Professional Documents

Culture Documents

Industries Served Mattei Landscape

Uploaded by

Dewanjee AshrafOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Industries Served Mattei Landscape

Uploaded by

Dewanjee AshrafCopyright:

Available Formats

The Industry-Wide Benefits of

Rotary Vane Air Compressors

The Industry-Wide Benefits of Rotary Vane Air Compressors • Page 2 of 16

Contents

Introduction | 3

Rotary Vane Vs. Rotary Screw Air Compressors: The Advantages | 3

Rotary Vane Compressors: Industries Served | 4

Agriculture | 5

Body Shop & Automotive | 6

Dry Cleaning | 7

Energy | 8

Food & Beverage | 9

Manufacturing | 10

Medical & Dental | 11

Natural Gas | 12

Pharmaceutical | 13

Plastics | 14

Woodworking | 15

Conclusion | 16

About Mattei | 16

9635 Liberty Road, Suite E • Randallstown, MD 21133 • www.MatteiComp.com • (410) 521-7020

The Industry-Wide Benefits of Rotary Vane Air Compressors • Page 3 of 16

Introduction

Rotary vane air compressors are one of the most widely used products in use today. They serve a wide range of industries, universally providing superior energy savings across

many varying levels of air demand. In addition to the necessary air supply they provide, their benefits include greater efficiency at lower costs.

Through the use of rotary vane compressors, no matter what the specific industry and/or application, compressed air provides the flexible, critical element to the production

process. In fact, compressed air represents over 10% of total industrial costs; for this reason, it is crucial that it is supplied in the most cost-effective, efficient way possible.

Furthermore, with the ever growing emphasis on energy savings, it is in every company’s interest to use compressed air in the most efficient way—which is precisely what

advanced rotary vane compressors do.

Here, we will look closely at the overall advantages of rotary vane air compressors, as well as the specific ways they benefit a variety of industries.

Rotary Vane Vs. Rotary Screw Air Compressors: The Advantages

Mattei rotary vane compressor technology is both innovative and simple: they feature a single off-set rotor supported by two metal Babbitt bushings spinning at 1,800 rpm

or less. Blades/vanes slide in and out of the rotor, forming compression pockets, while a zero-wear MeehaniteTM treating process combined with high quality synthetic oil to

prevent wear to the stator wall or the cast iron blades. The technology is extremely efficient, as well as durable, often providing over 100,000 hours of service life.

Alternatively, rotary screw air compressors are both sensitive and complex. They are comprised of two parallel rotors with external helical screws, and each of the rotors

are fitted with four roller bearings and two thrust bearings, placed inside a stator made from two intersecting cylinders. The rotors rely on the bearings to maintain critical

tolerances to avoid contacting end plates or stator walls while turning at speeds typically between 3,000 and 8,000 rpm. Thrust loads cause the

thrust bearings to wear which causes the precise tolerances to deteriorate until the bearings fail or are replaced. Installed airend life is typically

between 35,000 to 40,000 hours.

Therefore, the inherent design of rotary vane compressors is far superior to rotary screw compressors, with unmatched efficiency, service life,

and cost-effectiveness. It is for this reason that they are counted on by so many industries, for so many different applications.

9635 Liberty Road, Suite E • Randallstown, MD 21133 • www.MatteiComp.com • (410) 521-7020

The Industry-Wide Benefits of Rotary Vane Air Compressors • Page 4 of 16

Rotary Vane Compressors: Industries Served

Beyond their exceptional technology and energy efficiency, what makes Mattei rotary vane compressors so unique is their universal demand; from agriculture to

pharmaceuticals, and much in between, countless businesses in a wide variety of industries count on them.

Here we will examine their applications and advantages for specific industries.

• Agriculture • Medical & Dental

• Body Shop & Automotive • Natural Gas

• Dry Cleaning • Pharmaceutical

• Energy • Plastics

• Food & Beverage • Woodworking

• Manufacturing

9635 Liberty Road, Suite E • Randallstown, MD 21133 • www.MatteiComp.com • (410) 521-7020

The Industry-Wide Benefits of Rotary Vane Air Compressors • Page 5 of 16

Agriculture

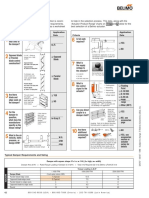

Within the agriculture industry, rotary vane compressors serve a variety of functions. They Mattei Product Recommendation for Agricultural Applications:

supply high amounts of continuous compressed air, on demand, for jobs such as operating far

equipment, material conveying, planting produce and milking cows, to name a few. Good Option: Better Option: Best Option:

ERC Series BLADE Series AC Series

They serve these functions while consuming less energy than traditional rotary screw

compressors—offering up to 35% in energy savings. Vane compressors are also extremely cost

effective, with a lifespan that often doubles or triples that of rotary screw compressors. Within

the very competitive agriculture industry, these features are a critical factor to the cost of day-to-

day operations.

Click here to learn more about the AC Series and why this is the best

system for the agriculture industry.

9635 Liberty Road, Suite E • Randallstown, MD 21133 • www.MatteiComp.com • (410) 521-7020

The Industry-Wide Benefits of Rotary Vane Air Compressors • Page 6 of 16

Body Shop & Automotive

Within the automotive repair industry, there are numerous functions for which rotary vane Mattei Product Recommendation for Body Shop/Automotive

compressors play a critical role. Automotive repair shops, auto body painting shops, and tire Applications:

and wheel shops use these compressors for welding and cutting, tire inflation, air tool operation,

paint pump operation, and a variety of auto finishing tools. They also assist in the operation of Good Option: Better Option: Best Option:

air-operated robots, an increasingly common and relied upon technology in auto body shops ERC Series BLADE Series AC Series

around the country.

For the operators of these facilities, the benefits and ROI are in stark contrast to older systems.

The advantages of Mattei rotary vane compressors for the automotive industry start at a very

basic level, smaller footprint, pulse-free air, low oil consumption, very little maintenance, and

decreased power consumption.

Cost constraints in this industry are just as important as in any other industry—as major service

Click here to learn more about the AC Series and why this is the best

centers, body shops, and even local garages are actively seeking ways to reduce operating

system for body shops and automotive repairs.

costs. Mattei rotary vane systems are an answer to that need because they are engineered to

perform like no other compressors on the market today. Our rotary vane compressors supply the

efficient, clean, dry, durable air needed for most body shop and automotive applications, while

keeping costs and energy usage down.

9635 Liberty Road, Suite E • Randallstown, MD 21133 • www.MatteiComp.com • (410) 521-7020

The Industry-Wide Benefits of Rotary Vane Air Compressors • Page 7 of 16

Dry Cleaning

The many chemical applications used within the dry cleaning environment

depend upon accurate amounts of compressed air. Air must be delivered in

such a way that clothing is cleaned precisely and effectively, and there is no

room for error. The success of a dry cleaning business, no matter the size,

depends on this accuracy and quality.

In this very competitive service industry, finding the right combination of low-

cost operations and high reliability is a crucial advantage. Mattei manufactures

the highest quality, most efficient, and quietest compressors that are counted

on for their reliability. They are also very compact, taking up less floor space,

and Mattei’s innovative design also equates to a very a low maintenance

profile. For users in the dry cleaning industry, this means they can concentrate

on their core business, rather than on operating systems.

Rotary vane compressors not only consume less energy than rotary screw

compressors, but ensure the precision and reliability that is needed by the

dry cleaning industry. They are the best and only compressor of choice when

quality cannot be compromised.

Mattei Product Recommendations for Dry Cleaning Applications:

Good Option: Better Option: Best Option:

ERC Series BLADE Series AC Series

Learn more about the AC Series and why this is the best system for the dry

cleaning industry.

9635 Liberty Road, Suite E • Randallstown, MD 21133 • www.MatteiComp.com • (410) 521-7020

The Industry-Wide Benefits of Rotary Vane Air Compressors • Page 8 of 16

Energy

As many varied applications and jobs as there are within the energy industry,

there are demands for rotary vane compressors. Applications range from

compressed air for drilling rigs and platforms within the energy exploration

sector, to air pumps for drilling, and turbine operation in sewage, oil, coal,

biogas, and waste gas plants and systems. They are also used as a source of

energy in the manufacturing of wind generators.

The extremely long lifespan, coupled with uncompromised energy efficiency

and cost savings, make rotary vane compressors an integral part of the energy

industry. They can withstand and endure the harshest of applications and

environments, all the while remaining 100% reliable.

Mattei Product Recommendations for Energy Applications:

Good Option: Better Option: Best Option:

ERC Series AC Series Optima Series or

Maxima Series

Learn more about the Optima Series and Maxima Series and how these

systems can benefit the energy industry.

9635 Liberty Road, Suite E • Randallstown, MD 21133 • www.MatteiComp.com • (410) 521-7020

The Industry-Wide Benefits of Rotary Vane Air Compressors • Page 9 of 16

Food & Beverage

Within the food and beverage industry, the applications for rotary vane compressors are Mattei Product Recommendation for Food & Beverage

practically limitless—as wide and varied as the industry itself. Applications for these compressors Applications:

include food/beverage product handling, operation of air knives for cutting and peeling produce,

handling of bulk products and materials through cylinders and hoists, vacuums in the packaging Good Option: Better Option: Best Option:

process, chocolate making, and even the delicate task of filling cakes, pastries and pies. ERC Series AC Series Optima Series or

Maxima Series

In the food and beverage industry, automation is the key to efficient high volume production.

Compressed air is the power behind an endlessly varied range of specialty processes: from

the filling of delicate cakes and pies to the making of chocolate and the handling of food and

beverage products. They are used in air knives that cut and peel produce, and are used to

operate pumps that move and fill liquids. Air compressors ensure the smooth, fast handling of

bulk products and materials through cylinders and hoists, and can be used as vacuums during

the packaging process. From the beginning to the end of the production cycle, air compressors

make the food & beverage industry run. Discover why our Optima Series and Maxima Series are valuable to

food and beverage applications.

Not only do rotary vane compressors provide the quiet, consistent, reliable efficiency and

savings these food and beverage companies need, but they also have the ability to supply air

that is completely free of contaminants—an absolutely critical function in the handling of food

and beverages.

9635 Liberty Road, Suite E • Randallstown, MD 21133 • www.MatteiComp.com • (410) 521-7020

The Industry-Wide Benefits of Rotary Vane Air Compressors • Page 10 of 16

Manufacturing

In almost every facet of manufacturing imaginable, no matter what the product

or part being made—and no matter what stage in the process—rotary vane

compressors are a huge part of the entire manufacturing industry. Rotary vane

compressors serve in a variety of welding operations, in the use of air-operated

metal and wood working tools, in cylinders used in paper pressing, in many

industrial cooling operations, throughout material handling operations, in

printing pumps and equipment, and much more. They also play a large role in

the use of robotics and automation, which is a major part of today’s advanced

manufacturing.

Their reliability is second-to-none, and the longevity and superior cost savings

help manufacturers remain competitive and at an economic advantage. In so

many ways, they are critical to the success of today’s manufacturers of all types

and sizes.

Mattei Product Recommendations for Manufacturing

Applications:

Good Option: Better Option: Best Option:

ERC Series AC Series Optima Series or

Maxima Series

Learn how Mattei’s Optima Series and Maxima Series benefit the

manufacturing industry.

9635 Liberty Road, Suite E • Randallstown, MD 21133 • www.MatteiComp.com • (410) 521-7020

The Industry-Wide Benefits of Rotary Vane Air Compressors • Page 11 of 16

Medical & Dental

Rotary vane air compressors are the only compressors that offer the precision,

technology, and complete cleanliness that is necessary to every aspect of the

healthcare industry. With suitable filtration, vane compressors provide reliable,

uninterrupted air supply that is compliant, sterilized and medical grade for

air-driven medical tools. Doctors’ and dentists’ offices, clinics, surgical centers,

labs, and veterinary offices utilize compressed air systems for countless, often

lifesaving procedures and functions.

These technologically-advanced compressors ensure the safety, reliability, ad

accuracy that is needed by any and all healthcare facilities. Their energy savings

deliver the added benefit of keeping costs down, and their long service life

allows the focus to be solely on the patient.

Mattei Product Recommendations for Medical & Dental

Applications:

Good Option: Better Option: Best Option:

ERC Series AC Series Optima Series or

Maxima Series

Learn more about Mattei’s Optima Series and Maxima Series and how these

systems provide value to the healthcare industry.

9635 Liberty Road, Suite E • Randallstown, MD 21133 • www.MatteiComp.com • (410) 521-7020

The Industry-Wide Benefits of Rotary Vane Air Compressors • Page 12 of 16

Natural Gas

Gas operations, no matter what the specific job, demand reliability and consistency. Mattei Product Recommendation for Natural Gas Applications:

Compressed air is often highly preferable in hazardous environments, as it is safe to have in

contact with materials. It also provides a harmless, effective way to clean equipment, while Good Option: Better Option: Best Option:

minimizing downtime and extending equipment life, and is used throughout a variety of gas ERC Series AC Series Optima Series or

operations, including vapor recovery, gas gathering, gas transfer, flare elimination, and in gas Maxima Series

turbines.

As the natural gas industry continues to evolve and thrive, rotary vane compressors provide the

cost-effective, energy-saving, reliable air source that helps make this growing industry run.

Discover why Mattei’s Optima Series and Maxima Series are the best

rotary vane systems for the natural gas industry.

9635 Liberty Road, Suite E • Randallstown, MD 21133 • www.MatteiComp.com • (410) 521-7020

The Industry-Wide Benefits of Rotary Vane Air Compressors • Page 13 of 16

Pharmaceutical

Rotary vane compressors are used throughout all processes of pharmaceutical

manufacturing. They serve to control the equipment used to manufacture

pharmaceutical products, as well as to produce nitrogen. Oftentimes,

compressed air is mixed with various products to accelerate drying, and

serves many functions throughout various chemical applications. The use

of compressed air eliminates explosion risks associated with alternative

substances, making it especially suitable for volatile environments.

In all areas of pharmaceutical manufacturing, air supplied via rotary vane

compressors, with suitable filtration, ensures a clean, safe, quiet work

environment. It’s also the best way to make sure downtime is avoided and

energy savings are achieved.

Mattei Product Recommendations for Pharmaceutical

Applications:

Good Option: Better Option: Best Option:

ERC Series AC Series Optima Series or

Maxima Series

Learn more about Mattei’s Optima Series and Maxima Series and how these

systems can benefit the pharmaceutical industry.

9635 Liberty Road, Suite E • Randallstown, MD 21133 • www.MatteiComp.com • (410) 521-7020

The Industry-Wide Benefits of Rotary Vane Air Compressors • Page 14 of 16

Plastics

Within the plastics industry, there are seemingly endless uses for rotary vane

compressors. They play an extremely important role in automation—widely

used by the plastics industry today—ensuring accuracy and consistency. Rotary

vane compressors are used within the tools used by the industry, as well as

in the cleaning of equipment and facilities, throughout material handling

operations, along production and assembly lines, and in the operation of

plastics manufacturing equipment.

Plastics manufacturers require systems that last long and function optimally.

Their success also depends on keeping energy costs down, which is ensured

with rotary vane compressors. The many advantages provided by the

compressors keep plastics manufacturers competitive and successful.

Mattei Product Recommendations for Plastic Applications:

Good Option: Better Option: Best Option:

ERC Series AC Series Optima Series or

Maxima Series

Discover why our Optima Series and Maxima Series are the best options for

the plastics industry.

9635 Liberty Road, Suite E • Randallstown, MD 21133 • www.MatteiComp.com • (410) 521-7020

The Industry-Wide Benefits of Rotary Vane Air Compressors • Page 15 of 16

Woodworking

Every wood product business, no matter the specific product or final operation, can benefit from Mattei Product Recommendation for Woodworking

the use of rotary vane compressors. OEMs working with wood products, furniture manufacturers, Applications:

construction companies, millwork operations, and so many more rely on compressed air

provided by rotary vane compressors. They assist in the use of air-operated tools, which are Good Option: Better Option: Best Option:

lighter and easier to operate than electrically-operated tools, which reduces labor time and ERC Series AC Series Optima Series or

allows jobs to be completed faster. They are also the most reliable, effective way to ensure Maxima Series

accurate painting and finishing of wood products.

No matter the size or specific role of the woodworking task, rotary vane compressors deliver

the energy- and cost-savings that keep these businesses running smoothly and profitably. They

ensure accuracy the way no other compressor can, and make any woodworking operation more

efficient.

Learn more Mattei’s Optima Series and Maxima Series and how

these systems can benefit woodworking applications.

9635 Liberty Road, Suite E • Randallstown, MD 21133 • www.MatteiComp.com • (410) 521-7020

The Industry-Wide Benefits of Rotary Vane Air Compressors • Page 16 of 16

Conclusion

Due to their superior design and function, and countless advantages—including energy efficiency, significant cost savings, reliability, and unsurpassed quality—Mattei

rotary vane compressors are relied upon for myriad applications throughout so many industries around the world. They are simply the best choice for continuous, accurate

compressed air.

About Mattei

More than 50 years of business has allowed Mattei to serve nearly every industry and market—thereby providing us with the valuable experience that is necessary to fully

understand our customers’ needs.

Our understanding of our customers has significantly contributed to the superior design, construction and performance of our rotary vane technology—and allowed us to

engineer the best systems for a variety of applications. We understand your industry, the challenges you face and the solution you need.

Today, Mattei is proud to serve a multitude of industries including agriculture, automotive and body shop, dry cleaning, energy, food and beverage, manufacturing, medical

and dental, natural gas, pharmaceutical, plastics, woodworking and more.

To learn more about Mattei compressors and how they can benefit your specific industry and applications, visit www.matteicomp.com.

9635 Liberty Road, Suite E • Randallstown, MD 21133 • www.MatteiComp.com • (410) 521-7020

You might also like

- California State Bar Order of Discipline of Louis "Skip" Miller For Jury TamperingDocument33 pagesCalifornia State Bar Order of Discipline of Louis "Skip" Miller For Jury TamperingAlan RomeroNo ratings yet

- Amtrol HandbookDocument112 pagesAmtrol HandbookKokchuan WangNo ratings yet

- List of Registered Non Govt and Govt Secondary SchoolDocument200 pagesList of Registered Non Govt and Govt Secondary SchoolDennisEudes78% (9)

- IRM G 8779 CentrifugalBroch GabaritoDocument16 pagesIRM G 8779 CentrifugalBroch Gabaritoralfi85No ratings yet

- Mechanical Seal AramcoDocument18 pagesMechanical Seal AramcoMohamed AbdelsalamNo ratings yet

- Mattei-MC-M SeriesDocument8 pagesMattei-MC-M SeriesDelarenus SianiparNo ratings yet

- NASA: 181330main Jun29colorDocument8 pagesNASA: 181330main Jun29colorNASAdocumentsNo ratings yet

- HamletDocument37 pagesHamlethyan teodoroNo ratings yet

- Unica GBDocument12 pagesUnica GBDelarenus SianiparNo ratings yet

- Maxima en 1Document8 pagesMaxima en 1Jose SantosNo ratings yet

- GDW RO Prospekt EnglischDocument13 pagesGDW RO Prospekt EnglischRamón Ariel AstudilloNo ratings yet

- Blade Series BrochureDocument8 pagesBlade Series BrochureDelarenus SianiparNo ratings yet

- sr1601 new-NUJOJFDocument4 pagessr1601 new-NUJOJFGuntani SambodoNo ratings yet

- # Choosing The Right ScrewDocument4 pages# Choosing The Right Screwsec.ludhiana112No ratings yet

- D Series: 75 kW-160 KW Oil-Free Rotary Screw Compressors Fixed & Regulated Speed (RS)Document16 pagesD Series: 75 kW-160 KW Oil-Free Rotary Screw Compressors Fixed & Regulated Speed (RS)Luran JuNo ratings yet

- For Each Type: Always The Right SolutionDocument20 pagesFor Each Type: Always The Right SolutionPavel PavelNo ratings yet

- Enviroaire T/Tvs Series: 75Kw-160Kw Oil-Free Rotary Screw Compressors Fixed & Variable SpeedDocument16 pagesEnviroaire T/Tvs Series: 75Kw-160Kw Oil-Free Rotary Screw Compressors Fixed & Variable SpeedSuresh NathNo ratings yet

- Delbag Filter System MultiAir Eco 2000-MWFDocument12 pagesDelbag Filter System MultiAir Eco 2000-MWFnileshNo ratings yet

- Miniaturization FinalDocument3 pagesMiniaturization FinalleosashNo ratings yet

- Spesifikasi HCR 910 DSDocument7 pagesSpesifikasi HCR 910 DSYudi YusufNo ratings yet

- Blade 1 3 PDFDocument8 pagesBlade 1 3 PDFYohan JanantoNo ratings yet

- Tribology and Gear ReducersDocument7 pagesTribology and Gear ReducersAnibal Rios100% (1)

- Modec Case StudiesDocument15 pagesModec Case Studiessamah eskanderNo ratings yet

- DH Series: 15 kW-110 KW Oil-Less Rotary Screw CompressorsDocument16 pagesDH Series: 15 kW-110 KW Oil-Less Rotary Screw CompressorsVijay KumarNo ratings yet

- Mining ThriveniDocument28 pagesMining ThriveniAnonymous GBge2ED1O100% (2)

- Rollair Rotary Screw Compressors GuideDocument12 pagesRollair Rotary Screw Compressors Guidepragnesh prajapatiNo ratings yet

- JIP Compressor FoulingDocument3 pagesJIP Compressor FoulinglvicencioaNo ratings yet

- Sealmatic Design Manual2.1Document113 pagesSealmatic Design Manual2.1varunzhao86No ratings yet

- Technical InfoDocument17 pagesTechnical InfoJosue GonzalezNo ratings yet

- 11 Benefits of Robotic AutomationDocument9 pages11 Benefits of Robotic Automationshahdad sayedNo ratings yet

- Lavadoras Continental Series LDocument6 pagesLavadoras Continental Series LAlejandro AlvarezNo ratings yet

- Compressors Explained: Types, Applications & MoreDocument12 pagesCompressors Explained: Types, Applications & MoreR R Siva KiranNo ratings yet

- 2.auto Indexing Drilling MachineDocument7 pages2.auto Indexing Drilling Machinesasitharan33No ratings yet

- Worthington-Creyssensac Rollair 500-200!10!20e enDocument12 pagesWorthington-Creyssensac Rollair 500-200!10!20e enpragnesh prajapatiNo ratings yet

- Efficient and Reliable Air Compressors for All Your NeedsDocument8 pagesEfficient and Reliable Air Compressors for All Your Needspragnesh prajapatiNo ratings yet

- g110 250Document12 pagesg110 250rudyNo ratings yet

- Mke Series Air DryersDocument7 pagesMke Series Air DryersFarjallahNo ratings yet

- Machinery Reliability Secrets of Extremely Reliable Mechanical Shaft SealsDocument30 pagesMachinery Reliability Secrets of Extremely Reliable Mechanical Shaft Sealsi.kamalNo ratings yet

- Oil Free Centrifugal CompressorDocument24 pagesOil Free Centrifugal CompressorAnonymous zMWvcT0% (1)

- ZH355-900 Plus ZH630-1600 Plus ZH1000-3150 EN Antwerp 2935063413Document24 pagesZH355-900 Plus ZH630-1600 Plus ZH1000-3150 EN Antwerp 2935063413karun agrawalNo ratings yet

- D1 010 03 enDocument18 pagesD1 010 03 en3238NDNo ratings yet

- Contents Centrifugal Oil CleanersDocument12 pagesContents Centrifugal Oil Cleanersg33sp0tNo ratings yet

- Mers Global ENG 2023Document4 pagesMers Global ENG 2023fadi fadiNo ratings yet

- How Industrial Blowers Are MadeDocument15 pagesHow Industrial Blowers Are MadeJH PerlasNo ratings yet

- Extend Equipment Life with Effective Oil FilteringDocument10 pagesExtend Equipment Life with Effective Oil FilteringBrayan MejiaNo ratings yet

- CABP Feb 07 LRDocument52 pagesCABP Feb 07 LRkarun agrawalNo ratings yet

- Oilflooded 437 KwbrochurescreenDocument12 pagesOilflooded 437 KwbrochurescreenJose Miguel SánchezNo ratings yet

- Cartucho Secador de Aire Giratorio con Filtro CoalescenteDocument2 pagesCartucho Secador de Aire Giratorio con Filtro CoalescenteElver Tintaya MamaniNo ratings yet

- Compressed Air 2Document32 pagesCompressed Air 2jaime100% (1)

- List Chemtech 2015 Exhibitors DirectoryDocument410 pagesList Chemtech 2015 Exhibitors Directoryindusexposium100% (1)

- FINI Cat MicroPlus enDocument24 pagesFINI Cat MicroPlus enGuilherme RochaNo ratings yet

- Micro - Plus: Industrial RangeDocument24 pagesMicro - Plus: Industrial Rangesljiva11No ratings yet

- Pneumatics Ensure Reliability in Food ProcessingDocument5 pagesPneumatics Ensure Reliability in Food ProcessingJaikishan KumaraswamyNo ratings yet

- Micro - Plus: Industrial RangeDocument24 pagesMicro - Plus: Industrial RangeMuhammadIsmail Engr.No ratings yet

- A Simply Strategy For Eliminating Plant FailuresDocument17 pagesA Simply Strategy For Eliminating Plant FailuresElvis DiazNo ratings yet

- Aerzen Turbo Generation 4 5 PDFDocument8 pagesAerzen Turbo Generation 4 5 PDFherrerafaridNo ratings yet

- MD ND MDG Series Leaflet EN - LRDocument16 pagesMD ND MDG Series Leaflet EN - LRMahesh MishraNo ratings yet

- Case Study of Rolls RoyceDocument9 pagesCase Study of Rolls Roycecdrrmo training divisionNo ratings yet

- Advancements in Compression Technology For Syn Gas Applications Efficiency and ReliabilityDocument7 pagesAdvancements in Compression Technology For Syn Gas Applications Efficiency and Reliabilityvaratharajan g rNo ratings yet

- 3 Types of Air Compressors For Your Industrial Engine Application - VMACDocument5 pages3 Types of Air Compressors For Your Industrial Engine Application - VMACKontrak Service PEP-CepuNo ratings yet

- Oil-Free Centrifugal CompressorsDocument6 pagesOil-Free Centrifugal CompressorsAatish ChandrawarNo ratings yet

- Cost of Sweeper PDFDocument13 pagesCost of Sweeper PDFKittipong DurngtaphaNo ratings yet

- Optima Rotary Vane Compressors Product InformationDocument8 pagesOptima Rotary Vane Compressors Product InformationDelarenus SianiparNo ratings yet

- DL 75 FINI Vijačni KompresoriDocument59 pagesDL 75 FINI Vijačni Kompresoripvbtan4No ratings yet

- Some Aspects of Estimating Geometric Characteristics of Screw ComDocument11 pagesSome Aspects of Estimating Geometric Characteristics of Screw ComDewanjee AshrafNo ratings yet

- Select An Actuator - DamperDocument1 pageSelect An Actuator - DamperDewanjee AshrafNo ratings yet

- ERV-500 IC Energy Recovery VentilatorDocument3 pagesERV-500 IC Energy Recovery VentilatorDewanjee AshrafNo ratings yet

- Global Steel Plant Tracker March 2022Document420 pagesGlobal Steel Plant Tracker March 2022Dewanjee AshrafNo ratings yet

- ARANER International Seminar On Cooling Energy StorageDocument66 pagesARANER International Seminar On Cooling Energy StorageDewanjee AshrafNo ratings yet

- WHP Reference-Guide FINALDocument24 pagesWHP Reference-Guide FINALDewanjee AshrafNo ratings yet

- 886 - Hajj Preparation Week 4Document25 pages886 - Hajj Preparation Week 4Dewanjee AshrafNo ratings yet

- Guide To A Walking Hajj - FlipHTML5 PDFDocument63 pagesGuide To A Walking Hajj - FlipHTML5 PDFDewanjee AshrafNo ratings yet

- SDH Technology - Slide PackDocument21 pagesSDH Technology - Slide PackDewanjee AshrafNo ratings yet

- Carrier Sanyo 16NK IOMDocument193 pagesCarrier Sanyo 16NK IOMDewanjee AshrafNo ratings yet

- The Condition Monitoring of An Upstream Oil and Gas Dry Screw ComDocument11 pagesThe Condition Monitoring of An Upstream Oil and Gas Dry Screw ComDewanjee AshrafNo ratings yet

- A Review of Absorption RefrigerationDocument30 pagesA Review of Absorption RefrigerationSoni Rodríguez Castellanos100% (1)

- Options in Gas Turbine Power Augmentation Using Inlet Air ChillingDocument10 pagesOptions in Gas Turbine Power Augmentation Using Inlet Air ChillingDewanjee AshrafNo ratings yet

- Surge Detection and Surge Control Systems For Centrifugal Compressors - Part 2Document3 pagesSurge Detection and Surge Control Systems For Centrifugal Compressors - Part 2Dewanjee AshrafNo ratings yet

- High Performance VAM For District CoolingDocument6 pagesHigh Performance VAM For District CoolingDewanjee AshrafNo ratings yet

- YR Chiller Point ListDocument4 pagesYR Chiller Point ListDewanjee AshrafNo ratings yet

- Isoflow Absorption Chillers With Buffalo Pumps: Installation InstructionsDocument44 pagesIsoflow Absorption Chillers With Buffalo Pumps: Installation InstructionsDewanjee AshrafNo ratings yet

- 600TR VAPOR ABSORPTION CHILLER SPECDocument36 pages600TR VAPOR ABSORPTION CHILLER SPECaleemhakNo ratings yet

- Why absorption chillers fail: Air leaks and improper chemistryDocument9 pagesWhy absorption chillers fail: Air leaks and improper chemistryDewanjee AshrafNo ratings yet

- Maintaining VAMs - ASHRAEDocument8 pagesMaintaining VAMs - ASHRAEDewanjee AshrafNo ratings yet

- Model Yr TB TB T0 Thru Yr VD VD T1 Style A 200 THRU 300 TONS (525 THRU 880 KW)Document20 pagesModel Yr TB TB T0 Thru Yr VD VD T1 Style A 200 THRU 300 TONS (525 THRU 880 KW)Dewanjee AshrafNo ratings yet

- YR ModA-EG1Document40 pagesYR ModA-EG1Dewanjee AshrafNo ratings yet

- Liquid Cooled Solid State Starter: OperationDocument28 pagesLiquid Cooled Solid State Starter: OperationDewanjee AshrafNo ratings yet

- Yr-Sss Point ListDocument4 pagesYr-Sss Point ListDewanjee AshrafNo ratings yet

- Product Drawing M E: Performance SpecificationsDocument20 pagesProduct Drawing M E: Performance SpecificationsDewanjee AshrafNo ratings yet

- Yr SGDocument8 pagesYr SGDewanjee AshrafNo ratings yet

- Product Drawing M E: Performance SpecificationsDocument20 pagesProduct Drawing M E: Performance SpecificationsDewanjee AshrafNo ratings yet

- Model Yr TB TB T0 Thru Yr VD VD T1 Style A 200 THRU 300 TONS (525 THRU 880 KW)Document20 pagesModel Yr TB TB T0 Thru Yr VD VD T1 Style A 200 THRU 300 TONS (525 THRU 880 KW)Dewanjee AshrafNo ratings yet

- Oil Injected Rotary Screw Compressors With Direct Transmission, Fixed or Variable SpeedDocument12 pagesOil Injected Rotary Screw Compressors With Direct Transmission, Fixed or Variable SpeedDewanjee AshrafNo ratings yet

- The Definition and Unit of Ionic StrengthDocument2 pagesThe Definition and Unit of Ionic StrengthDiego ZapataNo ratings yet

- PH.D Scholars UGCDocument25 pagesPH.D Scholars UGCUsha MurthyNo ratings yet

- Student (Mechanical Engineering), JECRC FOUNDATION, Jaipur (2) Assistant Professor, Department of Mechanical Engineering, JECRC FOUNDATION, JaipurDocument7 pagesStudent (Mechanical Engineering), JECRC FOUNDATION, Jaipur (2) Assistant Professor, Department of Mechanical Engineering, JECRC FOUNDATION, JaipurAkash yadavNo ratings yet

- Hacking Web ApplicationsDocument5 pagesHacking Web ApplicationsDeandryn RussellNo ratings yet

- IFCRecruitment Manual 2009Document52 pagesIFCRecruitment Manual 2009Oklahoma100% (3)

- Proposal to Enhance Science InstructionDocument4 pagesProposal to Enhance Science InstructionAzzel ArietaNo ratings yet

- What Is The Time Value of MoneyDocument6 pagesWhat Is The Time Value of MoneySadia JuiNo ratings yet

- Tute I IIDocument4 pagesTute I IIsachini weesingheNo ratings yet

- UITM Faculty of Business Entrepreneurship Rubric Social Media PortfolioDocument9 pagesUITM Faculty of Business Entrepreneurship Rubric Social Media PortfolioShamsyul AriffinNo ratings yet

- On Healing Powers: Asclepius, Caduceus and AntibodiesDocument4 pagesOn Healing Powers: Asclepius, Caduceus and AntibodiesasclepiuspdfsNo ratings yet

- How to Stop Overthinking and Make DecisionsDocument39 pagesHow to Stop Overthinking and Make DecisionsDeepak SinghNo ratings yet

- UNIT 2 Ielts Speaking Part 1 Questions Sample Answers IELTS FighterDocument15 pagesUNIT 2 Ielts Speaking Part 1 Questions Sample Answers IELTS FighterVi HoangNo ratings yet

- Charles Henry Brendt (1862-1929)Document2 pagesCharles Henry Brendt (1862-1929)Everything newNo ratings yet

- Wiring Diagram Obp 1 v2Document5 pagesWiring Diagram Obp 1 v2Jorge Luis Vera AlmeidaNo ratings yet

- Masai School Code of Conduct - Prefinal 11.10.2019Document3 pagesMasai School Code of Conduct - Prefinal 11.10.2019xavigatorNo ratings yet

- Density and Buoyancy Practice Test AnswersDocument9 pagesDensity and Buoyancy Practice Test AnswersYesha ShahNo ratings yet

- Packex IndiaDocument12 pagesPackex IndiaSam DanNo ratings yet

- ISL201-Solved MCQs 100 - Correct For Mid Term Papers (WWW - Virtualstudysolutions.blogspot - Com)Document70 pagesISL201-Solved MCQs 100 - Correct For Mid Term Papers (WWW - Virtualstudysolutions.blogspot - Com)bc190200669 BUSHRANo ratings yet

- Target products to meet 20% demandDocument12 pagesTarget products to meet 20% demandAlma Dela PeñaNo ratings yet

- How to Launder Money in Real EstateDocument58 pagesHow to Launder Money in Real EstateSpeedyGonsalesNo ratings yet

- SriRaghavendra StotraDocument15 pagesSriRaghavendra StotravedanthiNo ratings yet

- Lesson Plan-MethodsDocument6 pagesLesson Plan-Methodsapi-272643370No ratings yet

- Emerson Field Tools Quick Start GuideDocument48 pagesEmerson Field Tools Quick Start Guidepks_2410No ratings yet

- 41 Programmer Isp RT809F PDFDocument3 pages41 Programmer Isp RT809F PDFArunasalam ShanmugamNo ratings yet

- Sec 4 RA 6713 & Sec 3 RA 3019 OutlineDocument4 pagesSec 4 RA 6713 & Sec 3 RA 3019 OutlineAivan Charles TorresNo ratings yet

- SMEspdfDocument13 pagesSMEspdflilpumpdidnothingwrong dNo ratings yet