Professional Documents

Culture Documents

Strong Points of Conic

Uploaded by

Hung LeOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Strong Points of Conic

Uploaded by

Hung LeCopyright:

Available Formats

2. Conic tool is using slug catcher shape for die as standard specification.

This specification is effective to anti slug comes up.

1. We use the best quality highspeed steel materials.

Punch (1)Material is (2)Slug is push and

Conic uses carefully selected high speed steel for punch. cut at “A” Punch pressed to coming

position. process to “B”

2. Even D2 steel(SKD-11) is different from standard. Die Die

Slug

position.

a) Conic uses improved D2 steel for die.

This material has twice of spring character and hardness is Frictional wear HSS

higher than general D2 steel. (HRC 58 to 60) D2 (3)After slug is (4)Area of “B”

Improved D2 steel

Also more better anti- chipping and crack than standard D2 lower than position is smaller

Punch

steel. position “B” than “C” position

Spring character Die

This imp This improved D2 steel has good performance for wire EDM scrap is released therefore slug would

Die

because material does not have residual stress in the to the scrap box. not comes up to upper

material. area.

“ Price example (Japanese Yen)”

b) Conic uses super sub-zero heat treatment process on D2 Additional

Maker Standard price Total

steel for standard punch. anti-slug comes up

Material is put into –130cent degree just after heat Punching test :

Conic 5,000JPY 0JPY 5,000JPY

treatment. Silicon steel plate 0.35mm thickness

Company “A” 10,000JPY 3,000JPY 13,000JPY

This process gives material structure fine and better for Punch material is D2 steel (SKD-11)

stability and hardness.

(Hits)

Normally sub-zero process is done only for precision 3. Minute Corner R on the punching side edges.

equipment or gages.

Conic put the minute corner R on the edge of

14,500

the punching side edges because this corner Put the minute corner R

7,000 is the weakest point of shaped tools. After on the edge of the

put small R on the corner tool life is much punching side edges.

longer and prevent the unusual wear of the

“Super sub-zero process” “Standard”

punch body. >>>Example of damage of the corner.

Punching life which height of burr is

higher than general D2 steel.

Conic makes a lot of special tools.

Our sales result of special tools are proof of quality and customer satisfaction.

Production of grand total (special shapes and forming tool)

(Sets)

1. Back taper on side of the punch. 520,000 Conic keeps drawings of

special tools for 30 years,

500,000

This specification makes better performance for less touching so that, it is easy to order

Back taper on side

area on the side face of punch body and less sticking material repeatedly.

on the side face. 480,000

2012 2013 2014 2015 2016 2017 2018 (Year)

Tooling life

“Japan Technology”

(Stainless steel plate 2.0mm thickness)

Super Dry Punch(SDP) 80,000

CONIC Long Life Punch(CLP) 30,000

CONIC Hard Punch(CHP) 20,000

TiN Coating 20,000

HSS 15,000

Super Dry Punch (SDP) D2 10,000 (Hits)

◆Material surface quality change(it does not have peeling off such as PVD coating)

Name Color Average Note Good for

hardness(HV)

SDP Mat Gray 2,800 No lub oil necessary Stainless…

CLP Dark Gray 3,000 High hardness Coated material…

CHP Material 1,000 Smooth surface no sticking Aluminum,Color…

◆PVD coating (thickness 2 to 3 microns)

Name Color Average Note Good for

hardness(HV)

TiN Gold 2,000 General use Mild steel…

TiAlN Dark purple 2,500 Anti heating Coated material…

“Thick turret tooling”

The Most Popular Tooling “PROTECH-3”

New Style for Easy Operation!

Anybody can maintain this tool safety, accurately and speedy!

Strong Points of

Since 1976

Tool Sales Desk

Conic Turret Punch Press Tools

CONIC Co., Ltd.

10-5 Taiheidai, Shoo-cho, Katsuta-gun, Okayama, 709-4321, Japan

TEL : +81-868-38-6154 FAX : +81-868-38-6331

E-mail : tools@conic.co.jp

URL : https://www.conic.co.jp/

Oct.2019

You might also like

- Product MANUAL: L110H, L120HDocument42 pagesProduct MANUAL: L110H, L120HHaris100% (2)

- H PDFDocument83 pagesH PDFvivianeNo ratings yet

- PD1005 / PD1010: DLC-Coated Inserts For Non-Ferrous MetalsDocument8 pagesPD1005 / PD1010: DLC-Coated Inserts For Non-Ferrous Metalsxmen norNo ratings yet

- CHQ WebDocument4 pagesCHQ WebSa RaNo ratings yet

- SENA STD 1112-000009Document1 pageSENA STD 1112-000009Andy AcostaNo ratings yet

- Technical Information: Material of Punch Material of PunchDocument2 pagesTechnical Information: Material of Punch Material of PunchأبومحمدالزياتNo ratings yet

- Change !!: Change Change Change ChangeDocument20 pagesChange !!: Change Change Change Changexmen norNo ratings yet

- 2012 Jjtools Catalogue PDFDocument180 pages2012 Jjtools Catalogue PDFAnonymous aZKer3gNo ratings yet

- Acc 0910 Sabresaws Gb-EnDocument11 pagesAcc 0910 Sabresaws Gb-EnannedierNo ratings yet

- IIW1Document13 pagesIIW1Ante CrnicaNo ratings yet

- Misu Tool CatalogDocument24 pagesMisu Tool CatalogDuy ĐôngNo ratings yet

- Project 2 ScrewedDocument7 pagesProject 2 ScrewedDjuro SavkinNo ratings yet

- MO Info SchaanDocument9 pagesMO Info SchaanDENIGSON CARDONANo ratings yet

- Tacos de ExpansiónDocument6 pagesTacos de ExpansiónPer CYNo ratings yet

- Deformación Plástica en FríoDocument103 pagesDeformación Plástica en FríoNoé V.G.No ratings yet

- Finish Standard Plastic MaterialDocument1 pageFinish Standard Plastic Materialsalvatore.bassoNo ratings yet

- BenefitsDuctileIron SDF SDDocument27 pagesBenefitsDuctileIron SDF SDChintan ShahNo ratings yet

- SLD Magic 2Document12 pagesSLD Magic 2Deny Arisandi DarisandNo ratings yet

- Training Handbook en LQDocument95 pagesTraining Handbook en LQprakashp111No ratings yet

- (JIS SKD61) : FeaturesDocument6 pages(JIS SKD61) : FeaturestaknevNo ratings yet

- Rhine Adjustable FloorDocument4 pagesRhine Adjustable FloorhersonNo ratings yet

- Star Teck Jacketed Metal-Clad Cable FittingsDocument2 pagesStar Teck Jacketed Metal-Clad Cable FittingsAnonymous AsIbqUNo ratings yet

- Outline Spek Tahap III (Revisi2)Document138 pagesOutline Spek Tahap III (Revisi2)Dionisius BudiNo ratings yet

- Pan Head Self-Drill Drywall Screw: Product DatasheetDocument1 pagePan Head Self-Drill Drywall Screw: Product DatasheetRobNo ratings yet

- Hydrant Pillar - NikitaDocument1 pageHydrant Pillar - NikitaCitra mas0% (1)

- Check List Retaining Spiral Rings: E-Mail To 250@gandini - It or Fax To +39 02 241 047 74Document1 pageCheck List Retaining Spiral Rings: E-Mail To 250@gandini - It or Fax To +39 02 241 047 74arda akkayaNo ratings yet

- WEG WMO WCR Wormdrive 50137788 Brochure English WebDocument16 pagesWEG WMO WCR Wormdrive 50137788 Brochure English WebLucas Araujo de AlmeidaNo ratings yet

- Ch-27.11 Hardness TestDocument24 pagesCh-27.11 Hardness TestasjfgauojfgfNo ratings yet

- Mold BaseDocument1 pageMold BaseRizky MahendraNo ratings yet

- CatalougeDocument15 pagesCatalougeBarbara OrtigozaNo ratings yet

- Ball Screws: Precision GroundDocument8 pagesBall Screws: Precision GroundJoao SilvaNo ratings yet

- Fire EquipmentDocument7 pagesFire Equipmentamal_postNo ratings yet

- Carbocast 1 - eDocument1 pageCarbocast 1 - eali torabiNo ratings yet

- Technical Information 20: Dimensional Legend FinishesDocument26 pagesTechnical Information 20: Dimensional Legend FinishesJulian RiverosNo ratings yet

- Oerlikon Fluxofil 42Document1 pageOerlikon Fluxofil 42karthiksaadhanaNo ratings yet

- Internal Details of The Machine .: Design & Analysis of Pelton Wheel TurbineDocument49 pagesInternal Details of The Machine .: Design & Analysis of Pelton Wheel TurbineASHITA K BNo ratings yet

- What Is Stud WeldingDocument4 pagesWhat Is Stud WeldingMithun MuraleedharanNo ratings yet

- Data Sheet ALBROMET W130Document1 pageData Sheet ALBROMET W130Paolo MilaniNo ratings yet

- Domex Welding PDFDocument16 pagesDomex Welding PDFAgourame Abderrahmane100% (1)

- EMI+Shielding+WIre+Mesh+Gasket ENG Jan.2021Document2 pagesEMI+Shielding+WIre+Mesh+Gasket ENG Jan.2021Anil KumarNo ratings yet

- Power Fast IiDocument24 pagesPower Fast IiJuan PalomoNo ratings yet

- Er 0262Document7 pagesEr 0262CarlosFeLipeReinosoNo ratings yet

- Casting Technology: DC School Text BookDocument22 pagesCasting Technology: DC School Text Bookhasan waqarNo ratings yet

- Concept of CENA1Document6 pagesConcept of CENA1taknevNo ratings yet

- Section V PDC Bit ManufacturingDocument24 pagesSection V PDC Bit ManufacturingVitaliy PopovychNo ratings yet

- 2022 - 07 - HBS Plate - UsaDocument11 pages2022 - 07 - HBS Plate - UsaJonathanFallasNo ratings yet

- UTP 306 PaDocument1 pageUTP 306 PaVIRPOPNo ratings yet

- Thermal Spray CoatingsDocument12 pagesThermal Spray CoatingsRobert ShinNo ratings yet

- 1 - Rectangular Duct (Single & Double Wall)Document40 pages1 - Rectangular Duct (Single & Double Wall)Tariq AsgharNo ratings yet

- Sample Question Bank-18me43Document6 pagesSample Question Bank-18me43YogeshPalanisamyNo ratings yet

- Complaint Investigation Report: Report No. Date Customer Name Supplied Part Grade SizeDocument3 pagesComplaint Investigation Report: Report No. Date Customer Name Supplied Part Grade Sizepm metlabNo ratings yet

- Two Solid Cylindrical Rods AB and 2. Select The Appropriate Pair of ElementsDocument4 pagesTwo Solid Cylindrical Rods AB and 2. Select The Appropriate Pair of ElementsAhmed Dhempsey Hali AbdulbasikNo ratings yet

- Plastic Mold Steels High Quality: HI-PM SeriesDocument6 pagesPlastic Mold Steels High Quality: HI-PM SeriestaknevNo ratings yet

- Cable Tray Perforated Tray NOBIDocument11 pagesCable Tray Perforated Tray NOBItRiaS eGanTeaNo ratings yet

- Cheat Sheet (Better Version)Document2 pagesCheat Sheet (Better Version)gokusmile776No ratings yet

- Welding Inspection: Multi-Choice Questions Paper 4 Please Return This Paper UnmarkedDocument5 pagesWelding Inspection: Multi-Choice Questions Paper 4 Please Return This Paper UnmarkedSuffian AliNo ratings yet

- Pipe HangersDocument26 pagesPipe HangersAhmed YousriNo ratings yet

- Reound Hardness TesterDocument3 pagesReound Hardness TesterpoongodiskNo ratings yet

- QuintSonic 7 E Okt 7Document6 pagesQuintSonic 7 E Okt 7Sivasankar JeyabaskaranNo ratings yet

- Maintenance and Service Guide: HP Compaq nc8000 Business Notebook HP Compaq nw8000 Mobile WorkstationDocument189 pagesMaintenance and Service Guide: HP Compaq nc8000 Business Notebook HP Compaq nw8000 Mobile WorkstationGlen GadowskiNo ratings yet

- TUP 18 20 en PDFDocument2 pagesTUP 18 20 en PDFRachid SmailiNo ratings yet

- Icwc Ups Budget Boq 251018Document3 pagesIcwc Ups Budget Boq 251018Rahul AldarNo ratings yet

- Low Cost Ground Power Jack For Your Airplane.: Bob Nuckolls Aeroelectric ConnectionDocument5 pagesLow Cost Ground Power Jack For Your Airplane.: Bob Nuckolls Aeroelectric ConnectionAdrian TodeaNo ratings yet

- Pump Unit KFA en KFAS EngDocument45 pagesPump Unit KFA en KFAS EngkujkojaNo ratings yet

- Liquip Gantry Plugs: Title: PurposeDocument5 pagesLiquip Gantry Plugs: Title: PurposePatricio AguilarNo ratings yet

- Oversea List No. Material Material Description QTYDocument2 pagesOversea List No. Material Material Description QTYAhmad Mursyidi KamaludinNo ratings yet

- 20 Main Blower Roots URAI Manual Highlighted For Oil ChangeDocument28 pages20 Main Blower Roots URAI Manual Highlighted For Oil ChangePorfirioDuarteZarateNo ratings yet

- Rodeo PDFDocument2,613 pagesRodeo PDFluigimasterNo ratings yet

- Guidelines Implementing Customs Concerns Under Executive Order 156Document19 pagesGuidelines Implementing Customs Concerns Under Executive Order 156Dreiron CastilloNo ratings yet

- TH PBLDocument11 pagesTH PBLAlbert FredriekNo ratings yet

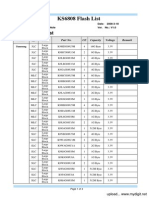

- KS6808 Flash ListDocument4 pagesKS6808 Flash ListopcrisNo ratings yet

- EngineDocument470 pagesEnginehristoforNo ratings yet

- Technology and Livelihood Education: Quarter 1, Wk.8 - Module 2Document43 pagesTechnology and Livelihood Education: Quarter 1, Wk.8 - Module 2Mary Jean MagdayNo ratings yet

- S8AENDocument8 pagesS8AENGuss33No ratings yet

- 001-Plumbing Tools PDFDocument26 pages001-Plumbing Tools PDFcha yokNo ratings yet

- MCT68ME Installation Manual: Roger Access Control SystemDocument2 pagesMCT68ME Installation Manual: Roger Access Control SystemMarkoNo ratings yet

- Panasonic Conduits PDFDocument1 pagePanasonic Conduits PDFAirvin John PalacioNo ratings yet

- 8X300 Reference Manual Oct77 PDFDocument154 pages8X300 Reference Manual Oct77 PDFMathias GutierrezNo ratings yet

- HGM180 180HC V1.0 enDocument8 pagesHGM180 180HC V1.0 enMiguel Angel Pavon CarbonellNo ratings yet

- How To Install Aftermarket Radio Into A Jetta 1999-2000.Document8 pagesHow To Install Aftermarket Radio Into A Jetta 1999-2000.Albert Suarez100% (1)

- Mr. Slim System Pre-Commissioning and Installation Check ListDocument4 pagesMr. Slim System Pre-Commissioning and Installation Check Listamerico zambrano contrerasNo ratings yet

- SIP 2011 CatalogueDocument44 pagesSIP 2011 CatalogueDave StewartNo ratings yet

- MODULENS-De Dietrich PDFDocument20 pagesMODULENS-De Dietrich PDFmikeNo ratings yet

- Minus 1 Bars - Minus 0.1: Nikuni KTM25F & 25N Circuit Diagram 00185Document1 pageMinus 1 Bars - Minus 0.1: Nikuni KTM25F & 25N Circuit Diagram 00185wacsii ccasullaNo ratings yet

- Чек листы и обязанности вахтенногоDocument2 pagesЧек листы и обязанности вахтенногоИлляNo ratings yet

- ct13 ct15 Engine Spec SheetDocument4 pagesct13 ct15 Engine Spec Sheetapi-277145483100% (1)

- Sample Electrical PlanDocument1 pageSample Electrical PlanMichael SabaulanNo ratings yet

- 5.3.2.A SimpleMachinesScavengerHuntDocument4 pages5.3.2.A SimpleMachinesScavengerHuntByed Pedroza VivesNo ratings yet