Professional Documents

Culture Documents

KG084 DDR NDC115 14020505 75 0

Uploaded by

reza hosseiniOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

KG084 DDR NDC115 14020505 75 0

Uploaded by

reza hosseiniCopyright:

Available Formats

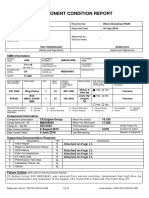

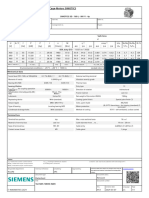

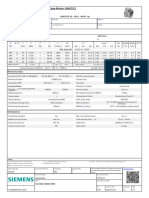

Daily Drilling Report

I.G.E.D.C

Gas Storage Development in Khangiran Field, Shurijeh “D” Reservoir Form Code: FO-TO-338-01

General Data

Country/ Province Iran / Khorasan Razavi Well Type Appraisal W.S.S. Day/ Night E.Shehni / M.Onagh Report No. 75

Field/ Well / Loc No. KHANGIRAN/ KG-084 / NW08 Spud Date/ Time 1402.02.24 / 06:00 Area Manager M.Aliabadi Report Date 7/27/2023 (1402.05.05)

Rig Contractor / Rig Name North Drilling Co. / 115 Est. Rig Days 135 Operation Manager M. Amini Actual Rig Days 75

Sub Surface Contractor Mapna Drilling Co. Hole Section 8 1/2" Geologist M.Ghasemi / H.Momenzadeh

Act Rig Days less NPT 64 Days + 17.5 hrs

Client IGEDC Section Start Date 1402.05.01 Senior/ Night Toolpusher J.Nasiri / A.Tavasoli

Well Data Bit Data Mud Data

Y (m) 4,036,775.81 Bit No. 7RR1 Mud Type CaCO3 / Polymer

Location (UTM):

X (m) 312,396.74 Bit Size TCI/ MT/ PDC 8 1/2" x 4" core head MW Min / Max (pcf) 68 / 69

Project TD (m): 3170 Bit Manufacture BESTE Flow Line Temp. (deg F) 140

R.T.E (m) G.L.E (m) 453.5 443 Bit Type MC13122 Funnel Vis (sec/qrt) 38

Morning Depth (m) 3090.5 Bit Serial No. 248482 Fann 600 26

Mid Night Depth (m) 3090.5 IADC Code M132 Fann 300 18

Previous Depth (m) 3084.0 Nozzle Number * Size ( /32 in) Fann 200/ 100 14 / 10

Drilled Interval (m) 6.5 W.O.B (klb) 8-12 Fann 6/ 3 5/3

Drilling Time (hr) 3.5 RPM / Total bit RPM 50-70 / 26085 PV (cp) 8

Average ROP (m/hr) 1.86 Torque (klb.ft) 1-3 YP (lb/100 sqft) 10

Cum. DRLG Time (hr) 691.5 Pump Type F1600 GEL 10 s/ 10 min/ 30 min 3/4/

Estimated / Actual Rig Days 135 75 Pump Liner Size (in) 6.7 / 6.3 / 6.3 API Fluid Loss (cc/30 min) 5.5

KOP (m) - Flow Rate (gpm) 255 Mud Cake Thickness (1/32") 0.5

Last Formation MD TVD (m) Shurijeh-D 3072 Standpipe Pressure (psi) 375 Oil % 0

Lithology Sst TFA (in2) Water % 92

Last casing/ liner shoe 9 5/8" CSG Shoe @ 3070 m Jet Velocity (ft/s) Solid/ Sand Content (%) 8/0

Last liner lap (m) Bit Daily Drilled (m) 6.5 Salinity(ppm)/Chlorides (mg/l) / 93000

Last FIT TVD (m) EMW (pcf) Bit On BTM Hours 3.5 PH / MBT 9.8 / 0

Waste Management Consumption Waste Management Data Cum Drill Out CMT/ Ream (m) - Total Hardness/Calcium (mg/l) 960 / 880

Cement/(Coagulant) [sxs] Recycled (m3) 100 Cum Drill Out CMT/ Ream (hr) / KCl (%WT)/ Glycol (%Vol) 0

Sodium Silicate [drum] PH 8.5 Bit Cum. Drilled (m) (Prev.: 36)+ 9 Vol. in Hole (bbl) 646

Soda Ash/(Citric Acid) [sxs] /1 Turbidity (ntu)/TSS 147 / 136 Bit Cum. Hours (Prev.: 35.5)+ 8 Vol. in Pits (bbl) 802

Anionic Flocculant [sxs] Ca++(mg/lit) 1240 Bit In / Bit Out(m) 3081.5 / Mud Sys./ Daily Made (bbl) 906 / 72

Lime [sxs]/(Biocide) [drum] 5/ Hardness (mg/lit) 1520 Bit Dull Condition Form. Loss/ MP Repair/ Sand Trap 0/0/0

Caustic Soda [CAN]/Coagulant Cutting Trans.(m3) Weight Below Jar in mud (klb) 30 Evap./ Shaker/ Pit Cleaning / Others 8 / 5 / 86 / 0

Mud Materials & Chemicals BHA # 15 Dump/ Trip/ Centrifuge/ M. Cleaner 0/0/0/0

Material Type Unit Rec/ Sent Used STK Item Description Length (m) OD (in) ID (in) Cum. L. (m) Total Loss 99

Barite 1.5 MT 12 8 1/2" x 4" core Head 0.3 8 1/2 4 0.30 POB

Bentonite 1 MT 11 8 15/32" S.Stab (N.B) 1.03 8 15/32" 1.33 MDCO 8

Soda Ash 25 kg 4 31 1 Jt 6 3/4" outer tube 7.67 6 3/4 9.00 Client

Salt (NaCl) 1 MT 11 80 6 3/4" slick sub 0.995 6 3/4" 10.00 Services Catering 25 14

Caco3 (Weight agent) 1 MT 28 8 15/32" S.Stab 0.56 8 1/2 10.56 Rig crew Guests 40

Caustic Soda 25 kg 50 6 3/4" safety joint 0.73 6 3/4 11.29 Casual labors 13

H2S Scavenger / O2 Scv. 55 Gal 5/8 D.Pin 4 1/2" IF x 4 1/2" REG 0.59 6 7/8 2 1/4 11.88 Drivers 13

Xanthan Gum 25 kg 12 58 BIT SUB (W/ F.V) 1.06 6 1/2 3 12.94 Security 8

Starch 25 kg 89 415 5 STD 6 1/2" DC 135.59 6 1/2 2 7/8 148.53 Total 121

Lime 25 kg 18 12 6 1/2" D.Jar 9.31 6 1/2 2 3/4 157.84 HSE

184.99 Cum / Last

Nut plug (F-M-C) 25 kg 53 / 74/ 80 1 STD 6 1/2" DC 27.15 6 1/2 2 7/8 HSE Cases Daily

Date

CaCO3 (M/C) 1 MT 2/2 1 STD 5" HWDP 27.44 5 3 212.43 LTI free days 1 215

MICA (F-M) 25 kg 80 / 80 Man-hours 1452 100420

Oyster shell ( F-M-C) 25 kg 80 / 80 / 86 LTI Accidents 0 0

Quickseal (F-M-C) 25 kg 80 / 80 / 80 Non LTI Accidents 0 0

drilling detergent 55 gal 2 BHA # BOP Drill 0 2 / 02.04.31

PAC-LV 25 kg 71 Description length(m) OD (in) ID (in) Cum. L. (m) H2S Drill 0

Sulphonate Asphalt 25 kg 70 Fire Drill 0 10 / 02.04.31

Corrosion Inhibitor 55 gal 8 Medevac Drill 0 1 / 02.03.24

PIPELAX 55 gal 3 5 Stop Card 3 207

Defoamer 55 gal 11 PJSM 0 5

Biocide / Spersene 55 gal 2 / 50 Toolbox Meeting 3 217

Sodium Bicarbonate 25Kg 78

KCL / (CaCl2) 1 MT 4 / (2)

Citric Acid 25 kg 95

Cement & Cement Additive

Mat. Type Unit Rec/ Sent Used STK

Pumps Data

CMT "G" Kerman Sxs

CMT "G" W/Hidense Sxs Pump # 1 Pump # 2 Pump # 3

NaCl-Salt (1ton) bb Make Bamco Bamco Bamco

Antifaom Agent AA-01 can Type F-1600 F-1600 F-1600

Dispersant FR-02 sxs Size (in) Class Grade Nominal Weight (ppf) Power (hp) 1600 1600 1600

Light Weight Additive dr DP 5" G-105 S-135 19.5 19.5 Liner Size (in) 6/7 6.3 6.3

FLC 03/02 dr/sxs HWDP 5" 49 Stroke (in) 12 12 12

chemical wash, CW-01 can DC 6 1/2" 169 93 Max Press (psi) 3350 3750 3750

Retarder(Boric acid) sxs Down Hole Equipment

Accelerator sxs Equipment (Quantity, OD and Description) ID (in) Serial Number Cum Drlg (hr) Cum W&R/ D/O (hr)

Cement Equipment 6 1/2" DC 11204, 1101102, 112036, NDC1146005, NDC11261, 0/5

2 7/8 17

7115221, 503518, 533303, 11308, 709, NDCK13,

Equipment Unit Rec Send STK 5" HWDP 3 N/A 82 0/5

Cement Unit no 1 6 1/2 " D.Jar 2 3/4 620 8.5 0/0

Solution Tank no 2

CMT Silo no 4 Solid Control Equipment

Hook Load Data

Air Compressor no 1 Equipment Working Time (hr) Remarks

Batch Mixer no Shakers 1 / 2 / 3 21 0 0 4*200/ 2*120+2*140/ 2*165+2*140 H.L (Klb) Pump On Pump Off

Fuel & Water Desilter / Desander / Degasser 0/0/0 Pick Up 276

Fluid Type Unit Rec. Used STK Mud Cleaner 0 4*250 Slack-Off 278

DIESEL (Rig / Camp) Liter 29,000 9,000 91000 / 4000 Centrifuge #1 / #2 0 0 Rotation 273

Drill Water bbl 210 1,300 Super Clone TDS & Block Weight 58 Klb

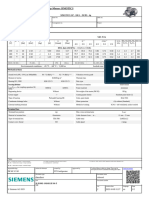

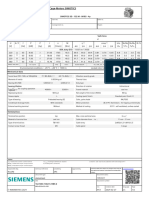

KOP : Survey Casing Data

No. MD (m) INC (deg) AZ (deg) TVD (m) NS EW DLS Remark Casing Size Liner Lap

Grade Weight (ppf) Thread Length (m)

1 159.0 1.0 N/A TOTCO (in) (m)

2 622.0 1.0 N/A TOTCO 20 K-55 133.0 BTC 159.5 159.5

3 1290.0 1.00 N/A TOTCO 13 3/8 N-80 72 & 68&72 BTC 387.2/1155.2/22.6 1565.0

4 9 5/8 P110 - L80 53.5& 47 &53.5 PJE (New Vam) 1280/1766.5/23.5 3070.0

5 7

6

7

8

Daily Drilling Report

Gas Storage Development in Khangiran Field, Shurijeh “D” Reservoir

I.G.E.D.C

Form Code: FO-TO-338-01

Formation Data Well Control (SCR)

Forecasted MW (pcf)/ SPP 1

Formation Name Actual Top (m) Lithology SPM# 1 SPM# 2 SPP 2 (psi) Depth (m) Time

Top (m) FV (s/qrt) (psi)

Khangiran Surface Surface Clst/ Mrl / Sh / Sst 1

Chehel-Kaman 813 801.0 Lst/ Anhy/ Sh/ Clst/ Dol 2

Pesteh-Leigh 1021 1011.0 Rd Clst/ Sst/ Lst/ Sh/ Clst 3

Kalat 1108 1092.0 Dol / Anhy/ Sdy Lst/ Lst/ Clst/ Mrl

Wellhead BOP Test Record

Neyzar 1152 1149.0 Sdy Lst/ Sst/ Clst/ Mrl

Abtalkh 1457 1424.0 Clst/ Sh/ Mrl

Component Top FLG (Size/ WP) BTM FLG (Size/ WP) Component Type and Size Test Pressure

Abderaz 1567 1549.0 Lst/ Clst/Mrl/Sh

Atamir 2024 1999.0 SlClst/Sst/Clst/Mrl/Lst Xmas Tree

Annular 5k - 13 5/8" 2500 psi

(TOP Sec.)

Sanganeh 2488 2463.0 Clst/Shale/SltyClst/Slst Xmas Tree

Top Rams 5" fix, 5k - 13 5/8" 4500 psi

(BTM Sec.)

Sarcheshmeh 2836 2809.0 Lst, Arg Lst,Mrl, Clst THS 11" / 5K 13-5/8" / 5K Blinde Rams 5k - 13 5/8" 4500 psi

Tirgan 3043 3014.0 Lst, Clst, Sh DSA P. Off 13 5/8" / 5K 13 5/8" / 5K Bottom Rams 5" fix, 5k - 13 5/8" 4500 psi

Shurijeh-E 3082 3060.0 Rd Clst, Gry Clst, Anhy CHS 13 5/8" / 5K 21 1/4" / 2K Choke Manif. 10K 4500 psi

Shurijeh-D 3097 3072.0 SSt CHH 21 1/4" 2-K Welded Accumulator 3K function test

Shurijeh-C 3144 LAST BOP TEST Date 1402.04.29

Wear Bushing Size: 11" IN/ OUT: IN

Well TD 3170 Days Since Last BOP Test 7

Received

Sent

Request

Outstanding

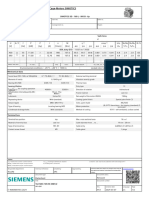

Detail of Operations within Last 24 hours

Code /Activity Hrs From To Hrs Code Remarks

1. Rigging and Moving 00:00 Cont. coring F/ 3084 to 3090.5 m (end of coring point), NL-NG (Lithology: Sst).

2. Drilling 03:30 3.5 4A Coring parameters: WOB: 8-12 klb, Rot.: 50-70 rpm, F.R: 255 gpm, SPP: 375 psi, TQ: 1-3 klb*ft, Avg. ROP: 1.8 mph.

3. Hole Conditioning 03:30 In order to cut the core, P/U string (as 30 cm) and got 15 klb overpull, slack off 5 klb of Strg weight, apply again 15 klb overpull, apply rotation to

4. Coring 4.0 cut the core, "No Succ." (TQ. increased to 7 klb*ft & string stalled), Release the TQ., slack off string to neutral point weight & try to apply rotation

5. Mud Condition & Circ. (Max. 9 klb*ft TQ.), No Succ., Strg was stucked.

6. Trips >> Normal parameters before stuck: PUHL/SOHL/ROT.: 276/278/273 klbs and Rot.: 70 rpm, TQ: 1-3 klb*ft, F.R: 255 gpm, SPP: 375 psi.

7. Rig Services >> The parameters after stuck: F.R: 255 gpm, SPP: 375 psi, weak point: The first Jt of 5" DP grade "G" @ 900 m, Max allowable overpull: 175 klb).

8. Slip and Cut DRLG Line Pump 30 bbl HVP, work on stuck with Max. 80 klb overpull (gradually) & F.R: 300 gpm, SPP: 450 psi and Max. 9 klb*ft right hand TQ. (in neutral

9. Deviation Survey point) several times, No Succ.

10. Logging 09:00 5.5 22E >> Detect Max. 8.6 % TG while work on stuck & gradually decreased to "zero".

11. Running Casing/ Liner 09:00 11:30 2.5 22E While work on stuck with Max. 80 klb overpull (350 klb on WT indicator) & F.R: 300 gpm, SPP: 450 psi, increase MW F/ 68 to 69 pcf.

12. Cementing 11:30 Made 30 bbl (15 bbl pumpable) pipelax, pump & displace same while spot it in Ann. (step by step) around coring BHA (step#1: 5bbl, step#2: 2.5

13. Nipple up/ down bbl, step#3: 2.5 bbl, step#4: 2.5 bbl) & work on stuck w/ applying gradually max 120 klbs overpull & also Max. 9 klb*ft right hand TQ. (in neutral

14. BOP Test 21:00 9.5 22E weight point ), string got free after several attempts (Check Strg weight: same as before stuck).

15. Formation Testing 21:00 POOH to 3045 m (inside 9 5/8" CSG shoe), Circ. out 90 bbl contaminated mud with pipelax. Cont. Circ. mud to balance in & out (No detected any

16. Directional Drilling 23:30 2.5 22E gas in Btm's up).

17. Well Completion 23:30 24:00 0.5 6L Obs. The well, " Static".

18. Perforation

19. Stimulation

20. Production & Well Testing

21. Suspension/Abandonment Note: 20 Hrs. NPT due to work on stuck.

22. NPT 20.0 >> 13 3/8" x 9 5/8" Ann. Press: 50 psi.

23. Other >> Work on VSP pit is in progress.

>> Rig personnel shortage: 1 person day shift Roughneck + 1 person night shift Roughneck.

Offline Operation:

>> Monitor space between the rig's sub-base & well pad: 3.5 cm @ 24:00'.

>> Rec. 3 loads (210 bbl) drilling water on location.

*** Rig shortages:***

1- lack of spare parts of mud tank equipments (butter fly valves, plug valves) and mud pumps (Liner, P.Gauge, …). 2- There is no spare parts for

ground manifold valves. 3- Clinic and Ambulance equipment shortage. 4- Some caravans need to be repaired. 5- Walkie-talkie (2 No.). 6- Lack of 4

1/2"x7" VBR ram. 7- 1No. of VFD air conditions is out of service.

24.0 24.0

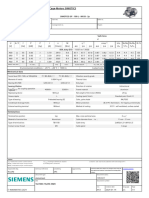

From To Hrs Code Morning Report

00:00 POOH coring Assy. F/ 3045 to 1600 m while Circ. mud across wellhead, NL-NG.

06:00 6.0 4A >> POOH speed: 8 STD / Hr. as per coring supervisor instruction.

>> 13 3/8" x 9 5/8" Ann. Press: 50 psi.

Total (Hrs) 6.0

Operations Summary

Cont. coring F/ 3084 to 3090.5 m (end of coring point), NL-NG. Try to cut the core, Strg was stucked, spot pipelax in Ann. & work on stuck w/ applying max 120 klbs overpull & also Max. 9 klb*ft right hand TQ., string got free

after several attempts. POOH to 3045 m, Circ. out contaminated mud with pipelax & Obs. The well," Static".

Next Operations

Cont. POOH coring Assy. to Surf. & recover the core. P/U & M/U Coring Assy. (2 Jts Core barrel) & RIH to 3090.5 m. Perform the second run of coring operation.

You might also like

- Manufacturing Surface Technology: Surface Integrity and Functional PerformanceFrom EverandManufacturing Surface Technology: Surface Integrity and Functional PerformanceRating: 5 out of 5 stars5/5 (1)

- Daily Drilling ReportDocument3 pagesDaily Drilling ReportHamed NazariNo ratings yet

- Daily Drilling Report: Danan Oilfield DevelopmentDocument3 pagesDaily Drilling Report: Danan Oilfield DevelopmentHamed NazariNo ratings yet

- Da13 DDR N1 13991207 164 0Document3 pagesDa13 DDR N1 13991207 164 0Hamed NazariNo ratings yet

- Da13 DDR N1 13991129 156 0Document3 pagesDa13 DDR N1 13991129 156 0Hamed NazariNo ratings yet

- Da13 DDR N1 13991115 142 0Document3 pagesDa13 DDR N1 13991115 142 0Hamed NazariNo ratings yet

- Da13 DDR N1 14000229 247 0Document3 pagesDa13 DDR N1 14000229 247 0Hamed NazariNo ratings yet

- Da13 DDR N1 14000104 191 0Document3 pagesDa13 DDR N1 14000104 191 0Hamed NazariNo ratings yet

- Da13 14000103 190 0Document3 pagesDa13 14000103 190 0Hamed NazariNo ratings yet

- Da DDR N1 1Document3 pagesDa DDR N1 1Hamed NazariNo ratings yet

- Daily Drilling Report: Danan Oilfield DevelopmentDocument3 pagesDaily Drilling Report: Danan Oilfield DevelopmentHamed NazariNo ratings yet

- Da13 DDR N1 13991130 157 0Document3 pagesDa13 DDR N1 13991130 157 0Hamed NazariNo ratings yet

- Da13 DDR N1 13991121 148 0Document3 pagesDa13 DDR N1 13991121 148 0Hamed NazariNo ratings yet

- Da13 DDR N1 13991122 149 0Document3 pagesDa13 DDR N1 13991122 149 0Hamed NazariNo ratings yet

- Daily Drilling Report: Danan Oilfield DevelopmentDocument3 pagesDaily Drilling Report: Danan Oilfield DevelopmentHamed NazariNo ratings yet

- Da13 DDR N1 14000305 254 0Document3 pagesDa13 DDR N1 14000305 254 0Hamed NazariNo ratings yet

- Daily Drilling Report: Danan Oilfield DevelopmentDocument3 pagesDaily Drilling Report: Danan Oilfield DevelopmentHamed NazariNo ratings yet

- Da13 DDR N1 13991116 143 0Document3 pagesDa13 DDR N1 13991116 143 0Hamed NazariNo ratings yet

- Da13 DDR N1 14000316 265 0Document3 pagesDa13 DDR N1 14000316 265 0Hamed NazariNo ratings yet

- Daily Drilling Report: Danan Oilfield DevelopmentDocument3 pagesDaily Drilling Report: Danan Oilfield DevelopmentHamed NazariNo ratings yet

- Daily Drilling Report: Danan Oilfield DevelopmentDocument3 pagesDaily Drilling Report: Danan Oilfield DevelopmentHamed NazariNo ratings yet

- Daily Drilling Report: Danan Oilfield DevelopmentDocument3 pagesDaily Drilling Report: Danan Oilfield DevelopmentHamed NazariNo ratings yet

- Daily Drilling Report: Danan Oilfield DevelopmentDocument3 pagesDaily Drilling Report: Danan Oilfield DevelopmentHamed NazariNo ratings yet

- Da14 DDR N2 14000103 175 0Document3 pagesDa14 DDR N2 14000103 175 0Hamed NazariNo ratings yet

- Daily Drilling Report: Danan Oilfield DevelopmentDocument3 pagesDaily Drilling Report: Danan Oilfield DevelopmentHamed NazariNo ratings yet

- Da13 DDR N1 14000315 264 0Document3 pagesDa13 DDR N1 14000315 264 0Hamed NazariNo ratings yet

- Daily Drilling Report: Danan Oilfield DevelopmentDocument3 pagesDaily Drilling Report: Danan Oilfield DevelopmentHamed NazariNo ratings yet

- Daily Drilling Report: Danan Oilfield DevelopmentDocument3 pagesDaily Drilling Report: Danan Oilfield DevelopmentHamed NazariNo ratings yet

- Daily Drilling Report: Danan Oilfield DevelopmentDocument3 pagesDaily Drilling Report: Danan Oilfield DevelopmentHamed NazariNo ratings yet

- Da14 DDR N2 13991117 129 0Document3 pagesDa14 DDR N2 13991117 129 0Hamed NazariNo ratings yet

- Daily Drilling ReportDocument3 pagesDaily Drilling ReportHamed NazariNo ratings yet

- DDR1402 02 09Document26 pagesDDR1402 02 09Hamed Nazari100% (1)

- CCR JN 5646488-Sis-C9 Engine en Mbd09063-High BlowbyDocument15 pagesCCR JN 5646488-Sis-C9 Engine en Mbd09063-High Blowbyahmat ramadaniNo ratings yet

- FAR Transmission PEX 3030 300 766Document4 pagesFAR Transmission PEX 3030 300 766yohanes moningkaNo ratings yet

- Silnik - Karta Katalogowa 1LE1002 1AB42 2FA4 Z Y99Document2 pagesSilnik - Karta Katalogowa 1LE1002 1AB42 2FA4 Z Y99artur.sowaNo ratings yet

- Steel Design (Track 2) Beam 9957 Check 1: Job No Sheet No RevDocument2 pagesSteel Design (Track 2) Beam 9957 Check 1: Job No Sheet No RevwaquarstrNo ratings yet

- NOV Drill Bits New Technologies Helios Cutters and Hybrid FuseTek Bit To Drill Silurian and Ordivician On Rotary ModeDocument27 pagesNOV Drill Bits New Technologies Helios Cutters and Hybrid FuseTek Bit To Drill Silurian and Ordivician On Rotary ModeSlim.BNo ratings yet

- FAR D6R LH Final Drive FailureDocument9 pagesFAR D6R LH Final Drive Failurealisa alainaNo ratings yet

- CML 1borehole Log NakambeleswaDocument9 pagesCML 1borehole Log NakambeleswaJohannes KyaruziNo ratings yet

- 1LE1603-1DC43-4AB4-Z H01+Q01 Datasheet enDocument2 pages1LE1603-1DC43-4AB4-Z H01+Q01 Datasheet ennarminaNo ratings yet

- Daily ReportDocument4 pagesDaily ReportAhmedNo ratings yet

- 1le1523 1eb43 4FB4Document2 pages1le1523 1eb43 4FB4pmf engineering limitedNo ratings yet

- Colocation Application Form (CAF) : Bogor West Java 03CBN251 BatujajarDocument1 pageColocation Application Form (CAF) : Bogor West Java 03CBN251 BatujajarPanji LanangNo ratings yet

- Daily Drilling Report: Bha Tally Bit Record Mud Report Mud PumpDocument26 pagesDaily Drilling Report: Bha Tally Bit Record Mud Report Mud PumpHamed NazariNo ratings yet

- 1LE1601 2DC03 4AB4 Z L51 Datasheet enDocument2 pages1LE1601 2DC03 4AB4 Z L51 Datasheet enFaziNo ratings yet

- Procedure Qualification Record (PQR) Pipeline: Metal Nonfusing Metal Nonmetallic OtherDocument2 pagesProcedure Qualification Record (PQR) Pipeline: Metal Nonfusing Metal Nonmetallic OtherPanneer SelvamNo ratings yet

- 1LE1023-1AA43-4AB4-Z L22+L23 Datasheet enDocument2 pages1LE1023-1AA43-4AB4-Z L22+L23 Datasheet enTien NguyenNo ratings yet

- DDR # 324 - Dhok Sultan 02 ST-1 - (CCDC-23) - 25.04.2021Document3 pagesDDR # 324 - Dhok Sultan 02 ST-1 - (CCDC-23) - 25.04.2021Maryem ZubairNo ratings yet

- 1le1523 1eb43 4ab4Document2 pages1le1523 1eb43 4ab4pmf engineering limitedNo ratings yet

- CCR 980NG AbkDocument13 pagesCCR 980NG AbkSMKN 6 SAMARINDA PANGESTUNo ratings yet

- 1LE1604 1DB43 4GB4 Datasheet enDocument1 page1LE1604 1DB43 4GB4 Datasheet ennarminaNo ratings yet

- 1LE1503-1CB21-7AB4-Z B02+D22+L22+Y82 Datasheet enDocument2 pages1LE1503-1CB21-7AB4-Z B02+D22+L22+Y82 Datasheet enMostafaElrakhawyNo ratings yet

- DGA-53H Drilling Fluid Report No 28Document1 pageDGA-53H Drilling Fluid Report No 28Over KeelNo ratings yet

- Workover Daily Report - PHR - Benar-066 - 2024-03-18Document7 pagesWorkover Daily Report - PHR - Benar-066 - 2024-03-18maikelmareaNo ratings yet

- L&t-Ut-Se-1678 - R1 30-03-2023Document1 pageL&t-Ut-Se-1678 - R1 30-03-2023SamirNo ratings yet

- 1MB1533-1EB49-0FB4-Z B43+M4B Datasheet enDocument2 pages1MB1533-1EB49-0FB4-Z B43+M4B Datasheet enrianandiyahooNo ratings yet

- 1LE1003-1AA43-4AB4 Datasheet enDocument1 page1LE1003-1AA43-4AB4 Datasheet enAhmed Mahmoud AliNo ratings yet

- Radiography OfferDocument1 pageRadiography OfferRavi patelNo ratings yet

- 1LE1503-1DB43-4FK4 Datasheet enDocument1 page1LE1503-1DB43-4FK4 Datasheet enNicolas RossettoNo ratings yet

- 3 Biochemical Engineering CH 3Document36 pages3 Biochemical Engineering CH 3yordanos gulilatNo ratings yet

- 2.1.2 AlkanesDocument25 pages2.1.2 Alkaneslocus448450No ratings yet

- Combinatorial Chemistry: Medicinal Chemistry & Drug Discovery II (MSB)Document34 pagesCombinatorial Chemistry: Medicinal Chemistry & Drug Discovery II (MSB)Md. Abir Hossain100% (3)

- Gaskets For Tunnel Segments PDFDocument10 pagesGaskets For Tunnel Segments PDFPratik SinhaNo ratings yet

- Assignment Week 10Document5 pagesAssignment Week 10Shikha SinghNo ratings yet

- V. Mosfet PDFDocument33 pagesV. Mosfet PDFleeminho_janxiNo ratings yet

- Vishay Transducer Application NotesDocument31 pagesVishay Transducer Application Notesxevi00No ratings yet

- Notes - Separation of SubstancesDocument4 pagesNotes - Separation of SubstancesJumayma MaryamNo ratings yet

- LearningmenuDocument6 pagesLearningmenuapi-480153144No ratings yet

- PROCIRC 9611: Circoat OspDocument5 pagesPROCIRC 9611: Circoat OspNgô TrungNo ratings yet

- EdExcel A Level Chemistry Unit 9 Mark Scheme Jan 2000Document3 pagesEdExcel A Level Chemistry Unit 9 Mark Scheme Jan 2000Nabeeha07No ratings yet

- ParacelsusDocument420 pagesParacelsusmassimo100% (12)

- Iodination of AcetoneDocument5 pagesIodination of Acetonearyajs2017No ratings yet

- Soil Stabilization From Mechanical MethodsDocument21 pagesSoil Stabilization From Mechanical MethodslazamNo ratings yet

- Suturing TechniquesDocument32 pagesSuturing TechniquesRez QNo ratings yet

- Application of Micronutrients in The Rice-Wheat Cropping Systems of South Asia: A ReviewDocument17 pagesApplication of Micronutrients in The Rice-Wheat Cropping Systems of South Asia: A ReviewAnuragNo ratings yet

- Specification FOR Electrical Insulation Coating: EDMS 29-300-1Document12 pagesSpecification FOR Electrical Insulation Coating: EDMS 29-300-1Mina RemonNo ratings yet

- Phoenix Metals Product Catalog 2012Document42 pagesPhoenix Metals Product Catalog 2012Norazmi Abdul RahmanNo ratings yet

- TDS - 3765 - Texotile Spray-On - Euk - GB PDFDocument3 pagesTDS - 3765 - Texotile Spray-On - Euk - GB PDFSomanith KoumNo ratings yet

- Grade 10 ProteinDocument29 pagesGrade 10 ProteinJaneNo ratings yet

- Waste Resources Recycling in Achieving Economic and Environmental Sustainability: Review On Wood Waste IndustryDocument10 pagesWaste Resources Recycling in Achieving Economic and Environmental Sustainability: Review On Wood Waste IndustryElena Raluca DraguNo ratings yet

- Difference Between Glycolysis and Krebs CycleDocument10 pagesDifference Between Glycolysis and Krebs CycleKuresh RabidNo ratings yet

- ALERT - MCC CENTRALINA - BO0349675320 - SIDOC PLANTA 2 ACERIAS - VALVULA DESLIZANTE 3 - 1 - en - EsDocument2 pagesALERT - MCC CENTRALINA - BO0349675320 - SIDOC PLANTA 2 ACERIAS - VALVULA DESLIZANTE 3 - 1 - en - EsLuis CortesNo ratings yet

- BernsteinMedical Post-Op Instructions FUTDocument6 pagesBernsteinMedical Post-Op Instructions FUTOmer JunaidNo ratings yet

- Z0628276 CDocument32 pagesZ0628276 CDavidgrilliniNo ratings yet

- (PDF) FINAL REPORT INORGANIC LABWORK SYNTHESIS Cis-K (CR (H2O) 2 (C2O4) 2) AND Trans-K (CR (H2O) 2 (C2O4) 2 - Dini Izzaty - Academia - Edu PDFDocument1 page(PDF) FINAL REPORT INORGANIC LABWORK SYNTHESIS Cis-K (CR (H2O) 2 (C2O4) 2) AND Trans-K (CR (H2O) 2 (C2O4) 2 - Dini Izzaty - Academia - Edu PDFTawanda KamutanhoNo ratings yet

- Walter B. Cannon and " Voodoo' Death": A Perspective From 60 Years OnDocument3 pagesWalter B. Cannon and " Voodoo' Death": A Perspective From 60 Years OnPatricksia Utopian STsetia Ciel'erNo ratings yet

- Tech D (048-069)Document22 pagesTech D (048-069)Alejandro CouceiroNo ratings yet

- Individual Paper Proposal For Biochar Literature ReviewDocument2 pagesIndividual Paper Proposal For Biochar Literature ReviewraiiinydaysNo ratings yet

- Suma Multi D2.3 PDFDocument3 pagesSuma Multi D2.3 PDFChaitanya VamsiNo ratings yet