Professional Documents

Culture Documents

Keijer 2019

Uploaded by

rafaelpulidoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Keijer 2019

Uploaded by

rafaelpulidoCopyright:

Available Formats

comment

Circular chemistry to enable a circular economy

By expanding the scope of sustainability to the entire lifecycle of chemical products, the concept of circular

chemistry aims to replace today’s linear ‘take–make–dispose’ approach with circular processes. This will optimize

resource efficiency across chemical value chains and enable a closed-loop, waste-free chemical industry.

Tom Keijer, Vincent Bakker and J. Chris Slootweg

A

wareness of the finite nature of many what defines a sustainable chemical process,

resources — including the issue of and needs to take into account the people,

element scarcity, shown in Fig. 1 — as planet and profit level (referred to as the Raw materials

well as the limited environmental tolerance ‘triple bottom line’)11. Notably, innovative Design

towards our chemical industry has grown chemistry designed with sustainability in

tremendously in the past few decades. mind is only effective when translated into Production,

remanufacturing

It has become painfully obvious that the economically viable applications. Recycling

Circular economy

linear route of production, in which scarce An illustrative example is the reported

resources are consumed and their value- green synthesis of adipic acid — a key Distribution

added products are degraded to waste, is component for the manufacture of nylon- Residual

waste

a route cause of several impending global 6,6 — by the direct oxidation of cyclohexene

crises such as climate change, diminished with hydrogen peroxide12. Solvent-free Collection

Consumption, use,

reuse, repair

biodiversity, as well as food, water and conditions are applied (GC 2), avoiding the

energy shortages. use of the corrosive nitric acid (GC 3)

Advocates of the circular economy and thus side-stepping the formation of Credit: European Parliament

such as The Ellen MacArthur Foundation the environmentally taxing gas nitrous

(https://www.ellenmacarthurfoundation. oxide, N2O — a waste product of the

org) cleared the path for the emergence of current industrial synthesis (GC 4). The an increase in water and air pollution, both

novel policy frameworks that aim to green method, however, requires hydrogen of which threaten to destabilize the Earth’s

redesign current economic systems, peroxide, H2O2, as starting material, which system beyond the proposed ‘planetary

exemplified by the European Union’s 2013 means that this process is currently not boundaries’ or “safe operating space” for

‘manifesto for a resource-efficient Europe’. commercially viable, since H2O2 is more anthropogenic activities14. This highlights

A circular economy is defined as “restorative expensive than the adipic acid product. the importance of looking beyond the

and regenerative by design, and aims to Although this route obeys green chemistry scientific discovery and analysing the global

keep products, components and materials at principles, it violates the value chain. As impact of chemistry using a

their highest utility and value at all times”1. a result, this green adipic acid synthesis systems approach15.

Chemistry is crucial for achieving this2–7. has not been applied industrially, and has

Chemists understand their role in designing therefore not led to an overall increase in Circular chemistry for sustainability

and developing indispensable materials sustainability. Thus, accounting for the In this Comment, we provide a holistic

and technologies, but also simultaneously profit level of the triple bottom line is an view on how chemistry can contribute to

recognize the potentially detrimental effects essential component in the design the development of a circular economy, and

that this may have on their practice; they are of sustainable chemistry. formulate twelve principles for a ‘circular

therefore becoming increasingly aware that Other chemical processes may satisfy chemistry’ (Fig. 2 and Box 2, CC 1–12). In

each step must be designed or reassessed the green chemistry principles while doing so, we provide a framework analogous

with sustainability in mind. being economically viable, yet remain to that of green chemistry, which has been

unsustainable. For example, the Haber– adapted to facilitate the transition to a

Green chemistry for linear processes Bosch process uses iron for the conversion circular economy. This approach aims to

Since it was first introduced in the 1980s, of dinitrogen, N2, into ammonia, NH3, make chemical processes truly circular

green chemistry has provided a framework which in turn is used in the production of by expanding the scope of sustainability

for teaching and performing sustainable agricultural fertilizers. It is a key industry from process optimization to the entire

chemistry, and has delivered an impetus showcase for the use of catalysts (GC 9) in lifecycle of chemical products. It promotes,

for developing cleaner products and increasing energy efficiency (GC 6). The in particular, resource efficiency across

processes8–10 — which have enhanced current process requires high temperatures chemical value chains and highlights the

chemical sustainability in industry and and pressures, and further optimization need to develop novel chemical reactions

academia. Its twelve guiding principles has stagnated. After its use as fertilizer, to reuse and recycle chemicals, to in turn

(Box 1, GC 1–12) focus on the direct large portions of the fixated nitrogen enable development towards a closed-loop,

sustainability assessment of chemical are lost to the environment, causing waste-free chemical industry16–19.

reactions, and are perfectly suited for the eutrophication, a global environmental

optimization of linear production routes. concern, the importance of which should Waste is a resource

The developments towards a circular not be underestimated13. The cascade of Regarding waste as a resource is a

economy, however, require a re-evaluation of environmental changes that results includes prerequisite for circularity. Redirecting

190 Nature Chemistry | VOL 11 | MARCH 2019 | 190–195 | www.nature.com/naturechemistry

comment

initial design of an entire process will mean

that products will lend themselves well to

being turned into separated waste-streams

at the end of their lifecycle. In turn, this

approach should enable the subsequent full

recycling of any feedstock and product.

Securing renewability

Circular chemistry seeks to replace

today’s linear ‘take–make–dispose’

approach with processes in which

materials are continuously cycled back

through the value chain for reuse,

thereby optimizing resource efficiency

and preserving finite feedstocks (CC 3).

Renewable resources offer the chemical

industry an opportunity to diversify its

raw materials base24, but ‘greenwashing’

(presenting a process or product as greener

than it actually is) should be prevented:

bio-based materials are typically classified

as being sustainable, simply because of

renewability of the resource (GC 7), yet

Fig. 1 | Periodic table representing element scarcity. In this representation of the periodic table these resources are often created in a linear

prepared by the European Chemical Society (EuChemS) for the International Year of the Periodic production process without sustainable

Table, naturally occurring elements (except some of the rarest ones beyond uranium53) are depicted end-of-life options.

through tiles, the size of which gives an indication — on a logarithmic scale — of how much of the Resource renewability alone is not a

element is present in the Earth’s crust and atmosphere. The areas are approximate for all elements and measure of sustainability. Furthermore,

exaggerated in the case of the least abundant ones shown here (technetium, promethium, polonium, if, for a given application, either oil-based

astatine, radon, francium, radium, actinium and protactinium) so that they are noticeable. Technetium plastics or bio-based plastics can be used

and promethium, shown here in white and marked as synthetic elements, do also occur naturally on (for example PET or bio-PET, produced

Earth, though only in very small amounts. This illustration highlights the speed with which elemental from mono-ethylene glycol, itself derived

supplies are being used, and draws attention to elements that are at risk of being depleted completely from agricultural products), both types of

unless recycling routes are developed, as well as those that come from countries in which wars are plastics are based on similar building blocks

fought over the ownership of the relevant mineral rights. This table mentions 31 elements (though other and their function and properties, defined

sources list other numbers, up to around 70) that are used in smart phones, which are typically replaced at the molecular level, are also alike. One

more rapidly than necessary. Credit: © EuChemS, reproduced from https://www.euchems.eu/euchems- may ask: ‘what is the difference between an

periodic-table/ under a Creative Commons license CC BY-ND 4.0 oil-based or bio-based plastic soup in our

oceans?’25,26. Unfortunately, cherry-picking

a metric (for example, here, renewability

waste streams and using them as chemical impact of the resulting waste products over recyclability and environmental

feedstocks should become ubiquitous in on the environment, novel chemical and risk) is common practice. The popular

the synthesis of marketable products biochemical conversions are urgently opinion that oil, gas and coal are harmful,

in order to achieve complete recirculation needed that allow for their efficient recovery whereas renewables are clean, removes

of molecules and materials (CC 1, and recycling. attention from the true sustainability

Box 2)20–22. It is imperative to reduce In order to succeed in eliminating or problem: material circulation. What is most

uncirculated waste in any given process reusing waste, an optimal process design important is the use of waste as a resource.

(GC 1, Box 1), yet it will not be possible to is needed that allows for the efficient Reversible polymerization could be a

eliminate degraded materials or products separation, purification, reuse and recycling major driver towards the development of

completely. Waste management will of waste products in an environmentally

therefore always be required for the effective benign way. In organic chemistry, Trost’s

circulation of materials. atom-economy concept stimulated the 1. Collect and

use waste

Eutrophication and climate change are synthetic efficiency of individual steps 12. Unify industry and

2. Maximize atom

provide coherent

two of the biggest global environmental (GC 2)23. In a similar manner, at the process policy framework circulation

concerns, largely caused by excess use level, circular chemistry targets maximizing 3. Optimize resource

11. Reject lock-in efficiency

of phosphorus and nitrogen-based atom circulation in chemical products along Circular

fertilizers, and the utilization of fossil their entire life cycles, regardless of whether 10. Sell service

not product

chemistry 4. Strive for energy

persistence

fuels, respectively. The excess of carbon chemical bonds are modified or not (Box 2, 9. Apply ladder 5. Enhance

dioxide, nitrous oxide, ammonia and CC 2). Using waste as resource presents a of circularity process efficiency

phosphate waste lost to air, water and tremendous challenge for the development 8. Assess 6. No out-of-plant

land perturbs the carbon, nitrogen and of novel chemical conversions that can cope sustainability

7. Target

toxicity

phosphorus cycles, creating a host of adverse with complex waste mixtures as feedstocks optimal design

environmental impacts14. To mitigate these for the production of value-added molecules

environmental concerns and reduce the and materials. Addressing this during the Fig. 2 | The twelve principles of circular chemistry.

Nature Chemistry | VOL 11 | MARCH 2019 | 190–195 | www.nature.com/naturechemistry 191

comment

chemistry, circular chemistry strives

Box 1 | The twelve principles of green chemistry (GC)8

to reduce the harmful impact of these

compounds on the environment. Although

1. Prevent waste. It is better to 7. Use renewable feedstocks. A raw the use of substances of concern may be

prevent waste than to treat or material or feedstock should be renewable unavoidable at some facilities35, these should

clean up waste after it has been rather than depleting. not be released to the environment (CC 6).

created. This approach requires the continued

8. Reduce chemical derivatives. Reduce conglomeration of industrial sites and

2. Maximise atom economy. Chemical generation of derivatives, since such enhanced cooperation between companies.

processes should maximize incorporation chemical steps require more reagents and Optimal product design should target

of all materials used into the final produce additional waste. the most favourable end-of-life state,

product. avoiding persistence in the environment and

9. Use catalytic (versus stoichiometric) breakdown into harmful products (CC 7).

3. Less hazardous synthesis. Chemical conditions. Using catalysts is preferable Biodegradable materials are often seen as

processes should avoid using or producing compared to using reagents in sustainable — yet the fact that the product

substances toxic to humans and the stoichiometric amounts. can simply be disposed of in the environment

environment. may promote littering. Another issue

10. Design for degradation. Chemical often overlooked is that micro plastics and

4. Design benign chemicals. products should be designed to deteriorate polymers partially degraded from a plastic

Chemicals should be designed to achieve after fulfilling a function without persisting bottle cause more harm to the environment

their function while minimizing their in the environment. than the original bottle26,36. Here, again,

toxicity. following the green chemistry principles that

11. Real-time analysis for pollution encourage chemists to design materials for

5. Use safer solvents and auxiliaries. prevention. Analytical methods allow degradation (GC 10) does not unequivocally

Auxiliary substances should be rendered in-process monitoring and control prior to lead to an increase in sustainability.

redundant wherever possible and harmless the formation of hazardous substances. Therefore, rather than aiming for product

when used. degradation, it is preferable to collect

12. Minimize potential for accidents. waste streams and instead convert them in

6. Increase energy efficiency. Energy Substances used in a chemical process dedicated plants into value-added materials.

requirements of chemical processes should should be chosen to minimize the potential

be minimized. for accidents. The life cycle assessment and the

ladder of circularity

Environmental assessments, typified by the

life cycle assessment (LCA), which assesses

renewable plastics. A few examples of such additional energy inputs. Constant the impact on the environment of the entire

plastics that display comparable properties innovation is required to promote the life cycle of a chemical product, should

to conventional plastics yet can be returned recycling (and therefore the separation) of become prevalent to identify inefficiencies

to their monomeric form have been materials during both a chemical process in current chemical processes (CC 8)37,38.

developed that may reshape product and the collection of the desired products. Such sustainability metrics, which provide

life cycles27–30. These ‘in-process’ developments are information on the environmental impact of

followed by ‘post-process’ developments, as a chemical from its design to its disposal39,40

Energy input is an investment the repurposing of the consumed products can help to identify opportunities for

Using waste as a resource can also contribute through chemical or biochemical methods innovation in a process and can also

considerably to the energy efficiency of a (CC 5) is required to reduce primary pinpoint which feedstock is most sustainable

chemical product over its entire life cycle31,32. feedstock use, optimize resource yields and to use as resource.

In order to repurpose waste material into increase renewability, durability and multi- Resource hierarchy (Fig. 3) urges that

a feedstock, it is important to achieve a functionality of chemicals and products. the necessity of material use is examined

recirculation of molecules and materials that There is a strong ambition towards by asking the following questions: ‘Do we

ensure an energy economy33. For example, developing chemically renewable energies, need this material to achieve our goal?’, ‘Do

CO2 can be converted into a variety of for example, solar-driven chemistry. we need to make something new or can

other molecules (ranging from methane to Meanwhile, the energy invested in chemical available material be reused or repaired?’,

alcohols to amides), which can, in turn, be products should be retained as much and ‘Does the used product really need to

used for a variety of purposes — but the as possible during circulation. Energy, be disposed of?’. The actions associated

conversion process shouldn’t necessitate ultimately derived from natural sources, will with these questions are summarized

more energy than that offered by the always be required for the transportation in the ladder of circularity (reject, reduce,

product obtained (CC 4). and processing of materials to enable the full reuse, redistribute, repair, refurbish,

This emphasis on the reusability of recycling of all chemical elements, especially repurpose, remanufacture, recycle, recover,

materials means that their longevity — those that are in limited supply. return, which can be referred to as the

which requires they remain chemically ‘11 Rs’)41,42 that provides a means by which

stable over many product cycles — is valued Controlled environment to assess the end-of-life options (CC 9).

over their degradability (GC 10)34. By The inherent reactivity of chemicals When considering the various routes

viewing the energy stored in materials as a enables their conversion into value-added of circulation, it is required to aim for

long-term investment, circular chemistry compounds, but can also lead to adverse the highest possible forms of recycling

aims to conserve energy, and thus reduces effects. In a similar manner to green (shown at the top of the ladder). The most

192 Nature Chemistry | VOL 11 | MARCH 2019 | 190–195 | www.nature.com/naturechemistry

comment

desirable courses of action are to avoid or

Box 2 | The twelve principles of circular chemistry (CC)

prevent use of resources. Redistribution

(reintroducing a used product in a new

market) is placed slightly lower than reuse 1. Collect and use waste. Waste is accounting for separation, purification and

(a widespread example of which is a library) a valuable resource that should be degradation.

because reusing products in the same transformed into marketable products.

location doesn’t require transportation. At 2. Maximize atom circulation. 8. Assess sustainability. Environmental

the bottom of the ladder, the least desirable Circular processes should aim to assessments (typified by the LCA) should

options are landfill dumping or incineration maximize the utility of all atoms in become prevalent to identify inefficiencies

of materials as waste. It is true that existing molecules. in chemical processes.

incineration as a disposal method generates

heat, which can be used as energy, but this 3. Optimize resource efficiency. 9. Apply ladder of circularity. The end-

should be the last resort when there are no Resource conservation should be targeted, of-life options for a product should strive

viable recycling options. promoting reuse and preserving finite for the highest possibilities on the ladder of

It is important to account for material feedstocks. circularity.

separation, purification and degradation to

sustain chemical processes. An example of 4. Strive for energy persistence. Energy 10. Sell service, not product. Producers

aiming to redesign products for a circular efficiency should be maximized. should employ service-based business

economy while recognizing the triple models such as chemical leasing,

bottom line is the joint venture between 5. Enhance process efficiency. Innovations promoting efficiency over production rate.

Dutch State Mines (DSM) and Niaga should continuously improve in- and

(whose name stems from the backwards post-process reuse and recycling, 11. Reject lock-in. Business and regulatory

spelling of ‘again’). The venture’s first project preferably on-site. environment should be flexible to allow the

was the redesign of the carpet-making implementation of innovations.

process, which has been identified as a 6. No out-of-plant toxicity. Chemical

huge contributor to landfill in the United processes should not release any toxic 12. Unify industry and provide coherent

States and European countries. Separation compounds into the environment. policy framework. The industry and

and recycling of glued carpet was never policy should be unified to create an

economically viable; instead, DSM–Niaga 7. Target optimal design. Design should optimal environment to enable circularity

now produce their entire carpets out of be based on the highest end-of-life options, in chemical processes.

the same material (polyester) and have

also developed a reversible glue that allows

carpets consisting of two different materials

to be taken apart. This is an example where their painting operations, the companies quo of continued process optimization

chemical innovation turned an everyday devised a process in which expenses were — it is simply easier to keep relying on

product in a fully recyclable one, where the charged per square metre of metal material the established system of production and

waste has value (as another carpet). coated, and powder waste was returned to consumption through, for example, chemical

AkzoNobel for recycling. The arrangement plants and companies. When business-as-

Product stewardship also included the training of workers, usual is preferred over conceptually novel

The circular economy relies on a decoupling resulting in products of better quality and a means of providing a service because of the

of material consumption and economic reduction in the number of reject products, financial cost of adopting the new approach,

growth43. To promote this, ownership of as well as a reduction in maintenance which often involves the necessary

goods needs to be directed away from the costs. The resulting process is closed-loop, development of supporting technology and

user and back to the producer. This can be generates nil waste, and ABB ARAB saw a infrastructure, the situation can be referred

achieved by shifting payment models from 20% reduction in coating used. A service- to as a ‘lock-in’45–48. Therefore, circular

ownership-based to service-based systems based chemical industry is vital to circular chemistry innovations also need to promote

— an example is the use of shared cars. chemistry, as companies have the assets and transitions and overcome lock-ins to

Similarly, in circular chemistry, producers the know-how to retrieve and repurpose realize market opportunities for long-term

are encouraged to use service-based chemical products, and the chemical sustainability ambitions (CC 11). A chemical

business models (such as chemical leasing, industry is far better equipped to target innovation befitting circular chemistry

www.chemicalleasing.org)44 to promote the management of molecule-circulating yields a process that is both flexible and

efficiency and longevity of the materials over loops — for example infrastructure for the adaptive. Companies can prevent lock-

production rate and quantity, and to shift reuse or recycling of materials (a step called ins by focusing on entrepreneurs and

the focus towards a value-added approach ‘reverse logistics’) — than the user. This type creating space for change in their available

targeting the service that is linked with of industry will lead to the more efficient infrastructure from the start.

the chemicals. use of chemicals and to the improved health Finally, in order to facilitate the adoption,

A successful example of this approach and safety, environmental and economic development and implementation of circular

can be found in Egypt. Asea Brown Boveri benefits (CC 10). chemistry, a supportive policy framework

(ABB) ARAB is a manufacturer of electrical is also required (CC 12) to ensure that the

appliances, who resolved high costs in Circumventing lock-ins value chain is balanced over the whole

electrostatic powder coating by collaborating Transitioning towards a circular economy cycle of materials circulation. Key drivers

with paints and coatings supplier AkzoNobel requires immediate action. Currently, to induce this transition are: enabling and

from 2008. Instead of ABB ARAB buying moving to more sustainable chemical rewarding chemical and environmental

the coating material per kilogram for processes is often limited by the status regulations; sustainable supply chains and

Nature Chemistry | VOL 11 | MARCH 2019 | 190–195 | www.nature.com/naturechemistry 193

comment

LEVELS OF THE

RESOURCE HIERACHY LEVEL DEFINITION

Rejection has an effect on the take-stage.

By preventing the usage of material or energy

resources they do not need to be mined. It is

Reject considered the highest level of the hierarchy.

Prevent food loss Simplify

Reduction is generally about turning down the

Lengthen product life

tap. You still use some resources, but fewer through

Reshore the simplification of the product, increased product

Reduce Reshore life span and reduced distance for transport.

The library is the most common example of reuse.

Share product This level is about reuse on a local level, for

example through sharing or leasing. Little

Reuse transport is necessary.

Product-service

Distribute as human food Redistribution is also about reusing resources,

(food bank) but more transport is needed. For example,

reintroducing a second-hand product in a new

Redistribute market.

Reintroduce

Once resources are broken but in their fixed

state are still valuable, repairing and maintenance

Maintain product

are generally the least resource-intensive solutions

Repair to extend the life of resources.

For electronic materials, refurbishment means

Convert to combining repaired and redistributed products.

human food In many other cases, it means updating a product to

Refurbish the current standards.

Convert to Cascade parts Repurposing is the updating or adaptation of a product

animal feedstock such that it can be used to serve a new function

Repurpose or within another context.

Convert to

industry feedstock

Remanufacture is generally a more thorough

process of disassembling a product, replacing worn

Remanufacture and broken parts with new ones and reassembling it.

Recycle is a term often used for the simple reuse

of materials. It also comprises the process

of liquifying materials (such as smelting)

Recycle to act as a feedstock for new material production.

Compost to fertilizer

Recovery is retrieving the lowest forms of

Anaerobic digestion energy or feestock for energy production from a

material. The actual material is broken down and

Sustainable energy Recover cannot be recycled further.

resource Incineration

Most hierarchies call this landfill. However, this

stage is more than that; it encompasses the return

of solids, but also liquids and gases, back to the

Return Sequestration environment after use.

BIOLOGICAL TECHNICAL

MATERIALS Resource separation MATERIALS

Fig. 3 | A comprehensive illustration of the resource hierarchy. The widely known ‘3 Rs’ approach — reduce, reuse and recycle — has been expanded and

throughout the past few decades a variety of ladders and scales have been used to represent this concept. Figure 3 serves as a visual guide to help the

understanding and application of the ‘11 Rs’, depending in particular on the types of materials being used (biological versus technical ones). Whereas biological

materials can largely be regenerated, this is not the case for human-made materials, and so for efficient waste management these different types of resources

should be kept separate as much as possible. Credit: Maurits Korse, https://blog.mauritskorse.nl/en/2016/01/waste-hierarchy-explained/

194 Nature Chemistry | VOL 11 | MARCH 2019 | 190–195 | www.nature.com/naturechemistry

comment

chemical logistics (https://tfs-initiative. of Amsterdam, Science Park 904, Amsterdam, 29. The future of plastic. Nat. Commun. 9, 2157 (2018).

30. Kaur, G., Uisan, K., Ong, K. L. & Lin, C. S. K. Curr. Opin. Green

com)49; and optimal university–industry– Netherlands. Sust. Chem. 9, 30–39 (2018).

government relations (which has been Twitter handle: @ChrisSlootweg 31. Patt, J. J. & Banholzer, W. F. The Bridge 39, 15–22 (2009).

referred to as the ‘triple helix’)50. *e-mail: j.c.slootweg@uva.nl 32. Facts & Figures 2018 of the European Chemical Industry

(Cefic, 2018).

33. Das Neves Gomes, C. et al. Angew. Chem. Int. Ed. 51,

Conclusions Published online: 21 February 2019 187–190 (2012).

Within our linear economy, green https://doi.org/10.1038/s41557-019-0226-9 34. Figge, F., Stevenson Thorpe, A., Givry, P., Canning, L. &

Franklin-Johnson, E. Ecol. Econ. 150, 297–306 (2018).

chemistry has allowed the optimization References 35. Chemicals and the Circular Economy: Dealing with Substances of

of chemical processes, leading to less 1. Stahel, W. R. Nature 531, 435–438 (2016). Concern (European Parliament, 2017).

environmentally demanding chemistry 2. Matlin, S. A., Mehta, G., Hopf, H. & Krief, A. Nat. Chem. 7, 36. Hurley, R., Woodward, J. & Rothwell, J. J. Nat. Geosci. 11,

251–257 (2018).

practices. In doing so, it has laid the 941–943 (2015).

37. Mulvihill, M. J., Beach, E. S., Zimmerman, J. B. & Anastas, P. T.

3. Clark, J. H., Farmer, T. J., Herrero-Davila, L. & Sherwood, J. Green

groundwork for an environmentally friendly Chem. 18, 3914–3934 (2016). Annu. Rev. Environ. Resour. 36, 271–293 (2011).

culture in the chemical discipline. Now, 4. Anastas, P. T. & Zimmerman, J. B. Chem. 1, 10–12 (2016). 38. Sustainability hotspot scan: Sustainability opportunities and

risks for the chemical value chain. TNO https://go.nature.

further steps need to be taken towards 5. Sheldon, R. A. Green Chem. 18, 3180–3183 (2016).

com/2UvZURB (2019).

6. Kümmerer, K. Angew. Chem. Int. Ed. 56, 16420–16421 (2017).

sustainability. With the development of 7. Linder, M. Green Chem. Lett. Rev. 10, 428–435 (2017). 39. Constable, D. J. C., Jiménez-González, C. in Handbook of

a circular economy, we introduce a set 8. Anastas, P. T & Warner, J. C (eds) in Green Chemistry: Theory and Green Chemistry: Green Synthesis Vol. 7 (eds Chao-Jun, L. &

of principles for sustainable chemistry Practice (Oxford University Press, 1998). Anastas, P. T) 69–92 (Wiley-VCH, 2012).

9. Marteel-Parrish, A. E. & Abraham, M. A. (eds) Green Chemistry and 40. Saidani, M., Yannou, B., Leroy, Y. & Cluzel, F. Recycling 2,

practice that is analogous to those of Engineering: A Pathway to Sustainability (Wiley, Hoboken, 2014). 6 (2017).

green chemistry, and introduce the term 10. Erythropel, H. C. et al. Green Chem. 20, 1929–1961 (2018). 41. Korse, M. Resource hierachy explained. Facio https://go.nature.

circular chemistry. 11. Elkington. J. 25 years ago I coined the phrase “Triple bottom line.” com/2UkLTFW (2016).

Here’s why it’s time to rethink it. Harvard Business Review https:// 42. Lansink, A. Waste Manag. Res. 36, 872 (2017).

Circular chemistry offers a holistic go.nature.com/2DfwKPk (2018). 43. Raworth, K. Doughnut Economics. (Cornerstone, London, 2017).

systems approach: by making chemical 12. Sato, K., Aoki, M. & Noyori, R. Science 281, 1646–1647 (1998). 44. Moser, F. & Jakl, T. Environ. Sci. Pollut. Res. Int. 22,

processes truly circular, products can — 13. Erisman, J. W., Sutton, M. A., Galloway, J., Klimont, Z. & 6325–6348 (2015).

Winiwarter, W. Nat. Geosci. 1, 636–639 (2008). 45. Suurs, R. & Roelofs, E. Systemic Innovation: Concepts and Tools

ideally — be repurposed near-indefinitely, 14. Steffen, W. et al. Science 347, 1259855 (2015). for Strengthening National and European Eco-policies https://

with energy as the only input. The chemical 15. Matlin, S. A., Mehta, G., Hopf, H. & Krief, A. Nat. Chem. 8, go.nature.com/2DbanuB (TNO, 2014).

sector has the opportunity to take a 393–398 (2016). 46. Frantzeskakia, N. & Loorbach, D. Technol. Forecast. Soc. Change

77, 1292–1301 (2010).

leading role in combatting scarcity and 16. Cavani, F., Centi, G., Perathoner, S. & Trifiró, F. (eds) Sustainable

47. Etzkowitz, H. & Leydesdorff, L. Res. Policy 29, 109–123 (2000).

Industrial Chemistry (Wiley-VCH, Weinheim, 2009).

environmental crises as a result of ineffective 17. Nuijten, B. No time to waste: the state of the circular economy 48. Governments going Circular – Global Scan Best Practices.

waste management, as the development of innovation within the chemical industry. Finch & Beak https:// De Groene Zaak http://www.govsgocircular.com (2019).

49. Reniers, G. L. L., Sörensen, K. & Vrancken, K. Management

novel chemical reactions to reuse molecules go.nature.com/2UlCbmM (2016).

Principles of Sustainable Industrial Chemistry: Theories, Concepts

18. Elser, B. & Ulbrich M. Taking the European chemical industry

and materials will lead to a closed-loop into the circular economy. Accenture https://go.nature. and Industrial Examples for Achieving Sustainable Chemical

chemical industry. Life cycle thinking and com/2DE4Uh6 (2017). Products and Processes from a Non-Technological Viewpoint

circularity will reinvent chemistry51, and 19. Accelerating Europe Towards a Sustainable Future (Wiley-VCH, Weinheim, 2013).

(ChemistryCAN, Cefic, 2017). 50. Blum, C. et al. Sustainable Chem. Pharm. 5, 94–104 (2017).

should be the basic principles for developing 20. Behr, A. & Johnen L. in Handbook of Green Chemistry: Green 51. Whitesides, G. M. Angew. Chem. Int. Ed. 54, 3196–3209 (2015).

novel chemical products and processes Synthesis Vol. 7(eds Chao-Jun, L. & Anastas, P. T) 69–92 52. Transforming our world: the 2030 Agenda for Sustainable

that use waste as resource. In turn, this will (Wiley-VCH, 2012). Development. Sustainable Development Goals Knowledge Platform

21. Clark, J. H. Curr. Opin. Green Sust. Chem. 8, 10–13 (2017). https://go.nature.com/2FWSseG (2015).

contribute to realizing the circular economy 22. Olivetti, E. A. & Cullen, J. M. Science 360, 1396–1398 (2018). 53. Thornton, B. F. & Burdette, S. C. Nat. Chem. 11, 4–10 (2019).

and securing our sustainable future by 23. Trost, B. M. Science 254, 1471–1477 (1991).

addressing the United Nations Sustainable 24. Bender, T. A., Dabrowski, J. A. & Gagné, M. R. Nat. Rev. Chem. 2, Acknowledgements

35–46 (2018).

Development Goals52. ❐ 25. Greene, J. P. Sustainable Plastics: Environmental Assessments of

This work was supported by the Council for Chemical

Sciences of The Netherlands Organization for Scientific

Biobased, Biodegradable, and Recycled Plastics (Wiley,

Research (NWO/CW and NWO/TTO) by a VIDI grant

Tom Keijer1, Vincent Bakker1 and Hoboken, 2014).

26. Iwata, T. Angew. Chem. Int. Ed. 54, 3210–3215 (2015). (J.C.S.) and a STW Take-off grant (J.C.S.). We gratefully

J. Chris Slootweg1* acknowledge the MChem Green Chemistry class of 2016

27. Zhu, J.-B., Watson, E. M., Tang, J. & Chen, E. Y.-X. Science 360,

1

Van ‘t Hoff Institute for Molecular Sciences, Research 398–403 (2018). and 2017 and D. Appel (Index Initiative) and T. Cantat

Priority Area Sustainable Chemistry, University 28. Sardon, H. & Dove, A. P. Science 360, 380–381 (2018). (CEA Saclay) for stimulating discussions.

Nature Chemistry | VOL 11 | MARCH 2019 | 190–195 | www.nature.com/naturechemistry 195

You might also like

- Science Class 7 Topic: Solutions Reinforcement WorksheetDocument7 pagesScience Class 7 Topic: Solutions Reinforcement WorksheetLee-Ann ZerimarNo ratings yet

- Basic Chemical Calculations-MergedDocument184 pagesBasic Chemical Calculations-MergedVishwajeet DhanwadeNo ratings yet

- Circularity Indicators An Approach To Measuring Circularity: Project OverviewDocument12 pagesCircularity Indicators An Approach To Measuring Circularity: Project OverviewFilena Rubio100% (2)

- Astm e 200 97 Standard Practice For PDFDocument15 pagesAstm e 200 97 Standard Practice For PDFSergioFernandoMendozaMendozaNo ratings yet

- Circular Economy Strategies - Petrochemical SustainabilityDocument7 pagesCircular Economy Strategies - Petrochemical SustainabilitydsukocoNo ratings yet

- Chemical Recycling's Potential to Reduce GHG EmissionsDocument24 pagesChemical Recycling's Potential to Reduce GHG EmissionsJayanth KumarNo ratings yet

- Battista 2020Document18 pagesBattista 2020Ingryd Mayer KrinskiNo ratings yet

- Macro Chemistry Physics - 20hvbhiojDocument17 pagesMacro Chemistry Physics - 20hvbhiojCarlo TonelloNo ratings yet

- 1-S2.0-S2212827115001596-Waste ManagementDocument6 pages1-S2.0-S2212827115001596-Waste Managementharis.accessNo ratings yet

- 19 - DFR - Systematic Integration of Design-For-Recycling Into Product Design (1995)Document8 pages19 - DFR - Systematic Integration of Design-For-Recycling Into Product Design (1995)Aleena KanwalNo ratings yet

- Biogas 1Document24 pagesBiogas 1Sherin Novia Dwi PareraNo ratings yet

- Energies 15 01475 v2Document21 pagesEnergies 15 01475 v2José CoelhoNo ratings yet

- Product Disposal PenaltyDocument16 pagesProduct Disposal PenaltyAbhinay BayyapuNo ratings yet

- Accelerating wastewater treatment researchDocument8 pagesAccelerating wastewater treatment researchBad boyNo ratings yet

- Chemical Engineering and Processing: Process Intensi FicationDocument11 pagesChemical Engineering and Processing: Process Intensi FicationAndika MardiantoNo ratings yet

- Lecture - Design For EnvironmentDocument23 pagesLecture - Design For EnvironmentParth ChauhanNo ratings yet

- wasteprevention (1)Document9 pageswasteprevention (1)aanitahpNo ratings yet

- How Green Chemistry Will Change Chemical Engineering: Gaetano Iaquaniello, Agnese CicciDocument14 pagesHow Green Chemistry Will Change Chemical Engineering: Gaetano Iaquaniello, Agnese CicciFabianNo ratings yet

- 1 s2.0 S2452223621000705 MainDocument6 pages1 s2.0 S2452223621000705 MainYoya LoyaNo ratings yet

- Applsci 12 01917 v2Document20 pagesApplsci 12 01917 v2Nathanael Basana HisarNo ratings yet

- Nwad 193Document2 pagesNwad 193kai06071eNo ratings yet

- Chen 2021Document15 pagesChen 2021Michelle NatasyaNo ratings yet

- Broadbent2016 Article SteelSRecyclabilityDemonstratiDocument8 pagesBroadbent2016 Article SteelSRecyclabilityDemonstratimichaelNo ratings yet

- Spent Coffee Waste As A Renewable Source For The PDocument10 pagesSpent Coffee Waste As A Renewable Source For The Pzahiasarni1998No ratings yet

- 6. Waste to EnergyDocument11 pages6. Waste to EnergyshaielNo ratings yet

- Capolupo-Faraco2016 Article GreenMethodsOfLignocellulosePrDocument17 pagesCapolupo-Faraco2016 Article GreenMethodsOfLignocellulosePrAlejandra GutierrezNo ratings yet

- Rpa Chemical Recycling StatementDocument5 pagesRpa Chemical Recycling StatementPruthvi Mundalamane JagadishchandraNo ratings yet

- 2019 - 07 - Ebook Circular Economy PlasticsaimplasDocument18 pages2019 - 07 - Ebook Circular Economy PlasticsaimplasSébastien MermetNo ratings yet

- Sustainability 14 07650Document20 pagesSustainability 14 07650WO AHNo ratings yet

- 27 - Modeling - and - Simulation - of - Biomass - Anaerobic - DigesDocument12 pages27 - Modeling - and - Simulation - of - Biomass - Anaerobic - DigesslmokraouiNo ratings yet

- Solid Waste Management in Petroleum RefineriesDocument9 pagesSolid Waste Management in Petroleum RefineriesThiyagaraj RamanNo ratings yet

- Concept - Closed-Loop EconomyDocument6 pagesConcept - Closed-Loop EconomygumaiNo ratings yet

- 1 s2.0 S1364032117310936 MainDocument19 pages1 s2.0 S1364032117310936 Mainfarah al-sudaniNo ratings yet

- Renewable Energy: Nur Izzah Hamna A. Aziz, Marlia M. Hana FiahDocument11 pagesRenewable Energy: Nur Izzah Hamna A. Aziz, Marlia M. Hana Fiahagungtiyo21No ratings yet

- Jurnal 1Document6 pagesJurnal 1RatriNo ratings yet

- Knowledge 03 00001Document17 pagesKnowledge 03 00001Park JiminNo ratings yet

- Sustainable Energy Generation From Municipal Solid Waste: A Brief Overview of Existing TechnologiesDocument8 pagesSustainable Energy Generation From Municipal Solid Waste: A Brief Overview of Existing TechnologiesZaki KhanNo ratings yet

- Sistemasdereactores 9349Document8 pagesSistemasdereactores 9349IlireaNo ratings yet

- Perspectives: Green Chemistry: A Tool For The Sustainable Development of The Chemical IndustryDocument2 pagesPerspectives: Green Chemistry: A Tool For The Sustainable Development of The Chemical IndustryRodolfo Angulo OlaisNo ratings yet

- 1.8 - An Introductory Note On The Environmental Economics of The Circular EconomyDocument9 pages1.8 - An Introductory Note On The Environmental Economics of The Circular EconomyKaroline Brito Coutinho FerreiraNo ratings yet

- Catalytic Transformation or Waste Polymers To Fuel OilDocument8 pagesCatalytic Transformation or Waste Polymers To Fuel Oilsanty cuervoNo ratings yet

- Coupling Dark Fermentation and Microbial Electrolysis To Enhance Bio-Hydrogen Production From Agro-Industrial Wastewaters and By-Products in A Bio-Refinery FrameworkDocument13 pagesCoupling Dark Fermentation and Microbial Electrolysis To Enhance Bio-Hydrogen Production From Agro-Industrial Wastewaters and By-Products in A Bio-Refinery FrameworkBENGUERBA YacineNo ratings yet

- AIChE Journal - 2020 - Zhao - Waste High Density Polyethylene Recycling Process Systems For Mitigating Plastic PollutionDocument25 pagesAIChE Journal - 2020 - Zhao - Waste High Density Polyethylene Recycling Process Systems For Mitigating Plastic PollutionAhmet AltunNo ratings yet

- Life Cycle Assessment As An Engineer's Tool?: Anneliese Niederl-Schmidinger, Michael NarodoslawskyDocument8 pagesLife Cycle Assessment As An Engineer's Tool?: Anneliese Niederl-Schmidinger, Michael NarodoslawskyLeynis Algarín100% (1)

- Enhancement of Production and Upgradation of Biogas Using Different Techniques-A ReviewDocument17 pagesEnhancement of Production and Upgradation of Biogas Using Different Techniques-A ReviewZainul Fikri TampengNo ratings yet

- 1 s2.0 S0016236123029125 MainDocument13 pages1 s2.0 S0016236123029125 Mainfajar marendraNo ratings yet

- Journal of Cleaner Production: Muhammad Tayyab, Jihed Jemai, Han Lim, Biswajit SarkarDocument20 pagesJournal of Cleaner Production: Muhammad Tayyab, Jihed Jemai, Han Lim, Biswajit SarkarahtashamNo ratings yet

- A Systematic Review On Waste As Sustainable Feedstock For Bioactive Molecules-Extraction As Isolation TechnologyDocument25 pagesA Systematic Review On Waste As Sustainable Feedstock For Bioactive Molecules-Extraction As Isolation TechnologyCsaba AndrásNo ratings yet

- 1 s2.0 S2590174521000969 MainDocument16 pages1 s2.0 S2590174521000969 MainMd ShihabuzzamanNo ratings yet

- United Nations Circular Economy Sustainable DevelopmentDocument9 pagesUnited Nations Circular Economy Sustainable DevelopmentAna Carolina MendesNo ratings yet

- Resources, Conservation & RecyclingDocument8 pagesResources, Conservation & RecyclingMiftahur RahmiNo ratings yet

- Laboratorio SostenibleDocument4 pagesLaboratorio SostenibleCAMILO ANDRES BERNAL RAMOSNo ratings yet

- An Evaluation of Feedstocks For Sustainable Energy and Circular Economy Practices in A Small..Document13 pagesAn Evaluation of Feedstocks For Sustainable Energy and Circular Economy Practices in A Small..duo.zhang13No ratings yet

- Spent Coffee Ground Reuse in Lime-Based Mortars. A Preliminary Assessment For Innovative Green Thermo-PlastersDocument13 pagesSpent Coffee Ground Reuse in Lime-Based Mortars. A Preliminary Assessment For Innovative Green Thermo-Plastersdanvco100% (1)

- Macam Macam PelarutDocument12 pagesMacam Macam PelarutSarayati Khairunisah KpNo ratings yet

- Recycling and Recovery Routes of Plastic Solid Waste (PSW)Document19 pagesRecycling and Recovery Routes of Plastic Solid Waste (PSW)ManiaNo ratings yet

- Exploring Environmental and Economic Costs and Benefits of A CircularDocument26 pagesExploring Environmental and Economic Costs and Benefits of A CircularHoàng BanNo ratings yet

- Anaerobic Digestion Use in Wastewater Treatment - Sustainable DevelopmentsDocument7 pagesAnaerobic Digestion Use in Wastewater Treatment - Sustainable DevelopmentsUmutNo ratings yet

- Cradle To Cradle DesignDocument12 pagesCradle To Cradle DesignMiguel BarreraNo ratings yet

- Recycling of Polymers A ReviewDocument15 pagesRecycling of Polymers A ReviewChristhy Vanessa Ruiz MadroñeroNo ratings yet

- From Capturing Carbon to Sustainable Circular BioeconomyDocument2 pagesFrom Capturing Carbon to Sustainable Circular BioeconomyRUBY BHULLAR GARCHANo ratings yet

- 2019 - Environmental Optimisation of Mine Scheduling Through Life Cycle Assessment IntegrationDocument10 pages2019 - Environmental Optimisation of Mine Scheduling Through Life Cycle Assessment IntegrationYusuf Efe OzdemirNo ratings yet

- Al-Kutti - Hybrid Binders Containing Date Palm AshDocument11 pagesAl-Kutti - Hybrid Binders Containing Date Palm AshFerisma RatugiriNo ratings yet

- Coordination Chemistry Reviews, 60 (1984) 255-276Document22 pagesCoordination Chemistry Reviews, 60 (1984) 255-276Veneta GizdakovaNo ratings yet

- Stereoisomerism: Solutions To Review QuestionsDocument18 pagesStereoisomerism: Solutions To Review QuestionsTADZMALYN JINANGNo ratings yet

- Ap06 Chemistry FormB Samples q5Document10 pagesAp06 Chemistry FormB Samples q5Majlinda HalitiNo ratings yet

- Activity Series of Metals Lab - 2Document6 pagesActivity Series of Metals Lab - 2Isra Bint zahedNo ratings yet

- Rahmawati IndikatorDocument2 pagesRahmawati IndikatorDaffa amri MaulanaNo ratings yet

- 1-6 Chemical Reactions of Alkanes and AlkenesDocument2 pages1-6 Chemical Reactions of Alkanes and AlkenesBryan100% (1)

- Ally TestDocument17 pagesAlly TestAhmed MasoudNo ratings yet

- Analisa AgriculturalDocument6 pagesAnalisa AgriculturalFEBRINA SARLINDA, STNo ratings yet

- CHE-0905554 Fertilizers Technology-Sep-2014-FallDocument4 pagesCHE-0905554 Fertilizers Technology-Sep-2014-FalllaminarsNo ratings yet

- Photoreduction, Maida PDFDocument8 pagesPhotoreduction, Maida PDF'Sebastian OrtizNo ratings yet

- Dissertation Pollution de LeauDocument6 pagesDissertation Pollution de LeauCustomNotePaperCanada100% (2)

- Acetic Silicone: Technical Data SheetDocument2 pagesAcetic Silicone: Technical Data SheetAli BakorNo ratings yet

- Basf - 2015-Agro Brochure Asia Pacific enDocument9 pagesBasf - 2015-Agro Brochure Asia Pacific enAlfredo MéndezNo ratings yet

- DERIVATION OF TERM SYMBOLDocument34 pagesDERIVATION OF TERM SYMBOLAqsa AslamNo ratings yet

- Chem Notes (Yr11)Document46 pagesChem Notes (Yr11)nguyenbohaeNo ratings yet

- ESE GS Material Science MCQ PDFDocument175 pagesESE GS Material Science MCQ PDFPrashant ShekharNo ratings yet

- Distance Geometry BookDocument543 pagesDistance Geometry BookIgnacio Pérez-VictoriaNo ratings yet

- Price List Hyper RB Categorized 13 02 23Document18 pagesPrice List Hyper RB Categorized 13 02 23hh6cjnnnhvNo ratings yet

- Tetrahedral and octahedral void sizes in close packingDocument7 pagesTetrahedral and octahedral void sizes in close packingPrachi Agarwal100% (1)

- CHEM316 Report2Document13 pagesCHEM316 Report2Jake GerolagaNo ratings yet

- CHM361 - CHAPTER 2 Molecular Orbital TheoryDocument35 pagesCHM361 - CHAPTER 2 Molecular Orbital TheoryEhaz100% (1)

- 422 - Report TCP PUREDocument3 pages422 - Report TCP PURENazar JabbarNo ratings yet

- Footing Design (WSD Method) PDFDocument2 pagesFooting Design (WSD Method) PDFFaruque AbdullahNo ratings yet

- Science 8 Unit A PlanDocument11 pagesScience 8 Unit A Planapi-485112258No ratings yet

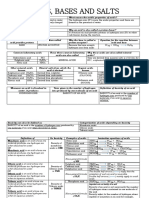

- Acids Bases and Salts 1Document16 pagesAcids Bases and Salts 1nsamba sethNo ratings yet

- Comparative Analysis of Smokeless Gunpowders by Fourier Transform Infrared and Raman SpectrosDocument8 pagesComparative Analysis of Smokeless Gunpowders by Fourier Transform Infrared and Raman SpectrosmrenaultNo ratings yet