Professional Documents

Culture Documents

GB 162

Uploaded by

eurodigitalproiecteOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GB 162

Uploaded by

eurodigitalproiecteCopyright:

Available Formats

6 720 646 148 - 11/2010 US/CA (en) For the user

User’s Instructions

Condensing gas boiler

Logamax plus GB162-L.B. 80 kW/100 kW

This manual is available in the English and French

language.

This manual must be retained for future use.

Please read thoroughly before operating

Downloaded from www.Manualslib.com manuals search engine

Warning: If the information in these instructions is not followed exactly, a fire or

explosion may result causing property damage, personal injury or loss of life.

– Do not store or use gasoline or other flammable vapors and liquids in the

vicinity of this or any other boiler.

– What to do if you smell gas

• Do not try to light any boiler.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas

supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

– Installation and service must be performed by a qualified installer,

service agency or the gas supplier.

CAUTION !

The operating manual is part of the documentation that is delivered to the instal-

lation's operator. Go through the information in this manual with the owner/oper-

ator and make sure that he or she is familiar with all the necessary operating

instructions.

http://www.buderus.net 2

Downloaded from www.Manualslib.com manuals search engine

Contents

1 For your safety . . . . . . . . . . . . . . . 5 4 Starting up the boiler . . . . . . . . . 18

1.1 Designated use . . . . . . . . . . . . . . . . . . 5 4.1 Boiler settings . . . . . . . . . . . . . . . . . . . 18

1.2 Safety instructions . . . . . . . . . . . . . . . . 6 4.2 Check the system pressure . . . . . . . . . 19

1.3 Quality of the heating system water . . . 8 4.3 Fill the heating system . . . . . . . . . . . . 20

4.4 Frost protection . . . . . . . . . . . . . . . . . . 23

2 Lighting Instructions . . . . . . . . . . . 9

5 Shutting down the boiler . . . . . . 24

3 Operating the BC10 basic

controller 10 6 Operating and error messages . 25

3.1 General . . . . . . . . . . . . . . . . . . . . . . . 11 6.1 Normal operation menu . . . . . . . . . . . . 25

3.2 Switching ON and OFF . . . . . . . . . . . 11 6.2 Manual Operation menu . . . . . . . . . . . 26

3.3 Setting the DHW temperature value . 12 6.3 Settings menu . . . . . . . . . . . . . . . . . . . 28

3.4 Setting the space heating water 6.4 Display codes . . . . . . . . . . . . . . . . . . . 31

temperature 15 6.5 Identifying and resetting faults . . . . . . 34

3.5 "Burner ON" LED . . . . . . . . . . . . . . . . 17

3.6 Other functions and economic

heating 17

http://www.buderus.net 3

Downloaded from www.Manualslib.com manuals search engine

Preface

About these instructions Subject to technical changes!

These user's Instructions contain important Changes may be made following technical

information for the safe and proper operation improvements!

of Logamax plus GB162-L.B. 80kW/100kW

condensing gas boilers.

Updating of documentation

If the information in this manual is not followed Please contact us if you have any suggestions

exactly, a fire or explosion may result causing for improvements or corrections.

property damage, personal injury or loss of

life.

http://www.buderus.net 4

Downloaded from www.Manualslib.com manuals search engine

For your safety

1 For your safety

Logamax plus GB162 L.B. condensing gas Hazard definitions

boilers are designed and built according to the A DANGER

latest technological advances and safety Indicates the presence of hazards that

requirements.

will cause severe personal injury, death

The design is specifically focused on ease of

or substantial property damage.

use. To ensure the safe, economical and envi-

ronmentally friendly use of the heating system A WARNING

we urge you to read and observe the User's Indicates the presence of hazards that

Instructions. can cause severe personal injury, death

1.1 Designated use or substantial property damage.

The boiler was designed for heating water for A CAUTION

a central heating system and generating Indicates presence of hazards that will

domestic hot water. The boiler can be installed or can cause minor personal injury or

either as a single system or as part of a property damage.

multiple system (cascade system) with a H CAUTION

maximum of 8 boilers connected together. Risk of electric shock.

Indicates presence of hazards due to

electric shock.

http://www.buderus.net 5

Downloaded from www.Manualslib.com manuals search engine

For your safety

I NOTICE – Have a trained service provider check,

Indicates special instructions on instal- clean and service the heating system once

lation, operation or maintenance that a year.

are important but not related to Buderus recommends a contract for annual

personal injury or property damage. service and maintenance.

1.2 Safety instructions – The condensate collection and disposal

system must be periodically cleaned by a

Make sure to observe these safety instruc- trained service technician.

tions. Failure to do so can result in property

damage, personal injury or loss of life. – Have your trained service provider give you

detailed instructions about the operation of

– Installation, gas and flue connection,

the heating system.

commissioning, electrical connection and

– Carefully read these user's instructions.

maintenance activities must only be carried

out by a trained service provider. – Immediately have all defects to the heating

system repaired.

– Certain work, e.g. on gas lines, may require

a professional license. Only carry out such – Ensure that air intake and outlet openings

work if you are licensed to do so. are open and free from obstructions at all

times.

– Only use the boiler for its intended purpose

and only when it is in working order.

http://www.buderus.net 6

Downloaded from www.Manualslib.com manuals search engine

For your safety

– Do not store any flammable material or – Should overheating occur or the gas supply

liquids in the immediate vicinity of the fails to shut off, do not turn off or disconnect

boiler. the electrical supply to the pump. Instead,

– Never use chlorinated detergents or shut off the gas supply at a location

halogenated hydrocarbons (e.g. in external to the boiler.

spraycans, solvents and detergents, – The venting system must be inspected

paints, adhesives) in the room where the annually. Replace any parts which show

boiler is installed. deterioration from corrosion or any other

– When Calcium Chloride is present in sources.

concrete floors (when poured in winter) it is – This boiler does not have a pilot. It has an

necessary to seal the floor with a suitable ignition device which automatically lights

paint. the burner.

– Do not allow too much dust to collect on the – Check for smell of gas around the boiler

device. area. Be sure to smell next to the floor

– Do not use the boiler if any part has been because propane gas is heavier than air

under water. Immediately call a trained and will settle on the floor.

service technician to inspect the boiler and – Use only your hand to turn the gas control

to replace any part of the control system knob (fig. 4 on page 18). Never use tools. If

and any gas control which has been under the knob will not turn by hand, don't try to

water.

http://www.buderus.net 7

Downloaded from www.Manualslib.com manuals search engine

For your safety

repair it, call a trained service technician. 1.3 Quality of the heating system water

Force or attempted repair may result in a Use only untreated tap water when filling or

fire or an explosion. topping up the heating system. The use of

– When the vent system is blocked, this unsuitable heating system water will lead to

boiler will shut off automatically with code build-ups of sludge and corrosion, which can

'3C'. Immediately call a trained service in turn result in the malfunctioning of the boiler

technician to inspect and reset the boiler. and damage to the heat exchanger.

DO NOT treat the water with products such as

pH-adjusting substances (chemical additives)

and antifreeze or water softeners.

http://www.buderus.net 8

Downloaded from www.Manualslib.com manuals search engine

Lighting Instructions

2 Lighting Instructions

A STOP!

Read the chapter "For your safety" on page 5

before lighting the boiler.

Follow the instructions to start up the boiler in

“Starting up the boiler” on page 18

http://www.buderus.net 9

Downloaded from www.Manualslib.com manuals search engine

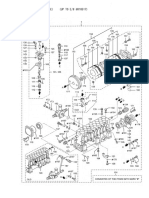

Operating the BC10 basic controller

3 Operating the BC10 basic controller

10 9 8

110 110 130 150

100 120

90

888

90 130 170

140 190

11 1 2 3 4 5 6 7

1

Fig. 1 Logamatic BC10 basic controller – Controls

1: Main power switch 5: Service Tool connector 9: Display

2: "Reset" button 6: LED "Burner operation" 10: DHW temperature knob

3: "Chimney sweep" button 7: LED "Heating system status" 11: LED "DHW status"

4: "Service" button 8: Space heating water temperature knob

http://www.buderus.net 10

Downloaded from www.Manualslib.com manuals search engine

Operating the BC10 basic controller

3.1 General

The boiler is equipped with a control unit, the BC10

basic controller (fig. 2). This controller can be used

to control the heating system.

I NOTICE

If your heating system consists of several

boilers (cascade system), you have to

carry out the settings on the control units of Fig. 2 Opening the control panel

all individual boilers.

Push on the control panel to open it (fig. 2) and

get access to the controller.

3.2 Switching ON and OFF

Set the main switch on the BC10 to position "1"

(ON) to switch ON the boiler and set it to "0" to

switch the boiler OFF.

http://www.buderus.net 11

Downloaded from www.Manualslib.com manuals search engine

Operating the BC10 basic controller

H CAUTION

Risk of electric shock.

If a hazardous situation occurs, shut OFF power to the boiler using the emergency shutoff

switch or the boiler circuit breaker (see chapter 4 "Starting up the boiler", page 18). Make

yourself familiar with the location of the emergency shutoff switch and the boiler loop

circuit breaker.

3.3 Setting the DHW temperature value

Check the local code for the max. DHW temper- 110

ature. 100 120

Turn the "DHW temperature" rotary knob to set 90 130

the desired temperature of the hot water in the 140

DHW tank.

http://www.buderus.net 12

Downloaded from www.Manualslib.com manuals search engine

Operating the BC10 basic controller

Condition Explanation LED

0 OFF No hot water supply (only heating mode). OFF

1

Eco Economy mode, The DHW will only be reheated to 140 °F (60 °C), ON 2

Hot water temperature if the temperature has signifcantly fallen. This

140 °F (60 °C) reduces the number of burner starts and saves

energy. As a result the water may be a bit cooler

initially.

86 – 140 Direct setting on BC10 The temperature set on the BC10 is a fixed ON 2

in °F temperature that cannot be changed using a

RC thermostat.

Aut Entry via thermostat The temperature setting defaults to the maximum ON 2

(presetting) DHW temperature of 140 °F (60 °C).

Table 1 Settings of "DHW temperature" knob

1

This function has been optimized for boilers with combined DHW heating (combi-units).

2 The LED under the rotary knob lights if the DHW temperature is below the target value (heat request for

DHW).

http://www.buderus.net 13

Downloaded from www.Manualslib.com manuals search engine

Operating the BC10 basic controller

Anti-scald table

Temperature of Minimum time for Minimum time for second or third

water first degree burn degree burn

111 °F (44 °C) 5 hours 7 hours

116 °F (47 °C) 35 minutes 45 minutes

118 °F (48 °C) 10 minutes 14 minutes

122 °F (50 °C) 1 minute 5 minutes

131 °F (55 °C) 5 seconds 25 seconds

140 °F (60 °C) 2 seconds 5 seconds

149 °F (65 °C) 1 second 2 seconds

158 °F (70 °C) – 1 second

Table 2 Temperature/Time/Burn Chart

http://www.buderus.net 14

Downloaded from www.Manualslib.com manuals search engine

Operating the BC10 basic controller

3.4 Setting the space heating water

temperature

Turn the "space heating water temperature" knob

110 130

to set the upper limit value of the heater water for 90 150

the heating operation. This limitation does not

170

apply to DHW preparation.

190

http://www.buderus.net 15

Downloaded from www.Manualslib.com manuals search engine

Operating the BC10 basic controller

Condition Explanation LED

0 OFF No supply to heating system (only DHW heating OFF

operation).

86 – 190 Direct setting on The temperature set on the BC10 acts as a high limit. ON 1

BC10 in °F With a AM10 or RC10 control, the water temperature

will be at a equal or lesser value. With a On/Off

thermostat the water temperature will always be the

set temperature. Supply temperature never rises

above the set temperature.

Aut Entry via thermostat The temperature high limit setting defaults to the ON 1

(presetting) maximum boiler water temperature of 180 °F (82 °C).

Table 3 Settings of "space heating water temperature" rotary knob

1 The LED under the rotary knob lights when the heating system is switched ON and heat is requested.

In summer mode the heating system is switched OFF (LED OFF).

http://www.buderus.net 16

Downloaded from www.Manualslib.com manuals search engine

Operating the BC10 basic controller

3.5 "Burner ON" LED

The LED indicates the operating condition of the

burner.

LED Condition Explanation

ON Burner active The water in the boiler is being heated.

OFF Burner OFF The water in the boiler has reached the required temperature or

there is no heat request.

Table 4 LED indication

3.6 Other functions and economic heating

The functions described above are basic functions, carried out directly on the boiler using the

BC10 basic controller.

http://www.buderus.net 17

Downloaded from www.Manualslib.com manuals search engine

Starting up the boiler

4 Starting up the boiler

4.1 Boiler settings

Turn the "space heating water temperature" and 110

110 130

"DHW temperature" rotary knobs to "Aut" (auto- 100 120

150

90

matic mode).

The control unit will now take control.

90 130 + 170

140

190

Slowly open the gas valve by pushing on the gas

valve and turning it ¼ rotation in an counterclock-

wise direction (fig. 3, pos. 1). The gas valve is

open when it is in its vertical position.

1

Open the pump group isolating valves (fig. 3,

pos. 2).

2

Fig. 3 Opening gas- and isolating valves

http://www.buderus.net 18

Downloaded from www.Manualslib.com manuals search engine

Starting up the boiler

Set the main switch on the basic controller to

position "1" (ON). The basic controller checks the

current system status and the burner becomes

operational as soon as there is a heat request.

This procedure takes approx. 30 seconds.

Adjust the settings on the control unit (see the

Operating Instructions for the control unit).

4.2 Check the system pressure

If the heating system has just been filled, the system

pressure must initially be checked every day, for

1 week.

The maximum pressure in the heating system,

measured directly at the boiler, must not exceed

51 psi (3.5 bar).

Press the "Service" button (fig. 1, pos. 4) until the

system pressure ("P22") is shown in the display

(pos. 9).

http://www.buderus.net 19

Downloaded from www.Manualslib.com manuals search engine

Starting up the boiler

Fill the heating system if the system pressure

has dropped below 15 psi (1.0 bar) according

to paragraph “Fill the heating system” on

page 20.

4.3 Fill the heating system

Remove the lower casing from the pump group

(fig. 4).

Fig. 4 Removing the lower casing

http://www.buderus.net 20

Downloaded from www.Manualslib.com manuals search engine

Starting up the boiler

Unscrew the sealing cap (fig. 5).

Fig. 5 Removing cap from drain cock

http://www.buderus.net 21

Downloaded from www.Manualslib.com manuals search engine

Starting up the boiler

Fill the heating system to a pressure of appx.

20 psi (1.5 bar). Read the pressure from the 20 30

pressure gauge on the pump group or on the 10

control panel of the BC10 (fig. 6). psi

The pressure in the heating system, which is 100

110

120

90

110 130 150

measured directly at the boiler, must be at least

P22

90 130 170

140 190

equal to the required pre-pressure of the expansion

vessel plus 7 psi (0.5 bar). The minimum pressure

must not be less than 15 psi (1.0 bar) (if the heating

1

system is cold). The maximum pressure in the

heating system must not exceed 50 psi (3.5 bar). Fig. 6 Reading the pressure gauge

I NOTICE

It is very important that the heating

system is now purged, since all air will

collect at the highest point of the heating

system when the system is slowly filled

with water.

http://www.buderus.net 22

Downloaded from www.Manualslib.com manuals search engine

Starting up the boiler

Purge the heating system via the air vents/valves

on the heating bodies. Start at the first floor of the

premises and then work your way up (fig. 7).

The pressure loss in a heating system is caused by

air bubbles escaping via fittings and (automatic) air

vents. The oxygen contained in the fresh heating

water will also escape from the heating water after

some time and cause a pressure loss.

Topping up once a year is normal. If it is necessary

to top up more frequently, there might be a leak in

the system or a defective expansion vessel. This Fig. 7 Purging a radiator (example)

must be remedied as soon as possible.

4.4 Frost protection

When switched on, the boiler has an integrated frost

protection system. This means that no further frost

protection facilities should be installed on the boiler.

The frost protection switches the boiler on at a flow

temperature of 45 °F (7 °C) and off at a flow temper-

ature of 59 °F (15 °C). The heating system itself is

not protected against frost.

http://www.buderus.net 23

Downloaded from www.Manualslib.com manuals search engine

Shutting down the boiler

5 Shutting down the boiler

Set the main switch on the basic controller to

position "0" (OFF).

Close the gas shut-off valve and disconnect the

boiler from the power supply.

A DANGER

The heating system may freeze if it is not

operational in times of freezing weather.

– Protect the heating system against

freezing if there is a danger of frost affec-

ting the system.

– Drain the heating system water from the

lowest point of the heating system using

the boiler filling and draining cock. The

vent screw at the highest point of the

heating system must then be open.

http://www.buderus.net 24

Downloaded from www.Manualslib.com manuals search engine

Operating and error messages

6 Operating and error messages

In normal operating mode, the display shows the

10 9 8

current heater water temperature. You can display

other information using the "Service" button. 100

110

120

90

110 130 150

888

Also see section 6.4. 90 130 170

Push the "Service" button (pos. 4) a number of 140 190

times to switch between the various status

11 1 2 3 4 5 6 7

displays.

1

6.1 Normal operation menu Fig. 8 Basic controller BC10

Normal Operation menu

[\/2/4| Shows currently measured space heating water temperature in °F.

e [p/2/2| Shows currently measured system pressure in psi.

e [-/h/\| Current display code. In this case: Operating phase: Boiler in heating mode.

Table 5 Normal operation

http://www.buderus.net 25

Downloaded from www.Manualslib.com manuals search engine

Operating and error messages

6.2 Manual Operation menu

In manual mode, the heating system can be operated independent of a room controller

(e. g. RC35).

I NOTICE

Re-start manual operation after switching on the heating system, so that the

system is permanently in operation (especially if there is a risk of freezing).

Manual Operation menu

To activate manual operation: Press and hold the d button for more than 5 seconds.

d [\/2/4} A flashing dot in the right-hand bottom corner of the display shows manual

operation is active. This means that the boiler is permanently in heating mode:

– Space heating water temperature is as set on the BC10 basic controller.

– The LED "Heating system status" lights.

– DHW mode is possible during manual operation.

e [p/1.6} Shows currently measured system pressure in psi(pounds per square inch).

Table 6 Manual operation

http://www.buderus.net 26

Downloaded from www.Manualslib.com manuals search engine

Operating and error messages

Manual Operation menu

e [-/h/\} Display code: Operating phase: Also see section 6.4. The boiler is in manual

operation mode. During manual operation the "Settings" menu (table 7 from step 2) can

be used to temporarily change the target boiler performance.

Notice: If the boiler output has been changed temporarily, this must be set again after

ending manual operation, according to the "Settings" menu (table 7).

e [\/2/4}Shows currently measured space heating water temperature in °F.

After a power interruption manual operation ends automatically.

To end manually press and hold the d button for more than 2 seconds until the dot

disappears.

Table 6 Manual operation (continued)

http://www.buderus.net 27

Downloaded from www.Manualslib.com manuals search engine

Operating and error messages

6.3 Settings menu

Three settings can be made in the Settings menu:

– Modulation rate

– Post purge time

– DHW mode (On/off).

I NOTICE

The modulation rate and the DHW mode should be set by a trained installer.

If you will be on vacation for a long period while there is a risk of freezing, the post purge time

will have to be set (section 4.1 on page 18).

Settings menu

d To open the "Settings" menu: Press and hold the d+ e buttons for more than

2 seconds.

e

[l/?/?| This shows the "Settings" menu is open. You can adjust the setting of this

parameter.

Table 7 Settings

http://www.buderus.net 28

Downloaded from www.Manualslib.com manuals search engine

Operating and error messages

Settings menu

[l/?/?| modulation rate. Adjust as follows, or press e:

Lower:Decrease the modulation rate with the c button. The minimum setting is

[l/3/6| = 36 % with an 80-kW boiler and [l/3/0| = 30 % with a 100-kW boiler.

Higher: Increase the modulation rate with the d button. The maximum setting is

[l/?/?| = 100 %. This is equal to the factory setting.

e [f/\/5| Pump run-over time in minutes (starts when the heating mode has ended).

Adjust as follows or or go to the next step:

Lower: Decrease the time with the c button.

The minimum setting is [f/\/0| = 0 minutes. The factory default setting is 5 minutes.

CAUTION Do not set the post purge time to less than 5 minutes.

Higher: Increase the time with the d button.

The maximum setting is [f/6/0| = 60 minutes or [f/1/d| = 24 hours.

Table 7 Settings (continued)

http://www.buderus.net 29

Downloaded from www.Manualslib.com manuals search engine

Operating and error messages

Settings menu

e [c/\/1| DHW mode status setting. Adjust as follows, or press e:

DHW mode can be switched OFF or ON. This setting has priority over other DHW

mode settings, such as those made on the room thermostat.

Set the DHW mode with the c or d buttons. [c/\/1| means "ON", [c/\/0| means "OFF".

NOTE: Setting [c/\/0| also switches OFF the hot water cylinder frost protection.

After 5 seconds or after a power interruption the settings menu ends automatically. To

end manually press the e button. Any adjustments that you have made have been

confirmed.

Table 7 Settings (continued)

http://www.buderus.net 30

Downloaded from www.Manualslib.com manuals search engine

Operating and error messages

6.4 Display codes

The display shows the condition of the boiler with a code. The table below shows normal

operation codes. If a different code shows, please refer to section 6.5, "Identifying and resetting

faults" on page 34 .

Display codes

[\/-/\| Communication test while starting up.

[-/a/\] Any display code with a dot in the bottom right-hand corner.

dot The boiler is in flue gas test or service mode.

[-/h/\| The boiler is in heating mode.

[-/h/} Any display code with a flashing dot in the bottom right-hand corner.

flashing The boiler is in manual operation mode.

dot

Table 8 Display codes

http://www.buderus.net 31

Downloaded from www.Manualslib.com manuals search engine

Operating and error messages

Display codes

[=/h/\| The boiler is in DHW (domestic hot water) mode, or

The boiler is in pump run-over time via the external hot water cylinder

130 seconds at the minimum speed. The "Burner" LED (On/Off) is off.

[0/a/\| Boiler interval circuit.

The boiler cannot start-up more than once every 10 minutes. This program is acti-

vated if there has been a DHW request from an RC regulator more frequently

than once every 10 minutes.

[0/c/\| The boiler prepares for a burner start-up.

There is a current heat demand or a DHW request.

[0/e/\| The boiler is standby.

There is a current heat demand, but too much energy has been supplied.

[0/h/\| The boiler is standby. There is no current heat demand.

[0/l/\| Ignition phase. The gas valve is activated.

Table 8 Display codes (continued)

http://www.buderus.net 32

Downloaded from www.Manualslib.com manuals search engine

Operating and error messages

Display codes

[0/u/\| Start-up phase. The boiler starts up after activation of the main power supply or

completion of a system reset.

[0/y/\| The flow temperature is higher than set.

[2/e/\| Fault (subcode [2/0/7|). The system pressure is too low (less than 3 psi (0.2 bar)).

[8/8/8| Display test during start-up phase (max. 1 second).

The system pressure is too low (less than 12 psi (0.8 bar)).

[h/\/7|

[h/\/7| The system pressure is too low (less than 12 psi (0.8 bar)).

[p/?/?| The system pressure is too high (higher than 58 psi (4.0 bar)).

[\/r/e| The boiler is resetting.

Table 8 Display codes (continued)

http://www.buderus.net 33

Downloaded from www.Manualslib.com manuals search engine

Operating and error messages

6.5 Identifying and resetting faults

If a fault occurs, the error code flashes ON and OFF

on the display of the BC10 basic controller.

Push the "Reset" button for approx. 5 seconds to

reset the fault.

The display shows "rE" while resetting. Reset is only

possible if there is a flashing error message.

If the display then shows a normal operation

message from tabel 8, this means that the fault has

been remedied. If the fault recurs, you must repeat

resetting two or three more times.

If the fault cannot be reset:

Write down the error message and contact your

heating equipment service company.

Make sure that the heating system is not damaged

by frost (see the safety instructions in chapter

“Shutting down the boiler” on page 24).

http://www.buderus.net 34

Downloaded from www.Manualslib.com manuals search engine

Notes

http://www.buderus.net 35

Downloaded from www.Manualslib.com manuals search engine

Bosch Thermotechnology Corporation

50 Wentworth Ave

6720646148 0001

Londonderry, NH 03053

Tel: (603)-552-1100 Fax: (603)-421-2719

Toll Free: 1-800-BUDERUS

www.buderus.net

Downloaded from www.Manualslib.com manuals search engine

You might also like

- Automotive Air Conditioning and Climate Control SystemsFrom EverandAutomotive Air Conditioning and Climate Control SystemsRating: 4 out of 5 stars4/5 (6)

- 320cl Hydraulic System-testing&AdjustingDocument60 pages320cl Hydraulic System-testing&Adjustingnegro83100% (7)

- Procedure To Diagnose Common Causes of Hard Steering in Certain Backhoe Loaders (4313, 5079)Document13 pagesProcedure To Diagnose Common Causes of Hard Steering in Certain Backhoe Loaders (4313, 5079)Jorge0% (1)

- Electrical Design CalculationsDocument88 pagesElectrical Design CalculationsStanley ClermontNo ratings yet

- Critical Wear Areas & Vacuum Test Locations: Valve & Pump BodiesDocument2 pagesCritical Wear Areas & Vacuum Test Locations: Valve & Pump BodiesAndersonNo ratings yet

- Piston Pump High Pressure - HPRDocument20 pagesPiston Pump High Pressure - HPRAlawdin Grand HydraulicNo ratings yet

- Allowable Nozzle LoadsDocument6 pagesAllowable Nozzle LoadskparthypanNo ratings yet

- Using CHEMCAD For Piping Network Design and AnalysisDocument51 pagesUsing CHEMCAD For Piping Network Design and AnalysisRawlinsonNo ratings yet

- HydraulicsDocument41 pagesHydraulicsbhadouriyaNo ratings yet

- GT 22 OperationDocument81 pagesGT 22 OperationFelipe Saraiva100% (1)

- Boiler Efficiency and SafetyDocument147 pagesBoiler Efficiency and SafetyPedro Henrique RebelattoNo ratings yet

- FSP PresentationDocument35 pagesFSP PresentationAshwani KumarNo ratings yet

- PG-PL Governor 36694Document54 pagesPG-PL Governor 36694Fahad Bashir67% (3)

- RDP Reciprocating Plunger Pump Brochure enDocument8 pagesRDP Reciprocating Plunger Pump Brochure enJavierAlvarezNo ratings yet

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- IGC Document 133 06 EDocument30 pagesIGC Document 133 06 Elutfirashid87No ratings yet

- Manuale Rinnova Cond SDocument72 pagesManuale Rinnova Cond SRuben TinoNo ratings yet

- Vela CompactDocument36 pagesVela CompactGaby GabrielNo ratings yet

- Vitogas 050-Ecd IsDocument28 pagesVitogas 050-Ecd IsIñaki GonzalezNo ratings yet

- American Residential Gas Water Heater Power Vent With FVIRDocument25 pagesAmerican Residential Gas Water Heater Power Vent With FVIRDmitriy SemakovNo ratings yet

- Users Manual: Wall-Mounted Condensing Gas Combi Boiler Buderus 500 - 24/C, 500 - 28/CDocument28 pagesUsers Manual: Wall-Mounted Condensing Gas Combi Boiler Buderus 500 - 24/C, 500 - 28/Cmcondic87No ratings yet

- CGa Series3 - CGi Series 4 Users Manual 0420 Web VersionDocument20 pagesCGa Series3 - CGi Series 4 Users Manual 0420 Web VersionSonaina KhanNo ratings yet

- Wallcon: Installation and User ManualDocument44 pagesWallcon: Installation and User Manualdimitri shalikianiNo ratings yet

- Manual de Servicio Knight LonchivarDocument52 pagesManual de Servicio Knight LonchivarNahum Cesar Hernandez SorianoNo ratings yet

- Worcester Bosch Greenstar 24i-28i Junior (EN)Document20 pagesWorcester Bosch Greenstar 24i-28i Junior (EN)Gisell ZapataNo ratings yet

- Buderus GA244 - 44 Installation ManualDocument72 pagesBuderus GA244 - 44 Installation ManualSaman SafdarNo ratings yet

- Econcept 50A 6bar ManualDocument36 pagesEconcept 50A 6bar ManualcrapciuNo ratings yet

- KBX-SER-Rev F Lochinvar Knight XL Boiler ManualDocument44 pagesKBX-SER-Rev F Lochinvar Knight XL Boiler ManualJeffery OsvoldNo ratings yet

- Greenstar 24-28 I Junior Combi Operating InstructionsDocument20 pagesGreenstar 24-28 I Junior Combi Operating InstructionsJake WestlakeNo ratings yet

- 03 ENG - THB - CmaxxDocument99 pages03 ENG - THB - Cmaxxlevuthien2902No ratings yet

- Co2refridgeapplication EngineeringDocument15 pagesCo2refridgeapplication EngineeringSior AlpinNo ratings yet

- Internal Compact Ci10 Ci13 Ci16Document24 pagesInternal Compact Ci10 Ci13 Ci16vr2No ratings yet

- TurboMAX Pro User ManualDocument8 pagesTurboMAX Pro User ManualPaulo BravoNo ratings yet

- Knight Service ManualDocument48 pagesKnight Service ManualKevin JonesNo ratings yet

- Water Heater Manual 318052-002 - American Water Heater CompanyDocument32 pagesWater Heater Manual 318052-002 - American Water Heater CompanybowcoastieNo ratings yet

- EcoMAX User ManualDocument12 pagesEcoMAX User ManualMichail KyriakidisNo ratings yet

- Steam O&MDocument28 pagesSteam O&MmadiNo ratings yet

- Isomax: This Is A Cat I2E+ ApplianceDocument32 pagesIsomax: This Is A Cat I2E+ AppliancePéter BegidsánNo ratings yet

- Vitotronic 100 CTC HC1Document28 pagesVitotronic 100 CTC HC1Florin BocanetNo ratings yet

- Water Characteristics - B002Document14 pagesWater Characteristics - B002Buddhi Raj SharmaNo ratings yet

- Vitodens 100-B1ha IsDocument92 pagesVitodens 100-B1ha IsIancu AndreiNo ratings yet

- Combat 040 PGPDocument62 pagesCombat 040 PGPPaul BoultonNo ratings yet

- Bosch Standard User ManualDocument20 pagesBosch Standard User ManualZian HennNo ratings yet

- ProMax® High EfficiencyDocument32 pagesProMax® High EfficiencyMSILVAJRNo ratings yet

- Owner's Manual: WarningDocument14 pagesOwner's Manual: WarningfptstopNo ratings yet

- Vitodens 100 W Service InstructionsDocument100 pagesVitodens 100 W Service InstructionsbruatiNo ratings yet

- Calentador de Agua PiscinaDocument67 pagesCalentador de Agua Piscinacristyan manuel mateo liberatoNo ratings yet

- User Manual For Greenstar Si Manufactured From Feb 2011Document24 pagesUser Manual For Greenstar Si Manufactured From Feb 2011horace35No ratings yet

- Installation & Servicing Instructions: Powermax HEDocument44 pagesInstallation & Servicing Instructions: Powermax HENakama Sombrero de PajaNo ratings yet

- Intalaccion Calentador de Paso Rheem PDFDocument84 pagesIntalaccion Calentador de Paso Rheem PDFedenfriasNo ratings yet

- Generador de Vapor Cu360Document36 pagesGenerador de Vapor Cu360Jonatan medran ochoaNo ratings yet

- FB4 Installation ManualDocument12 pagesFB4 Installation ManualArturo ValladaresNo ratings yet

- Installation and Servicing InstructionsDocument40 pagesInstallation and Servicing InstructionsOwain JonesNo ratings yet

- Calentador ManualDocument52 pagesCalentador Manualspanpict8905No ratings yet

- 4P457484-1B - DBP - Manual de Operação - Controle Sem FioDocument24 pages4P457484-1B - DBP - Manual de Operação - Controle Sem FioIocas SoluçõesNo ratings yet

- CGa Series 3 Boiler Manual 0520Document68 pagesCGa Series 3 Boiler Manual 0520Sonaina KhanNo ratings yet

- LGB Manual 1Document40 pagesLGB Manual 1maver2rickNo ratings yet

- Aplicación para Compresores Scroll ZB CopelandDocument12 pagesAplicación para Compresores Scroll ZB CopelandelperpetuoNo ratings yet

- RTGH ManualDocument84 pagesRTGH ManualRichardNo ratings yet

- Winterwarm DXC Manual DXC - ENDocument28 pagesWinterwarm DXC Manual DXC - ENdancdcNo ratings yet

- Buderus Installation Manual GB142Document64 pagesBuderus Installation Manual GB142plunkplunkNo ratings yet

- Leopard: User and Installation InstructionsDocument34 pagesLeopard: User and Installation InstructionsDrraggan GabborrovNo ratings yet

- Whirlpool HPE2K80HD046V Manual enDocument22 pagesWhirlpool HPE2K80HD046V Manual enJohn WalesNo ratings yet

- Eberspacher Heater D24W D30W Repair and Parts ManualDocument44 pagesEberspacher Heater D24W D30W Repair and Parts ManualRomas VarnaNo ratings yet

- 2mcw-2mww Manual de Usuario Op R-22Document20 pages2mcw-2mww Manual de Usuario Op R-22Anonymous DOHIEjNo ratings yet

- Ae-1376 R4Document24 pagesAe-1376 R4Nelson GutierrezNo ratings yet

- I200 I250 Gen II V2 Manual 08 31 2021Document64 pagesI200 I250 Gen II V2 Manual 08 31 2021tommyatNo ratings yet

- 4825 - Itelco Clima AQL 100Document63 pages4825 - Itelco Clima AQL 100ZakiFroidNo ratings yet

- Cadet Boiler Installation ManualDocument92 pagesCadet Boiler Installation ManualAnonymous pkqcrsfmF100% (1)

- Installation & Service Manual Models: 497 - 2067: - What To Do If You Smell GasDocument72 pagesInstallation & Service Manual Models: 497 - 2067: - What To Do If You Smell GasSamuel HernándezNo ratings yet

- Group 5 RCV Lever: 1. StructureDocument7 pagesGroup 5 RCV Lever: 1. StructurethierrylindoNo ratings yet

- KG084 DDR NDC115 14020505 75 0Document2 pagesKG084 DDR NDC115 14020505 75 0reza hosseiniNo ratings yet

- L1.0406-L1.0807 BreathersDocument8 pagesL1.0406-L1.0807 BreathersShirdish PatilNo ratings yet

- Process Equipment Design 1Document26 pagesProcess Equipment Design 1KaizerNo ratings yet

- Tetra Aldose: Aseptic In-Line DosingDocument2 pagesTetra Aldose: Aseptic In-Line DosingcarloscarinelliNo ratings yet

- BOMBA NEUMATICA ARGAL-ASTRA-EVO-DDE-Instruction-Manual-rev-11-2021Document58 pagesBOMBA NEUMATICA ARGAL-ASTRA-EVO-DDE-Instruction-Manual-rev-11-2021Jose Luis Ari AchahuiNo ratings yet

- Fuel - in Tank Fuel Pump Replacement PDFDocument14 pagesFuel - in Tank Fuel Pump Replacement PDFBeniamin KowollNo ratings yet

- Fakulti Teknologi Kejuruteraan Mekanikal Dan Pembuatan Universiti Teknikal Malaysia MelakaDocument17 pagesFakulti Teknologi Kejuruteraan Mekanikal Dan Pembuatan Universiti Teknikal Malaysia MelakasyukzzNo ratings yet

- Submitalls Bomba 250 GPM A 101 Psi ElectricaDocument65 pagesSubmitalls Bomba 250 GPM A 101 Psi Electricajuan velandiaNo ratings yet

- Updated Startup Procedure - FD West - Hyduke - Phoenix Manual Rev 03Document31 pagesUpdated Startup Procedure - FD West - Hyduke - Phoenix Manual Rev 03Francisco Wilson Bezerra FranciscoNo ratings yet

- Fives Cryogenics DELTA N BrochureDocument2 pagesFives Cryogenics DELTA N BrochureAhmed BenjellounNo ratings yet

- 03-2022-Connections Newsletter DoosanDocument8 pages03-2022-Connections Newsletter DoosanGEOVANNINo ratings yet

- Critical Parts ListDocument8 pagesCritical Parts ListMaintenance PlannerNo ratings yet

- Mini & Maxi Orange Pump: / BombaDocument15 pagesMini & Maxi Orange Pump: / BombaPaulitha AlejithaNo ratings yet

- 2011 McQuay Chilled Water CatalogueDocument26 pages2011 McQuay Chilled Water CatalogueRCYABONo ratings yet

- Watex Pumps Industries, Qwzu - Ex27019 - Ul Product SpecDocument10 pagesWatex Pumps Industries, Qwzu - Ex27019 - Ul Product SpecAzhar HussainNo ratings yet

- Integrated Water Resources Management / Akhouryan River: ArmeniaDocument2 pagesIntegrated Water Resources Management / Akhouryan River: ArmeniaLaperaNo ratings yet

- Fuel System 2Document5 pagesFuel System 2Falgon IslamNo ratings yet