Professional Documents

Culture Documents

Eta - 11-0474 - Smk-Smki

Eta - 11-0474 - Smk-Smki

Uploaded by

XavierOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Eta - 11-0474 - Smk-Smki

Eta - 11-0474 - Smk-Smki

Uploaded by

XavierCopyright:

Available Formats

Member of

Designated

according to

Article29 of www.eota.eu

Regulation (EU)

Nº 305/2011

INSTITUTO DE CIENCIAS

DE LA CONSTRUCCIÓN

EDUARDO TORROJA

C/ Serrano Galvache n. 4 28033 Madrid (Spain)

Tel.: (34) 91 302 04 40 Fax: (34) 91 302 07 00

direccion.ietcc@csic.es www.ietcc.csic.es

European Technical ETA 11/0474

Assessment of 01/10/2014

English translation prepared by IETcc. Original version in Spanish language

General Part

Technical Assessment Body issuing

Instituto de Ciencias de la Construcción Eduardo

the ETA designated according to Art.

Torroja (IETcc)

29 of Regulation (EU) 305/2011:

Trade name of the construction Anchor SMART® SMK

product Anchor SMART® SMKI

Product family to which the Torque controlled expansion anchor made of zinc

construction product belongs plated galvanized steel or stainless steel of sizes

M6, M8, M10, M12, M14, M16 and M20 for use in

non-cracked concrete.

Manufacturer pgb - Polska Sp. z.o.o.

ul. Jondy 5

PL 44-100 Gliwice

Polska (Poland)

www.pgb-polska.com

Manufacturing plants pgb Polska P.1

This European Technical 13 pages including 4 annexes which form an

Assessment contains integral part of this assessment. Annex E contains

confidential information and is not included in the

European Technical Assessment when that

assessment is publicly available.

This European Technical Guideline for European Technical Approval ETAG

Assessment is issued in accordance 001 “Metal anchors for use in concrete”, ed. April

with regulation (EU) No 305/2011, on 2013, Parts 1 and 2 used as European

the basis of Assessment Document (EAD)

This version replaces ETA 11/0474 issued on 29/06/2013

Translations of this European Technical Assessment in other languages shall fully correspond to the

original issued document and should be identified as such.

Communication of this European Technical Assessment, including transmission by electronic means, shall

be in full (excepted the confidential annex referred to above). However, partial reproduction may be made,

with the written consent of the issuing Technical Assessment Body. Any partial reproduction has to be

identified as such.

This European Technical Assessment may be withdrawn by the issuing Technical Assessment Body, in

particular pursuant to information by the Commission according to article 25 paragraph 3 of Regulation

(EU) No 305/2011.

ETA 11/0474 of 01/10/2014 – Page 2 out of 13

SPECIFIC PART

1. Technical description of the product

The SMK in the range of M6 to M20 is an anchor made of zinc plated steel. The SMKI in the range

of M6 to M20 is and anchor made of stainless steel. Both are placed into a drilled hole and anchored

by torque-controlled expansion.

The SMK/SMKI anchors in the range of M6 to M20 correspond to the picture and provisions given

in annexes A and B. The characteristic material values, dimensions and tolerances of the anchors not

indicated in annexes A and B shall correspond to the respective values laid down in the technical

documentations (1) of this European Technical Assessment.

For the installation process see figure given in annex C; for the installed anchor see figure given in

annex D.

Each expansion sleeve is marked with the identifying mark of the producer, the trade name and

the anchor diameter; each anchor bolt is marked with the diameter (metric) and the total anchor

length. A red colour ring(s) marking identifies the embedment depth(s).

The performance of the anchors, including installation data, characteristic anchor values,

displacements and fire resistance, for the design of anchorages is given in chapter 3.

The anchors shall only be packaged and supplied as a complete unit.

2. Specification of the intended use in accordance with the applicable EAD.

2.1 Intended use

The anchors are intended to be used for anchorages for which requirements for mechanical

resistance and stability and safety and accessibility in use in the sense of the basic requirements 1

and 4 of Construction Product Regulation no 305/21011 shall be fulfilled and failure of anchorages

made with these products would compromise the stability of the works, cause risk to human life

and/or lead to considerable economic consequences.

The anchors are to be used only for anchorages subject to static or quasi-static loading in

reinforced or unreinforced normal weight concrete of strength class C20/25 to C50/60, according to

EN 206: 1990-03. It may be anchored in non-cracked concrete only.

The SMK anchor may only be used in concrete subject to dry internal conditions.

The SMKI anchor may be used in concrete subject to dry internal conditions and also in concrete

subject to external atmospheric exposure (including industrial and marine environments), or exposure

in permanently damp internal conditions, if no particular aggressive conditions exist. Such particular

aggressive conditions are e.g. permanent, alternating immersion in seawater or the splash zone of

seawater, chloride atmosphere of indoor swimming pools or atmosphere with extreme chemical

pollution (e.g. in desulphurization plants or road tunnels where de-icing materials are used).

The provisions made in this European Technical Assessment are based on an assumed working

life of the anchor of 50 years. The assumed working life is the foreseen period of time throughout

which the construction product, as installed into the construction work, will keep its performances

(1) The quality plan has been deposited at Instituto de ciencias de la construcción Eduardo Torroja and is only made available to the approved bodies

involved in the AVCP procedure.

ETA 11/0474 of 01/10/2014 – Page 3 out of 13

allowing the construction work, behaving under predictable actions and with normal maintenance, to

meet the basic requirements for construction works.

3. Performance of the product and references to the methods used for its assessment

The identification tests and the assessment for the intended use of this anchor according to the

Basic Work Requirements (BWR) were carried out in compliance with the ETAG 001. The

characteristics of the components shall correspond to the respective values laid down in the technical

documentation of this ETA, checked by IETcc.

3.1 Mechanical resistance and stability (BWR 1)

Mechanical resistance and stability has been assessed according to ETAG 001 “Metal anchors to

be used in concrete”, parts 1 and 2.

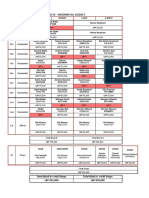

SMK: GALVANIZED ANCHOR Performances

Installation parameters M6 M8 M10 M12 M14 M16 M20

do Nominal diameter of drill bit: [mm] 6 8 10 12 14 16 20

df Fixture clearance hole diameter: [mm] 7 9 12 14 16 18 22

Tinst Nominal installation torque: [Nm] 7 20 35 60 90 120 240

Standard embedment depth

Lmin [mm] 60 75 85 100 120 125 160

Total length of the bolt:

Lmax [mm] 180 155 230 250 250 280 270

hmin Minimum thickness of concrete member: [mm] 100 100 110 130 150 168 206

h1 Depth of drilled hole: [mm] 55 65 75 85 100 110 135

hnom Overall anchor embed depth in concrete: [mm] 49.5 59.5 66.5 77 91 103.5 125

hef,std Effective anchorage depth: [mm] 40 48 55 65 75 84 103

tfix Thickness of fixture [mm] L-58 L-70 L-80 L-92 L-108 L-122 L-147

smin Minimum allowable spacing: [mm] 50 65 70 85 100 110 135

cmin Minimum allowable distance: [mm] 50 65 70 85 100 110 135

Reduced embedment depth

Lmin [mm] -- 60 70 80 -- -- --

Total length of the bolt:

Lmax [mm] -- 155 230 250 -- -- --

hmin Minimum thickness of concrete member: [mm] -- 100 100 100 -- -- --

h1 Depth of drilled hole: [mm] -- 50 60 70 -- -- --

hnom Overall anchor embed depth in concrete: [mm] -- 46.5 53.5 62 -- -- --

hef,red Effective anchorage depth: [mm] -- 351) 42 50 -- -- --

tfix Thickness of fixture: [mm] -- L-57 L-67 L-77 -- -- --

smin Minimum allowable spacing: [mm] -- 65 70 85 -- -- --

cmin Minimum allowable distance: [mm] -- 65 70 85 -- -- --

1)

Use restricted to anchoring of structural components which are statically indeterminate

ETA 11/0474 of 01/10/2014 – Page 4 out of 13

SMK: GALVANIZED ANCHOR Performances

Characteristic values of resistance to

tension loads of design method A M6 M8 M10 M12 M14 M16 M20

STEEL FAILURE

NRk,s Characteristic resistance: [kN] 7.7 16.4 25.6 35.4 51.7 65.0 104.4

3)

γM,s Partial safety factor: [-] 1.40 1.40 1.40 1.43 1.43 1.43 1.47

PULL OUT FAILURE

Standard embedment depth

Char. resistance in C20/25 non cracked

NRk,p concrete:

[kN] -- 2) 12 16 25 30 35 50

3)

γM,p Partial safety factor: [-] -- 1.5 1.8 1.8 1.8 1.8 1.8

Reduced embedment depth

Char. resistance in C20/25 non cracked 1)

NRk,p concrete:

[kN] -- 2) 9 12 16 -- -- --

3)

γM,p Partial safety factor: [-] -- 1.5 1.5 1.5 -- -- --

Ψc C30/37 1.22

Increasing factors for both embedment

Ψc C40/50 1.41

depths:

Ψc C50/60 1.55

CONCRETE CONE FAILURE

Standard embedment depth

hef,std Effective anchorage depth: [mm] 40 48 55 65 75 84 103

Characteristic resistance in C20/25 non

NRk,c [kN] 12.7 16.7 20.5 26.4 32.7 38.8 52.6

cracked concrete:

γM,c=

Partial safety factor: 3) [-] 1.5 1.5 1.8 1.8 1.8 1.8 1.8

γM,sp

scr,N [mm] 120 144 165 195 225 252 309

Spacing:

scr,sp [mm] 160 192 220 260 300 336 412

ccr,N [mm] 60 72 83 98 113 126 155

Edge distance:

ccr,sp [mm] 80 96 110 130 150 168 206

Reduced embedment depth

hef,std Effective anchorage depth: [mm] -- 35 1) 42 50 -- -- --

Characteristic resistance in C20/25 non

NRk,c [kN] -- 10.4 13.7 17.8 -- -- --

cracked concrete:

γM,c=

Partial safety factor: 3) [-] -- 1.5 1.5 1.5 -- -- --

γM,sp

scr,N [mm] -- 105 126 150 -- -- --

Spacing:

scr,sp [mm] -- 140 168 200 -- -- --

ccr,N [mm] -- 53 63 75 -- -- --

Edge distance:

ccr,sp [mm] -- 70 84 100 -- -- --

Ψc C30/37 1.22

Ψc Increasing factor: C40/50 1.41

Ψc C50/60 1.55

1) Use restricted to anchoring of structural components which are statically indeterminate

2) Pull out failure is not decisive

3) In absence of other national regulations

SMK: GALVANIZED ANCHOR Performances

Displacements under tension loads in

C20/25 to C50/60 concrete M6 M8 M10 M12 M14 M16 M20

Standard embedment depth

Tension load in non cracked concrete: [kN] 2.8 5.0 6.0 9.3 10.7 16.0 17.0

δN0 [mm] 0.70 1.12 1.07 1.32 1.82 2.38 3.56

Displacement:

δN∞ [mm] 1.47 2.34 2.24 2.77 3.82 4.99 7.47

Reduced embedment depth

Tension load in non cracked concrete: [kN] -- 4.2 5.7 7.6 -- -- --

δN0 [mm] -- 0.20 0.13 0.06 -- -- --

Displacement:

δN∞ [mm] -- 1.78 1.78 1.78 -- -- --

ETA 11/0474 of 01/10/2014 – Page 5 out of 13

SMK: GALVANIZED ANCHOR Performances

Characteristic values of resistance to

shear loads of design method A M6 M8 M10 M12 M14 M16 M20

STEEL FAILURE WITHOUT LEVER ARM

VRk,s Characteristic resistance: [kN] 5.1 9.3 14.7 20.6 28.1 38.4 56.3

2)

γM,s Partial safety factor: [-] 1.25

STEEL FAILURE WITH LEVER ARM

M0Rk,s Characteristic bending moment: [Nm] 7.7 19.1 38.1 64.1 102.2 163.1 298.5

2)

γM,s Partial safety factor: [-] 1.25

CONCRETE PRYOUT RESISTANCE

k Factor in equation (5.6) of for hef,std [-] 1.0 1.0 1.0 2.0 2.0 2.0 2.0

k ETAG, Annex C §5.2.3.3: for hef,red [-] -- 1.0 1.0 1.0 -- -- --

γM,c Partial safety factor: 2) [-] 1.5

CONCRETE EDGE FAILURE

lf Effective length of anchor for hef,std [mm] 40 48 55 65 75 84 103

lf under shear loads: for hef,red [mm] -- 351) 42 50 -- -- --

dnom Outside diameter of anchor: [mm] 6 8 10 12 14 16 20

γM,c Partial safety factor: 2) [-] 1.5

1 Use restricted to anchoring of structural components which are statically indeterm.. 2. In absence of other national regulat..

SMK: GALVANIZED ANCHOR Performances

Displacements under shear loads in

C20/25 to C50/60 concrete M6 M8 M10 M12 M14 M16 M20

Standard embedment depth

Shear load in non cracked concrete: [kN] 2.9 5.3 8.4 11.8 16.0 21.9 32.1

δN0 [mm] 0.65 2.80 1.75 2.45 2.78 3.53 4.13

Displacement:

δN∞ [mm] 0.98 4.20 2.63 3.68 4.16 5.29 6.19

Reduced embedment depth

Shear load in non cracked concrete: [kN] -- 5.3 8.4 11.8 -- -- --

δN0 [mm] -- 0.59 1.22 1.10 -- -- --

Displacement:

δN∞ [mm] -- 0.89 1.83 1.65 -- -- --

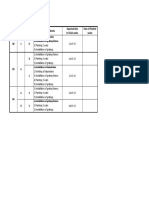

SMKI: STAINLESS STEEL ANCHOR Performances

Installation parameters M6 M8 M10 M12 M16 M20

do Nominal diameter of drill bit: [mm] 6 8 10 12 16 20

df Fixture clearance hole diameter: [mm] 7 9 12 14 18 22

Tinst Nominal installation torque: [Nm] 7 20 35 60 120 240

Standard embedment depth

Lmin [mm] 60 75 85 100 125 160

Total length of the bolt:

Lmax [mm] 180 155 170 180 170 220

hmin Minimum thickness of concrete member: [mm] 100 100 110 130 168 206

h1 Depth of drilled hole: [mm] 55 65 75 85 110 135

hnom Overall anchor embed depth in concrete: [mm] 49.5 59.5 66.5 77 103.5 125

hef,std Effective anchorage depth: [mm] 40 48 55 65 84 103

tfix Thickness of fixture [mm] L-58 L-70 L-80 L-92 L-122 L-147

smin Minimum allowable spacing: [mm] 50 65 70 85 110 135

cmin Minimum allowable distance: [mm] 50 65 70 85 110 135

Reduced embedment depth

Lmin [mm] -- 60 70 80 -- --

Total length of the bolt:

Lmax [mm] -- 155 170 180 -- --

hmin Minimum thickness of concrete member: [mm] -- 100 100 100 -- --

h1 Depth of drilled hole: [mm] -- 50 60 70 -- --

hnom Overall anchor embed depth in concrete: [mm] -- 46.5 53.5 62 -- --

hef,red Effective anchorage depth: [mm] -- 351) 42 50 -- --

tfix Thickness of fixture [mm] -- L-57 L-67 L-77 -- --

smin Minimum allowable spacing: [mm] -- 65 70 85 -- --

cmin Minimum allowable distance: [mm] -- 65 70 85 -- --

1)

Use restricted to anchoring of structural components which are statically indeterminate

ETA 11/0474 of 01/10/2014 – Page 6 out of 13

SMKI: STAINLESS STEEL ANCHOR Performances

Characteristic values of resistance to

tension loads of design method A M6 M8 M10 M12 M16 M20

STEEL FAILURE

NRk,s Characteristic resistance: [kN] 10.1 19.1 34.3 49.6 85.9 140.7

3)

γM,s Partial safety factor: [-] 1.68

PULL OUT FAILURE

Standard embedment depth

Char. resistance in C20/25 non cracked

NRk,p concrete:

[kN] -- 2) 12 16 25 35 50

3)

γM,p Partial safety factor: [-] -- 1.5 1.8 1.8 1.8 1.8

Reduced embedment depth

Char. resistance in C20/25 non cracked

NRk,p [kN] -- 9 1) 12 16 -- --

concrete:

3)

γM,p Partial safety factor: [-] -- 1.8 1.8 1.8 -- --

Ψc C30/37 1.22

Increasing factors for both embedment

Ψc C40/50 1.41

depths:

Ψc C50/60 1.55

CONCRETE CONE FAILURE

Standard embedment depth

hef,std Effective anchorage depth: [mm] 40 48 55 65 84 103

Characteristic resistance in C20/25 non

NRk,c [kN] 12.7 16.7 20.5 26.4 38.8 52.6

cracked concrete:

γM,c=

Partial safety factor: 3) [-] 1.5 1.5 1.8 1.8 1.8 1.8

γM,sp

scr,N [mm] 120 144 165 195 252 309

Spacing:

scr,sp [mm] 160 192 220 260 336 412

ccr,N [mm] 60 72 83 98 126 155

Edge distance:

ccr,sp [mm] 80 96 110 130 168 206

Reduced embedment depth

hef,std Effective anchorage depth: [mm] -- 35 1) 42 50 -- --

Characteristic resistance in C20/25 non

NRk,c [kN] -- 10.4 13.7 17.8 -- --

cracked concrete:

γM,c=

Partial safety factor: 3) [-] -- 1.8 1.8 1.8 -- --

γM,sp

scr,N [mm] -- 105 126 150 -- --

Spacing:

scr,sp [mm] -- 140 168 200 -- --

ccr,N [mm] -- 53 63 75 -- --

Edge distance:

ccr,sp [mm] -- 70 84 100 -- -

Ψc C30/37 1.22

Ψc Increasing factor: C40/50 1.41

Ψc C50/60 1.55

1) Use restricted to anchoring of structural components which are statically indeterminate

2) Pull out failure is not decisive

3) In absence of other national regulations

SMKI: STAINLESS STEEL ANCHOR Performances

Displacements under tension loads in

C20/25 to C50/60 concrete M6 M8 M10 M12 M16 M20

Standard embedment depth

Tension load in non cracked concrete: [kN] 4.3 5.7 6.3 9.9 13.8 19.8

δN0 [mm] 0.42 0.22 0.17 0.19 0.19 0.11

Displacement:

δN∞ [mm] 1.33 1.33 1.33 1.33 1.33 1.33

Reduced embedment depth

Tension load in non cracked concrete: [kN] -- 4.2 5.7 7.6 -- --

δN0 [mm] -- 0.07 0.04 0.32 -- --

Displacement:

δN∞ [mm] -- 0.60 0.60 0.60 -- --

ETA 11/0474 of 01/10/2014 – Page 7 out of 13

SMKI: STAINLESS STEEL ANCHOR Performances

Characteristic values of resistance to

shear loads of design method A M6 M8 M10 M12 M16 M20

STEEL FAILURE WITHOUT LEVER ARM

VRk,s Characteristic resistance: [kN] 6.0 10.9 17.4 25.2 47.1 73.5

γM,s Partial safety factor [-] 1.52

STEEL FAILURE WITH LEVER ARM

M0Rk,s Characteristic bending moment: [Nm] 9.2 22.5 44.9 78.6 200 389

γM,s Partial safety factor: [-] 1.52

CONCRETE PRYOUT FAILURE

k Factor in equation (5.6) of for hef,std [-] 1.0 1.0 1.0 2.0 2.0 2.0

k ETAG, Annex C §5.2.3.3: for hef,red [-] -- 1.0 1) 1.0 1.0 -- --

γM,c Partial safety factor: 2) [-] 1.5

CONCRETE EDGE FAILURE

lf Effective length of anchor for hef,std [mm] 40 48 55 65 84 103

lf under shear loads: for hef,red [mm] -- 35 1) 42 50 -- --

dnom Outside diameter of anchor: [mm] 6 8 10 12 16 20

γM,c Partial safety factor: 2) [-] 1.5

1 Use restricted to anchoring of structural components which are statically indeterminate

2.In absence of other national regulations

SMKI: STAINLESS STEEL ANCHOR Performances

Displacements under shear loads in

C20/25 to C50/60 concrete M6 M8 M10 M12 M16 M20

Standard embedment depth

Shear load in non cracked concrete: [kN] 2.8 5.1 8.1 11.8 22.1 34.5

δN0 [mm] 1.66 1.79 3.83 4.13 5.75 6.59

Displacement:

δN∞ [mm] 2.49 2.68 5.74 6.19 8.62 9.88

Reduced embedment depth

Shear load in non cracked concrete: [kN] -- 5.1 8.1 11.8 -- --

δN0 [mm] -- 0.60 3.83 4.13 -- --

Displacement:

δN∞ [mm] -- 0.90 5.74 6.19 -- --

3.2 Safety in case of fire (BWR 2)

Reaction to fire has been assessed according to Commission Decision 96/603/EC, amended by

2000/605/EC. See class in table below:

Reaction to fire M6 M8 M10 M12 M14 M16 M20

Reaction to fire anchors SMK / SMKI [--] Class A1

Resistance to fire: No Performance Determined

3.3 Hygiene, health and the environment (BWR 3)

This requirement is not relevant for the anchors.

3.4 Safety in use (BWR 4)

Requirements with respect to the safety in use are not included in this Essential Requirement but

are treated under the Essential Requirement Mechanical Resistance and Stability (see section 3.1)

3.5 Protection against noise (BWR 5)

This requirement is not relevant for the anchors.

ETA 11/0474 of 01/10/2014 – Page 8 out of 13

3.6 Energy economy and heat retention (BWR 6)

This requirement is not relevant for the anchors.

3.7 Sustainable use of natural resources (BWR 7)

No Performance Determined

4. Assessment and verification of constancy of performance (hereinafter AVCP) system

applied, with reference to its legal base

According to the decision 96/582/EC of the European Commission (2) the system of assessment

and verification of constancy of performance (see Annex V to Regulation (EU) No 305/2011) given in

the following table applies:

Product Intended use Level or class System

To be used for fixing

SMK anchor

and/or supporting All / any 1

SMKI anchor

structural elements

The system 1 referred above is described in Construction Products Regulation (EU) no. 305/211

Annex V §. 1.3 as follows:

a) The manufacturer shall carry out:

(i.) Factory production control.

(ii.) Further testing of samples taken at the factory by the manufacturer in accordance with the

prescribed quality plan;

b) The notified production control certification body shall issue the certificate of conformity of the

factory production control on the basis of:

(i.) Determination of the product-type on the basis of type testing (including sampling)

calculation, tabulated values of descriptive documentation of the product:

(ii.) Initial inspection of factory and of factory production control.

(iii.) Continuous surveillance, assessment and evaluation of factory production

5. Technical details necessary for the implementation of the AVCP system, as provided for in

the applicable EAD

The ETA is issued for this anchor on the basis of agreed data/information which identifies the

product that has been assessed and judged. Detailed description and conditions of the manufacturing

process of the anchor, and all the relevant design and installation criteria of this anchor are specified

in the manufacturer’s technical documentation deposited with the IETcc. The main aspects of this

information are specified in the following sections. It is the manufacturer’s responsibility to make sure

that all those who use the anchor are appropriately informed of specific conditions according to

sections 1, 2, 4 and 5 including the annexes of this ETA.

5.1 Tasks of the manufacturer

5.1.1 Factory production control

(2) Published in the Official Journal of the European Union (OJEU) L254 of 24.06.1996 see www.new.eur-lex.europa.eu/oj/direct-access.html)

ETA 11/0474 of 01/10/2014 – Page 9 out of 13

The manufacturer has a factory production control system and shall exercise permanent internal

control of production. All the elements, requirements and provisions adopted by the manufacturer

shall be documented in a systematic manner in the form of written policies and procedures, including

records of results performed. This production control system shall insure that the product is in

conformity with this ETA.

The manufacturer shall only use raw materials supplied with the relevant inspection documents as

laid down in the quality plan (3). The incoming raw materials shall be subjected to controls by the

manufacturer before acceptance. Check of materials shall include control of the inspection documents

presented by suppliers by verifying dimension and material properties, e.g. chemical composition,

mechanical properties etc. The manufactured components are checked visually, for dimensions and

properties, where appropriate.

The quality plan which is part of the Technical Documentation of this ETA, includes details of the

extent, nature and frequency of testing and controls to be performed within the factory production

control and has been agreed between the assessment holder and IETcc. The results of factory

production control shall be recorded and evaluated in accordance with the provisions of the qualityl

plan. The records include at least the following information:

• Designation of the product, the basic materials and components;

• Type of control or testing and minimum frequencies of them;

• Date of manufacture of the product and date testing of the product or basic material and

components;

• Results of controls and testing and, if appropriate, comparison with requirements;

• Signature of person responsible for factory production control.

The records shall be presented to the notified body involved in the continuous surveillance. On

request, they shall be presented to the IETcc.

5.2 Tasks of notified bodies

5.2.1 Determination of the product-type on the basis of type testing

For type-testing the results of the tests performed as part of the assessment for the European

Technical Assessment shall be used unless there are changes in the production line or plant. In such

cases the necessary type testing has to be agreed between ETA holder and the notified body.

5.2.2 Initial inspection of factory and of factory production control

The notified body shall ascertain that, in accordance with the quality plan, the factory and the

factory production control are suitable to ensure continuous and orderly manufacturing of the product

according to the specifications mentioned in Annexes of this the European Technical Assessment.

5.2.3 Continuous surveillance, assessment and evaluation of factory production control

The notified body shall visit the factory at least once a year for regular inspection.

This continuous surveillance and assessment of factory production control have to be performed

according to the quality plan. The system of factory production control and the specified

manufacturing process has to be verified that they are maintained as the quality plan defined. The

results of product certification and continuous surveillance shall be made available on demand by the

product certification body or factory production control body, respectively, to IETcc. In cases where

(3)

the quality plan has been deposited at IETcc and is only made available to the approval bodies involved in the ACVP procedure.

ETA 11/0474 of 01/10/2014 – Page 10 out of 13

the provisions of the European Technical Assessment and the quality plan are no longer fulfilled the

conformity certificate shall be withdrawn.

Instituto de ciencias de la construcción Eduardo Torroja

CONSEJO SUPERIOR DE INVESTIGACIONES CIENTÍFICAS

C/ Serrano Galvache n.º 4. 28033 Madrid.

Tel: (+34) 91 302 04 40 Fax. (+34) 91 302 07 00

www.ietcc.csic.es

On behalf of the Instituto de Ciencias de la Construcción Eduardo Torroja

Madrid, 1st of October 2014

Marta Mª Castellote Armero

Director

ETA 11/0474 of 01/10/2014 – Page 11 out of 13

INDEX OF ANNEXES:

Annex A: Assembled anchor

Annex B. Materials

Annex C. Installation process

Annex D. Schema of the anchor in use

Annex A: Assembled anchor

Identification on anchor:

• Expansion clip:

o Anchor SMK: Company logo + “SMK “ + Metric.

o Anchor SMKI: Company logo + “SMKI” + Metric.

• Anchor body: Metric x Length

• Red ring marks to show embedment depths

Annex B. Materials

Item Designation Material for SMK Material for SMKI

Carbon steel wire rod, electro zinc

1 Anchor Body plated ≥ 5 μm ISO 4042 A2, cold Stainless steel, grade A4

forged

DIN 125 or DIN 9021 electro zinc DIN 125 or DIN 9021, stainless

2 Washer

plated ≥ 5 μm ISO 4042 A2 steel grade A4

DIN 934 electro zinc plated ≥ 5 μm

3 Nut DIN 934, stainless steel grade A4

ISO 4042 A2, class 6

Carbon steel strip, electro zinc

4 Expansion clip Stainless steel, grade A4

plated ≥ 5 μm ISO 4042 A2

Annex C. Installation process

ETA 11/0474 of 01/10/2014 – Page 12 out of 13

Annex D. Schema of the anchor in use

df f

h min hmin

h1 h1

M12 x 110

d0

M12 x 110

d0

M12

M12

h ef t fix h ef t fix

h nom h nom

STANDARD EMBEDMENT DEPTH REDUCED EMBEDMENT DEPTH (M8, M10 AND M12)

hef: Effective anchorage depth

h1: Depth of drilled hole

hnom: Overall anchor embedment depth in the concrete

hmin: Minimum thickness of concrete member

tfix: Thickness of fixture

d0: Nominal diameter of drill bit

df: Diameter of clearance hole in the fixture

ETA 11/0474 of 01/10/2014 – Page 13 out of 13

You might also like

- En 1090 IngDocument17 pagesEn 1090 IngAkademi NDTNo ratings yet

- Eurofins Product Testing PDFDocument1 pageEurofins Product Testing PDFsobhiNo ratings yet

- PMA Workpack Structure Inspection 2020 - Rev1Document16 pagesPMA Workpack Structure Inspection 2020 - Rev1Raznan Ramli100% (1)

- European Technical Assessment ETA 18/0675: Technical and Test Institute For Construction PragueDocument19 pagesEuropean Technical Assessment ETA 18/0675: Technical and Test Institute For Construction PragueJianhua WuNo ratings yet

- 20-123 Stainless Steel and Metal Works BOQDocument4 pages20-123 Stainless Steel and Metal Works BOQsobhiNo ratings yet

- SEMA Racking User CodePDF PDFDocument47 pagesSEMA Racking User CodePDF PDFJawad RafiqNo ratings yet

- Cnca C11-09-2014Document12 pagesCnca C11-09-2014raybchNo ratings yet

- Jsa. Cable Laying and TerminationDocument10 pagesJsa. Cable Laying and TerminationMon Trang NguyễnNo ratings yet

- Manual RegoDocument222 pagesManual RegoRuben Mantilla100% (1)

- ETA 13-0730 MaxxFast PromaxDocument11 pagesETA 13-0730 MaxxFast PromaxXavierNo ratings yet

- Eta - 13-0397 Injection System DeWalt PURE110-PRODocument32 pagesEta - 13-0397 Injection System DeWalt PURE110-PRORachel BushNo ratings yet

- TecfiSpA SWE01 ETA120253Document23 pagesTecfiSpA SWE01 ETA120253bkprodhNo ratings yet

- AJE01 Declaración de RendimientoDocument11 pagesAJE01 Declaración de RendimientoFrancisco IvÁn MuÑoz ValdebenitoNo ratings yet

- European Technical Assessment ET A - 0 3 / 0 0 0 8 o F 0 1 / 0 8 / 2 0 1 8Document10 pagesEuropean Technical Assessment ET A - 0 3 / 0 0 0 8 o F 0 1 / 0 8 / 2 0 1 8karthik1amarNo ratings yet

- FM744 - ETA 05-0169 - EN - Op7 - 2015-01-29Document12 pagesFM744 - ETA 05-0169 - EN - Op7 - 2015-01-29Kareem HelalNo ratings yet

- Eta - 17-0183 - 2021 R-XPT - enDocument9 pagesEta - 17-0183 - 2021 R-XPT - enNG Wee JunNo ratings yet

- FM753 Crack - ETA 09-0056 - EN - Op1 Seismic - 2017-07-18Document18 pagesFM753 Crack - ETA 09-0056 - EN - Op1 Seismic - 2017-07-18Kareem HelalNo ratings yet

- FM753 - ETA 01-0014 - EN - Op7 - 2017-05-29Document13 pagesFM753 - ETA 01-0014 - EN - Op7 - 2017-05-29Kareem HelalNo ratings yet

- Eta Fix3 UkDocument13 pagesEta Fix3 UkTunisianoCANo ratings yet

- European Technical Assessment ETA 20/0640: Technical and Test Institute For Construction PragueDocument11 pagesEuropean Technical Assessment ETA 20/0640: Technical and Test Institute For Construction PragueDavid SeeNo ratings yet

- Eta Ancu enDocument8 pagesEta Ancu enk2No ratings yet

- Eta Trigaz UkDocument22 pagesEta Trigaz UkTunisianoCANo ratings yet

- European Technical Assessment ETA 17/0185: Technical and Test Institute For Construction PragueDocument12 pagesEuropean Technical Assessment ETA 17/0185: Technical and Test Institute For Construction PragueLi Juen GamNo ratings yet

- European Technical Assessment ETA 18/0675: Technical and Test Institute For Construction PragueDocument19 pagesEuropean Technical Assessment ETA 18/0675: Technical and Test Institute For Construction PragueJianhua WuNo ratings yet

- THRUMAXX ZPL DoP 30551rev1 EngDocument3 pagesTHRUMAXX ZPL DoP 30551rev1 EngRicardo MagalhãesNo ratings yet

- Eta Guardia UkDocument9 pagesEta Guardia UkTunisianoCANo ratings yet

- rsc1130 2022070712504Document18 pagesrsc1130 2022070712504Rethish KochukavilakathNo ratings yet

- Eta 09-0013 TTM Multistrand enDocument56 pagesEta 09-0013 TTM Multistrand enjasamnaj100% (1)

- ETA Epcon C8 XtremDocument25 pagesETA Epcon C8 Xtremעמי עמרניNo ratings yet

- La ImpDocument13 pagesLa ImplydiaNo ratings yet

- Declaration of Performance Dop Mtp-En: Metric Fixture Thickness (MM)Document5 pagesDeclaration of Performance Dop Mtp-En: Metric Fixture Thickness (MM)Anonymous qNg1aj05No ratings yet

- ETA MOH en Rev1Document18 pagesETA MOH en Rev1Marian SimaNo ratings yet

- CatalogoDocument52 pagesCatalogoDiego SánchezNo ratings yet

- Agrement Mastic Acrilic Antifoc CFS-S - ACR - J RosturiDocument18 pagesAgrement Mastic Acrilic Antifoc CFS-S - ACR - J RosturiOvidiu NeaguNo ratings yet

- ETA EPCONC8 Bar UKDocument17 pagesETA EPCONC8 Bar UKTunisianoCANo ratings yet

- HIT - HY 100 Eta-14-0009-2019-09-06-EnDocument21 pagesHIT - HY 100 Eta-14-0009-2019-09-06-Enעמי עמרניNo ratings yet

- ETA-14-0345-Safety Plus IIDocument14 pagesETA-14-0345-Safety Plus IISamsutheen SNo ratings yet

- Hilti - Calculo Manual de Re500Document41 pagesHilti - Calculo Manual de Re500James ClaytonNo ratings yet

- DSI DYWIDAG ETA-09-0068 DYWIDAG External Strand Post-Tensioning System For 3 To 37 Strands e 01Document47 pagesDSI DYWIDAG ETA-09-0068 DYWIDAG External Strand Post-Tensioning System For 3 To 37 Strands e 01suvraNo ratings yet

- Eta 15-0140 2018 06 29Document15 pagesEta 15-0140 2018 06 29Youssef HoussineNo ratings yet

- Eta XradDocument18 pagesEta XradJonathan Henry Jara AlcarrasNo ratings yet

- Hilti - Hit Hy 150 Max Cu Hit TZ - 1Document12 pagesHilti - Hit Hy 150 Max Cu Hit TZ - 1Mihnea-Bogdan NicolaescuNo ratings yet

- European Technical Assessment ETA 17/0694: Technical and Test Institute For Construction PragueDocument20 pagesEuropean Technical Assessment ETA 17/0694: Technical and Test Institute For Construction Praguepayaso1973No ratings yet

- ETA 20 0540 HIT RE 500 V4 Rebar EC2 100years 112020 Approval Document ASSET DOC 13313367 1Document135 pagesETA 20 0540 HIT RE 500 V4 Rebar EC2 100years 112020 Approval Document ASSET DOC 13313367 1eng.msc.pnNo ratings yet

- ETAG 029: Guideline For European Technical Approval ofDocument33 pagesETAG 029: Guideline For European Technical Approval ofandreamercuriNo ratings yet

- CT1 CSTB ETA-11 0390 RebarDocument22 pagesCT1 CSTB ETA-11 0390 RebarsaidNo ratings yet

- Ramset - C101J C101C - ETA - UltraFix™ PLUS ChemSet™ 101 PLUSDocument13 pagesRamset - C101J C101C - ETA - UltraFix™ PLUS ChemSet™ 101 PLUSScott McCallumNo ratings yet

- Questionnaire - en 1090-1 - Fill in All Parts: C I F FDocument3 pagesQuestionnaire - en 1090-1 - Fill in All Parts: C I F FHong Phong LeNo ratings yet

- Macalloy Tension Rod SystemsDocument25 pagesMacalloy Tension Rod Systemsakajsi0% (1)

- Hilti Hvu HasDocument12 pagesHilti Hvu HasAMCRUZ77No ratings yet

- Eta 11-0190 Wurth AssyDocument112 pagesEta 11-0190 Wurth Assymrc8327No ratings yet

- European Technical Approval ETA-98/0001: Hilti Stud Anchor HST, HST-R and HST-HCRDocument23 pagesEuropean Technical Approval ETA-98/0001: Hilti Stud Anchor HST, HST-R and HST-HCRHemang KhandelwalNo ratings yet

- Rothoblaas - Typ S.certificate Eta - enDocument47 pagesRothoblaas - Typ S.certificate Eta - enAndrei GheorghicaNo ratings yet

- TENSACCIAI - PostTensioningDocument28 pagesTENSACCIAI - PostTensioningnovakno1No ratings yet

- CT1 CSTB Eta-11 0354Document19 pagesCT1 CSTB Eta-11 0354Alden CayagaNo ratings yet

- DOP CE EGGER Eurospan Mmex Rec301 ENDocument2 pagesDOP CE EGGER Eurospan Mmex Rec301 ENMateusz Latosiński LSD.STUDIO ✖No ratings yet

- EJOT Eta 22 0126 JT JF JZ Screws ENDocument14 pagesEJOT Eta 22 0126 JT JF JZ Screws ENCesar AugustoNo ratings yet

- En 15048 PPSDocument17 pagesEn 15048 PPSVera100% (1)

- Eta 08-0339Document9 pagesEta 08-0339MihaelaBeatriceVladNo ratings yet

- EJOT Eta 07 0013 Fasteners For Flexible Roof Waterproofing Membrane ENDocument8 pagesEJOT Eta 07 0013 Fasteners For Flexible Roof Waterproofing Membrane ENMaris FlorinNo ratings yet

- ETA 08-0115 RESTON Spherical and Cylindrical Bearings PDFDocument27 pagesETA 08-0115 RESTON Spherical and Cylindrical Bearings PDFAnonymous apmOvzVzmj100% (1)

- ETA210053 Tension Rod System Macalloy 355 460 S460 520 and S520 17 - 849Document26 pagesETA210053 Tension Rod System Macalloy 355 460 S460 520 and S520 17 - 849Gino TironiNo ratings yet

- Tecfispa Vs Dop enDocument16 pagesTecfispa Vs Dop enThe DarkNo ratings yet

- TCVN 10332-2014 Precast Thin Wall Reinforced Concrete DitchesDocument24 pagesTCVN 10332-2014 Precast Thin Wall Reinforced Concrete Ditchesdavesmithies2012No ratings yet

- Declaration of Performance: Construction Product: System 2+Document1 pageDeclaration of Performance: Construction Product: System 2+Moon SzDarknessNo ratings yet

- BOQ CAT Steel Bridge 24062021Document1 pageBOQ CAT Steel Bridge 24062021sobhiNo ratings yet

- Cat Bridge Cover Detail 4Document1 pageCat Bridge Cover Detail 4sobhiNo ratings yet

- Calculation Note Fire Escape Stairs 02032022Document22 pagesCalculation Note Fire Escape Stairs 02032022sobhiNo ratings yet

- Cat Bridge Cover 10Document1 pageCat Bridge Cover 10sobhiNo ratings yet

- Autodesk Robot IDCDocument405 pagesAutodesk Robot IDCsobhiNo ratings yet

- Pipe and Tube RailingsDocument10 pagesPipe and Tube RailingssobhiNo ratings yet

- CASA 55 - INCOMES For 12/2017: Total Block B + Half Shops Total Block A + Half Shops LBP 925,000 LBP 850,000Document7 pagesCASA 55 - INCOMES For 12/2017: Total Block B + Half Shops Total Block A + Half Shops LBP 925,000 LBP 850,000sobhiNo ratings yet

- To Sobhe Report (2) 19-09-2019Document4 pagesTo Sobhe Report (2) 19-09-2019sobhiNo ratings yet

- Facade Calculation NoteDocument9 pagesFacade Calculation NotesobhiNo ratings yet

- 1 Input DataDocument6 pages1 Input DatasobhiNo ratings yet

- Client:-Al Arabia Project: - M F Bridge Led Sign: Existing Ipe200 Existing Upn 125Document1 pageClient:-Al Arabia Project: - M F Bridge Led Sign: Existing Ipe200 Existing Upn 125sobhiNo ratings yet

- Block Catwalk Remaining Works Expected Date To Finish Works Date of Finished WorksDocument1 pageBlock Catwalk Remaining Works Expected Date To Finish Works Date of Finished WorkssobhiNo ratings yet

- 1-KAIG - Nursery REPORT-rev.01Document32 pages1-KAIG - Nursery REPORT-rev.01sobhiNo ratings yet

- VOC Emissions Test ReportDocument3 pagesVOC Emissions Test ReportsobhiNo ratings yet

- Front Elevation: Road Level Road Level Road LevelDocument1 pageFront Elevation: Road Level Road Level Road LevelsobhiNo ratings yet

- Title Page: Project: Structure B4 - F2Document18 pagesTitle Page: Project: Structure B4 - F2sobhiNo ratings yet

- Existing Ipe200 Existing Upn 125: Road Level Road LevelDocument1 pageExisting Ipe200 Existing Upn 125: Road Level Road LevelsobhiNo ratings yet

- 01 Huawu Technical Specifications 1Document22 pages01 Huawu Technical Specifications 1Đinh Như ThànhNo ratings yet

- Quality Management in Procurement (1FM - IN) : Test Script SAP S/4HANA - 08-05-20Document60 pagesQuality Management in Procurement (1FM - IN) : Test Script SAP S/4HANA - 08-05-20sowjanyaNo ratings yet

- C224-78 (2014) Standard Practice For Sampling Glass ContainersDocument2 pagesC224-78 (2014) Standard Practice For Sampling Glass ContainersAhmed AlzubaidiNo ratings yet

- Resume: S.SomasundaramDocument6 pagesResume: S.SomasundaramShankker KumarNo ratings yet

- PSM 1Document28 pagesPSM 1Afiq FawwazNo ratings yet

- For Piling and Excavation Works: (To Be Submitted Together With Permit Application Form)Document13 pagesFor Piling and Excavation Works: (To Be Submitted Together With Permit Application Form)Dicky DjayadiNo ratings yet

- Factory Acceptance Test of Fan Coil UnitsDocument74 pagesFactory Acceptance Test of Fan Coil UnitsWin100% (1)

- Calibration Procedures Virginia PDFDocument81 pagesCalibration Procedures Virginia PDFraja qammarNo ratings yet

- API 510 Course Malaysia 2020Document6 pagesAPI 510 Course Malaysia 2020Ahmed Imtiaz RaoNo ratings yet

- 15 Structural Painting SpecificationsDocument66 pages15 Structural Painting SpecificationsAjajul AnsariNo ratings yet

- Til 2069Document4 pagesTil 2069BouazzaNo ratings yet

- BS en 10130 - 2006Document16 pagesBS en 10130 - 2006Артем Титов100% (1)

- Breaker Driving Machine InspectionDocument2 pagesBreaker Driving Machine InspectionMochammad AriefNo ratings yet

- Specification For Plumbing Drainage Fire Fighting LPG and Electrical Works-1Document68 pagesSpecification For Plumbing Drainage Fire Fighting LPG and Electrical Works-1Bosco WasikeNo ratings yet

- Krautkrämer USM 100 Brochure - ENDocument7 pagesKrautkrämer USM 100 Brochure - ENNur Achmad BusairiNo ratings yet

- Inspection Flash Report: RFI NO & Date: 1.0 Type of VisitDocument2 pagesInspection Flash Report: RFI NO & Date: 1.0 Type of VisitFahad AhmadNo ratings yet

- STS QAC SOP 008 Tube Plugging ProcedureDocument7 pagesSTS QAC SOP 008 Tube Plugging Proceduremohd as shahiddin jafriNo ratings yet

- Art of Precast ConcreteDocument80 pagesArt of Precast ConcreteShrinivas HansanpalliNo ratings yet

- Project Profile On Metal CastingDocument11 pagesProject Profile On Metal Castingchaggan AggarwalNo ratings yet

- CE6021 SCAD MSM by WWW - Learnengineering.inDocument97 pagesCE6021 SCAD MSM by WWW - Learnengineering.inVENKATANARAYANANNo ratings yet

- Co2 SpecificationDocument15 pagesCo2 SpecificationrkasiviswanathanNo ratings yet

- Belema Profile CorrectDocument22 pagesBelema Profile CorrectMoses anedoNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument3 pagesInspection & Testing Requirements Scope:: Test and Inspection PerWael ChouchaniNo ratings yet

- Inspection Checklist For: Control ValvesDocument2 pagesInspection Checklist For: Control Valvesabdelkader benabdallahNo ratings yet

- CIAP Document 102 PDFDocument33 pagesCIAP Document 102 PDFCarol SantosNo ratings yet