Professional Documents

Culture Documents

16 Movement Manual

16 Movement Manual

Uploaded by

JC AMARO0 ratings0% found this document useful (0 votes)

21 views33 pagesOriginal Title

16_movement_manual

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views33 pages16 Movement Manual

16 Movement Manual

Uploaded by

JC AMAROCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 33

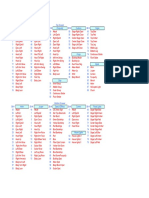

Table of Contents

4. Welcome and 16 Function CEC Information Page 1

2. CEC Figure Maintenance Pages 2-10

3. CEC Wiring Chart Page 11

4. CEC Costume Pages 12-43,

5. CEC Drawings / Parts List Pages 14-34

So —____——

\pudeting/

Welcome to the NEW Chuck E. Cheese!

This new Chuck E, Cheese figure was built with care taken in the design for reliable

‘operation, and ease of maintenance. This figure is considered to be a fairly elaborate

‘animated figure that contains 16 individual digital functions.

‘THESE FUNCTIONS ARE AS FOLLOWS:

Right Arm Swing

Left arm Swing

Right Elbow Up

Left Elbow Up

Right Wave

Left Wave

Head Tur Right

Head Turn Left

Head Nod

Eye Blink

Eye Turn Right

Eye Tum Left

Body Forebend

Torso Twist Right

Torso Twist Left

Mouth,

The following maintenance sections are intended to offer a brief outline of the systems

and devices employed in this figure. Its purpose is to assist maintenance personnel in

performing maintenance andior repair as required. Being a mechanical / electrical

system, items are eventually bound to deteriorate, (Wear items are deemed to bo

primarily: bearings, cylinders, valves, and friction points.) Other wear items include:

costumes, skins, and undergarments, The wear is caused by friction, age, and simple

repetitive use, A dedicated program of daily and weekly checks and maintenance

practices are important to keep the figure operating and costs down. If and when @ part

no longer performs as desired, follow the maintenance and repair procedures specified

by this manual. If there is any difficulty in doing this, feel free to contact your corporate

headquarters for assistance,

|

|

\ipu

‘THE FOLLOWING PROCEDURES MUST BE FOLLOWED ON A DAILY

BASIS BEFORE THE FIGURES ARE TURNED ON.

1, FILTER / REGULATOR (VALVE BOX):

‘A, Check Filter (drain water).

2, CHECK FIGURE FOR PROPER OPERATION.

NOTE: Always observe and follow the manufactures maintenance

recommendations for servicing and repair on these items.

BEFORE ATTEMPTING ANY MAINTENANCE

PROCEDURE ON THE FIGURE OR SYSTEMS,

THROUGHLY READ ALL APPLICABLE INFORMATION

AND PRECAUTIONS. CONSULT YOUR CORPORATE

HEADQUARTERS FOR ASSISTANCE, IF NEEDED.

‘THROUGHLY READ THE FOLLOWING BEFORE OPERATING OR PERFORMING

ANY MAINTENANCE PROCEDURE ON THE ANIMATRONIC FIGURE (S), SHOW

ELEMENTS OR ANY OF THEIR OPERATIONAL SYSTEMS.

41, Maintenance should only be attempted by competent qualified

personnel familiar with all systoms and their components.

2. Never begin any maintenance procedure on a figure or show element

unless the air, andior electric is off

3. When working near electrical or electronic systems, make sure power Is

off and avoid touching exposed electrical areas such as terminals and

ther points where voltage may be present.

4. Never replace any component with any other than an identical

component. Cylinders and other components different than the original

parts can cause extreme damage to the figure.

5. Observe all manufacturers recommendations for service, maintenance,

and part replacement on system components,

6. Prior to operation, inspect show area figures and equipment tor any

obstructions, hazards, problems, etc.

7. Make sure the figute and all related systems are kept in 2 clean,

moisture free environment for which they are intended.

FIGURE MAINTENANCE

TROUBLE SHOOTING (cont.)

2. Higsing may also mean that a hose has slipped off of afiting or cylinder. I this should occur,

find the cylinder location and you should find both ends (look for the same color hose). Ifthe

hissing is inlermittent then the line is being turned on and off by the valve.

4, MECHANICAL NOISE

4, The figure contains a number of pivot points, joints, clevises and bearings. The plastic

boarings and spherical rod ends, within the figure, are normally silent. Occasionally a squeak

Will develop. I this should occur, a single drop of 8:1 ol, at the joint itself, wil solve this problem.

Do not lubricate any part of the cylinder rod of any actuator, except for the rod end spherical

bearings. The seals In the actuator requite special factory lubrication. Petroleum based oils or

greases may ruin the seals

6, LIMB ATTACHMENT

1. fa catastrophic fallure (such as a detached limb) would occur, tur the figure off immediately.

‘This problem may be the result ofa joint pin working its way out ofthe clevis. After maintenance,

‘special care must be taken when reassembling the character, being careful to use the necessary

locking fasteners and Locktte where required

FIGURE MAINTENANCE

COSMETICS / COSTUME

FIGURE MAINTENANCE ~ CLEANING PROCEDURE

1. FACE AND HANDS (ALL SKIN AREAS)

‘The figure skin is made of specially formulated elastomer that is not affected

by sunlight or the elements. Dust will settle on the material to some degree

land should be cleaned as required. An air hose with nozzle may be used on

a regular basis (dally, if required) to dust the figure. A soft, damp makeup

‘sponge can be used fo gently wipe (not scour oF fu) the dust off the facial

or skin areas,

Do not use any chemicals or solvents. A feather duster will also work for

removing dust from skin,

EYEBALL CLEANING

‘The eyes may be cleaned, by rubbing gently with a soft cloth / cheese

cloth, dampened with warm water. After they have been cleaned, they

can be lightly polished to remove streaks by using a dry swab or piece

of Kleenex.

Take care not to scratch the eyes in any way.

Bo not nub hard or force eyelids open or closed.

3. FUR AND COSTUME AREAS

Fur areas should be dusted using an air gun and feather duster on a

Fegular basis. Fur fabric can be gently brushed using a soft brush,

‘Care must be taken to not harshly brush colored areas of fur-this may

brush out color.

‘A damp sponge may be used, before brushing, to help remove dust or

{grime discoloration. Do not use solvents of any kind on fir materials.

Costumes may be air blasted andor feather dusted. Most costume

‘material may be treated as normal clothing and can be dry cleaned as

needed (do not wash).

Da ll

FIGURE MAINTENANCE

BODY FORMS / SHELLS

FIGURE MAINTANANCE = Chuck E. Cheese

NOTE: TURN OFF ALL AIR AND ELECTRICAL POWER TO THE FIGURE

BEFORE BEGINNING ANY MAINTENANCE PROCEDURE.

————— ee

4, HEAD ACCESS

Remove the baseball cap. This is attached by 2 snaps, one on each side of the hat,

under the brim. Chuck E's head is split around sides (behind the ears) and is

attached tothe front shell with pan head screws,

Upon their removal, the rear ofthe head can be separated from the front. Ths allows

‘access into the head for repairs. Do not remove the front ofthe head f face from the

‘mechanical frame. This should not be necessary for normal maintenance.

2, COSTUME REMOVAL

The costume is spit in the back, on a central seam that allows for removal of the

clothing without moving the ims, The seams are altached with Velo stips and

‘must be opened carefully.

3, TORSO ACCESS

“The torso mechanics can be accessed, by removing the rear half of the body shell,

‘This is done by removing the fasteners on the clips along the seam of the shell

4, ARM ACCESS

The arm fur is spit up the back of the arm with a Velero seam, Pull the fur out of

the hand glove and split the arm all the way up. The arm fur also has an

‘attachment point at the shoulder, using Velero to attach it to the torso shell, The

hand glove is altached with Velero on a seam atthe thumb,

5. LEG ACCESS:

‘The tog fur is split up the back of each leg. Carefully spit the fur from the botiom

up. The pelvis area fur is folded over the top of the pelvis shell and Velcro'd. The

fur was created to fit very tight to avoid creases and wrinkles on the characters

legs. Use care and patience while re-nsteling the fur onto the pelvis and lags

6, BASE ACCESS

‘The base is accessible by first removing the carpet covered panels under the

figuies feet. The valve bank is located under these panels,

Patents ONINT=N VAN Cols

ACTUATOR REPLACEMENT

ACTUATOR REPLACEMENT- Chuck E. Cheese

NOTE: TURN OFF ALL AIR AND ELECTRIC POWER TO THE FIGURE

BEFORE BEGINNING ANY MAINTENANCE PROCEDURE.

4, ACTUATOR REPLACEMENT

AcTU INDERS)

‘The movement of each individual function is caused by the actuatoricylinder. The

actuator Is constructed with only one moving part, the pistonfrod assembly. As air

pressure is applied to one end, the cylinder extends ~ moving the part in one direction.

‘When pressure 1s applied to the opposite end, the cylinder retracis in the reverse

tion, Air and hydraulic cylinders are constructed to ast for milions of cycles. If any

leakage is detected, or the cylinder fails or becomes damaged, It should be replaced.

In some cases they can be repaired, but only qualified personnel should do ths.

"Never replace any actuator wih a diferent size, stoke, or manufacturer.

\When changing out an actuator assembly, the most important issues are:

+1, Replacing with the correct replacement actuator.

2. Replacing all components in the exact place, before they were removed.

3, Replacing hoses properly with correct color code.

2, FLOW RESTRICTORS

A set of colored flow control restritors will be mounted in each line between the

‘valve and the eylinder, one pair per function. These are usually found inside the

figure a few inches from the actuator. One rostrictor controls the speed that the

cylinder extends, and one controls the speed thatthe cylinder retracts.

When replacing, itis cctcal that the color remains the same and the arrow on the

Festictors pointing in the direction of the actuator.

“The show computer is programmed with control signals that are timed in relation to

the size of the flow restrctors. If the flow restrictors are not the proper size, the

timing of the figure wil be incorrect, and the shove will not function properly.

FIGURE MAINTENANCE

ACTUATOR REPLACEMENT

ACTUATOR REPLACEMENT- Chuck E. Cheese

NOTE: TURN OFF ALL AIR AND ELECTRIC POWER TO THE FIGURE

BEFORE BEGINNING ANY MAINTENANCE PROCEDURE.

ACTUATOR REPLACEMENT SCREW THREAD CALIBRATION

When replacing an actuator, iis important thatthe replacement has the same

length from pivot center to center, as the one being removed. I this length is

‘changed, it will affect the performance of the function and will possibly damage the

character. Since the replacement actuator sizeis the same, adjustment can only be

‘made by tightening or loosening the rod ends (at each end of the actuator),

‘When removing the defective actuator, count the threads on each end, as shown

below and write It down, When you replace the actuator and rod ends, make sure

‘counts are the samo. Bo careful as to the correct count on the proper end, either

back end “A” or front end “B". These thread counts are used when originally

‘manufacturing Chuckie. If they are observed during replacement, your figure should

‘remain properly calibrated.

Back End * Front End "8" T

“Thread Count Cxample #4 ‘Theoad Count Example #2

'Tineads Showing No Threads Showing

6k

A

7 m pos

FIGURE MAINTENANCE

NNO =o Voy)

VALVE CARD OPERATION- Chuck E. Cheese

NOTE: TURN OFF ALL AIR AND ELECTRIC POWER TO THE FIGURE

BEFORE BEGINNING ANY MAINTENANCE PROCEDURE.

4. VALVE CARD.

‘The valve bank contains valves that actuated by an electrical signal sent from Chuck

E's control system. When opened by an electric signal, these valves release high-

pressure air that travels into the hoses that lead to each inclvidual figure movement

This fils the air cylinders, which then extend causing motion. When the electrical

signal is removed - the air pressure is exhausted through the valve and the cylinder

retracts back to its normal positon,

2. CHUCK E.'S BASE

Chuck E's base (under his feet) contains a valve bank on which Is mounted 16

individual electric air valves. When each valve is activated, an indicator lamp on

that valve illuminates to show the presence of a control signal. Also, a button is

Provided on each valve that allows manual operation of each individual valve for

testing purposes. (See valve diagram). High-pressure (80 PSI) air enters the

valve manifolds on one end, and the exhaust exits the manifolds through tubes

‘connected to an exhaust chamber. This chamber mufies the air noises so no

“popping” is heard,

3. COMPONENT REPLACEMENT.

Valves that become clogged or cease to operate for any reason may be unscrewed

from the manifold and replaced (see valve card component sheet). Make sure that the

area is clean before removal, ana during replacement.

‘Take care when the valve is unscrewed thatthe rubber seal between itand the

‘manifold Is removed carefully and replaced in the correct orientation,

Be careful not to over tighten the valve screws.

Take care to make a good electrical connection when placing the valve pins into the

torminal, and tighten the terminal screws securely.

‘Be sure that if at any time the hoses are removed from the manifold, they are replaced

to the proper port they came from observing the color code.

After replacement, check for correct operation,

10

er uRTaTa] Sr wa ag a a 3

aaa] — Sr Fer a er a

TROD WAR SFa] — Fr 7a i 735 % wr

eR — wa arg] 78} wa] © =

Ca ar] a] ees] a m a

BTR Bea] TT a) Ta ag] Tas iT 7

Tara Besa] — OT 75 fam) Ta 75 7 oF

Tae] —F 725 ma] ay = e

Wore] — 725] a 3 7

PaRRIOS APO) a7 a T T

Tree] a | 7a] 5 3

Trane] a i) a 5 =

oo aa sia] wasn) 3575) >

waren) —e Fag a) my F =

wana] —z TH or) a) z z

WeaRe ay] —T arg a a) T cs

‘womBung | FesoVETIay] Z0}65 SOTO] FOT0D @aGHO| s0109 SSH |TO}OD 95H [PIED SABA [Fuld FOPDeUUCD | FINO

ponen | sa wv. | woa.e. | woa.v. | sige | ansa uid ze

yey Suiy uopoUNy esee49 “3 ONY

MAINTENANCE

Pers

FIGURE / SUBJECT: Chuck E. Cheese Costume

Hat C-t

Silcone Right,

Ear Liner

c2 Silicone Left

Ear Liner C-3

Silicone

‘Snout |

ca f Eyelash Stips (2)

cs

Right Arm,

Sleeve Fur C-7

Right Hand Fur Left Arm Sleeve Fur

co

aon Left Hand Fur:

c-10

Pelvis

Leg / Feet Fur

cA2

CHUCK E, CHEESE

COSTUME

PARTS LIST

[C12 [ees LeiFest Fur

CLIENT ___Chuck E. Cheese Enteinent PROJECT.

GATE SHOW,

SCENE LOCATION,

vo] ew fre] _oasonron | F* | _wores

[c= frat fl jrreasea

[C-2 |sticone Right Ear Liner 1 freon

[C3 stone Lot Ear Liner 1 jreore

[C4 |siicone Snout + [resin std saparately presasa

ICS feyotan stipe 2 jareonea

[o-6 [sna 4 SresniRT

IC-7_ |Right Arm Stoove Fur + [iecudes eather ner [rreooor

IC-B ften arm Steove Fur “1 finaudes lather nor [svesa0e

[C9 frig and Fur 1 areoasa

[C=10 ften Hand Fur 1 jareoaoa

(C=11 |snons| ni Tera

1 lareanee

CHUCK E. CHEESE IDEPT: ant

PLASTIC ASSEMBLIES pan 08108

PARTS LIST PAGE: + of

CLIENT____ChuckE. Choose Entertainment PROJECT.

GATE, ‘SHOW.

SCENE, LOCATION

No. em lay] DESCRIPTION PRICE NOTES

PA-T [snout Assombiy 1 [proonee

PA-2 et Hand Assemby 1 bresaes

IPA-3 _|Right Hand Assembly 1 leToonee

IPA-4 [Jaw Assembly 1 [erearr

IPA-5 eye assem 1 sreoaee

IPA-6 [eyebrow Assembly 4 jrrearae

[PA-7_|Washer 2 [eso jsrearre

lock Not 2 oa ren

Nytock Nut 2 [en re

ender Washer 2 6 ppreaeaz

eth 1 jareonee

Socket Heed Gap Screw SS. 2 lesextim reao

eel sy

oy CHUCK E. CHEESE DEPT: ant

z 4 BODY SHELLS BATE: eas

\peaeglona "i

aa PARTS LIST a

CLIENT Che E, Ghee Enernmont oie

GATE. SHOW,

SCENE LOCATION.

No. rem bn DESCRIPTION PRICE NOTES

IBS-1 [Front Ley Snen [sreanee

IBS-2 |sody shot Rivet [steaer

IBS-3 [body snett iip areaeae

IBS-4 [rear eg she preoase

IBS-5 [ody she Screw Ho-32 Pan Head [rea

lareorr

[sree

lsreaass

IBS-6 [Rear Torso Shot

IBS-7_ [From Torso Shot

[BS-8 [Front Hoad Shet

[BS-9 |Rear Head Shot

fanned ttn

CHUCK E. CHEESE DEPT: ant

HEAD DATE: 0203

PARTS LIST

CLIENT____Chuck E. Cheese Entertainment PROJECT.

GATE, SHOW,

SCENE LOCATION,

S$

No. em lay] DESCRIPTION PRICE NOTES

[H=1_[He0d Frame Post 1 pTeaTee

[H-2 [Snow Frame As 4 [preva

1-3 |Heod Snett Mount Grossbar 1 preaTea

1-4 [aw Pivot site Pates 2 presres

H-5 [bead Noa Civis Block 1 jpreovae

H-6 [Lower taw Lover sy. 1 irreare

H-7 eye Bink Gievis Block 1 sTOaTET

H-8 Jaw Gyinder Cleve ook 1 freeze

H-9 [Socket esd Cap Serow 4 [osex 9 Preoree

4-10 [Socket Head Cap Serow 2 |to20x 12 [ereoore |

1-11 [Socket Head Gap Screw 8 [ose 616 presore

11-12 [Upper Head Nod Glevis, + |e 169 [rresoar

14-13 [Head Nod Cynder 1 [rrearao

H=14 [out Cylinder + jreare

15 [eye Bink cylinder 1 breone

1-16 [eye Turn Cylinder 1 io

H-17 [socket Head Cap Seren 2 lesen rToaTee

116 [aw Pivot Pin 1 preove

11-19 feed snot mount Ange Bracket [3 eaTee

1-20 [washer 11 10 [eTeaeve

H-21 [socket Head Gap Screw 3 fto2ax 3 [rreoore

1-22 [socxet nese Cop screw w [wwe x 50 levoaerr

H-23 [Jaw Pivot igus Bushing 2 |pr ass [prenaee

1-24 [socket Head Cop Sexow Pa reer [rreaeer

1-25 |Nod igus Bushing 2 [ppase jsTeone

1-26 [socket Head Cap Serow 2 |a20 1 wa ren

H-27 [socket Head Cap Serow 2 [tozx11

“£28 [Head Nod Pivot Pin + fap 345 [preva

1-29 [socket Head Cap serew 2 fiozax lrreere

f 2 [20.78

Glee CHUCK E. CHEESE

Z HEAD

PARTS LIST

CLIENT Chuck E. Cheese Entertainment PROJECT.

CAE SHOW,

SCENE, LOCATION,

DESCRIPTION PRICE NoTEs

Eye inc Lever 7 lurve jean

H-32 leye Assy. Plate 4 [preo7e8

]H-33 [eye Bunk and Tun Cievis Block | 2 |p a75 [ste-oaee

|H-34 |eye Plate 2 _|MP 677 |stc-0407

|H-35 Jee Blink Clevis Arm 4 _|MP 673. jste-oaea

|H-36 Jeyelid Plate: 2_|up 874

H-37 [eyebiink Pivot Pin 1

|H-38 |Socket Head Cap Screw 4 \e-32 x 12" |sTe-0910

|H-39 |Eye Tum Pivot Pin 2_|up 887 [ste0aa7

“4-40 [Socket Head Cap Screw 8 [10-24 x 6/6" [steoor7

-414 |short Eye Turn Lever 4_|up 872 |sTe-0402,

JH-42 |Long Eye Tun Lever 1 [wp ort [areoaor

|H-43 |Eye Twin Linkage Threaded Rod_|_1_|6-32x3 3/4" [eTeceoe

4-44 [eye Turn igus Bushing 4 [pp aar [prea

|H-45 |Rod End 2_|PP 100 7-06

|H-46 |Socket Head Cap Screw 4 |[5-40x1" jsvc-o80t

|H-47 |eyetid Shell 2 70-0907

|H-48 |Button Head Cap Screw 16 |4-40 x 3/16" pTCOOTE

|H-49 |eyeball Shell 2 |stc-0386

H-50 |Socket Head Cap Screw 2 |e-32x 12" |ste-0919

JH-51 |Socket Head Gap Screw 4 |uazox0 [sre-o020

1-52 [opecae 2 | =

|H-53 [Spacer 4 |e jsTe-0009

|H-54 |Rod End 2_|PP 101 pT C0460

|H-55 |Jam Nut_ 4_|6-32 [stc-0886

]H-56 |Nylon Locknut 3 (5-40 [ste-0004

|H-57 Jeushing 2 [PP 456 jeve-oae

1-58 [Truss Phit Machine Screw 3 [10-32 x 12" pTe-st

|H-59 |Socket Head Cap Screw 2_|14-26 x 1" pre-0004

|H-60 |Nylon Locknut 2 |va-28 ete-o903

Liane. CHUCK E. CHEESE DEPT: ant

HEAD DATE: o2103

\pegine/ PARTS LIST esas

CLIENT___ Chuck &. Cheese Entertainment PROJECT.

‘SHOW.

TY} DESCRIPTION PRICE NOTES

[Rod Ena 4 [pp s07 [stones

[rod Ena 2 [ep 103 isreaass

[Jam nut 2 frog [sreao00

[socket Head Cap Screw 1 hosxt jareaoae

socket Head Cap Screw 1 rose x1 va" [are-vo28

Nylon Locknut 2 fros2 bre:

dam Nut 4 |uaze lsreao0s

a

8

.y == ==

FOREBEND CLEWS,

@.

@

8

"

f a

se == ee

ee CHUCK E. CHEESE DEPT: ant

. ¢ DATE: 03703

ee sec:

PARTS LIST PAGE: + 0F2

ae ooseeael

|Head Nod Clamp Block preewe

|Socket Head Cap Screw eer

1 pe. Clamp Shaft Cot

ire

[Socket Head Cap Serow

Joutin Head Cap Serew

ire

7

2

4

6

4

Head Turn Ciamp Lever 1 [steo000

[socket Hess Cap Serow 1 reae%0

[Nyon Thin Locknat 2 lereaves

Ia Rod End 1 [srewasa

[Jem nut 1 lereo0

[cemate Stud Rod End 1 lsteoore

[shett Spacer 1 [oreo

[esa Tun shat a jareanre

[cing 1 cd

[Hood Turn Shaft Bearing 2 [ste0are

lead Tun Cylinder 1 [arene

[aody Forward Cylinder 1 [sreoove

InAs Washer 2 jareaeee

[Socket Head Gap Serow 2 eave

[ben Crank Pivot Pin 1 [areoara

[ben Crank Bushing 2 lsreaaaa

k1ead Turn Bearing Block ere-aese

[pon Crank Block [sreoore

Nylon Thin Locknat [areas

[Uoper Body Shell Angle Bracket jereaaor

lex Head Cap Screw

[rorso Weldment

lsieaoee

Lower Body Shell Angle Bracket

washer

CHUCK E. CHEESE IDEPT: AN

TORSO DATE: oss

SEC:

PARTS LIST PAGE: 2012

CLIENT __Chuck &. Cheese Entertainment PROJECT.

GATE ‘SHOW. a

SCENE. LOCATION,

No. rem bn] pescriprion = |“""* NoTes

HT=31 [Socket ead Gap Screw 4 frosaxa eae

FT-32 [socket Head Cap Serew 1+ fovt6-10 13% lere-o007

[T=33 }yionLocknw 3 [ones [rreaeae

[T-34 [socket Need Cop Screw [em x mm rTeae7e

[1-365 frorevena Creve Snat 1 jsreaoa

T-36 [socket teas Cap Scr 2 lereoa na a lsreaare

[T-37 [snot cote 2 [pp 503 jreeaee

T-38

'T-39 |rod Ena 4 [pp 109 freon

'T-A0 |Forebend & Head Nod Bushing | 2 [pP 458 co]

f-44 foot sor + fino xe [rresoae

FT=42 [rorenend Gave Bock + jereonsa

FT=43 [russ Pai Mechine Screw 4 fosee wz prose

ES

a es

CHUCK E. CHEESE IDEPT: ant

ARM DATE: os

Npeggione? SEC:

PARTS LIST __ [paces 1012

CLIENT___ Chick. Chowse Entrainment PROJECT.

GATE. SHOW.

SCENE LOCATION

NO. ITEM br DESCRIPTION — NOTES

|A-1_JArm Swing Cylinder 1 ley s2 sTC-4300,

[A-2 [eutionhead Allen Cap Screw 2 |to26 x12 [sroaote

|A-3_|Washer 2 |#10 [ste-0776

JA-4__|Acm Swing Bumper 2 _|pP 203 [ste-0460

JA-6 [right vm Swing Bumper Bicck | 1 |wPea4R [rewear

JA-6 _|Left Arm Swing Bumper Block 4_ [MP 834. presses

[A-7_[pyion Locknut + faze renee

JA-8 [Socket Head Gap Screw 2 [va20%1" jsreonae

JA-9 elbow Pivot Block 4_|mp 816 jsve-osT7

‘4-10 [Socket Head Cap Screw, 4 [14-28 x 1 1/4" fere-sess

JA=11 |Eloow Pivot Pin 4_ |p 631 sTC-0642

JA-12 |Arm Plate Spacer 1_|up 636

teow Pivot Bushing 2 [pp ass

fautonnead Aten Cap Screw | 2 [10-24 616°

Lower Am Prete 2 jreaeze

wow Cynder Tunnion Gusting | 2 jena

et ond Pat 4 reese

Etvow Cyl. Tun Bushing Washer | 2 faveooas

[Etbow cyt Turion Shoulder Bot | 2 prease

Jewtonneas Aten Cap Sccow | 4 |o-s2x." reoose

lm Plate Spacer/ wrist Post | 1 jrreooar

list wave Pivot Block + |p 620 pre

sot Serow 1+ foe x ue fereaoae

Socket Hood Gap Screw 2 [ese xan faresore

list Wave Cevis Bushing 2 [pp 450 freon

[Buttonhead Allen Cap Screw 2 [10-32 x 1/2" pene

[st wave Cvs Pin 1 |p ose jsreosa

lit Wave Clovis 1 fue 639 ron

Nylon Thin Lockout © fos m8

Socket Head Cap Sow 4 froze

INAS Washer

ly10

lwave Cytinger

OB CHUCK E. CHEESE DEPT: aw

EZ > ARM DATE: 03103

\ eee JSEC:

PARTS LIST PAGE: 20t2

CLIENT __ Chuck E. Cheese Entertainment PROJECT.

GATE SHOW,

SCENE LOCATION

No. mew hry] vescririon | rare NOTES

JA-31 right Hana Pate 7 jarcone

|A-82 [Socket Head Cap Screw 2 fiosax ie lereooas

JA-33 [waist wave Gyinder Givis + [pe soe jsreoure

bow Uo oytnder 1 od

set scow + foaaxaner Te0028

Socket Head Cap Sew + fro-se 1" raaoR

Jeuion Head Alen Cop Screw | 2 [omm X 5mm [sTeans0

4 levers

1

CHUCK E. CHEESE DEPT: ant

PELVIS ASSEMBLY miley 03103

PARTS LIST PAGE: 1011

hack E. Cheese Entertainment PROJECT

GATE ‘SHOW,

‘SCENE, LOCATION.

No. mew bry Descriprion — | PA# NOTES

P-1__|Socket Head Cap Serew_ 3 [5116-24 x 1 112"

P-2 [Torso Twist Lever 1+ |p eo lereosea

|P-3__}Set Screw_ 4_|10-24 x 1/4" jere-oesa

[P-4 _|Nylon Locknut 4 |sr6-24 jeve-sesa

P-5 [Clamping Lever + |r eae lereousa

P-6 _|Male Rod End 2_|PP 109 [ste-0cce

P-7 Jam Nut 2 |sre24 [ste

P-8 _|Connecting Rod 4_ [mp 842 |ere-<

P-9 — |ousning 2 [pp 456 jrreama

'P-10 [Torso Twist Cylinder 4 |stc-0893,

PAT [shat Spacer + fae os reas

P-12 _|cylinder Clevis 4p sat |ste-0404

P13 [Pin + fue 3s jsreoaa

|P-14 _|Socket Head Cap Screw 2_|14-20 x 3/4" [srcos26

|P=15 [pews tock 1 [sre

P-16 | Bearing 2 [pp 410 aioe

P-17_|shatt 4_|MP 853 [sTo-0614

P18 [Socket Heed Gap Seow 4 fos [ereowee

P-19 _|Socket Head Cap Screw A |10-24 x 1/2" |sto-0916

P-20_|Washer A [#10 |ste-0776

P-21_|angte Bogy Snet ctp 4 lereowr

P-22 _|shaft Collar 4_|PP 507 [ere

1P-23_|socket Head Cap Screw 4 |sn6-18 x1" ——

P-24 _|Body Shell Mount Plate 2 _|MP 638 |sre-o540

P-25 _|Socket Head Cap Screw 4_|sr16-24 x 4 114" reenre

P-26 [socket Head Gap Seow + forte-10 x1 ua" leone

P27 [russ Primachino Seow | 4 [10:22 v2" id

2-28

P-29

EE

qe

‘@

Sena

CHUCK E. CHEESE

BASE & VALVES ASSY.

PARTS LIST

DEPT: aw

DATE: 03103

SEC:

PAGE: 1 0f1

CLIENT ___ Chuck E. Cheese Entertainment

PROJECT.

SHOW,

LOCATION,

Tem

DESCRIPTION

NOTES

[base / Legs Weldment

[preane

fae" “T= Tube Fiing

live Tie Adhesive Ped

fexinuast Mutter

lon rat

[Connecter interface Card

lsreoe

[Veter mount Sips

valve Manifola Assembly

Ivawe

lari Exhaust Tube

[6 air Feed Tube / Shor

[sri ar Feed Tube / Long

[s16" Reguator Tube

5116" Suaight Tube Fnting

valve Fier Regulator

includes gauge

jareoare

Ja.c. Fitna

sTeav

Fe

RE-1 [Rod End (ws)

froreo Twist UR

Cee CHUCK E. CHEESE DEPT: aw

, ACTUATOR AND DATE: cae

TS SEC:

PAR’ LisT PAGE: 1 of 2

CLIENT_ Chuck E. Cheese Entertainment, PROJECT_

GATE. ‘SHOW. -

SCENE LOCATION.

NO. ITEM ary} DESCRIPTION pee NOTES

im

Rea farn Sumg Rig Ratato| 1 [RERSSIANDOOS freon

facT=2 bow Up Right Acuator| i [REKSS4ANI0010= reese

JACT-3 [Wave RightActuator | 1 |US21381 [sreoae

fact [am Suing Left Acuslr [1 [RFKSS.IARDOOS——_[eTeast

[acr-5 bon Up Cat Acwator | “1 RFKSS.iAri0010 freer

JACT-6-_[WaveleR Acuator | + |usaiaet ream

|ACT-7 |Body Forward Actuator 4_|US21380 jsTc-0816

|ACT-8 [Torso Twist Right and x |stc-0833

JACT-9 _|Torso Twist Left Actuator| 1 |US15388_ [sre-0833,

JACT-10 |Head Turn Left and x |stc-0695

PAGT-1t Head Tun Fight Acuaod 1 |US2I003 rears

PACT =12 [Head Up Acustor | 1 [US2i900 freer

PACT=13 [Mouth Actuator ‘Justs9et rears

fAGT=14 eye Birk Down Aduator| 1 |us@i2e aia

JACT-15 [Eye Turn Left and x [sTc-0793

PACT =6 eye Tum Right Actuator [+ |USTSO6D preane

JOR-BL_[Blue Orifice 10 |F-2815-201 B80_ 576-0938

[OR-Gi [ory orice 10-2616 161830 [reo

JOR-BR_|rown orice it |F20is261 680 reweo

JOR-BKC tack orcs 10 |F2816 121 680 preamet

farsa

RE-2 [Rod End (MMS)

[acy Fwd, Ha Torn UR

IRE-3 [Rod End (MN4)

[Elbow UR, Head Up, Mouth

IRE-4 [Rod End (MM)

Wave UR, Eyeblink Down

IRE-5 [Rod End (MM2)

[Eyeturn UR

NOTE: 4, All actuators are sold without rod en

2, All actuators include hose fitings.

is.

33

yo CHUCK E. CHEESE DEPT: am

hil > ACTUATOR AND DATE: oxos

“puadeghona’) T SEC:

PARTS LIS IPAGE: 2 of 2

CUENT___Ghuek hess ntstanment PROJECT.

GATE Show.

‘SCENE. LOCATION.

No. ew ry] pescriPTion | PRICE | NOTES

TAS.VEL [ote oo ios [UBD mr

|HS-ORG |Orange Hose 400" | TIUBOTYR: [sT¢-09340

|HS-WHT |White Hose. 400" |TIUBO1W [sTc-o934w

|HS-BLK [Black Hose 100° | TIUBO1B sT6-09948

|HS-RED [Red Hose 100° | TIUBOIR1 |stc-o93an_

THS-CLR_ [Goer Hoss foo frivBoTe a

IHS-GRY [Grey Hose 400' |TIUBOIGR1 |sTc-os34on

FAS:BRN|sioHn Hose 100 TUBOTER peas

IiS-GRW|oreon Hose foo TuBoTet ede

TIS-5LU us Hose 100 TUBOTBUT ae

NOTE: 4 All actuators are sold without rod ends.

2. All actuators include hove fitings.

34

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Treasure Quest ManualDocument28 pagesTreasure Quest ManualJC AMARONo ratings yet

- 11-14-14 Um Bumper Cars Cec 2014.11 UkDocument60 pages11-14-14 Um Bumper Cars Cec 2014.11 UkJC AMARONo ratings yet

- 3stg Bit Final ChartDocument1 page3stg Bit Final ChartJC AMARONo ratings yet

- 3-Stage Cylinder ReferenceDocument1 page3-Stage Cylinder ReferenceJC AMARONo ratings yet

- 3 Stage Organ Wiring and Lay-OutDocument9 pages3 Stage Organ Wiring and Lay-OutJC AMARONo ratings yet

- 3 Stage Dual Pressure RegulatorDocument4 pages3 Stage Dual Pressure RegulatorJC AMARONo ratings yet

- Ticket Carnival Service ManualDocument35 pagesTicket Carnival Service ManualJC AMARONo ratings yet

- User Manual Marathon RunnerDocument17 pagesUser Manual Marathon RunnerJC AMARONo ratings yet

- 2016-01-21 Eiffel Tower Manual Cec RevisedDocument21 pages2016-01-21 Eiffel Tower Manual Cec RevisedJC AMARONo ratings yet

- Arduino Fencing Scoring ApparatusDocument8 pagesArduino Fencing Scoring ApparatusJC AMARONo ratings yet

- Cargo Express Manual 2019 D799C4DEE1DD5Document40 pagesCargo Express Manual 2019 D799C4DEE1DD5JC AMARONo ratings yet