Professional Documents

Culture Documents

FAR Transmission PEX 3030 300 766

Uploaded by

yohanes moningkaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FAR Transmission PEX 3030 300 766

Uploaded by

yohanes moningkaCopyright:

Available Formats

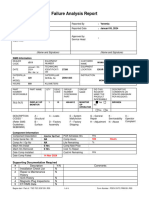

PRODUCT SUPPORT DIVISION Doc. No.

:

Department : Service TSD.TEC.FRM.001.R00

Branch : Manado

Subject FAILURE ANALYSIS REPORT Issued Date 25th June 2020

Owner Sammy Manorek Status Active

Trakindo WO : Reported By : YOHANES MONINGKA

Original WO : Reported Date : 25 June 2020

Checked by

Approved by

Foreman / : Alhert D. Tongka : Sammy Manorek

Service Head

Supervisor

SIMS Information

DEALER EQUIPMENT CUSTOMER

CODE J196 NUMBER NAME MERRY PRICILIA LEWIS

TECHNICIAN EQUIPMENT

DATE

07/22/2020 MANADO

IDENTIFICATION LOCATION

Mo / da / yr

CATERPILLAR CATERPILLAR INSTRUCTION

MODEL 3406 C SERIAL No ENGINE WHITE SMOKE

HOURS 1615 KILOMETERS

PART NUMBER PART QTY DESC,* GROUP GROUP NAME DID THIS INCIDENT DESCRIPTIVE COMMENTS (20

RESPONSIBLE NAME CODE NUMBER MAKE THE SPACES MAXIMUM PER

CONTAINING PRODUCT INCIDENT)

PART INOPERABLE

5P-9186 Seal O- 2 A 3T-1510 CONTROL GP- Yes No LEAKS OIL

ring TRANSMISSION

HYD

Yes No

Yes No

DESCRIPTION CODES * A – Structural C – Leaks E – System Malfunction G – General Repair K - Serviceability X – Operator

(Refer SIMS Guidelines : B – Surface D – Factory Assembly F – Factory Shipping H – Adjustment N - Abuse Complaint

SEBD0850)

Component Information

Component Description : Transmission PCR Schedule Hrs : CompTarget hrs (ex 12000)

Comp Serial No / ID : Comp Hours : Current hrs failed (ex 8000)

Comp Arr / Gp No : Life Remaining : Remain of target life (4000)

Mach Hrs Install : 19067 Comp New Price :

Mach Hrs Removed : 24178 Cost To Repair : (ex $ 10000 )

Date Comp Installed : 2 August 2019 Cost/Hr Remaining : (10000 / 4000 = 2.5 $ /hr)

Date Comp Failed : 25 June 2020

Supporting Documentation Required

# Description Y/N Comments

1 Installation Check List N

2 Repair & Maintenance History N

3 SOS History Y

4 Magnetic Plug Inspections Y

5 ET/VIMS Data Y

6 TPMS / Payload Data N

7 Performance Test Data N

8 Others

Failure Analysis Report 1 of 4 TSD.TEC.FRM.001.R00

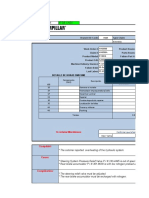

PRODUCT SUPPORT DIVISION Doc. No.:

Department : Service TSD.TEC.FRM.001.R00

Branch : Manado

Subject FAILURE ANALYSIS REPORT Issued Date 25th June 2020

Owner Sammy Manorek Status Active

Failure Outline: Brief outline of what the Customer reported.

Customer reported the can’t shifting while machine operate and transmission lever to drive position .

Customer replace torque converter Gp but the problem still appear and replace transmission Gp, found

machine normal shifting & operation.

Background / Research: Include all observations made during your Failure Analysis investigation including good and bad.

- The Transmission PEX install by customer 2 August 2019 at HM machine 19067

OBSERVATION

Part Number -Name – Modifier Code To Help Explain Progression/Stage of Failure, Use – Notes

(RH/LH/Upper/Lower etc) /Photos/Parts Book Illustration.

Identify Type, Amount, Location of Wear, Deposits,

Damage, Fractures etc.

This picture shows Damage Valve Gp. On progress

inspect

Failure Analysis Report 2 of 4 TSD.TEC.FRM.001.R00

PRODUCT SUPPORT DIVISION Doc. No.:

Department : Service TSD.TEC.FRM.001.R00

Branch : Manado

Subject FAILURE ANALYSIS REPORT Issued Date 25th June 2020

Owner Sammy Manorek Status Active

This picture shows magnetic screen normal condition.

No debris material and metals particle

This picture shows Control valve normal and clean oil

and no contaminant indication

This picture shows the control valve after separately

control valve and transmission planetary group.

Sealing tube line from housing to control valve has

damage.

This picture shows 2 pcs seal o ring PN 5P-9186 cut-

off

This picture shows hole at housing transmission

normal, no any scratch or sharpness

Dish and Clutch normal condition

Failure Analysis Report 3 of 4 TSD.TEC.FRM.001.R00

PRODUCT SUPPORT DIVISION Doc. No.:

Department : Service TSD.TEC.FRM.001.R00

Branch : Manado

Subject FAILURE ANALYSIS REPORT Issued Date 25th June 2020

Owner Sammy Manorek Status Active

Conclusions (What Caused the Failure): Describe the root cause and the sequence of events that caused it.

Oil pressure from transmission pump are not enough to supply control valve caused seal o ring PN 5P-9186,

2 pcs was damage while installation or recondition process.

Warranty Decision or Recommendation: Please mark X in only one box below.

Not warranty : Warranty Accepted : ASA Claim* :

Comments:

*) Application Severity Analysis

Solution to Prevent Reoccurrence:

Check SIS for Service Letters and Service Magazines related to this failure. AMT history, MIM’s history, Oil sample results,

please attach supporting documents below.

Failure Analysis Report 4 of 4 TSD.TEC.FRM.001.R00

You might also like

- CCR JN 5646488-Sis-C9 Engine en Mbd09063-High BlowbyDocument15 pagesCCR JN 5646488-Sis-C9 Engine en Mbd09063-High Blowbyahmat ramadaniNo ratings yet

- D8R Abk D802Document6 pagesD8R Abk D802SMKN 6 SAMARINDA PANGESTUNo ratings yet

- CCR 980NG AbkDocument13 pagesCCR 980NG AbkSMKN 6 SAMARINDA PANGESTUNo ratings yet

- Failure Analysis Report: SIMS InformationDocument13 pagesFailure Analysis Report: SIMS InformationHasby PotterNo ratings yet

- Failure Analysis Report: Information - 01Document4 pagesFailure Analysis Report: Information - 01Budi ArtantoNo ratings yet

- FAR 8600041294 - PTP - Engine Black Smoke 16DZ0186Document7 pagesFAR 8600041294 - PTP - Engine Black Smoke 16DZ0186Fros DiamonNo ratings yet

- Far ZBN41205Document4 pagesFar ZBN41205yeremia kristianNo ratings yet

- Failure Analysis Report AFA 1Document5 pagesFailure Analysis Report AFA 1bartanto59No ratings yet

- FAR D6R LH Final Drive FailureDocument9 pagesFAR D6R LH Final Drive Failurealisa alainaNo ratings yet

- Failure Analysis Report Form (OLD)Document3 pagesFailure Analysis Report Form (OLD)YeremiaNo ratings yet

- C15 Additional Part Bushing Cam ShaftDocument7 pagesC15 Additional Part Bushing Cam ShaftYeremiaNo ratings yet

- Far Report Can't Crank D6R SN TTT00894 Site Patratani Pt. DizamatraDocument5 pagesFar Report Can't Crank D6R SN TTT00894 Site Patratani Pt. Dizamatrasumarno ajaNo ratings yet

- FA ReportDocument4 pagesFA ReportBudi ArtantoNo ratings yet

- CO2421 Inspect Engine Area LeakingDocument6 pagesCO2421 Inspect Engine Area LeakingNajib RahmanNo ratings yet

- Far PT - WBK Wht19 777e SN Kdp00831 Hmu 5713 Ps Rework DoorDocument7 pagesFar PT - WBK Wht19 777e SN Kdp00831 Hmu 5713 Ps Rework DoorNasirKodratNo ratings yet

- 故障分析报告 30112022Document15 pages故障分析报告 30112022Jimmy ManagaraNo ratings yet

- 故障分析报告 30112022 - compressedDocument15 pages故障分析报告 30112022 - compressedJimmy ManagaraNo ratings yet

- Report Genset TimbanganDocument4 pagesReport Genset TimbanganmahmudiNo ratings yet

- Failure Analysis ReportDocument9 pagesFailure Analysis ReportOka WansyahNo ratings yet

- E 001B1 MotorDocument2 pagesE 001B1 MotorBhihi RajaNo ratings yet

- Certificate of Calibration: CustomerDocument1 pageCertificate of Calibration: Customergaconvt92No ratings yet

- Coa Etsv Oam 001 f000 Rfi FormDocument1 pageCoa Etsv Oam 001 f000 Rfi FormRoger MahilumNo ratings yet

- Condition Report SIS 16M Daily Inspection GD16M-0053 (3 May 2016)Document4 pagesCondition Report SIS 16M Daily Inspection GD16M-0053 (3 May 2016)ahmat ramadani100% (1)

- Technical Service Report: PT Pama Persada Nusantara Distric Topb Kalimantan TengahDocument18 pagesTechnical Service Report: PT Pama Persada Nusantara Distric Topb Kalimantan TengahNanang AgustyaNo ratings yet

- Ripper Lift Cylinder LHDocument1 pageRipper Lift Cylinder LHaduytama349No ratings yet

- Sievert Emirates Inspection L.L.C.: Magnetic Particle Testing ReportDocument1 pageSievert Emirates Inspection L.L.C.: Magnetic Particle Testing ReportAvijit DebnathNo ratings yet

- V R47 e 0019 0003Document2 pagesV R47 e 0019 0003rajindo1No ratings yet

- Continuity/Insulation Resistance Test FormDocument1 pageContinuity/Insulation Resistance Test FormVictor BiacoloNo ratings yet

- Component Condition Report DM007Document9 pagesComponent Condition Report DM007ahmat ramadaniNo ratings yet

- TSR Drill JuliDocument10 pagesTSR Drill JuliFata KickbalNo ratings yet

- Emily-1 Project Fuel Terminal and Jetty Compaction Inspection ReportDocument9 pagesEmily-1 Project Fuel Terminal and Jetty Compaction Inspection Reportmuhammad sauqiNo ratings yet

- 1046A Sraf No.Document1 page1046A Sraf No.Imran KhanNo ratings yet

- Emily-1 Project Fuel Terminal and Jetty Compaction Inspection ReportDocument9 pagesEmily-1 Project Fuel Terminal and Jetty Compaction Inspection Reportmuhammad sauqiNo ratings yet

- WVGZZZ5NZAW107560Document9 pagesWVGZZZ5NZAW107560ionutgavriloviciNo ratings yet

- Storage Tank F-9026 Stone Column No SC-9026-52Document1 pageStorage Tank F-9026 Stone Column No SC-9026-52engmaar201037No ratings yet

- TR Power Window Depan Kanan Tidak BerfungsiDocument17 pagesTR Power Window Depan Kanan Tidak Berfungsihendra tb simatupangNo ratings yet

- TSR Drill Mei 2022Document8 pagesTSR Drill Mei 2022Fata KickbalNo ratings yet

- Repair Order: Icon Equipment Solutions Philippines, IncDocument2 pagesRepair Order: Icon Equipment Solutions Philippines, IncMark EsguerraNo ratings yet

- IMIRDocument10 pagesIMIRvizagnucalcuttaNo ratings yet

- Draft Work Order - BCF: (Mining Site Only) ) If Yes, Please Attach DBS Print Screen DSPSCMACDocument1 pageDraft Work Order - BCF: (Mining Site Only) ) If Yes, Please Attach DBS Print Screen DSPSCMACFajar WinarkoNo ratings yet

- CPP HT Pipeline ReportDocument301 pagesCPP HT Pipeline ReportAbdulkaderNo ratings yet

- Priming Pump 02Document3 pagesPriming Pump 02Bayu SaputraNo ratings yet

- K20 178 1 A Contact Oven Press 80TDocument20 pagesK20 178 1 A Contact Oven Press 80Tjouheyna hedhliNo ratings yet

- Anant Corr. MOM 7-08-18Document4 pagesAnant Corr. MOM 7-08-18Abhimanyu Singh ChundawatNo ratings yet

- Far Repair Final DriveDocument16 pagesFar Repair Final DriveRezhaNo ratings yet

- Work Order: VN 23980529 6 - MiscellaneousDocument2 pagesWork Order: VN 23980529 6 - MiscellaneousJohn SmithNo ratings yet

- CA10 20 DSI 12 02 en STDDocument183 pagesCA10 20 DSI 12 02 en STDDiego PietkowskyNo ratings yet

- Method Statement For Inst Cable LayingDocument24 pagesMethod Statement For Inst Cable LayingMallikarjun DevarapalliNo ratings yet

- TSR Cyl Tilt Cab LD 110Document2 pagesTSR Cyl Tilt Cab LD 110Ferry AndisNo ratings yet

- 632 - Port Main Engine Critical SparesDocument1 page632 - Port Main Engine Critical SparesAhmed HamdyNo ratings yet

- Metro Speedcom Corporation (G82) : Pull Out No. 42 Rma Form July 29 2022 Supplier: Asian Tech - Corp. Branch NameDocument3 pagesMetro Speedcom Corporation (G82) : Pull Out No. 42 Rma Form July 29 2022 Supplier: Asian Tech - Corp. Branch Namejumel blandoNo ratings yet

- S001032-14 (Datalogger Specification)Document2 pagesS001032-14 (Datalogger Specification)akramhomriNo ratings yet

- R1118111-S30002-COL-C00000-20019-H03-Rev.C QCDocument37 pagesR1118111-S30002-COL-C00000-20019-H03-Rev.C QCDIBYENDU BERA100% (1)

- Tar Turbo DZ 026 New 02Document59 pagesTar Turbo DZ 026 New 02Angga supriyantoNo ratings yet

- Acceptance-Cum-Release Note Date: 14.09.2017 Contract CodeDocument1 pageAcceptance-Cum-Release Note Date: 14.09.2017 Contract CodeAnakar SatpathyNo ratings yet

- Afex PDC MAINTENANCE PR Empty (3Document117 pagesAfex PDC MAINTENANCE PR Empty (3Thamizhselvan KNo ratings yet

- Anant SPG MOM 7-08-18Document4 pagesAnant SPG MOM 7-08-18Abhimanyu Singh ChundawatNo ratings yet

- Package Cover Sheet Line Maintenance: Certificate of Release To ServiceDocument6 pagesPackage Cover Sheet Line Maintenance: Certificate of Release To ServiceFemi AgbanaNo ratings yet

- Request Form KH08588Document4 pagesRequest Form KH08588nelsonNo ratings yet

- Performantele MTADocument5 pagesPerformantele MTAana aNo ratings yet

- 3 Composites PDFDocument14 pages3 Composites PDFKavya ulliNo ratings yet

- Fire Alarm SymbolsDocument6 pagesFire Alarm Symbolscarlos vasquezNo ratings yet

- FISPQ - Innova - Force - ADY - EN - 7143812336Document6 pagesFISPQ - Innova - Force - ADY - EN - 7143812336Talia EllaNo ratings yet

- Recovery in TrainingDocument7 pagesRecovery in TrainingAnonymous 92hWDcNo ratings yet

- Cell Organelles 2Document13 pagesCell Organelles 2Sadeeq ur RahmanNo ratings yet

- From Crème Fraîche To Sour Cream: What's The Difference?Document14 pagesFrom Crème Fraîche To Sour Cream: What's The Difference?Maricel BautistaNo ratings yet

- Cwts ThesisDocument7 pagesCwts Thesisbufukegojaf2100% (2)

- 3926 An Premium DxiDocument400 pages3926 An Premium DxiMartin Bugár100% (2)

- Health and Illness Answer-8Document2 pagesHealth and Illness Answer-8June DumdumayaNo ratings yet

- Recipe Book: Yule Logs 2020Document28 pagesRecipe Book: Yule Logs 2020Cwt Chan100% (1)

- Indian MaDocument1 pageIndian MaAnass LyamaniNo ratings yet

- IGACOS Marine Sanctuary Park and ResortDocument74 pagesIGACOS Marine Sanctuary Park and ResortPlusNo ratings yet

- Trash Chute-Compliance Sheet Sangir)Document5 pagesTrash Chute-Compliance Sheet Sangir)Li LiuNo ratings yet

- 1stweek Intro Quanti Vs QualiDocument18 pages1stweek Intro Quanti Vs QualiHael LeighNo ratings yet

- Park Ch. 1 - A1000 - Spring13Document21 pagesPark Ch. 1 - A1000 - Spring13lingyeeNo ratings yet

- Raymond Lo - The Feng Shui of Swine FluDocument1 pageRaymond Lo - The Feng Shui of Swine Fluay2004jan100% (1)

- Steen Kamp 2021Document16 pagesSteen Kamp 2021LARANSA SOLUNA GOGO SIMATUPANGNo ratings yet

- Recipe Booklet PRINT VERSIONDocument40 pagesRecipe Booklet PRINT VERSIONjtsunami815100% (1)

- DiffusionDocument25 pagesDiffusionbonginkosi mathunjwa0% (1)

- YuzurtDocument2 pagesYuzurtFranco Ascari100% (1)

- Solved Rail Chapter 1Document7 pagesSolved Rail Chapter 1spectrum_48No ratings yet

- Beta CaroteneDocument2 pagesBeta CaroteneValeria MarcuțăNo ratings yet

- P3 Chapter 2 End-Of-Chapter (Higher) Mark SchemeDocument3 pagesP3 Chapter 2 End-Of-Chapter (Higher) Mark SchemePaul LloydNo ratings yet

- Elephantgrass Bookchapter PDFDocument22 pagesElephantgrass Bookchapter PDFMuhammad rifayNo ratings yet

- Soal Post TestDocument70 pagesSoal Post Testananda96% (25)

- 8291 w13 Ms 22Document8 pages8291 w13 Ms 22Caterina De LucaNo ratings yet

- Scots-Supply Chain ManagementDocument3 pagesScots-Supply Chain Managementgamer godNo ratings yet

- 2021 Physician Compensation Report - Updated 0821Document24 pages2021 Physician Compensation Report - Updated 0821Michael Knapp100% (3)