Professional Documents

Culture Documents

General Data: Pictures May Not Show Every (All) Optional Feature (S) On Actual Bit

Uploaded by

Daniel NavarroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General Data: Pictures May Not Show Every (All) Optional Feature (S) On Actual Bit

Uploaded by

Daniel NavarroCopyright:

Available Formats

General Data

IADC Code 117

Bearing Type Friction - No Bushing

Seal Type O-RING - HNBR

Journal Angle 33.0°

Cone Skew 3.00°

Cutting Structure

Gauge Row Teeth

Count 27

Shape Tapered A

Main Row Teeth

Shape Straight A

Pictures may not show every (all) optional feature (s) on actual bit

Total Count 63

6 " S11G Connection Size(ins)

Connection Type

3.500"

API REG PIN

Design Features of this bit Nozzle Code A

RC™ Drill Bits

Recommended Operating

RC™ drill bits have been reengineered to provide stable and reliable directional performance

in interbedded and intrusive formations. Field proven design philosophies enable harsh directional Parameters

sections to be drilled faster, more consistently. RC™ is built on the new RC™ lug Maximum make-up 9000

platform which reduces g-forces experienced during intermittent and cyclical side loading. Each bit Torque (ft-lbs)

is equipped with a premium bearing system and designed with optimized RC™ hydraulics for Weight on Bit Range

increased cleaning and efficient drilling to TD. The RC™ product line is available in sizes 6"

through 12 1/4". Max (klbs) 30

Min (klbs) 5

Premium Journal Bearing

Max (tonne) 14

RC™ Lug Min (tonne) 2

Reengineered to deliver stable, reliable and faster drilling in the toughest directional applications. Rotary Speed (RPM) 60 - 200

Built-in stability reduces the amount of g-force experienced during intermittent and cyclical side

loading. The lug allows for a larger range of freedom for directed flow to support bit hydraulics

optimization and faster section completion.

RC™ Hydraulics

The bit hydraulics have been developed though iterative CFD simulations to choose the optimal Additional Information

nozzle placement and directed flow, improving cone cleaning and cuttings evacuation for the specific Min Annular Area (in²) 4.60

cutting structure and lug geometry. Bit Breaker 121565

RC™ Shirttail Protection

In some applications this bit is run successfully beyond these

Maximized amount of precision placed hardmetal and superior wear resistant inserts provide heavy parameters. Contact your NOV ReedHycalog Representative for

duty protection in harsh directional applications. Engineered to maximize stability without limiting recommended operating parameters in your application. NOV

annular flow for increased cleaning and efficient drilling to TD. ReedHycalog reserves the right to revise these specifications, based

on advances and improvements in technology.

O-Ring Seal - HNBR

Hydrogenated Nitrile Butadiene Rubber (HNBR) O-ring seal.

ArmorClad™ II Hardmetal

Superior abrasion-resistant, four-phase welded hardmetal with thicker full-tooth coverage.

© 2019 National Oilwell Varco

All U.S. and foreign rights reserved.

You might also like

- 12.250 TKC66Document1 page12.250 TKC66Leonardo BarriosNo ratings yet

- 17.500 Tffi716s-A4 PDFDocument1 page17.500 Tffi716s-A4 PDFpendexxNo ratings yet

- Product Specifications:: Bhitrackpage ("Bit","Bit Stylesheet") %Document1 pageProduct Specifications:: Bhitrackpage ("Bit","Bit Stylesheet") %Joe CruzNo ratings yet

- 6 '' STX-40Document1 page6 '' STX-40REGHIS HaouesNo ratings yet

- 1475in Bit EMS11Document1 page1475in Bit EMS11eng20072007No ratings yet

- 6'' VMG-55DVHX2Document1 page6'' VMG-55DVHX2REGHIS HaouesNo ratings yet

- Product Specifications: Specification Sheet 12 1/4" (311 MM)Document1 pageProduct Specifications: Specification Sheet 12 1/4" (311 MM)WHWENNo ratings yet

- Reed PDC NomenclatureDocument12 pagesReed PDC NomenclatureBaitaw WanwarangNo ratings yet

- NC20 Metric & Inch: YG1 NanoCut Solid Miniature TurningDocument5 pagesNC20 Metric & Inch: YG1 NanoCut Solid Miniature TurningferNo ratings yet

- 13.5 RWD2X60512.25X - E19039Document1 page13.5 RWD2X60512.25X - E19039Joe CruzNo ratings yet

- Product Specifications:: Bhitrackpage ("Bit","Bit Stylesheet") %Document1 pageProduct Specifications:: Bhitrackpage ("Bit","Bit Stylesheet") %Joe CruzNo ratings yet

- BP Roo: Product SpecificationsDocument1 pageBP Roo: Product SpecificationsWHWENNo ratings yet

- 12.250 - PDC BitDocument1 page12.250 - PDC BitMoh Syamsul BahriNo ratings yet

- 12 1/4'' RWD2S510.625Z: Reference PhotoDocument1 page12 1/4'' RWD2S510.625Z: Reference PhotoJoe CruzNo ratings yet

- 14.75 RWD2C512.250 - E18716Document1 page14.75 RWD2C512.250 - E18716Joe CruzNo ratings yet

- 8.500 DSF713M-B32Document1 page8.500 DSF713M-B32pendexxNo ratings yet

- HC606 Drill Bit ManualDocument1 pageHC606 Drill Bit ManualMahdy BasimNo ratings yet

- Magnum: Rock BitsDocument1 pageMagnum: Rock Bitsmohammad teimuriNo ratings yet

- Rr220 Series Standard Air Bearing Bits: Drilling ApplicationsDocument2 pagesRr220 Series Standard Air Bearing Bits: Drilling ApplicationsandraNo ratings yet

- Profile & Cutter Placement: Reference Photo: 17 1/2" FC619Document1 pageProfile & Cutter Placement: Reference Photo: 17 1/2" FC619Hendra SiswantoNo ratings yet

- 8.500 SK713MDocument1 page8.500 SK713MMiguelNo ratings yet

- 8 5-Mme65rDocument1 page8 5-Mme65rWHWENNo ratings yet

- MAGNUM Rock Bits IADC 515X Type 20MD 12-1/4" (311.2mmDocument1 pageMAGNUM Rock Bits IADC 515X Type 20MD 12-1/4" (311.2mmmohammad teimuriNo ratings yet

- TurningDocument766 pagesTurningDavid BahenaNo ratings yet

- 6.000 SKC613MDocument1 page6.000 SKC613MDaniel NavarroNo ratings yet

- 12-25 15MFD 447X 2Document1 page12-25 15MFD 447X 2mohammad teimuriNo ratings yet

- Axeblade Ps PDFDocument1 pageAxeblade Ps PDFpendexxNo ratings yet

- 122 He34d3dmrzv - 537Document1 page122 He34d3dmrzv - 537Adnane BensmaineNo ratings yet

- High Speed and High Efficiency Indexable DrillDocument20 pagesHigh Speed and High Efficiency Indexable DrillRacem RebaiNo ratings yet

- Analisis Penggunaan Bit For ChevronDocument15 pagesAnalisis Penggunaan Bit For Chevronfaishal hafizhNo ratings yet

- Product Specifications: Specification Sheet 16" (406 MM)Document1 pageProduct Specifications: Specification Sheet 16" (406 MM)Daniel NavarroNo ratings yet

- 6.75 GTD63C 1050637Document1 page6.75 GTD63C 1050637Leonardo BarriosNo ratings yet

- 12-25 15MFD 445X 2Document1 page12-25 15MFD 445X 2mohammad teimuriNo ratings yet

- BP Roo: Product SpecificationsDocument1 pageBP Roo: Product SpecificationsWHWENNo ratings yet

- Cutter HF 2020 LowresDocument1 pageCutter HF 2020 LowresSivaramanNo ratings yet

- SKF Bearings - Trouble-Free Operation PDFDocument19 pagesSKF Bearings - Trouble-Free Operation PDFOwenNo ratings yet

- Hydroseal Valves Legacy SeriesDocument16 pagesHydroseal Valves Legacy SeriesJuan David Alvarez CastroNo ratings yet

- 094 XS616Document1 page094 XS616AhmedNo ratings yet

- CSK FormspragDocument7 pagesCSK FormspragdenisNo ratings yet

- HC506ZDocument1 pageHC506ZLeonardo BarriosNo ratings yet

- Directional: 12 1/4in Sdi519 PDCDocument1 pageDirectional: 12 1/4in Sdi519 PDCKhairatul Nada BurhanuddinNo ratings yet

- Kymera Mach 4 Hybrid Drill Bit FlyerDocument2 pagesKymera Mach 4 Hybrid Drill Bit FlyerReginaMendozaNo ratings yet

- E1224Document3 pagesE1224Alejandro Garcia FloresNo ratings yet

- 12.25 QH1RC 627547 PDFDocument1 page12.25 QH1RC 627547 PDFpendexxNo ratings yet

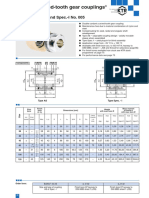

- Bowex Curved-Tooth Gear Couplings: Type As No. 004 and Spec.-I No. 005Document1 pageBowex Curved-Tooth Gear Couplings: Type As No. 004 and Spec.-I No. 005Mauricio Ariel H. OrellanaNo ratings yet

- Bevel Gears - KHK PDFDocument50 pagesBevel Gears - KHK PDFSantiago MolinaNo ratings yet

- XCD DrillBit BrochureDocument2 pagesXCD DrillBit BrochureebayksNo ratings yet

- 280 Eb1gs - 115Document1 page280 Eb1gs - 115Adnane BensmaineNo ratings yet

- 8.500 SKC713MDocument1 page8.500 SKC713MMiguelNo ratings yet

- AR700Document2 pagesAR700Paulo Santos da SilvaNo ratings yet

- Smith Tool: 10464 ER Purpose ER Purpose 9744 Design Specifications Design SpecificationsDocument1 pageSmith Tool: 10464 ER Purpose ER Purpose 9744 Design Specifications Design Specificationsmohammad teimuriNo ratings yet

- Encoder 7055Document2 pagesEncoder 7055Stephane RichardNo ratings yet

- d14-019-1_is_ts_vb45-sDocument1 paged14-019-1_is_ts_vb45-sDAVID SOTONo ratings yet

- MAPAL VersaCut enDocument16 pagesMAPAL VersaCut enPlant Head PrasadNo ratings yet

- YU-YBD21: AmericaDocument6 pagesYU-YBD21: AmericaMichel DominguesNo ratings yet

- 64983B0703 USL SpecSheetDocument1 page64983B0703 USL SpecSheetLeonardo do Amaral SilvaNo ratings yet

- Reference Photo:: 9-7/8 In. (250.8mm) QD503XDocument1 pageReference Photo:: 9-7/8 In. (250.8mm) QD503XpendexxNo ratings yet

- PDC HycalogDocument1 pagePDC HycalogDian SikumbangNo ratings yet

- Vibratory Contractors - AEHQ5837-01 08-08Document2 pagesVibratory Contractors - AEHQ5837-01 08-08Carlo PoliNo ratings yet

- 6.000 SKC613MDocument1 page6.000 SKC613MDaniel NavarroNo ratings yet

- Hydra-Jar AP Double-Acting Hydraulic Drilling Jar: Jarring DownDocument4 pagesHydra-Jar AP Double-Acting Hydraulic Drilling Jar: Jarring DownpendexxNo ratings yet

- Product Specifications: 16 MM 19 MM Face 0 57 Gauge 12 0Document1 pageProduct Specifications: 16 MM 19 MM Face 0 57 Gauge 12 0Daniel NavarroNo ratings yet

- 3 12 13.30 S NC38 DatasheetDocument4 pages3 12 13.30 S NC38 DatasheetDaniel NavarroNo ratings yet

- Product Specifications: Specification Sheet 16" (406 MM)Document1 pageProduct Specifications: Specification Sheet 16" (406 MM)Daniel NavarroNo ratings yet

- Product Specifications: Specification Sheet 16" (406 MM)Document1 pageProduct Specifications: Specification Sheet 16" (406 MM)Daniel NavarroNo ratings yet

- BJS C, Usa: Doug Lehr Doug Lehr Doug Lehr Doug LehrDocument17 pagesBJS C, Usa: Doug Lehr Doug Lehr Doug Lehr Doug LehrDaniel NavarroNo ratings yet

- Ext PDFDocument36 pagesExt PDFMisha KulibaevNo ratings yet

- Various Methods of Speed Control of Induction Motor-1Document11 pagesVarious Methods of Speed Control of Induction Motor-1Sufail ANo ratings yet

- MG 3 Cylinder Head Bolt Torque Settings PDFDocument2 pagesMG 3 Cylinder Head Bolt Torque Settings PDFMikeNo ratings yet

- Parts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 098902-0380-01Document23 pagesParts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 098902-0380-01Solofoniaina Ginô ChristianNo ratings yet

- Instruction Manual KPC - TMDocument22 pagesInstruction Manual KPC - TMNguyen AnNo ratings yet

- Integrated Safety Device Comem RIS2: Instruction ManualDocument12 pagesIntegrated Safety Device Comem RIS2: Instruction ManualMichel BrunoNo ratings yet

- Darley "Wasp" Quick Attack: #DemanddarleyDocument2 pagesDarley "Wasp" Quick Attack: #DemanddarleyAdvenser GroupNo ratings yet

- Parts List D905EBG2 EngineDocument134 pagesParts List D905EBG2 EngineJulio RamirezNo ratings yet

- An Analysis DC-Machine Commutation: JapanDocument9 pagesAn Analysis DC-Machine Commutation: JapanDanang AjiNo ratings yet

- Tts - Heavy Lift Cranes DK II Heavy - 2014Document2 pagesTts - Heavy Lift Cranes DK II Heavy - 2014Ruben Bartolome GarciaNo ratings yet

- Banda de Infusión, Baxter, Flo-Gard 6201, Manual de ServicioDocument202 pagesBanda de Infusión, Baxter, Flo-Gard 6201, Manual de ServicioRaul PerezNo ratings yet

- BV50 Actuator Replacement PDFDocument13 pagesBV50 Actuator Replacement PDFnicamarcosNo ratings yet

- Electrical Letter Notice Handling No of Letter Description Ramboll LetterDocument24 pagesElectrical Letter Notice Handling No of Letter Description Ramboll LetterWelday GebremichaelNo ratings yet

- HRPL Asset Details ReportDocument10 pagesHRPL Asset Details ReportSunil PatelNo ratings yet

- ZF Automatic Transmission 6hp26 Factory Service GuideDocument13 pagesZF Automatic Transmission 6hp26 Factory Service Guideanubisz9508No ratings yet

- Yokes Y6 Y7 Y8Document4 pagesYokes Y6 Y7 Y8KuKu FunNo ratings yet

- Jiangmen Wanneng Lock Inc Product CatalogDocument13 pagesJiangmen Wanneng Lock Inc Product CatalogSimone G. GoularteNo ratings yet

- Thermostatic Expansion Valves With Fixed Orifice,: Type TDE / TDEBDocument20 pagesThermostatic Expansion Valves With Fixed Orifice,: Type TDE / TDEBMeher YoussfiNo ratings yet

- Webench Design Report: Electrical BOMDocument14 pagesWebench Design Report: Electrical BOMrey_hadesNo ratings yet

- Ino 3120Document96 pagesIno 3120Juan JoseNo ratings yet

- AVR sps-101Document1 pageAVR sps-101Sunil SangaNo ratings yet

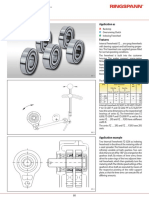

- Internal Freewheels FZ : With Ball Bearing PropertiesDocument6 pagesInternal Freewheels FZ : With Ball Bearing Propertiesmohammed kareemNo ratings yet

- Dual Source Meter EM 9024Document2 pagesDual Source Meter EM 9024ilaaNo ratings yet

- Expt No: 1 Mode Characteristics of Reflex Klystron 1.1 ObjectiveDocument6 pagesExpt No: 1 Mode Characteristics of Reflex Klystron 1.1 ObjectivePriya DarshuNo ratings yet

- Manual Cat Grader 24H 31-3-14Document29 pagesManual Cat Grader 24H 31-3-14Ahmad HandokoNo ratings yet

- Manual Fisher 655Document16 pagesManual Fisher 655Francisco EspinozaNo ratings yet

- Tadano GR 1600XL 2Document14 pagesTadano GR 1600XL 2Ag Shafiee Ag KassimNo ratings yet

- Clutch Systems: For Passenger Cars Up To 800 NMDocument10 pagesClutch Systems: For Passenger Cars Up To 800 NMTavi PetrisorNo ratings yet

- STP36NE06 Power MOSFET DatasheetDocument10 pagesSTP36NE06 Power MOSFET Datasheetbrunobrambilla90No ratings yet

- FA5i MR PDFDocument2 pagesFA5i MR PDFpramodh kumarNo ratings yet