Professional Documents

Culture Documents

Astm - c136 c136m 14

Uploaded by

Ajesh SohanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Astm - c136 c136m 14

Uploaded by

Ajesh SohanCopyright:

Available Formats

C136 / C136M: 1 of 3

09/2020

Performance Examination - Aggregate

Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates

(ASTM C136 / C136M-14) [AASHTO T 27-14]

Candidate Name: ______________________________________ NICET ID: ________________

Trial Trial

Apparatus 1 2

Balance

Fine aggregate: Balance, readable to 0.1 g, accurate to 0.1 g or 0.1% of test load (greater)

Coarse aggregate: Balance, readable & accurate to 0.5 g or 0.1% of test load (greater)

Optional: Mechanical sieve shakers, meet adequacy of sieving requirements. Shaker runs for

the correct amount of time (determined during annual standardization)

Oven Maintains 110 ± 5 °C (230 ± 9 °F)

Trial Trial

Procedures 1 2

Coarse Aggregate Gradation or Mixtures of Coarse and Fine Aggregate Gradation

Initial mass: _____________ Final mass: _____________

Test sample obtained by C702

Nominal Maximum Size, Test Sample Size, Minimum,

mm (in.) kg (lb)

9.5 (⅜) 1 [2]

12.5 (½) 2 [4]

19.0 (¾) 5 [11]

25.0 (1) 10 [22]

37.5 (1½) 15 [33]

50 (2) 20 [44]

63 (2½) 35 [77]

75 (3) 60 [130]

90 (3½) 100 [220]

100 (4) 150 [330]

125 (5) 300 [660]

1. Sample dried to constant mass at 110 ± 5 °C (230 ± 9 °F) or sieved surface dry (coarse

aggregate only)

2. Mass determined to nearest 0.1%

3. If hand sieving, particles not forced to pass through openings

4. Sieving continued until not more than 0.5% by mass of the total specimen passes a given

sieve during one minute of continuous hand sieving (check by hand with 8-in.

diameter sieve).

5. Residue on each sieve weighed to 0.1% of the original dry mass.

6. Sieves not overloaded

Examiner Name:__________________ Examiner Signature: ______________________Date: ________

C136 / C136M: 2 of 3

09/2020

Performance Examination - Aggregate

Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates

(ASTM C136 / C136M-14) [AASHTO T 27-14]

Candidate Name: ______________________________________ NICET ID: ________________

7. Mass of residue on each sieve [finer than 4.75 mm (No. 4) sieves] does not exceed

7 kg/m2 of sieving surface (200 g for 8-in. diameter sieve; 469 g for 12-in. diameter sieve)

8. Mass of residue on each sieve [for 4.75 mm (No. 4) sieves and larger] does not exceed

2.5 x (sieve opening, mm) x (effective sieving area, m2)

9. The total mass of material after sieving agrees with a mass before sieving to within 0.3% (If

not, do not use for acceptance testing)

10. Percentages calculated to nearest 0.1% and reported to the nearest whole number

(except 75-µm (No. 200) – if less than 10%, percentage – 200 reported to the

nearest 0.1%)

11. Percentage calculations. based on original dry sample mass, including the passing

75-μm fraction from C136

12. The sample obtained by C702 or whole field sample used, minimum sample mass 300 g

13. Sample dried to constant mass at 110 ± 5 °C (230 ± 9 °F)

14. Sieving continued until not more than 0.5% by mass of the total specimen passes a

given sieve during one minute of continuous hand sieving (check by hand with 8-in.

diameter sieve)

15. Residue on each sieve weighted to 0.1% of the original dry mass

16. Sieves not overloaded

17. Mass of residue on each sieve [finer than 4.75 mm (No. 4) sieves] does not exceed

7 kg/m2 of sieving surface (200 g for 8 in. Diameter sieve; 469 g for 12 in. diameter

sieve)

18. Mass of residue on each sieve [for 4.75 mm (No. 4) sieves and larger] does not exceed

2.5 x (sieve opening, mm) x (effective sieving area, m2)

19. The total mass of material after sieving agrees with a mass before sieving to within 0.3%

(If not, do not use for acceptance testing)

20. Percentages calculated to nearest 0.1% and reported to the nearest whole number

(except 75-µm (No. 200) – if less than 10%, percentage – 200 reported to the

nearest 0.1%)

21. Percentage calculations based on Original dry sample mass, including the passing

75-µm fraction if (C136) was used

Examiner Name:__________________ Examiner Signature: ______________________Date: ________

C136 / C136M: 3 of 3

09/2020

Performance Examination - Aggregate

Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates

(ASTM C136 / C136M-14) [AASHTO T 27-14]

Candidate Name: ______________________________________ NICET ID: ________________

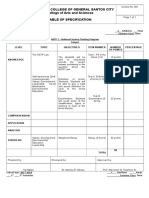

Maximum Allowable Quantity of Material Retained on a Sieve, kg (lb)

Nominal Dimensions of Sieve

Sieve 8-in. 10-in. 12-in. 14 by 14-in. 14.5 by 23-in.

Opening (203.2-mm) (254-mm) (304.8-mm) 350 by 350 mm 72 by 580 mm

diameter diameter diameter diameter diameter

Size,

mm (in.) Sieving Area, m2 (ft2)

0.0285 (0.3) 0.0457 (0.5) 0.0670 (0.7) 0.1225 (1.3) 0.2158 (2.3)

125 (5) ● ● ● ● 67.4 (148½)

100 (4) ● ● ● 30.6 (67½) 53.9 (118¾)

90 (3½) ● ● 15.1 (33¼) 27.6 (60¾) 48.5 (106¾)

75 (3) ● 8.6 (19) 12.6 (27¾) 23.0 (50¾) 40.5 (89¼)

63 (2½) ● 7.2 (15¾) 10.6 (23¼) 19.3 (42½) 34.0 (75)

50 (2) 3.6 (8) 5.7 (13) 8.4 (18½) 15.3 (33¾) 27.0 (59½)

37.5 (1½ ) 2.7 (6) 4.3 (9½) 6.3 (13¾) 11.5 (25¼) 20.2 (44½)

25.0 (1) 1.8 (4) 2.9 (6½) 4.2 (9¼) 7.7 (17) 13.5 (29¾)

19.0 (¾) 1.4 (3½) 2.2 (4¾) 3.2 (7½) 5.8 (12¾) 10.2 (22½)

12.5 (½) 0.89 (2) 1.4 (3) 2.1 (4¾) 3.8 (8¼) 6.7 (14¾)

9.5 (⅜) 0.67 (1) 1.1 (2½) 1.6 (3½) 2.9 (6¼) 5.1 (11¼)

4.75 (No. 4) 0.33 (¾) 0.54 (1¼) 0.80 (1¾) 1.5 (3¼) 2.6 (5¾)

● Sieves with less than five full openings; should not be used for sieve testing.

First Attempt: Pass: ______ Fail: ______ Second Attempt: Pass: ______ Fail: ______

Exam Administration: Remote ______ In-Person ______

Comments:

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

Examiner Name:__________________ Examiner Signature: ______________________Date: ________

You might also like

- AASHTO T 27, Sieve Analysis of Fine and Coarse Aggregates AASHTO T 11Document22 pagesAASHTO T 27, Sieve Analysis of Fine and Coarse Aggregates AASHTO T 11Yoisi Meza DominguezNo ratings yet

- Wsdot Errata To Waqtc Fop For Aashto T 27 - T 11: Sieve Analysis of Fine and Coarse AggregatesDocument30 pagesWsdot Errata To Waqtc Fop For Aashto T 27 - T 11: Sieve Analysis of Fine and Coarse AggregatesWaqas Ahmad AbbasiNo ratings yet

- University of Duhok College of Engineering Civil Department 2 Year, 2017-2018Document11 pagesUniversity of Duhok College of Engineering Civil Department 2 Year, 2017-2018Dakheel malekoNo ratings yet

- Aashto t27 t11Document22 pagesAashto t27 t11Mariana CabralNo ratings yet

- T27 T11 (SIeve ANalysis)Document46 pagesT27 T11 (SIeve ANalysis)Don Procopio IINo ratings yet

- AASHTO T27-T21 Sieve Analysis of Fine and Coarse Aggregates PDFDocument14 pagesAASHTO T27-T21 Sieve Analysis of Fine and Coarse Aggregates PDFSajedur Rahman Mishuk0% (1)

- Gradation and Fineness Modulus of Fine AggregateDocument7 pagesGradation and Fineness Modulus of Fine AggregateAlbert JanssenNo ratings yet

- Chapter14 PDFDocument7 pagesChapter14 PDFVasaNo ratings yet

- Aashto T 27 T 11 2012Document18 pagesAashto T 27 T 11 2012Aldrin SantosNo ratings yet

- CV3B EW1 Group5 Experiment2&3Document6 pagesCV3B EW1 Group5 Experiment2&3jml aguilarNo ratings yet

- Material Testing Laboratory ManualDocument22 pagesMaterial Testing Laboratory ManualSamirHashimNo ratings yet

- Sieve Analysis Of Fine And Coarse Aggregates Fop For Aashto T 27 Materials Finer Than 75 Μm (No. 200) Sieve In Mineral Aggregate By Washing Fop For Aashto T 11 ScopeDocument21 pagesSieve Analysis Of Fine And Coarse Aggregates Fop For Aashto T 27 Materials Finer Than 75 Μm (No. 200) Sieve In Mineral Aggregate By Washing Fop For Aashto T 11 ScopeNguyễn Văn MinhNo ratings yet

- Combined Gradation of Coarse Aggregate - Astm C33-Size 67-1Document106 pagesCombined Gradation of Coarse Aggregate - Astm C33-Size 67-1Hasan al MahmudNo ratings yet

- Testing of AggregatesDocument14 pagesTesting of AggregatesADIB AFIFINo ratings yet

- Aggregate Sieve Analysis Test PDFDocument9 pagesAggregate Sieve Analysis Test PDFYusman FoenayNo ratings yet

- Quality ControlDocument35 pagesQuality ControlvijayNo ratings yet

- Determination of Elongation IndexDocument8 pagesDetermination of Elongation IndexAnonymous 5soodVRnNo ratings yet

- Aashto T 19m-t 19-14Document2 pagesAashto T 19m-t 19-14Ajesh SohanNo ratings yet

- Lab 1 - Seive AnalysisDocument6 pagesLab 1 - Seive AnalysisMelad HaweyouNo ratings yet

- Experiment 3 Sieve Analysis TestDocument6 pagesExperiment 3 Sieve Analysis TestZul HaswalNo ratings yet

- Material Reports K0835110Document52 pagesMaterial Reports K0835110ikaNo ratings yet

- Laboratory Manual FinalDocument57 pagesLaboratory Manual Finalrohit kumarNo ratings yet

- Chapter XV Ac-BcDocument14 pagesChapter XV Ac-BcMUHAMMAD KENNYZYRA BINTANG SAM -No ratings yet

- t27 PDFDocument22 pagest27 PDFRodrigo Cuentas GallardoNo ratings yet

- Astm C136 Standard Test Method For Sieve Analysis of Fine and Coarse AggregatesDocument9 pagesAstm C136 Standard Test Method For Sieve Analysis of Fine and Coarse AggregatesCharissah Erika PechardoNo ratings yet

- Sheet 2Document1 pageSheet 2Eldsoky DabaNo ratings yet

- All-Welded (AW) Wire-Wrapped ScreensDocument2 pagesAll-Welded (AW) Wire-Wrapped ScreensKamal HamzahNo ratings yet

- Concrete AggregatesDocument34 pagesConcrete AggregatesjesNo ratings yet

- HW1 Problem2024Document2 pagesHW1 Problem2024duuudddauesfNo ratings yet

- University of MisanDocument9 pagesUniversity of MisanoNo ratings yet

- Karnataka State Highway Improvement Project - II, Stage 1Document1 pageKarnataka State Highway Improvement Project - II, Stage 1Karumuri JayaramNo ratings yet

- Sieve Analysis of Coarse and Fine AggregateDocument3 pagesSieve Analysis of Coarse and Fine AggregateWaqas Muneer Khan0% (2)

- University of Dar Es SalaamDocument4 pagesUniversity of Dar Es SalaamAdam HamzaNo ratings yet

- Particle Size DistributionDocument10 pagesParticle Size DistributionSaraswati Noor100% (1)

- Experiment No. 3: Sieve Analysis of Coarse and Fine Aggregate DiscussionDocument22 pagesExperiment No. 3: Sieve Analysis of Coarse and Fine Aggregate DiscussionRochelleNo ratings yet

- CE405 - E2 - Abello Braga Gavino Habichy Millona 1Document7 pagesCE405 - E2 - Abello Braga Gavino Habichy Millona 1Oren Hertz FaustoNo ratings yet

- Sieve Analysis of AggregatesDocument6 pagesSieve Analysis of AggregatesEj DiazNo ratings yet

- Lab 1 - Seive AnalysisDocument6 pagesLab 1 - Seive AnalysisamNo ratings yet

- 01-Sieve Analysis Coarse and Fine Aggregate.Document7 pages01-Sieve Analysis Coarse and Fine Aggregate.gsv988No ratings yet

- New Era University: Particle Size Analysis of Soil (Sieve and Hydrometer)Document7 pagesNew Era University: Particle Size Analysis of Soil (Sieve and Hydrometer)Khryz AbadNo ratings yet

- New Era University: Particle Size Analysis of Soil (Sieve and Hydrometer)Document7 pagesNew Era University: Particle Size Analysis of Soil (Sieve and Hydrometer)Khryz AbadNo ratings yet

- New Era University: Particle Size Analysis of Soil (Sieve and Hydrometer)Document7 pagesNew Era University: Particle Size Analysis of Soil (Sieve and Hydrometer)Khryz AbadNo ratings yet

- Tugas - Kegiatan - Belajar - III Brema Firdaus GintingDocument2 pagesTugas - Kegiatan - Belajar - III Brema Firdaus GintingBrema Firdaus GintingNo ratings yet

- Bil. Title PagesDocument9 pagesBil. Title PagesAlan ChinNo ratings yet

- AGG ChecklistDocument36 pagesAGG ChecklistEmran BanatNo ratings yet

- Soil of Mechanics: Analysis of Grain Size DistributionDocument6 pagesSoil of Mechanics: Analysis of Grain Size DistributionMarwah JMNo ratings yet

- Laboratory Experiment - Fine AggregateDocument4 pagesLaboratory Experiment - Fine AggregateNajiha KhairiNo ratings yet

- Experiment 3.7: LA Abrsion TestDocument6 pagesExperiment 3.7: LA Abrsion TestDaniel ImranNo ratings yet

- Practical Unit Operation Lab 3 Year Level: Department of Petrochemical College of Technical EngineeringDocument6 pagesPractical Unit Operation Lab 3 Year Level: Department of Petrochemical College of Technical EngineeringMaten NasradinNo ratings yet

- BallMill 2021chb1040Document8 pagesBallMill 2021chb1040bawankar152prathameshNo ratings yet

- Middle East Technical UniversityDocument16 pagesMiddle East Technical Universityiremnur keleşNo ratings yet

- Problem Solving: Write Your Step Solutions and Box Your Final AnswerDocument4 pagesProblem Solving: Write Your Step Solutions and Box Your Final AnswerClaire Pauline Besabella CaviteNo ratings yet

- Seive Analysis of Coarse Aggregate OnlyDocument3 pagesSeive Analysis of Coarse Aggregate OnlyYasirNo ratings yet

- Shape Tests For AggregatesDocument6 pagesShape Tests For AggregatesMohasin KamalNo ratings yet

- ASTM - C535-16Desgaste de Los AngeslesDocument2 pagesASTM - C535-16Desgaste de Los AngeslesGuillermoNo ratings yet

- Coarse Aggregate Sieve AnalysisDocument8 pagesCoarse Aggregate Sieve AnalysisBara VeckaNo ratings yet

- Manual With ReadingsDocument45 pagesManual With ReadingsAqeel ShahzadNo ratings yet

- 4.direct Shear TestDocument9 pages4.direct Shear TestPawan ChhetriNo ratings yet

- Lab 5 Group 4 Ce4aDocument5 pagesLab 5 Group 4 Ce4aJoshua OrcalesNo ratings yet

- What Are The Benefits of A Quality PlacementDocument5 pagesWhat Are The Benefits of A Quality PlacementpradeepkallurNo ratings yet

- List of Presidents of The People's Republic of China - WikipediaDocument10 pagesList of Presidents of The People's Republic of China - WikipediaAli Nawaz tanwariNo ratings yet

- NLPC FOIA Re: Jeffrey Epstein 'Suicide'Document5 pagesNLPC FOIA Re: Jeffrey Epstein 'Suicide'Peter FlahertyNo ratings yet

- Mitsubishi Spilt Type Air Conditioners Manual MSZ hr25vf MSZ hr35vf MSZ hr42vf MSZ hr50vfDocument21 pagesMitsubishi Spilt Type Air Conditioners Manual MSZ hr25vf MSZ hr35vf MSZ hr42vf MSZ hr50vfgerman tapiaNo ratings yet

- NSTP 1 - TosDocument2 pagesNSTP 1 - TosTaj NgilayNo ratings yet

- Electrical Machines and Drives Course Outline 2010Document2 pagesElectrical Machines and Drives Course Outline 2010talohole2No ratings yet

- Wooden Knife Handle and SheathDocument10 pagesWooden Knife Handle and SheathMehmet Emre Bastopcu100% (2)

- How To Start Modding Dungeons of DredmorDocument2 pagesHow To Start Modding Dungeons of DredmorChance BNo ratings yet

- Bomba Denison PVDocument34 pagesBomba Denison PVEdwin Quispe CarlosNo ratings yet

- Application Form For Entrance Exam 2020Document2 pagesApplication Form For Entrance Exam 2020Ma.carmela AquinoNo ratings yet

- 20+ Excel Table Tricks To Turbo Charge Your DataDocument21 pages20+ Excel Table Tricks To Turbo Charge Your DataangbohkNo ratings yet

- History of Social CaseworkDocument14 pagesHistory of Social Caseworknirmaljoy60% (5)

- YEF Final ReportDocument12 pagesYEF Final ReportNidhi SharmaNo ratings yet

- Janitza Main Catalogue 2019 en PDFDocument455 pagesJanitza Main Catalogue 2019 en PDFvicky_doshi096004No ratings yet

- Cereals and Pasta CookeryDocument48 pagesCereals and Pasta CookeryJoshua Guiriña100% (3)

- Notes Payable: Problem 1: True or FalseDocument16 pagesNotes Payable: Problem 1: True or FalseKim HanbinNo ratings yet

- Flight International 13 November 2018Document52 pagesFlight International 13 November 2018Adrian BistreanuNo ratings yet

- dISA-99 00 02Document175 pagesdISA-99 00 02Jason MullinsNo ratings yet

- Basic Offshore Survival and Emergency Training StandardDocument18 pagesBasic Offshore Survival and Emergency Training StandardAnas Abd Rahman100% (1)

- Sixnet Training - OSI ModelDocument16 pagesSixnet Training - OSI ModelBiswajit MohantyNo ratings yet

- Cartridge Valves Technical Information Directional Valves DCV 03Document12 pagesCartridge Valves Technical Information Directional Valves DCV 03francis_15inNo ratings yet

- Insulin As A Substance of MisuseDocument5 pagesInsulin As A Substance of MisuseStephany Mae ChiNo ratings yet

- NetstatDocument1 pageNetstatM Faaiq Al AzharNo ratings yet

- Set+1 Descriptive+statistics+Probability+Document4 pagesSet+1 Descriptive+statistics+Probability+Anusha MeesalaNo ratings yet

- Karlos KarlinaDocument2 pagesKarlos KarlinaTip RendahNo ratings yet

- Astm G 63 07Document26 pagesAstm G 63 07Ivan AlanizNo ratings yet

- Legprof Updated Full Text CasesDocument242 pagesLegprof Updated Full Text CasesKarmaranthNo ratings yet

- Determination of ZIP Parameters With Least Squares Optimization MethodDocument6 pagesDetermination of ZIP Parameters With Least Squares Optimization MethodEmmanuel PugaNo ratings yet

- CFOT SlidesDocument24 pagesCFOT SlidesShariff Oluoch OdiwuorNo ratings yet