Professional Documents

Culture Documents

LL KD Data Sheet 042720 1115

Uploaded by

Santii CampitelliOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LL KD Data Sheet 042720 1115

Uploaded by

Santii CampitelliCopyright:

Available Formats

LL KD

SUCKER ROD

The LL KD (API Special D) rod is extremely dependable and This alloy provides greater corrosion resistance than that of

is designed for medium to heavy-load service. the API standard grade D rod.

These rods are manufactured with an AISI 3130 The LL KD rods (API Special D) are manufactured to the

nickel-chrome-moly alloy SBQ steel, providing them with the current API dimensional and mechanical specifications.

capability of handling heavy stresses.

PROCESS

Rods are straightened and subjected to eddy current Random samples are subjected to Yield and Tensile

testing prior to any further operations. Any rods that testing. In addition, stringent hardness and Charpy

do not meet Liberty Lift’s specifications are removed Impact tests are conducted for further verification of

from further processing. The rods are forged per size. the desired mechanical properties, these tests are

The rods are brought to normalizing temperature to above API requirements. The pin ends are precision

relieve previously induced stress, and then water machined and threads are cold rolled, adding

quenched. All rods will be brought to a temper additional strength to the sucker rod pin connection.

temperature which will produce the desired

mechanical properties and then air cooled. The rods

are shot-peened for enhanced fatigue resistance.t

CHEMISTRY

CARBON MANGANESE PHOSPHORUS SULPHUR SILICON COPPER NICKEL CHROMIUM MOLYBDENUM

0.22-0.29 0.71-1.00 < 0.025 < 0.035 0.15-0.35 <0.35 0.70-1.00 0.41-0.65 0.01-0.06

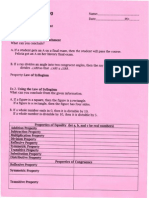

MECHANICAL PROPERTIES

MINIMUM YIELD TENSILE STRENGTH ELONGATION (% IN 8IN) REDUCTION OF AREA % ROCKWELL HARDNESS C

115,000 PSI 125,000-140,000 PSI 12Mn 55Mn 25 to 30

APPLICATIONS MAXIMUM OPERATING STRESS

Heavy load applications in effectively inhibited Sa = (T/4 + 0.5625 Smin) SF

corrosive wells.

16420 PARK TEN PLACE, SUITE 300

W W W. L I B E R T Y L I F T.CO M (713)-575-2300 HOUSTON, TEXAS 77084

You might also like

- DS350 Tadano Faun 1368Document61 pagesDS350 Tadano Faun 1368Mohamed Harb100% (2)

- Design Aspects of Cathodic ProtectionDocument24 pagesDesign Aspects of Cathodic ProtectionRahul AdityaNo ratings yet

- 11kV SF6Document6 pages11kV SF6ahmadgce04No ratings yet

- Sudhanshu Kumar: ResumeDocument3 pagesSudhanshu Kumar: ResumePradeepNo ratings yet

- Gajendra Singh (ONGC Training Report)Document55 pagesGajendra Singh (ONGC Training Report)Gajju12567% (6)

- 2021 Nov HG 1st PBDocument10 pages2021 Nov HG 1st PBGlaiza MarieNo ratings yet

- SAE 8620H Chemical Composition, SAE 8620H Mechanical Properties, SAE 8620H Heat TreatmentDocument2 pagesSAE 8620H Chemical Composition, SAE 8620H Mechanical Properties, SAE 8620H Heat TreatmentAnush Swaminathan100% (1)

- Advances in High Voltage Insulation and Arc Interruption in SF6 and VacuumFrom EverandAdvances in High Voltage Insulation and Arc Interruption in SF6 and VacuumNo ratings yet

- Landscape Products: Technical GuideDocument124 pagesLandscape Products: Technical Guidegabbo24No ratings yet

- Case Studies of Rehabilitation, Repair, Retrofitting, and Strengthening of StructuresDocument190 pagesCase Studies of Rehabilitation, Repair, Retrofitting, and Strengthening of StructuresAnca PuichitaNo ratings yet

- Conversion & Reactor Sizing: Dr. Kelly Yong Tau LenDocument16 pagesConversion & Reactor Sizing: Dr. Kelly Yong Tau LenAmandaEdwinNo ratings yet

- Datasheet-Sandvik-11r51-En-V2020-08-27 13 - 59 Version 1Document5 pagesDatasheet-Sandvik-11r51-En-V2020-08-27 13 - 59 Version 1Kashish100% (2)

- Aluminium Alloy 1050 H14 TDSDocument1 pageAluminium Alloy 1050 H14 TDSfaria1969No ratings yet

- LL HS Data SheetDocument1 pageLL HS Data SheetSantii CampitelliNo ratings yet

- First Philec DTDocument8 pagesFirst Philec DTJM Si MirNo ratings yet

- CuNiSi AlloyDocument6 pagesCuNiSi AlloyJdjoNo ratings yet

- Compression Tension LoadcellDocument3 pagesCompression Tension LoadcellkshripNo ratings yet

- Pinnacle Alloys E11018 MDocument2 pagesPinnacle Alloys E11018 MMoch_adiganjarNo ratings yet

- Domex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelDocument2 pagesDomex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelBo WangNo ratings yet

- Stainless Steel Bar 431 Atlas 431: Colour Code: Signal RedDocument3 pagesStainless Steel Bar 431 Atlas 431: Colour Code: Signal RedNitin AggarwalNo ratings yet

- Wilsons LTD Aluminium Alloy QQ A 25011 T6 Sheet 200Document2 pagesWilsons LTD Aluminium Alloy QQ A 25011 T6 Sheet 200williamNo ratings yet

- ABB Pararrayos XPS - CatalogueDocument8 pagesABB Pararrayos XPS - CatalogueEdwin QuispeNo ratings yet

- SNC Metal Clad Hucre 1Document6 pagesSNC Metal Clad Hucre 1draganbabicNo ratings yet

- F Series Ceramic Disc DC Capacitors, Class 1, Class 2, Low Loss (0.2 %), 500 V, 1 KV, 2 KV, and 3 KVDocument8 pagesF Series Ceramic Disc DC Capacitors, Class 1, Class 2, Low Loss (0.2 %), 500 V, 1 KV, 2 KV, and 3 KVHECHO EN MEXICO 2.0No ratings yet

- Welding WireDocument20 pagesWelding WirefoxmancementNo ratings yet

- RATNA 7014: Medium Heavy Coated, Iron Powder & Rutile Type Welding Electrode For High Deposition Efficiency 115% MinDocument1 pageRATNA 7014: Medium Heavy Coated, Iron Powder & Rutile Type Welding Electrode For High Deposition Efficiency 115% MinIkhsani IzaNo ratings yet

- PCB CapabilitiesDocument2 pagesPCB Capabilitiesatsushi885No ratings yet

- UTP 655 32 SpecSheetDocument1 pageUTP 655 32 SpecSheetFadi HasnNo ratings yet

- Echnical Ulletin: Used For Joining in Large Vehicle and Crane ManufacturingDocument1 pageEchnical Ulletin: Used For Joining in Large Vehicle and Crane ManufacturingSungJun ParkNo ratings yet

- Aalco Metals LTD - Aluminium Alloy - 1050 H14 - 57Document2 pagesAalco Metals LTD - Aluminium Alloy - 1050 H14 - 57lincinkrishnanNo ratings yet

- R100 R101Document2 pagesR100 R101Paulo CardosoNo ratings yet

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationIam FroilanNo ratings yet

- Air/Ship Microwave Material With High Performance: Excellent Dimensional Stability & Phase StabilityDocument4 pagesAir/Ship Microwave Material With High Performance: Excellent Dimensional Stability & Phase StabilityDale XiaoNo ratings yet

- Cast Resin Transformers Oil Immersed Transformer: Technical PerformanceDocument32 pagesCast Resin Transformers Oil Immersed Transformer: Technical PerformanceIm ChinithNo ratings yet

- 1 4509Document2 pages1 4509Umesh KotadiaNo ratings yet

- Dual Shield II 110Document1 pageDual Shield II 110Nicolas MaximilianoNo ratings yet

- L Series Details 26 COS 111213-3050574Document13 pagesL Series Details 26 COS 111213-3050574Ajay sangwanNo ratings yet

- Aalco Metals LTD Aluminium Alloy 6061 T6 Extrusions 145Document2 pagesAalco Metals LTD Aluminium Alloy 6061 T6 Extrusions 145Ahmad Jasir RasyidiNo ratings yet

- 2017 Kynar Wire and Cable SolutionsDocument8 pages2017 Kynar Wire and Cable SolutionsKaarthicNatarajanNo ratings yet

- A389 CuNiDocument1 pageA389 CuNiPrathamesh OmtechNo ratings yet

- HV Full CatalogueDocument17 pagesHV Full CataloguemaggamNo ratings yet

- RD 360R3Document1 pageRD 360R3Rachmad Budi WNo ratings yet

- Data MP35N Rev-2Document2 pagesData MP35N Rev-2Nishant MehtaNo ratings yet

- 210 Series: Dividohm® Vitreous Enamel Adjustable PowerDocument2 pages210 Series: Dividohm® Vitreous Enamel Adjustable PowerRustem öztürkNo ratings yet

- UTP A 6222 MoDocument1 pageUTP A 6222 MoKara WhiteNo ratings yet

- SME - Metal Enclosed SwitchgearsDocument4 pagesSME - Metal Enclosed SwitchgearsViorel BorsNo ratings yet

- Description Appearance: Voidless-Hermetically Sealed Fast Recovery Glass RectifiersDocument3 pagesDescription Appearance: Voidless-Hermetically Sealed Fast Recovery Glass RectifiersRenato Almeida AmorimNo ratings yet

- Pinnacle Alloys E9018-M Code and Specification DataDocument2 pagesPinnacle Alloys E9018-M Code and Specification DataPutra Panca WardhanaNo ratings yet

- Chemical CompositionDocument6 pagesChemical CompositionAkbar DarmawansyahNo ratings yet

- Case Hardening Alloy Steel Bar 6587 Atlas 6587: Colour Code: Signal Red (Band) - BlackDocument3 pagesCase Hardening Alloy Steel Bar 6587 Atlas 6587: Colour Code: Signal Red (Band) - BlackCelsoNo ratings yet

- 9Cr - 1mo Modified With V, NB, and N.: OdificationDocument1 page9Cr - 1mo Modified With V, NB, and N.: OdificationAshok RajNo ratings yet

- SS 6mo - 1.4547Document1 pageSS 6mo - 1.4547f_riseNo ratings yet

- Relays: Sil Relays David Use Photo SD0010Document9 pagesRelays: Sil Relays David Use Photo SD0010mikesoupNo ratings yet

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationIam FroilanNo ratings yet

- Level CombinedDocument25 pagesLevel CombinedDANIEL LNo ratings yet

- 1.1 - Distribution Deadend-Suspension Cat D-DS - 200108Document4 pages1.1 - Distribution Deadend-Suspension Cat D-DS - 200108Ali KhaniNo ratings yet

- Electrical Downhole Cable: ApplicationsDocument3 pagesElectrical Downhole Cable: ApplicationsAndrea VarasNo ratings yet

- E7018 1 Eutherme lh1 PDFDocument1 pageE7018 1 Eutherme lh1 PDFAnonymous dxsNnL6S8hNo ratings yet

- Aluminium Alloy QQ A 25011 T651 Plate - 222Document2 pagesAluminium Alloy QQ A 25011 T651 Plate - 222somashekar1510No ratings yet

- Catalogue D-DS D S I: Deadend / Suspension 15 KV To 69 KVDocument63 pagesCatalogue D-DS D S I: Deadend / Suspension 15 KV To 69 KVcarlosantunez111No ratings yet

- SOW 7018A11 8 SpecSheetDocument2 pagesSOW 7018A11 8 SpecSheetKmi GutierrezNo ratings yet

- Betobar DC CatalogueDocument30 pagesBetobar DC CatalogueMorteza MahdaviNo ratings yet

- 1.4462 SpecificationDocument2 pages1.4462 SpecificationSergeyNo ratings yet

- 20Mncr5: Steel GradeDocument4 pages20Mncr5: Steel GradeAhmad ShujaNo ratings yet

- 3310 Aluminum Sheer Beam Load Cell: Vishay Tedea-HuntleighDocument3 pages3310 Aluminum Sheer Beam Load Cell: Vishay Tedea-Huntleighsweet boy play boyNo ratings yet

- SD47ADocument3 pagesSD47Aasif.binance1988No ratings yet

- Aalco Metals LTD Aluminium Alloy 1050A H14 Sheet 57Document2 pagesAalco Metals LTD Aluminium Alloy 1050A H14 Sheet 57SathishbhaskarNo ratings yet

- Control Systems Design ProjectDocument3 pagesControl Systems Design ProjectHasan ÇalışkanNo ratings yet

- Interpretations of The IMO Gas Code: International Association of Classification SocietiesDocument53 pagesInterpretations of The IMO Gas Code: International Association of Classification SocietiesAlkaNo ratings yet

- Advantage of Oil CoolingDocument2 pagesAdvantage of Oil CoolingYin ThoNo ratings yet

- Gen Nav WeOneDocument272 pagesGen Nav WeOnecaptvivekNo ratings yet

- Day 4 and 5 - Deductive Reasoning and Two Column Proofs AnswersDocument4 pagesDay 4 and 5 - Deductive Reasoning and Two Column Proofs Answersapi-253195113No ratings yet

- Surveying 2 Final ExamDocument3 pagesSurveying 2 Final ExamRodin James GabrilloNo ratings yet

- Assignment NM 2Document1 pageAssignment NM 2Sunny KashyapNo ratings yet

- Electrical Systems (Engine) - (S - N 512911001 - 512911999) - 331Document3 pagesElectrical Systems (Engine) - (S - N 512911001 - 512911999) - 331Ronaldo Javier Vergara AnayaNo ratings yet

- AC Commutator Motors Repulsion Series Motor UniversalDocument3 pagesAC Commutator Motors Repulsion Series Motor UniversalwhrferNo ratings yet

- Mech 473 Lectures: Professor Rodney HerringDocument40 pagesMech 473 Lectures: Professor Rodney HerringWalid Ben AmirNo ratings yet

- Activities InterventionDocument2 pagesActivities InterventionDonabel Villasaya CariosNo ratings yet

- Ptical Oxygen Sensor: ATA HeetDocument14 pagesPtical Oxygen Sensor: ATA HeetZoran ConstantinescuNo ratings yet

- Application Note: Vishay General SemiconductorDocument4 pagesApplication Note: Vishay General SemiconductorMamoon AlrimawiNo ratings yet

- mv215fhm-n30 DatasheetDocument33 pagesmv215fhm-n30 DatasheetharshaNo ratings yet

- Definitions - Topic 9 The Periodic Table - CAIE Chemistry IGCSE PDFDocument1 pageDefinitions - Topic 9 The Periodic Table - CAIE Chemistry IGCSE PDFAtif BakhshNo ratings yet

- EARTHSCIENCE ppt2Document8 pagesEARTHSCIENCE ppt2Rommel DominguezNo ratings yet

- Wolkite University Department of Information TechnologyDocument27 pagesWolkite University Department of Information Technologytamirat alemayewNo ratings yet

- Busiess Analytics Data Mining Lecture 7Document37 pagesBusiess Analytics Data Mining Lecture 7utkarsh bhargavaNo ratings yet

- Part1 1countingDocument203 pagesPart1 1countingTrần Khánh LươngNo ratings yet

- Prelims Solution Ce18Document6 pagesPrelims Solution Ce18Mark Lester LualhatiNo ratings yet

- For And: Viterbi Decoding Satellite Space CommunicationDocument14 pagesFor And: Viterbi Decoding Satellite Space CommunicationRosi Marleny Machuca rojasNo ratings yet

- LAMIGAS - BSN2H-Laboratory No. 2Document3 pagesLAMIGAS - BSN2H-Laboratory No. 2Juliemae LamigasNo ratings yet