800 -------- --------- --------- 138 166 195 224 253 ---------- ----------

1300 x1050 -------- --------- --------- --------- --------- 176 203 230 283 335

TABLE 3 Equivalent Jaw Settings

Refer to Table 2 for TOP DEAD CENTRE (T.D.C.) closed side jaw setting.

Refer to body of Table for equivalent bottom dead centre jaw setting (mm) for ease of setting.

MACHINE T.D.C. CLOSED SIDE JAW SETTING (MM) Free Length

SIZE of Spring

mm

mm x mm 50 65 75 100 125 150 175 200 250 300

1100 x 760 -------- -------- 270 270 270 270 270 270 --------- --------- 336

(300) (300) (300) (300) (300) (300)

1100 x 800 -------- -------- -------- 270 270 270 270 270 --------- --------- 336

(300) (300) (300) (300) (300)

1300x1050 -------- --------- --------- --------- -------- 380 380 380 380 380

(430) (430) (430)

495

(430) (430)

TABLE 4 Minimum Drawback Spring Setting Length (mm)

Table figures are minimum spring length (mm) at top dead centre (equivalent bottom dead centre).

NOTE: Lengths quoted are ABSOLUTE MINIMUM. Springs must not be compressed more than

this figure or they will become coil-bound and could break the drawback rod assembly.

CRUSHER 4

You might also like

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- ASC Pressure Ratings Tech Data v05Document5 pagesASC Pressure Ratings Tech Data v05pt presisi engineering indonesiaNo ratings yet

- 04 AMFLEX Ball ElementsDocument5 pages04 AMFLEX Ball Elements'Muhammad Yusuf Sudirman'No ratings yet

- Jaw Crusher Series Technical Specification PDFDocument16 pagesJaw Crusher Series Technical Specification PDFHerman C Gallegos Macas100% (1)

- Metrosil 300-A and 600-A VaristorsDocument2 pagesMetrosil 300-A and 600-A Varistorsian.rowley4051No ratings yet

- Elastomeric Bearing Pads NR PDFDocument4 pagesElastomeric Bearing Pads NR PDFICPL-RWPNo ratings yet

- Shaping Machines: Machine Tool Exporters To The World Since 1940Document4 pagesShaping Machines: Machine Tool Exporters To The World Since 1940pedjaNo ratings yet

- Column Beam Design ReportDocument29 pagesColumn Beam Design ReportAmit PatelNo ratings yet

- BF4M 2012 C - Engine-ViewsDocument4 pagesBF4M 2012 C - Engine-ViewsKevinCollenNo ratings yet

- 4e HydraulischePressen PDFDocument28 pages4e HydraulischePressen PDFDenis Yasmin AlineNo ratings yet

- S002EN08-2203 - SE-EV-Dimensões e FundamentosDocument8 pagesS002EN08-2203 - SE-EV-Dimensões e FundamentosJean AlexNo ratings yet

- 2 Axis TurningDocument1 page2 Axis TurningMinh Sang TrầnNo ratings yet

- TEST-E Series Computer Controlled Electro-Hydraulic Servo Universal Testing MachineDocument3 pagesTEST-E Series Computer Controlled Electro-Hydraulic Servo Universal Testing MachineCirclesOnSandNo ratings yet

- Tuyau en Fonte Ductile Ekoval ChoixDocument52 pagesTuyau en Fonte Ductile Ekoval ChoixmmfayistNo ratings yet

- Common SizesDocument1 pageCommon Sizeskedar kavathekarNo ratings yet

- Elastomeric Bearing Pads and Strips Brochure 2010Document4 pagesElastomeric Bearing Pads and Strips Brochure 2010Anton Husen PurboyoNo ratings yet

- Steel Conveyor Roller: Rollers SERIES 1200Document6 pagesSteel Conveyor Roller: Rollers SERIES 1200Winston NoelNo ratings yet

- Price Fitting PVCDocument10 pagesPrice Fitting PVCtjiangtjiangsNo ratings yet

- PE Jaw crusher manual-英文Document22 pagesPE Jaw crusher manual-英文Edwin Forero100% (3)

- SEBF8149 - Specifications For Connecting Rods Used in 3500 Family of EnginesDocument24 pagesSEBF8149 - Specifications For Connecting Rods Used in 3500 Family of Enginesyahmanmahira4No ratings yet

- SKF BRG ClearenceDocument6 pagesSKF BRG ClearenceNath Boyapati100% (2)

- m1100 s08 v1.1f en - Safety - ProductsDocument4 pagesm1100 s08 v1.1f en - Safety - Productsdzul fiqarNo ratings yet

- Ac Motoren FCPL 60h Brake Motor Installation Guide en Iss201710 B 5282Document16 pagesAc Motoren FCPL 60h Brake Motor Installation Guide en Iss201710 B 5282Eric CNo ratings yet

- Stock Air Plate List 2020Document1 pageStock Air Plate List 2020Karina FatovyanaNo ratings yet

- Section 03Document6 pagesSection 03sertecs polNo ratings yet

- Grilles CDocument5 pagesGrilles Csyedkaleem55No ratings yet

- Guardrail DesignDocument8 pagesGuardrail Designundf25No ratings yet

- Charts & Tables Charts & Tables: TEKNOMEGA TOP Busbar Support Fault Level ChartDocument1 pageCharts & Tables Charts & Tables: TEKNOMEGA TOP Busbar Support Fault Level Chartmuqtar4uNo ratings yet

- Inertia Base: Feature and BenefitsDocument1 pageInertia Base: Feature and BenefitsKABIR CHOPRANo ratings yet

- Ducting SizeDocument4 pagesDucting Sizeheri monawir zebuaNo ratings yet

- PurlinsDocument9 pagesPurlinsrocky_oquendoNo ratings yet

- Jaw Crusher 2013Document8 pagesJaw Crusher 2013dexsaNo ratings yet

- Beam Column DesignDocument28 pagesBeam Column DesignAmit PatelNo ratings yet

- Ficha Técnica Manguera Contra IncendiosDocument1 pageFicha Técnica Manguera Contra IncendiosFernando Rocca VillalobosNo ratings yet

- Carbide Tipped Reamers - Technical Information - Hannibal Carbide Tool, IncDocument2 pagesCarbide Tipped Reamers - Technical Information - Hannibal Carbide Tool, Incsemarasik_651536604No ratings yet

- 2012 LMT Onsrud Production Cutting Tools Aluminum PDFDocument1 page2012 LMT Onsrud Production Cutting Tools Aluminum PDFguru2368No ratings yet

- 2018 SP Pumpkit Wear Parts GuideDocument76 pages2018 SP Pumpkit Wear Parts GuideDenis MartiniNo ratings yet

- Outboard Motor: Parts CatalogueDocument245 pagesOutboard Motor: Parts Catalogueernesto tejedaNo ratings yet

- Ball Transfer Units - Installation ExamplesDocument2 pagesBall Transfer Units - Installation ExamplesAdis TosunbegovićNo ratings yet

- Hydraulic Cylinder With A 50mm Bore, 30mm Rod, 900mm Strok - Buy Hydraulic Cylinders Online - Interfluid LTDDocument2 pagesHydraulic Cylinder With A 50mm Bore, 30mm Rod, 900mm Strok - Buy Hydraulic Cylinders Online - Interfluid LTDmtriNo ratings yet

- Capacity-Chart Rev0 A984Document2 pagesCapacity-Chart Rev0 A984b.bouhmadi1965No ratings yet

- Elecon Gear CouplingDocument7 pagesElecon Gear CouplingVipul Chaudhari100% (4)

- CAD Sales Request 72530-0 Scope of Supply Preview: TCD 2.2 L3Document4 pagesCAD Sales Request 72530-0 Scope of Supply Preview: TCD 2.2 L3emrah kucukakcaNo ratings yet

- Die Cut PartsDocument2 pagesDie Cut PartsAbdelrhman ElsayedNo ratings yet

- Speeds and Feeds For Metal CuttingDocument4 pagesSpeeds and Feeds For Metal CuttingAnonymous dh6DITNo ratings yet

- Thursday, September 01, 2022, 10:10 AM: Page 122 of 354 D:/Work/Sujit Bose/Sujit Bose .AnlDocument9 pagesThursday, September 01, 2022, 10:10 AM: Page 122 of 354 D:/Work/Sujit Bose/Sujit Bose .AnlRajat DeyNo ratings yet

- Amerigear CouplingsDocument48 pagesAmerigear Couplingsuak107080No ratings yet

- Thomson Super Metric Ball Bushing Bearings SpecsheetDocument11 pagesThomson Super Metric Ball Bushing Bearings SpecsheetElectromateNo ratings yet

- Effective Control: Spring BuffersDocument3 pagesEffective Control: Spring Buffersakın ersözNo ratings yet

- Wireway Price ListDocument7 pagesWireway Price ListUh NipatNo ratings yet

- THK PresisonDocument13 pagesTHK PresisonadolfovolumetricNo ratings yet

- Bumper FendersDocument6 pagesBumper Fenders8fsv8vpt84No ratings yet

- SA RawlboltDocument2 pagesSA Rawlboltpower_generator133850% (2)

- 8 t2 SC SeriesDocument16 pages8 t2 SC SeriesAntony VeNo ratings yet

- m1100 s03 v1.1f en - Multi Purpose - FendersDocument16 pagesm1100 s03 v1.1f en - Multi Purpose - Fendersdzul fiqarNo ratings yet

- SKF Taper RollerDocument18 pagesSKF Taper RollerJain AntonyNo ratings yet

- Discotom100 10 Tech EnglishDocument2 pagesDiscotom100 10 Tech EnglishKathia Bernal RamirezNo ratings yet

- Elign Gear Coupling-ManualDocument7 pagesElign Gear Coupling-ManualUrban JmfNo ratings yet

- Cat Dcs Sis ControllerDocument6 pagesCat Dcs Sis ControllerMechanical departmentNo ratings yet

- Rocksledger CrusherDocument1 pageRocksledger CrusherMechanical departmentNo ratings yet

- Crusher TerminologyDocument1 pageCrusher TerminologyMechanical departmentNo ratings yet

- Fig. 2 Trial Run: Rocksledger CrusherDocument1 pageFig. 2 Trial Run: Rocksledger CrusherMechanical departmentNo ratings yet

- Rocksledger CrusherDocument1 pageRocksledger CrusherMechanical departmentNo ratings yet

- BPW 1420809729Document4 pagesBPW 1420809729Mechanical departmentNo ratings yet

- p5 CrusherDocument1 pagep5 CrusherMechanical departmentNo ratings yet

- p4 CrusherDocument1 pagep4 CrusherMechanical departmentNo ratings yet

- P CrusherDocument1 pageP CrusherMechanical departmentNo ratings yet

- Jaw CrusherDocument1 pageJaw CrusherMechanical departmentNo ratings yet

- p3 CrusherDocument1 pagep3 CrusherMechanical departmentNo ratings yet

- p2 CrusherDocument1 pagep2 CrusherMechanical departmentNo ratings yet

- Crusher ParkerDocument1 pageCrusher ParkerMechanical departmentNo ratings yet

- Rocksledger: Primary Jaw CrushersDocument2 pagesRocksledger: Primary Jaw CrushersMechanical department100% (2)

- MID 039 - CID 1251 - FMI 04: TroubleshootingDocument3 pagesMID 039 - CID 1251 - FMI 04: TroubleshootingMechanical departmentNo ratings yet

- Primary CrusherDocument1 pagePrimary CrusherMechanical departmentNo ratings yet

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document20 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Terry JwNo ratings yet

- Parker Cone CrusherDocument1 pageParker Cone CrusherMechanical department100% (1)

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document12 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Teo Sil CasNo ratings yet

- Cat 325 3 Boom StickDocument7 pagesCat 325 3 Boom StickWassiem SayounNo ratings yet

- MID 039 - CID 1703 - FMI 03: TroubleshootingDocument3 pagesMID 039 - CID 1703 - FMI 03: TroubleshootingMechanical departmentNo ratings yet

- MID 039 - CID 1190 - FMI 04: TroubleshootingDocument5 pagesMID 039 - CID 1190 - FMI 04: TroubleshootingMechanical departmentNo ratings yet

- Parts JayDocument2 pagesParts JayMechanical departmentNo ratings yet

- Instruction Manual: Hand Spray GunDocument3 pagesInstruction Manual: Hand Spray GunMechanical departmentNo ratings yet

- Instruction Manual: Bead GunDocument4 pagesInstruction Manual: Bead GunMechanical departmentNo ratings yet

- Dw384 Spare Part ListDocument5 pagesDw384 Spare Part ListLuis Manuel Montoya RiveraNo ratings yet

- Rock DrillDocument16 pagesRock DrillESRANo ratings yet

- 1367 - 11 R220LC-9S Hyd-1Document78 pages1367 - 11 R220LC-9S Hyd-1Peace AlexNo ratings yet

- Analysis of Doubly Reinforced Beam (Investigation)Document6 pagesAnalysis of Doubly Reinforced Beam (Investigation)Kenny CantilaNo ratings yet

- Drill Grinding Attachment Form 825-55 6 PGDocument6 pagesDrill Grinding Attachment Form 825-55 6 PGAndy LNo ratings yet

- "Smart Dustbin Using Arduino": Maharashtra State Board of Technical Education, MumbaiDocument22 pages"Smart Dustbin Using Arduino": Maharashtra State Board of Technical Education, MumbaiEr Dinesh TambeNo ratings yet

- Floor DiaphragmsDocument4 pagesFloor DiaphragmsKiran BasuNo ratings yet

- Sae j846 Pg22Document1 pageSae j846 Pg22jcNo ratings yet

- TFP1420 09 2004 PDFDocument14 pagesTFP1420 09 2004 PDFPhuNguyenHoangNo ratings yet

- Pressure Reducing Valve (Inbuilt Strainer)Document1 pagePressure Reducing Valve (Inbuilt Strainer)Sanket SavlaNo ratings yet

- Nuts and Bolts Weight ListDocument11 pagesNuts and Bolts Weight ListLakshmana Rao NNo ratings yet

- Sertifikat 8mm SM 400b TESTDocument1 pageSertifikat 8mm SM 400b TESThafidNo ratings yet

- Design of Screw JackDocument12 pagesDesign of Screw JackKunal Ahiwale75% (4)

- Miting de Avance ScriptDocument4 pagesMiting de Avance Scriptfernando.gl559No ratings yet

- ZTT-540 Application GuideDocument8 pagesZTT-540 Application GuidesejlNo ratings yet

- D020aa00 Id S. Descensor AutofrenanteDocument31 pagesD020aa00 Id S. Descensor AutofrenanteFerreteros ingenierosNo ratings yet

- SOP-startup Shutdown and Operation of Raw MillDocument4 pagesSOP-startup Shutdown and Operation of Raw MillJCS100% (1)

- Major Axis Bending Minor Axis BendingDocument26 pagesMajor Axis Bending Minor Axis Bendingarunkumar.mgsNo ratings yet

- KA Series PDFDocument8 pagesKA Series PDFsancsa_74No ratings yet

- Prajwal PundeDocument2 pagesPrajwal PundeRohan KuldharNo ratings yet

- Welger D4006-4060-6006-6060 Owner Manual 1251-99-03-05 BADocument164 pagesWelger D4006-4060-6006-6060 Owner Manual 1251-99-03-05 BARui SilvaNo ratings yet

- Ped QRG 2014 68 EuDocument8 pagesPed QRG 2014 68 Eubekir kurtNo ratings yet

- Educational Qualificat IonDocument2 pagesEducational Qualificat Ionsrivenkatesh81No ratings yet

- ATPL Principles of Flight SummaryDocument8 pagesATPL Principles of Flight SummaryPrvoslav Vojinović86% (7)

- Herbert Metzendorff & Co. KGDocument2 pagesHerbert Metzendorff & Co. KGAymen BriniNo ratings yet

- Lta Gs (Lifting)Document11 pagesLta Gs (Lifting)Chan NaingNo ratings yet

- NESTING VS CUTTING STATUS (IHM 1225) AraDocument57 pagesNESTING VS CUTTING STATUS (IHM 1225) AraAjizul Rohim AkbarNo ratings yet

- Mangoes Industries - Production Docket - Hall 1Document24 pagesMangoes Industries - Production Docket - Hall 1Shivendra KumarNo ratings yet

- Kwik-Lock: Parts ListsDocument12 pagesKwik-Lock: Parts ListsJonah RagleNo ratings yet

- Revisión de Repúestos Bombas Titire y Vizcachas 09-03-2023Document171 pagesRevisión de Repúestos Bombas Titire y Vizcachas 09-03-2023CésarNo ratings yet