Professional Documents

Culture Documents

Desired Circulation Ratio For Natural Circulation

Uploaded by

olivegarden1900Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Desired Circulation Ratio For Natural Circulation

Uploaded by

olivegarden1900Copyright:

Available Formats

International Journal of Recent Technology and Engineering (IJRTE)

ISSN: 2277-3878, Volume-8 Issue-5, January 2020

Desired Circulation Ratio for Natural Circulation

in Water-Tube Boiler

Atul M. Elgandelwar, R. S. Jha, Mandar M. Lele

heat transfer tubes of the boiler. In a natural circulation boiler,

Abstract: The basic objective of the paper is to identify the the difference in density of circulating fluid in riser and

desired circulation ratio for the natural circulation of water tube downcomer tubes act like a motive force for the water and

boilers in different operating conditions. This requires the basic steam circulation in the boiler.

study of heat flux and the mode of the boiling heat transfer, and As the density of saturated water is higher than the density of

the phenomenon like a departure from nucleate boiling and tube

water and steam mixture, the pressure in downcomer column

overheating. The parameters, which need to be studied are heat

flux, pressure, dryness fraction, void fraction, liquid velocity and provides the necessary driving force for pushing water and

their impact on the required circulation ratio. The present work is steam mixture of riser tubes in the boiler drum. As the flow of

to develop a circulation analysis model for the natural circulation water and the water/steam mixture through the boiler circuits

of the water tube boiler and to check the boiler design for different is produced naturally by the force of gravity unlike the forced

failure modes. For a natural circulation boiler, the circulation circulation boiler, this type of boiler is called a natural

ratio is one of the most important design parameters as the other circulation boiler.

design parameter like critical heat flux and skin temperature are Syed-Ahmad M. Said [3] has developed models for water

mainly derived from the circulation ratio. The required

circulation ratio can vary with the boiler pressure, liquid velocity

circulation in boiler to calculate the circulation ratio and the

and maximum heat flux. This study is intended to provide input flow properties like velocity, steam quality, rate of steam

for the safe and optimum design of a natural circulation boiler. generation, void fraction, and surface temperature.

Circulation ratio is defined as the ratio of the mass flow rate of

Keywords: circulation ratio, departure from nucleate boiling, steam/water mixture in the circulation loop to the steam

stratification, void fraction, dryness fraction generation rate in evaporator tubes. V Ganapathy [4]

presented to study natural-circulation boiling circuits are in

I. INTRODUCTION successful operation with CRs ranging from 4 to 8 at high

Boiler Circulation is the movement of water, mixture of steam steam pressures and 15 to 50 at low steam pressures. The

& water, or steam through the boiler. Saturated water is, the circulation does not provide sufficient information about the

densest in a boiler circuit, and may contain some steam flow circulation in individual tubes, which is very important

bubbles. Salamah al-Anizi [1] investigated circulation in the for the thermal and hydraulic performance of the boiler. The

industrial boiler is the continuous supply of water to the boiler parameters which affect the distribution of the flow in the

heated tubes in order to sustain steady steam output without parallel channel are header area, tube diameter, size and

overheating tubes. Adequate circulation occurs when there is location of inlet port to the header, the direction of flow. Poor

sufficient flow of water into tubes for adequate cooling. Kim distribution and lower circulation ratio in a tube can lead to

and Choi [2] developed a model for providing an various problems like departure from nucleate boiling, phase

investigation of response of water level dynamics to change in stratification, higher void fraction and two-phase flow

steam demand and /or heating rate. instability. V.Ganapathy [5-6] presented the investigation to

Circulation analysis is very critical in the design of natural study allowable and actual steam qualities should be apart in

circulation boiler. Depending on the type of circulation, a order to avoid Departure from Nucleate Boiling (DNB)

boiler can be classified into forced circulation boiler and problems. Nayak et al. [7-8] observed instabilities during

natural circulation boiler. In a forced circulation boiler, a various stages of natural circulation systems such as single

circulation pump is used to ensure water and steam flow in the phase, boiling inception and fully developed two-phase flow.

Two phase flow distribution analysis in a natural

circulation boiler has different challenges as it has different

resistance and driving forces for each loop. Driving force for

Manuscript published on January 30, 2020. different loops can be different due to different height and

* Correspondence Author

Atul M. Elgandelwar*- Ph.D. Research Scholar, Department of

dryness fraction and dryness fraction is the function of flow

Mechanical Engineering, Maharashtra Institute of Technology Kothrud, and heat transfer. This makes the whole system of equation

Pune. SSPU (India) quite complex and circulation study is extremely useful for

R.S. Jha - Ph.D. Research Scholar, School of Mechanical Engineering, the design and analysis in natural circulation of boiler.

MIT-WPU, Kothrud, Pune. (India)

Mandar M. Lele- Professor, Department of Mechanical Engineering

MIT College of Engineering Kothrud, Pune. SSPU (India) II. NATURAL CIRCULATION IN BOILER

© The Authors. Published by Blue Eyes Intelligence Engineering and As the natural circulation circuit of the water tube boiler is

Sciences Publication (BEIESP). This is an open access article under the quite complex, the flow distribution among evaporating tubes

CC-BY-NC-ND license cannot be analyzed easily.

(http://creativecommons.org/licenses/by-nc-nd/4.0/)

Retrieval Number: E6646018520/2020©BEIESP Published By:

DOI:10.35940/ijrte.E6646.018520 Blue Eyes Intelligence Engineering

Journal Website: www.ijrte.org 3933 & Sciences Publication

Desired Circulation Ratio for Natural Circulation in Water-Tube Boiler

In the conventional approach, an equivalent flow resistance - Height of riser and downcomer column.

for parallel evaporating tubes, risers, and downcomer are And the pressure drop in the circuit can be calculated as

estimated to calculate the overall flow in the circulation follows,

circuit. (2)

This does not provide sufficient information about the flow Where,

circulation in individual tubes, which is very important for the - Flow resistance of the circulation loop,

thermal and hydraulic performance of the boiler. Circulation - Flow in the circulation loop.

analysis is very critical in a design of natural circulation boiler. - Pressure drop in circulation circuit

Depending on the type of circulation, a boiler can be Pressure drop can be calculated by Lockhart- Martinelli

classified in to forced circulation boiler and natural equation. In Lockhart Martinelli method of two-phase

circulation boiler. In a forced circulation boiler, a circulation pressure drop calculation, pressure drop calculation is done

pump is used to ensure water and steam flow in the heat assuming the single-phase flow and multiplying with two

transfer tubes of the boiler. phase multipliers (Marian Trela, et al [10]).

The following equation shows the application of a two-phase

multiplier for the calculation of pressure drop.

(3)

(4)

Where, and are the single-phase pressure drop for

liquid and gas.

Their respective two-phase multipliers are calculated by using

the following equation.

(5)

(6)

Here, is Martinelli parameter and calculated by using

following equation.

(7)

Fig. 1.Circulation circuit of boiler

Fig.1. shows the typical arrangement for the water-tube, As the density in the riser column is the function of flow, eq.

natural-circulation boiler with an external steam drum and (1) can be also written as a function of flow. These two

external downcomers and riser pipes. Feedwater enters the equations can be computationally solved to calculate the flow

drum from an economizer. This mixes with the steam/ water and the pressure drop in the circulation circuit. This can be

mixture inside the drum. Downcomers carry the resultant cool graphically shown in fig.2, where driving force decreases with

water to the bottom of the evaporator tubes while external increase in flow and the pressure drop increases with increase

risers carry the water/steam mixture to the steam drum. The in flow. The difference of density decreases at higher flow due

heat transfer tubes also act as risers for generating steam to decrease in dryness fraction in riser column, which finally

A. Mathematical Modelling- Natural Circulation results in decrease in driving force The intersecting point,

where these two lines join indicates the mass flow rate of the

A typical water tube boiler consists of drum, downcomer, circuit.

evaporator tubes and riser. Fig.1 shows the typical circulation

circuit of a boiler. Downcomer pipes are connected to the

drum and saturated water of the drum flows through the

downcomer. These downcomer pipes join the steam drum and

the evaporator tubes. Saturated water of drum enters the

evaporator tubes through the downcomer pipe and finally

rises due to decrease in density as the evaporation starts in

evaporator tubes. The evaporator tubes receive heat from flue

gas and transfer it to the saturated water flowing through these

tubes. This water and steam mixture re-enters the boiler drum

through riser pipes. The difference of density in riser and

downcomer column provides the driving head for the flow

circulation in the evaporator tube. The driving head can be

calculated as follows (Gullichsen J. [9]).

(1)

Fig. 2.The nature of circulation in a typical circulation

Where, circuit of a boiler.

,

Density of saturated water in downcomer column.

Density of saturated water and steam mixture in riser

column,

Retrieval Number: E6646018520/2020©BEIESP Published By:

DOI:10.35940/ijrte.E6646.018520 Blue Eyes Intelligence Engineering

Journal Website: www.ijrte.org 3934 & Sciences Publication

International Journal of Recent Technology and Engineering (IJRTE)

ISSN: 2277-3878, Volume-8 Issue-5, January 2020

III. DESIGN AND ANALYSIS B. Phase stratification

The design of the circulation circuit of a natural circulation of In a horizontal tube, if the flow velocity is not sufficiently

boiler is extremely critical as the heat transfer tubes require to high, the bubble generated at the bottom surface rises to the

have sufficient water flow to ensure cooling of these tubes. upper wall and get accumulated. This creates the phase

It becomes more critical, if these heat transfer tubes are stratification, where the water and steam flow as separated

exposed to high flame temperature radiation leading to very phase. The phase stratification is primarily due to the

high heat flux in a furnace section of a fired boiler. The dominance of gravitational force over the inertial force. It

performance of a circulation circuit is measured by circulation primarily occurs at lower velocity, where the inertial force is

ratio. Circulation ratio is defined as the ratio of the mass flow low. If the flow velocity is sufficiently high, the bubble

rate of steam/water mixture in circulation loop to the steam generated at the bottom surface is carried by the flow. This

generation rate in evaporator tubes. does not allow phase stratification to take place. If the heat

flux is high, it requires higher mass velocity to avoid phase

(8) stratification. The separated steam phase can lead the

This is just an indicator of the hydraulic performance of the overheating of the tube and cause tube burnout, if it gets

boiler but it does not provide the sufficient information about exposed to the high temperature flame. As the stratified flow

the failure mechanism of the boiler tubes. In some boiler can cause the tube burnout under high heat flux condition

design, a low circulation ratio like 5-10 can be sufficient, but and the flow rate should be large enough to avoid phase

in some other boiler design even a moderate circulation ratio stratification. The minimum mass flux required to avoid

like 20-30 is not enough. phase stratification is called the critical mass flux. At the

The required circulation ratio is very important parameter in moderate heat flux, it requires to have a critical mass flux to

the water tube boiler design and is the function of boiler type, avoid flow stratification. This critical mass flux is the

design and operating parameter. The design of a circulation function of steam dryness and boiler pressure. The critical

loop requires the insight about the various failure modes due mass flux increases with increase in steam dryness fraction.

to poor circulation in the boiler. The phase stratification phenomenon can be drastically

decreased by increasing the tube inclination. It almost

Some of the prominent circulation problems can be listed disappears if the inclination angle goes beyond 250 [11].

as follows.

C. Higher void fraction

A. Departure from nucleate boiling.

B. Phase stratification. Void fraction is the ratio of volumetric flow rate of vapour

C. Higher void fraction. phase to the total volumetric flow. Void fraction can be

D. Flow instability. calculated by using Smith’s correlation. (Smith, S. L. [12])

E. Flow mal-distribution

A. Departure from nucleate boiling (9)

In the normal circumstance, the mode of the boiling heat

Higher void fraction means higher volume of the heat transfer

transfer in a boiler is the nucleate boiling. In this condition

tube is occupied by steam. This is a very important parameter

bubble generation takes place at the heat transfer surface and

for the prediction of the tube burnout problem. This is often

this bubble is carried away due to buoyancy effect, keeping

used as an indicator to predict the reliability of a boiler, as the

the heat transfer surface wet. In this condition, the bubbles

higher void fraction can lead to departure from nucleate

generated on the wall are well distributed in the whole tube

boiling and multiphase flow instability. Due to the lower

cross section. If the heat flux is increased beyond a particular

difference of vapour and liquid density in a high-pressure

limit, the rate of bubble generation exceeds the rate at which it

boiler, it has low void fraction even at higher dryness fraction.

is carried away. This can cause steam blanketing over the heat

Due to this reason, a high-pressure boiler can tolerate lower

transfer surface and can cause overheating of heat transfer

circulation ratio in comparison with a low-pressure boiler.

tube due to reduction in cooling. This phenomenon is called

In a boiler design the void fraction should be kept below a

departure from nucleate boiling. In this condition, a thin film

specified limit to eliminate tube overheating problem due to

of steam will be adhered at the heat transfer surface, which

departure from nucleate boiling and two-phase flow

acts like insulation for the cooling of heat transfer tubes. This

instability.

is the most prominent failure mode in a natural circulation

boiler and is primarily function of heat flux, steam dryness & D. Flow instability

mass flow rate. In a normal steam generator, the average heat

If the boiler is made of many parallel tubes, some of these

flux is much lower than the critical heat flux. But the peak heat

tubes can acts like riser and other can act like a downcomer. If

flux can be higher due to higher flame temperature. Due to

a certain type of instability can cause upward flow in the

this reason the average heat flux should be limited to 25 % of

downcomer and downward flow in riser tubes, it can cause an

the critical heat flux. The critical heat flux is the function of

undesirable flow and pressure fluctuation in circulation

pressure, steam quality and the orientation of the heat transfer

circuit.

tube. A vertical tube can accept much higher heat flux than a

horizontal tube. The critical heat flux decreases with the

increase in boiler pressure and dryness-fraction.

As the circulation ratio is the inverse of steam dryness

fraction, the boiler with higher circulation ratio can accept

higher heat flux.

Retrieval Number: E6646018520/2020©BEIESP Published By:

DOI:10.35940/ijrte.E6646.018520 Blue Eyes Intelligence Engineering

Journal Website: www.ijrte.org 3935 & Sciences Publication

Desired Circulation Ratio for Natural Circulation in Water-Tube Boiler

This phenomenon can be explained as follows. In normal design, flow mal-distribution should be analysed and

condition, pressure drop increases with increase in flow but in corrected by changing the size and position of the riser and

certain circumstances pressure drop can actually decrease downcomer. All the analysis mentioned in previous section

with increase in flow rate. This primarily happens due to should be done on the most critical tube identified by flow

decrease in steam dryness at higher flow, which finally results distribution analysis of a circulation circuit.

in decrease in circuit pressure drop. This behaviour of

circulation circuit has been shown in fig.3. IV. RESULT & DISCUSSION

In this case for a same pressure drop, there are three possible

Case study

values of flow and flow can oscillate among these flow

conditions, if a certain disturbance in circuit arises. A. Geometrical description of a water tube boiler

In some of the situation, flow can be significantly low causing

A furnace of a water tube boiler of 35 TPH capacity designed

tube burnout problem and this situation should be avoided by

and manufactured by Thermax Ltd is selected for the natural

designing an appropriate circulation circuit.

circulation analysis. Fig.5 shows the schematic of a water tube

boiler with a reciprocating grate combustor. Boiler has two

drums and are referred as steam and water drum. Steam and

water drums are connected by set of convective tube bank.

Heat is generated in the furnace due to the combustion of

biomass over the reciprocating grate and is partially

transferred to the water wall placed around the furnace. Hot

flue gas enters the superheater tube bank and convective tube

bank. Furnace is made of water tube design and the

evaporation of water takes place after picking the heat from

the flue gas. The water and steam mixtures move upward due

to the buoyancy effect and finally enters the boiler drum

through the risers. Evaporator tubes receive the water from

downcomers connected to the water drum. This completes the

natural circulation. A natural circulation network consists of

downcomers to carry the drum water to evaporator tubes and

Fig.3. Flow pressure drop characteristics

risers to carry water-steam mixture to the steam drum.

E. Flow mal-distribution

As the circulation circuit in boiler is quite complex and

normally flow distribution among riser is not analysed. In

conventional approach, an equivalent flow resistance for

parallel risers and downcomer is estimated to calculate the

overall flow in circulation circuit. This does not provide the

sufficient information about the flow circulation in individual

tubes, which is very important for the thermal and hydraulic

performance of the boiler.

Fig.5. Schematic diagram of a water tube boiler

B. Basic construction of water tube boiler

Fig.6 shows the circulation flow diagram of the water tube

furnace of the boiler. Due to symmetry, one half of the circuit

has been taken for the analysis.

Fig.4. Flow mal-distribution in evaporator tubes (6 TPH The length and diameter of all tubes, headers, risers and

CPF boiler manufactured by Thermax Ltd.) downcomers are given in Table 1 circulation network

includes the drum with 7 risers, 4 downcomers and 94

Fig.4 presents the variation of dryness fraction in individual evaporating tubes, which are placed in lower and upper

tubes. This shows approximately 30 % variation in dryness manifolds.

fraction among the parallel riser tubes. This type of variation The dimensional details of the circulation circuit are listed in

can be seen in a well-designed circulation circuit. If proper Table1.

care is not taken during the design, this variation can be

extremely high and alarming. During the circulation circuit

Retrieval Number: E6646018520/2020©BEIESP Published By:

DOI:10.35940/ijrte.E6646.018520 Blue Eyes Intelligence Engineering

Journal Website: www.ijrte.org 3936 & Sciences Publication

International Journal of Recent Technology and Engineering (IJRTE)

ISSN: 2277-3878, Volume-8 Issue-5, January 2020

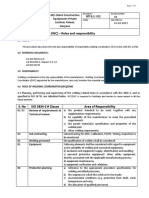

Table –I: Design parameters of the natural circulation in As departure from nucleate boiling is very important

water tube boiler parameter and it is dependent on the peak heat flux. Peak heat

flux has been calculated by using heat transfer data in the

Sr. Description Dimensions are in mm Quantity

No.

various zones. Peak heat flux is compared with critical heat

1 Bottom Header OD 273 X 9.27 THK X 2300 1 flux to check the possibility of departure from nucleate

Dimension boiling. Fig.8 shows the peak heat flux in the various zones of

2 Top Header OD 323.9 X 10.91 THK X 2300 1

Dimension-1 the furnace. Critical heat flux is 4 106W/m2 at 10 kg/cm2

3 Top Header OD 323.9 X 10.91 THK X 1200 1 pressure. As the peak heat flux is approximately 25 % of the

Dimension-2

4 Number of tubes OD 50.8 X 3.25 THK X 8000 12

critical heat flux, design can be considered as safe.

5 Number of tubes OD 50.8 X 3.25 THK X 6500 23

6 Number of tubes OD 50.8 X 3.25 THK X 6000 12

7 Downcomers OD 168.3 X 7.11 THK X 2500 4

8 Risers OD 219.1 X 8.18 THK X 4000 5

9 Risers OD 219.3 X 8.18 THK X 3000 2

Fig. 8. Peak heat flux of water tube boiler

D. Circulation analysis- Dryness fraction

Natural circulation has been analyzed and the dryness fraction

of the various tubes in the different walls have been plotted in

fig 9. This graph presents the dryness fraction of each tube

Fig.6. Flow diagram of a boiler present in the different wall. Circulation ratio is the inverse of

dryness fraction and the minimum value of circulation ratio is

Furnace has been divided in ten zones length wise and the

42.

heat transfer in these zones have been analyzed by using plug

flow model of furnace analysis. The result of plug flow

furnace model is plotted in fig.7 showing heat transfer in each

zone. These heat transfer data are used for the circulation

analysis. Due to symmetry, only half of the furnace has been

considered for the analysis. It consists of half of front wall

(12 tubes), side wall (23 tubes) and rear wall (12 tubes). 56

equations have been generated to balance driving head and

head loss for each loop. Lockhart Martinelli equations has

been used for two phase pressure drop analysis.

Fig. 9. Dryness fraction in the various wall of the boiler

E. Desired circulation ratio

Higher dryness fraction leads to higher void fraction and

two-phase flow instability. It is recommended to have

maximum void fraction of 0.7 at the outlet of evaporator tubes

[13]. For a safe operation of a natural circulation boiler, the

possibility of two-phase flow stability should be also checked.

The stability criterion for the density wave oscillation is

checked with phase change number and this number should be

less than 11 [13].

Fig.7. Heat transfer distribution in a water tube boiler

C. Heat flux – Departure from nucleate boiling

Retrieval Number: E6646018520/2020©BEIESP Published By:

DOI:10.35940/ijrte.E6646.018520 Blue Eyes Intelligence Engineering

Journal Website: www.ijrte.org 3937 & Sciences Publication

Desired Circulation Ratio for Natural Circulation in Water-Tube Boiler

Phase change number at the outlet of evaporator tube (Xe) is Table-II: Summary report of failure analysis of a water

calculated by following equation. tube boiler

Criteria Parameter Estimated Acceptable design

Value norms

Departure Heat flux 4 106

from W/m2 Maximum 106W/m2

(10) Nucleate

Using these two criteria, acceptable circulation ratio has been boiling

plotted. Fig.10 presents the required circulation ratio from the Void Circulation 42 Minimum 30

criteria of maximum void fraction and two-phase flow fraction ratio

instability. Maximum of the dryness fraction can be checked Two Circulation Minimum 15

for the void fraction & two-phase flow instability. As per this phase ratio 42

graph, actual circulation ratio is 42 against the required flow

circulation ratio of 30 at design pressure of 10 kg/cm2. instability

Phase Velocity Vertical Horizontal

stratificati 1.4 m/s2 tube tube

on 0.7 m/s2 1.2 m/s2

V. CONCLUSION

The circulation study of the boiler is the most important

aspect of the design of the natural circulation of water tube

boiler. In most of the boiler industry, circulation study is

limited to the estimation of an average circulation ratio of a

boiler. As discussed in the various section of this article, that

circulation ratio should be always studied for the various

failure modes to evaluate the robustness of hydraulic design

of a natural circulation of a water tube boiler. The circulation

analysis has been conducted for the water tube boiler and

checked against the different failure modes. Table-2 presents

the summary of the circulation analysis and failure analysis

Fig.10. Acceptable circulation ratio as a function of for the different failure criteria. The water tube boiler design

Pressure. has been found safe in all condition. This study presents the

systematic approach in circulation analysis and identification

F. Circulation analysis- velocity profile of desired circulation ratio.

Natural circulation boiler should be also checked for the The water tube boiler has been found safe in normal

possibility of phase stratification. Minimum velocity in tubes condition but heat flux may change in some abnormal

should be checked to avoid phase stratification. operating condition. The critical heat flux should be checked

Recommended minimum velocity for a vertical tube should in abnormal condition to eliminate failure.

be 0.7 m/s and 1.2 m/s for horizontal tube [13]. Flow NOMENCLATURE

distribution analysis of natural circulation model can be used

to plot the velocity distribution among the tubes. Fig.11 Driving force, kg/cm2

presents the velocity distribution among the tubes. This show Acceleration due gravity, m/s2

the minimum velocity as 1.4m/s, which is quite higher than Height of riser and downcomer column

the required velocity. Flow resistance of the circulation loop

Flow in the circulation loop

Pressure drop in circulation circuit

Martinelli parameter

Pressure drop multiplier

Flow, kg/s

Volumetric flux

Tube diameter, (equivalent diameter of channel

cross-section), m

Quality of mixture

Phase change number

Flow parameter

Heat transfer coefficient

Heat flux

Fig. 11. Velocity profile in water tube boiler

Retrieval Number: E6646018520/2020©BEIESP Published By:

DOI:10.35940/ijrte.E6646.018520 Blue Eyes Intelligence Engineering

Journal Website: www.ijrte.org 3938 & Sciences Publication

International Journal of Recent Technology and Engineering (IJRTE)

ISSN: 2277-3878, Volume-8 Issue-5, January 2020

GREEK

R.S. Jha is a Ph.D. research scholar of School of

Mechanical Engineering, MIT-WPU, Kothrud,

Void fraction Pune. Currently, he is working in Thermax Ltd

Pune. He has done M. Tech from IIT Bombay and

Density, kg/m3 is having industrial experience of 25 years. He has

Viscosity, kg/s-m published more than 10 papers in International

Journals. Ten candidates have completed M. Tech

under his guidance. He has been invited as a resource person and delivered

SUBSCRIPTS the talks on Heat Transfer. He has filed 20 patents and received 7 patents in

the area of heat and mass transfer.

Liquid Prof (Dr.) Mandar M. Lele has done Ph.D. from IIT

Vapour Bombay and is having teaching experience of 23

years. He is currently working as Professor,

Department of Mechanical Engineering in MAEER’s

ACKNOWLEDGMENT MIT COE, Pune. His areas of interest are HVAC,

Heat pipes, Cryogenics and heat transfer

The authors would like to thank Thermax Limited, Pune to applications. He has published more than 19 papers

provide design data for analysis. in International Journals. Three candidates have

completed Ph. D. under his guidance. He has worked as a session chair for

national and international conferences. He has been invited as a resource

REFERENCES person and delivered the talks on Heat Transfer and Cryogenics. He has filed

1. Salamah S.Al-Anizi ‘Simple and clear approach to industrial boiler 02 patents in the area of heat and mass transfer.

circulation analysis’ A international conference on heat transfer, 2010,

pp 266-269.

2. Kim, H.and Chios. ‘A model on water level dynamic in natural

circulation drum type boiler’, Int, commun Heat mass transfer, vol.32,

2005, pp 786-796.

3. Syed-Ahmad M. ‘Analysis of water circulation in boilers under

steady-state conditions ‘Computational Thermal Science: An

Intentional journal, vol 3, 2011, pp 261-275.

4. Ganapathy, V. Boiler Circulation Calculations. Hydrocarbon

Processing, 1998, pp 101-105.

5. ganapathy, industrial boilers and heat recovery steam generators

design, applications, and calculations 2003, pp 80-108.

6. V.Ganapathy, Understanding Boiler Circulation, Journal of Chemical

Engineering, 2013, pp. 52-53.

7. A.K. Nayak and P.K. Vijayan, “Flow Instabilities in Boiling

Two-Phase Natural Circulation Systems-A Review”, Reactor

Engineering Division, Bhabha Atomic Research Centre, Trombay,

Mumbai-400085, India, 2008, pp.5-9.

8. P.K. Vijayan and A.K. Nayak, ‘Natural circulation systems: Advantage

& challenges’, The Abdus Salam international Centre for theoretical

physics, 2010.

9. Gullichsen, J. & Fogelholm, C., ‘Chemical Pulping -Papermaking

science and technology’. Helsinki: Fapet Oy. 497 p. ISBN

952-5216-06-3, 1999.

10. Marian Trela, Roman Kwidzinski, and Marcin Lackowski

‘Generalization of Martinelli-Nelson method of pressure drop

calculation in two-phase flows’, E3S Web of Conferences 13, 0200

E3S Web of Conferences 13, 0200, 2017.

11. Atul M Elgandelwar, R S Jha, Mandar M Lele ‘Study of circulation

ratio for natural circulation in water-tube boiler at different operating

conditions- Accepted for publication’ Journal of Physics: Conference

Series (JPCS), to be published, 2020.

12. Smith, S. L., Void Fractions in Two-Phase Flow: A Correlation Based

upon an Equal Velocity Head Model. Proceedings of the Institution of

Mechanical Engineers, 184(1), 1969 pp 647–664.

13. Seikan Ishigai -Thermal & hydraulic design principle, pp 200-300.

AUTHORS PROFILE

Atul M.Elgandelwar is a Ph.D. Scholar of

MAEER’s MIT Kothrud, affiliated to SPPU, Pune

and working as an Associate Professor in

Mechanical Engineering at Maharashtra Institute of

Technology, Pune. He has completed his M.E.

(Mechanical - Heat Power Engineering). He has 02

years of industry experience and 18 years of

teaching experience. His areas of interest are Heat

Transfer and Numerical methods. He has published 02 papers in

International journals. He has worked on research projects in two phase flow

area.

Retrieval Number: E6646018520/2020©BEIESP Published By:

DOI:10.35940/ijrte.E6646.018520 Blue Eyes Intelligence Engineering

Journal Website: www.ijrte.org 3939 & Sciences Publication

You might also like

- Flow and Heat Transfer in Geothermal Systems: Basic Equations for Describing and Modeling Geothermal Phenomena and TechnologiesFrom EverandFlow and Heat Transfer in Geothermal Systems: Basic Equations for Describing and Modeling Geothermal Phenomena and TechnologiesNo ratings yet

- Study of Circulation Ratio For Natural CirculationDocument9 pagesStudy of Circulation Ratio For Natural CirculationAchmad sumantoNo ratings yet

- Pipeline Design for Water EngineersFrom EverandPipeline Design for Water EngineersRating: 5 out of 5 stars5/5 (1)

- Design Details of A Turbine Model Used For Energy Conversion in Low Flow Rate Water StreamsDocument5 pagesDesign Details of A Turbine Model Used For Energy Conversion in Low Flow Rate Water Streamsrabei romulusNo ratings yet

- Calculation of The Limiting Dryness Fraction at The End of Evaporating Surface of Steam BoilerDocument4 pagesCalculation of The Limiting Dryness Fraction at The End of Evaporating Surface of Steam BoilerjnmanivannanmechNo ratings yet

- 2 12 Power GenMiddleEast 2004Document17 pages2 12 Power GenMiddleEast 2004Satrio HaryoNo ratings yet

- Napitupulu 2020 IOP Conf. Ser. Mater. Sci. Eng. 725 012004Document7 pagesNapitupulu 2020 IOP Conf. Ser. Mater. Sci. Eng. 725 012004هادی طاهریNo ratings yet

- Effect of Pressure Tube Radial Creep On Thermal Hydraulic Performance of Pressure Tube Type Nuclear ReactorsDocument11 pagesEffect of Pressure Tube Radial Creep On Thermal Hydraulic Performance of Pressure Tube Type Nuclear ReactorsMukesh KumarNo ratings yet

- Study On Flow Instability Inside Multiple Parallel Pipes of Direct Steam GenerationDocument10 pagesStudy On Flow Instability Inside Multiple Parallel Pipes of Direct Steam Generationمحمد حسن عبدربهNo ratings yet

- ASME IMECE 2015 Paper FINALDocument14 pagesASME IMECE 2015 Paper FINALVigor ModemNo ratings yet

- Distribution Analysis of Fluid in Circular and Square HeaderDocument7 pagesDistribution Analysis of Fluid in Circular and Square HeaderDr. Mahesh GopalNo ratings yet

- Presentation 1Document45 pagesPresentation 1Gyan PrakashNo ratings yet

- Experimental and Numerical Analysis of A Cross-Flow Closed Cooling TowerDocument13 pagesExperimental and Numerical Analysis of A Cross-Flow Closed Cooling TowerMontserratt Escobedo ÁlvarezNo ratings yet

- CFD Analysis of Heat Transfer in Helical Coil Tube in Tube Heat ExchangerDocument8 pagesCFD Analysis of Heat Transfer in Helical Coil Tube in Tube Heat ExchangerIJIERT-International Journal of Innovations in Engineering Research and TechnologyNo ratings yet

- Tank Coils - Design and UseDocument7 pagesTank Coils - Design and UseMartin DanzeNo ratings yet

- Characteristic of Performance Pada Head Exchanger: Pengaruh Ketebalan Inner-Helical Fin TerhadapDocument7 pagesCharacteristic of Performance Pada Head Exchanger: Pengaruh Ketebalan Inner-Helical Fin TerhadapdaffaNo ratings yet

- Effect of Water Temperature On Centrifugal Pumps Performance Under Cavitating and Non-Cavitating ConditionsDocument8 pagesEffect of Water Temperature On Centrifugal Pumps Performance Under Cavitating and Non-Cavitating ConditionsBETPOQ VRDNo ratings yet

- Metals 11 00208 v2Document23 pagesMetals 11 00208 v2Abnet EthiopiaNo ratings yet

- Analysis of A Helical Coil Once-Through Molten Salt Steam Generator: Experimental Results and Heat Transfer EvaluationDocument10 pagesAnalysis of A Helical Coil Once-Through Molten Salt Steam Generator: Experimental Results and Heat Transfer EvaluationCristina VladutaNo ratings yet

- Design Procedure of Shell and Tube Heat Exchanger: Alok Shukla, Prakash Kumar, Dr. Deo. Raj TiwariDocument4 pagesDesign Procedure of Shell and Tube Heat Exchanger: Alok Shukla, Prakash Kumar, Dr. Deo. Raj TiwarierpublicationNo ratings yet

- The Royal SocietyDocument31 pagesThe Royal Societygsax1987No ratings yet

- Helical Coil SG Design CalculationDocument7 pagesHelical Coil SG Design Calculationlram70No ratings yet

- A Numerical Analysis of Hydrodynamic and Heat Transfer Effects of Shell-and-Tube Heat Exchanger For Different Baf e Space and CutDocument21 pagesA Numerical Analysis of Hydrodynamic and Heat Transfer Effects of Shell-and-Tube Heat Exchanger For Different Baf e Space and CutememNo ratings yet

- Heat Transfer in The Transitional Flow Regime: September 2011Document17 pagesHeat Transfer in The Transitional Flow Regime: September 2011JAIR DIEGO VIDAURRE QUISPENo ratings yet

- Pinched Tube ReactorDocument8 pagesPinched Tube ReactorManoj BNo ratings yet

- A Generalized Dynamic Water Side Model For A Once-Through Benson BoilerDocument6 pagesA Generalized Dynamic Water Side Model For A Once-Through Benson BoilerAnonymous lmCR3SkPrKNo ratings yet

- Effect of Fouling On Thermal and Hydraulic Parameter of Shell and Tube Heat ExchangerDocument10 pagesEffect of Fouling On Thermal and Hydraulic Parameter of Shell and Tube Heat ExchangerJoão Paulo VissottoNo ratings yet

- Experimental Study of Concentric Tube Heat Exchanger Using Cuo-Water Based Nano UidDocument10 pagesExperimental Study of Concentric Tube Heat Exchanger Using Cuo-Water Based Nano UidRajnishRanjanNo ratings yet

- Design Optimization of Shell and Tube Heat Exchang PDFDocument7 pagesDesign Optimization of Shell and Tube Heat Exchang PDFSaiful ShokriNo ratings yet

- Optimization of Shell and Tube Heat ExchangerDocument29 pagesOptimization of Shell and Tube Heat ExchangerAna QuintanaNo ratings yet

- Model For Calculating Steam Ejector PerformanceDocument15 pagesModel For Calculating Steam Ejector PerformanceMuhammad KhurramNo ratings yet

- 15 IJTPE Issue26 Vol8 No1 Mar2016 pp88 94Document7 pages15 IJTPE Issue26 Vol8 No1 Mar2016 pp88 94Siti nur azizahNo ratings yet

- eArt-Performance Analysis of Spiral Tube Heat ExchangerDocument4 pageseArt-Performance Analysis of Spiral Tube Heat ExchangerMoly69xNo ratings yet

- Liquid Phase Heat Transfer in Helical Coiled Heat ExchangerDocument66 pagesLiquid Phase Heat Transfer in Helical Coiled Heat ExchangerTushar Mahale50% (2)

- Experimental Analysis of Pressure Drop in CTUDocument39 pagesExperimental Analysis of Pressure Drop in CTUVirginia SitompulNo ratings yet

- Lab ReportDocument25 pagesLab ReportafiqahanuwarNo ratings yet

- Heat Transfer Analysis of Triple Tube Heat Exchanger Using Water and Titanium-Dioxide Nano UidDocument4 pagesHeat Transfer Analysis of Triple Tube Heat Exchanger Using Water and Titanium-Dioxide Nano UidrssardarNo ratings yet

- The Circulation Water and Steam in Water-Tube Boilers, and The Rational Simplification of Boiler DesignDocument35 pagesThe Circulation Water and Steam in Water-Tube Boilers, and The Rational Simplification of Boiler DesignAbdul Ghafoor BhattiNo ratings yet

- Design Calculation of Penstock and NozzlDocument3 pagesDesign Calculation of Penstock and NozzlHidza PowerNo ratings yet

- The Effect of Influent Temperature Variations in A Sedimentation TankDocument10 pagesThe Effect of Influent Temperature Variations in A Sedimentation TankSY LeeNo ratings yet

- Review Paper On Investigation of Perfomance For Shell and Tube Heat Exchanger - 45688Document5 pagesReview Paper On Investigation of Perfomance For Shell and Tube Heat Exchanger - 45688lvmengke1994No ratings yet

- Characteristics of Cooling Water Fouling in A Heat Exchange SystemDocument8 pagesCharacteristics of Cooling Water Fouling in A Heat Exchange Systemmonkey890No ratings yet

- Adenariwo AdepojuDocument225 pagesAdenariwo AdepojustarykltNo ratings yet

- Diameter RatioDocument10 pagesDiameter RatioDavid Fransiskus SimarmataNo ratings yet

- Heat Recovery Steam GeneratorDocument21 pagesHeat Recovery Steam GeneratorAbdullah AhmedNo ratings yet

- Heat Transfer Analysis of A Helical Coil Heat Exchanger by Using CFD AnalysisDocument6 pagesHeat Transfer Analysis of A Helical Coil Heat Exchanger by Using CFD AnalysisPRAVEEN HNo ratings yet

- Faculty of Engineering and Technology Department of Chemical EngineeringDocument10 pagesFaculty of Engineering and Technology Department of Chemical Engineeringmasedi malatjiNo ratings yet

- Icmere2015 Pi 224Document7 pagesIcmere2015 Pi 224BigNo ratings yet

- ReportDocument8 pagesReportعزيز فضلNo ratings yet

- Final Version - SYKhan Et AlDocument37 pagesFinal Version - SYKhan Et AlHassan AbdelmoamenNo ratings yet

- Boiler CirculationDocument7 pagesBoiler CirculationaruntpeNo ratings yet

- Kjell Strand 2005Document9 pagesKjell Strand 2005Ma RiemNo ratings yet

- Design Calculation of Penstock and Nozzle For 5kW Pelton TurbineDocument3 pagesDesign Calculation of Penstock and Nozzle For 5kW Pelton TurbineSahil AcharyaNo ratings yet

- 2019-Design of Helical Coil Heat Exchanger For A Mini Power Plant PDFDocument11 pages2019-Design of Helical Coil Heat Exchanger For A Mini Power Plant PDFAshish AgrawalNo ratings yet

- Ijesrt: International Journal of Engineering Sciences & Research TechnologyDocument6 pagesIjesrt: International Journal of Engineering Sciences & Research TechnologyBinoy Raj DávìdsoñNo ratings yet

- IN TO: Boiling Heat-Transfer Coefficients, Interface Behavior, A M Vapor Quality Rotating Boiler Operating G'SDocument43 pagesIN TO: Boiling Heat-Transfer Coefficients, Interface Behavior, A M Vapor Quality Rotating Boiler Operating G'SRassid BorhanudinNo ratings yet

- Experimental Study of Shell-Side Heat Transfer Coefficient and Pressure Drop For An Integrally Helical Baffled Heat Exchanger Combined With Different Enhanced Tubes PDFDocument6 pagesExperimental Study of Shell-Side Heat Transfer Coefficient and Pressure Drop For An Integrally Helical Baffled Heat Exchanger Combined With Different Enhanced Tubes PDFRengga Ahmad PrasetiaNo ratings yet

- Helical Baffle Design in Shell and Tube Type Heat Exchanger With CFD AnalysisDocument6 pagesHelical Baffle Design in Shell and Tube Type Heat Exchanger With CFD AnalysispriyabNo ratings yet

- ME130 2 Assignment 5 LUGODocument11 pagesME130 2 Assignment 5 LUGOMatthew MangubatNo ratings yet

- Case Studies in Thermal Engineering: Olubunmi Popoola, Yiding CaoDocument14 pagesCase Studies in Thermal Engineering: Olubunmi Popoola, Yiding CaoNarasimhan SuseendranNo ratings yet

- Filter Housing Catalog en B SartoriusDocument12 pagesFilter Housing Catalog en B Sartoriusolivegarden1900No ratings yet

- Using of Congruent Phosphate As Equilibrium PhosphDocument12 pagesUsing of Congruent Phosphate As Equilibrium Phosphhendra desfiantoroNo ratings yet

- Carbohydrazide Vs Hydrazine: A Comparative Study: September 2019Document17 pagesCarbohydrazide Vs Hydrazine: A Comparative Study: September 2019MohamedNo ratings yet

- Norsk Vann Report Microplastic DrinkingwaterDocument44 pagesNorsk Vann Report Microplastic Drinkingwaterolivegarden1900No ratings yet

- 1.7 Stress TensorDocument13 pages1.7 Stress TensorAstrini Nurul SentanuNo ratings yet

- Pipe Fittings Surface AreaDocument1 pagePipe Fittings Surface AreasajoNo ratings yet

- Pc200-8 Main Pump Test MethodDocument36 pagesPc200-8 Main Pump Test MethodPHÁT NGUYỄN THẾ93% (14)

- TRANSPORT PHENOMENA - Unit 1 NotesDocument150 pagesTRANSPORT PHENOMENA - Unit 1 NotesRathi ManiNo ratings yet

- Sauer Series 90 ManualDocument72 pagesSauer Series 90 ManualJCNo ratings yet

- Corolla 1.8 - 1Document4 pagesCorolla 1.8 - 1Diego496No ratings yet

- Two Stage Snow Engine Service Manual: Residential ProductsDocument48 pagesTwo Stage Snow Engine Service Manual: Residential ProductsBJ DixNo ratings yet

- Index Read FirstDocument47 pagesIndex Read FirstLeopoldo Del Campo75% (4)

- Design Equations For Flexural Strengthening of Singly Reinforced RC Rectangular Section With Steel PlatesDocument9 pagesDesign Equations For Flexural Strengthening of Singly Reinforced RC Rectangular Section With Steel PlatesMagdy Bakry100% (1)

- WP-8.5.1-02 Role of RWCDocument3 pagesWP-8.5.1-02 Role of RWCNitin SharmaNo ratings yet

- 60fpdftol106h2u20101 11122012153528Document64 pages60fpdftol106h2u20101 11122012153528augustinhodjNo ratings yet

- Turcon Glyd Ring T: Double Acting Rubber Energized Plastic Faced SealDocument14 pagesTurcon Glyd Ring T: Double Acting Rubber Energized Plastic Faced SealPhong DuongNo ratings yet

- IDOT 2020 Bridge Design Updates - Steel Analysis and Cross-Frame DetailsDocument50 pagesIDOT 2020 Bridge Design Updates - Steel Analysis and Cross-Frame DetailsJoe AndrewsNo ratings yet

- Principles of Groundwater Flow PDFDocument64 pagesPrinciples of Groundwater Flow PDFJhe TaguinesNo ratings yet

- 800 PDFDocument155 pages800 PDFdnageshm4n244No ratings yet

- Water Contamination in Hydraulic and Lube SystemsDocument11 pagesWater Contamination in Hydraulic and Lube SystemsBrayan MejiaNo ratings yet

- Tadano TM Zr500xlDocument6 pagesTadano TM Zr500xlRafael Durio EtgarNo ratings yet

- Bizhub 211 Parts ManualDocument70 pagesBizhub 211 Parts ManualAlexandru VasileNo ratings yet

- Pump System Labby 2015Document6 pagesPump System Labby 2015Azril DahariNo ratings yet

- Paper gt2016-56548 - Support Vibration Diagnostics and Limits in GT - 16jan2016 PDFDocument11 pagesPaper gt2016-56548 - Support Vibration Diagnostics and Limits in GT - 16jan2016 PDFbigsteve9088No ratings yet

- Fig. 900 Fig. 940: Safety ValveDocument36 pagesFig. 900 Fig. 940: Safety ValveJesús Santiago QuijadaNo ratings yet

- Thermal PhysicsDocument6 pagesThermal PhysicsDebojitNo ratings yet

- Pump & Motor Catalog: Aluminum Bushing SeriesDocument116 pagesPump & Motor Catalog: Aluminum Bushing SeriesMario SouzaNo ratings yet

- Planning of LISchemes Pathak 1552020Document70 pagesPlanning of LISchemes Pathak 1552020sachin2980No ratings yet

- Cadillac SRX V6-2.8 2010 SpecificationsDocument81 pagesCadillac SRX V6-2.8 2010 SpecificationsrodolfodiazNo ratings yet

- Manufacturing Process DiagramDocument3 pagesManufacturing Process DiagramCris Diane G. DatingginooNo ratings yet

- Volkswagen Touareg - Adaptive Cruise Control (ACC) With Front AssistDocument23 pagesVolkswagen Touareg - Adaptive Cruise Control (ACC) With Front AssistMarius Ioan BaleaNo ratings yet

- Algas SDI ZIMMER Brochure InternationalDocument4 pagesAlgas SDI ZIMMER Brochure InternationalTECKNIPETROL 001No ratings yet

- Load and Stress Distribution in Screw Threads With Modified WashersDocument11 pagesLoad and Stress Distribution in Screw Threads With Modified WashersminakirolosNo ratings yet

- S7-Lxje05a 3Document729 pagesS7-Lxje05a 3Andres GomezNo ratings yet

- The Laws of Thermodynamics: A Very Short IntroductionFrom EverandThe Laws of Thermodynamics: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (10)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseFrom EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseRating: 4.5 out of 5 stars4.5/5 (51)

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsFrom EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsNo ratings yet

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- Pilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CFrom EverandPilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CNo ratings yet

- Introduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsFrom EverandIntroduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsNo ratings yet

- Handbook of Mechanical and Materials EngineeringFrom EverandHandbook of Mechanical and Materials EngineeringRating: 5 out of 5 stars5/5 (4)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideFrom Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideRating: 3.5 out of 5 stars3.5/5 (7)

- Waves and Beaches: The Powerful Dynamics of Sea and CoastFrom EverandWaves and Beaches: The Powerful Dynamics of Sea and CoastRating: 4 out of 5 stars4/5 (1)

- The Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsFrom EverandThe Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsNo ratings yet

- Fuels, Furnaces and Refractories: International Series on Materials Science and TechnologyFrom EverandFuels, Furnaces and Refractories: International Series on Materials Science and TechnologyRating: 5 out of 5 stars5/5 (1)

- Advanced Computer-Aided Fixture DesignFrom EverandAdvanced Computer-Aided Fixture DesignRating: 5 out of 5 stars5/5 (1)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionFrom EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionRating: 4.5 out of 5 stars4.5/5 (3)

- Airplane Flying Handbook: FAA-H-8083-3C (2024)From EverandAirplane Flying Handbook: FAA-H-8083-3C (2024)Rating: 4 out of 5 stars4/5 (12)

- Practical Hydraulic Systems: Operation and Troubleshooting for Engineers and TechniciansFrom EverandPractical Hydraulic Systems: Operation and Troubleshooting for Engineers and TechniciansRating: 4 out of 5 stars4/5 (8)

- Heat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersFrom EverandHeat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersRating: 4 out of 5 stars4/5 (13)

- Rolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsFrom EverandRolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsNo ratings yet