Professional Documents

Culture Documents

Adesina

Uploaded by

ambo wellangCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Adesina

Uploaded by

ambo wellangCopyright:

Available Formats

American Journal of Research Communication www.usa-journals.

com

Production and characterization of fungal extracellular β-mannanase

Felicia C. Adesina*, Omolola A. Oluboyede, Oludare S. Agunbiade, Bolanle O.

Aderibigbe, Olatunji H. Kolade, Ekundayo M. Oluwole.

Department of Microbiology, Lead City University, Ibadan, Nigeria

*adesinafelicia@yahoo.com

ABSTRACT

Fungal isolates obtained from degrading wood were screened for their β-mannanase

production on plate agar containing locust bean gum as main carbon source. Two isolates

with relatively large zones of hydrolysis of mannan on the plate agar were identified and used

to produce β-mannanase in submerged fermentation and assayed at two day interval for six

days in stationary and agitated flasks. The amount of protein produced by these isolates into

the liquid medium was also monitored every other day for six days in differently incubated

flasks. β-mannanase produced by the isolates was afterwards characterized. All the isolates

screened showed zones of clearance on plate agar. Isolates with relatively large zones of

clearance among the screened isolates were identified as Aspergillus niger and Trichoderma

spp. Highest mannanase activity recorded for A. niger (0.427U/ml) and Trichoderma

spp(0.473U/ml) was on the 4th day of incubation in agitated flasks. Highest total protein

released by A. niger and Trichoderma spp. into the medium were 1.296mg/ml and

1.158mg/ml respectively on days 4 and 6 in agitated flasks. A.niger and Trichoderma spp.

had their highest specific β-mannanase activity of 0.466U/ml in agitated flask and 1.066U/ml

in stationary flask on the 6th and 4th days of incubation respectively. β- mannanase by both

isolates showed highest activity at pH 5 while peak activity of β- mannanase by A. niger was

at 30oC and Trichoderma spp. was at 30oC and 50oC.

Keywords: β - mannanase, Trichderma spp., Aspergilus niger, Screeening. Degrading wood

{Citation: Felicia C. Adesina, Omolola A. Oluboyede, Oludare S. Agunbiade, Bolanle O.

Aderibigbe, Olatunji H. Kolade, Ekundayo M. Oluwole. Production and characterization of

fungal extracellular β-mannanase. American Journal of Research Communication, 2013:}

www.usa-journals.com, ISSN: 2325-4076.

INTRODUCTION

β -d-Mannopyranosyl residues are widely distributed in nature occurring abundantly as

building blocks of several plant structural and storage polysaccharides (Buckeridge and dos

Santos, 2000). β -1,4-linked d-mannopyranosyl residues also form the main chain of

galactomannans occurring in various plant They are abundant particularly as building blocks

of several plant structural and storage polysaccharides. Together with d-glucopyranosyl

residues, d-mannopyranosyl residues form a β -1,4-linked backbone of galactoglucomannans

which is a type of hemicellulose in wood, (Timell, 1967; de Vries and Viser, 2001). Fungi

like Aspergillus tamarii (Civas et al., 1984), A. niger (Ademark et al., 1998; Siti Norita et al.,

2010), Sporotrichum cellulophilum (Araujo & Ward, 1991), Scopulariosis candida (Mudau

and Setati, 2008), Aspergillus fumigatus (Puchart et al., 2004) and Trichoderma reesei

(Arisan Atac et al., 1993) have been targeted for β-mannanases isolation. β-endomannanases

commonly produced by Aspergilli are responsible for degradation of mannan component of

Adesina, et al., 2013: ajrc.journal@gmail.com

American Journal of Research Communication www.usa-journals.com

plant polysacchrides. β - mannanases hydrolyze the backbone of galactoglucomannans,

producing mannooligosaccharides. The ability of A. niger to grow in palm kernel cake waste

containing mannan-based polysaccharides, for manannase production has been reported

(Abd-Aziz et al., 2008). The biotechnological potential of mannan-hydrolysing enzymes, in

particular the mannanases, has been demonstrated within various industries. Industrially

useful mannanase have recently attracted attention due to their role in the pulp and paper

industry to remove the hemicelluloses from pulps (Gubitz et al.,1997) and in pulp bleaching

processes. This positive role has minimized the use of environmentally harmful bleaching

chemicals in the pulp and paper industry (Lahtinen et al., 1995; Cuevas et al., 1996).

Mannanases have potential application in animal feed production (Wu et al., 2005; Lee et al.,

2005; Sae-Lee, 2007) and laundry detergents (Schafer et al., 2002). Bioconversion of

agriculture waste containing mannan-based polysaccharides into valuable products such as

animal feeds also required microorganisms capable of producing mannan degrading enzymes.

Mannanases are also used for the extraction of vegetable oils from leguminous seeds and the

clarification of fruit-juices in the food industry (Christgau et al., 1994). They are useful in

reducing the viscosity of extracts during manufacture of instant coffee, chocolate and cacao

liquor (Belitz & Grosch, 1987; Francoise et al., 1996) to lower the cost for subsequent

evaporation and drying (Wong & Saddler, 1993). Mannanases are potentially used in the

pharmaceutical industry for the production of physiologically interesting oligosaccharides

(Christgau et al., 1994). The objective of this study was to screen 15 fungal isolates obtained

from degrading wood for the production of β-mannanase, induce the most potent fungal

isolates to produce the enzyme in submerged fermentation flasks and characterize the enzyme

biochemically.

MATERIALS AND METHODS

Sample sources

Decaying wood samples were collected into clean, properly labeled, polythene bags obtained

from different locations in Ibadan metropolis, Oyo state Nigeria where they are cast as waste.

The samples were taken to the laboratory for further work.

Preparation of Culture medium for fungal isolation

Potato dextrose agar medium was prepared in 500ml Erlenmeyer flask according to

manufacturer’s instruction and sterilized by autoclaving at 121oC (15 psi) for 15 minutes.

This medium provided a balance mixture of required nutrients that permitted the rapid growth

of the fungal isolates.

Isolation and screening of fungal isolates

Each degrading wood sample was macerated into powder and transferred into potato dextrose

agar plates. The plates were thereafter incubated at 25oC + 2 oC. Screening of the isolates for

mannanase activity was performed using a chemically defined medium with the following

composition in g/l: Mg SO4.7H2O-0.5g; Fe SO4.7H2O-0.05g; KH2PO4-1g; agar 10g; KCl-

0.5g;NaNO3-2g, Locust bean gum-0.5% (w/v) dissolved in 0.1M citrate buffer at pH5.6. The

medium was sterilized by autoclaving at 121°C and 15 psi for 15 minutes and afterwards left

to cool to 40oC and decanted to petridishes. Agar plates were inoculated with the fungal

isolates and incubated for 5 days at 25oC + 2 oC. Culture plates were afterwards flooded with

0.4% (w/v) Congo red solution and 0.5M NaCl solution and for 15 minutes and mannan

hydrolysis observed by appearance of clear zones around the fungal growth (Downie et al.,

Adesina, et al., 2013: ajrc.journal@gmail.com

American Journal of Research Communication www.usa-journals.com

1994).. The relative activity was calculated as the percentage of the ratio of the diameter of

the clearing zone to the diameter of the fungi growth. Isolates with high relative mannanase

activities were selected for production of the enzyme. Selected isolates were maintained on

agar slants of a medium composed of the following in g/l: Mg SO4.7H2O- 0.5g ; Fe

SO4.7H2O- 0.05g; KH2PO4 -1g; agar 10g; KCl-0.5g;NaNO3-2g, Locust bean gum-0.5%(w/v)

dissolved in 0.1M citrate buffer with final pH adjusted to 5.6 and stored at 4oC until used

(Wiley et al., 2008).

Identification of selected Fungal isolates

The selected fungal isolates were identified using their cultural and morphological

characteristics, (Domsch et al.,1980) and (Kiffer Morrelet, 1994).

Mannanase Production

50 ml aliquots of a chemically defined medium with the following composition in g/l: Mg

SO4.7H2O- 0.12g ; Fe SO4.7H2O- 0.05g; KH2PO4 -0.25g; KCl-0.5g;NaNO3-0.25g, Locust

bean gum-0.5%(w/v), peptone water-3.75g 0.1M in citrate buffer( pH 5.6) were dispensed in

250ml Erlenmeyer flasks. The medium was sterilised at 121oC for 15 minutes and allowed to

cool afterwards. Each flask was inoculated with 2ml fungal spores suspension obtained from

7 day old slant cultures and incubated for 6 days at 28+2oC. Some of the incubated flasks

were subjected to agitation while some were incubated in stationary state. Each treatment was

carried out in triplicates and the results obtained throughout the work were the arithmetic

mean of three experiments + mean error. Samples from each flask were taken at 2 day

intervals for analysis.

Preparation of crude Enzyme

At the end of each incubation period, fungal cells were separated by contact method (Krishna

et al.,1996) and crude filtrates were centrifuged at 6000 rpm for 15 minutes in a cold

centrifuge to remove the cells. The supernatant was taken as the crude enzyme solution

(Naggar et al., 2006).

Determination of Protein Content

Protein content was determined by the method of Lowry et al., (1951). Standard curve was

plotted using Bovine serum albumin (Sigma, U.SA.).

Assay for mannanase activity

0.5 % (w/v) locust bean gum dissolved in 0.1 M citrate buffer at pH5.6 was used as the

substrate mixture. 1 ml of the substrate mixture was added to 1ml of the crude enzyme

solution and incubated in a water bath at 50oC for 15 minutes. Afterwards 1ml of

dinitrosalicylic acid (DNS) was added to 1 ml of each enzyme – substrate mixture and boiled

for 5 minutes. The absorbance of the mixture was thereafter measured at 540 nm in a

spectrophotometer ((752W UV-VIS Spectrophotometer). The amount of mannose released

was determined by the method of Miller, (1959). One unit of mannanase was defined as the

amount of mannanase that released 1 micro mole of mannose in one millimeter of the

reaction mixture under the assay conditions.

Adesina, et al., 2013: ajrc.journal@gmail.com

American Journal of Research Communication www.usa-journals.com

Characterisation of Enzyme

The crude enzyme solution was used for this test; the temperature optima of the crude β-

mannanases were determined by incubating the enzymes with 0.5%(w/v) locust bean gum

substrate for 30 min at different temperatures ranges of 30oC, 35oC, 40oC, 45oC and 50oC at

pH 5.6, followed by determination of reducing sugars in the mixture. Optimum pH for the

enzyme was also determined by monitoring the amount of reducing sugar released at

different pH ranges of 3, 4, 5, 6, 7 and 8 for 30 minutes.

RESULTS

Fifteen fungal isolates were obtained, the mean relative mannanase activities of the isolates

on plate screening test are shown on Table 1. Based on their high mean relative mannanase

activities (Table 1), isolates 3e2 and 3i were selected and identified.Isolates 3e2 and 3i were

identified as Aspergillus niger and Trichoderma sp. based on their cultural and

morphological characteristics respectively (Domsch et al.,1980) and (Kiffer Morrelet , 2000).

Table 1 shows the relative mannanase activities of screened fungal isolates from degrading

wood material. Isolates 3i(61.67) had the highest relative mannanase activity among them

followed by isolate 3e2(36.70), this informs why they were chosen for the production of

mannanase in submerged fermentation.

Table 1: Mean relative β-mannanase activity of isolates

ISOLATES CODE Mean relative mannanase

activities(%) of isolates

3a 19.33+0.064d

2f 15.67+0.176gh

2e 18.67+0.176e

3i 61.67+0.145a

2a 12.67+0.176j

1g 19.13+0.231d

3e1 11.73+0.634k

3d 16.00+0.231g

2b 13.70+0.174h

2d 13.67+0.073h

1b 13.33+0.145i

1a 18.33+0.145e

3e2 36.70+0.291b

3g 23.70+0.136c

1c 17.33+0,088f

AF 22.67+0.12cd

Each value is the mean of triplicate results + mean error. Means with different superscript within the same row are

significantly different (p<0.05).

Adesina, et al., 2013: ajrc.journal@gmail.com

American Journal of Research Communication www.usa-journals.com

Tables 2 shows the mannanase activities of each isolate on days 2, 4 and 6 of incubation in

stationary and agitated flasks respectively. Trichoderma spp. had its highest mannanase

activity in stationary flasks on the second day of incubation and the least on the sixth day

with no significant differences in activities on days 2 and 4 of incubation. However A niger

had the highest mannanase activity on the 6th day of incubation and least on the 2nd day, there

was significant difference in mannanase activity of this fungus on the days assays were

carried out. In agitated flasks, mannanase activity of Trichoderma spp. and A.niger were

highest on the 4th day if incubation and least on the second day for both fungi. There was

significance difference in the mannanase activities of A.niger in all the days assays were

carried out while for Trichoderma spp., there was no significant difference in activity on the

second and sixth days of incubation.

Total protein released into the medium by each of the fungal isolates are shown on Table 3,

protein was maximally produced into the medium in stationary flasks by Trichoderma spp.

and A.niger on the 6th day of incubation and least on the 4th and 2nd days respectively. In

agitated flasks, protein was released maximally by Trichoderma spp. on the 4th day and by A.

niger on the 6th day of incubation. Least amount of protein was released by Trichoderma spp.

into the medium in agitated flasks on the 6th day and by A. niger on the 2nd day of incubation.

There was significant difference in the amount of protein released by each fungus on the

different days assays were carried out.

Results of specific β - mannanase activity of the isolates were shown on Table 4.

Trichoderma spp. had its highest specific mannanase activity on day 4 of incubation while A.

niger had its highest on day 6 in stationary flasks. In agitated flasks, however Trichoderma

spp. had highest specific mannanase activity of 0.466U/mg on day 6 while 0.402U/mg was

recorded for A. niger on day 6 of incubation respectively. There was significant difference in

specific mannanase activities of each fungus throughout incubation.

Tables 5 and 6 show the result of characterisation of the β – mannanase produced by the

isolates. β – mannanase produced by Trichoderma spp. had optimum activity at two

temperatures (30oC and 50oC). Optimum activity for β –mannanase produced by A.niger was

at 30oC, although the activity was still stable at 35oC with a value that is not significantly

different from the value obtained at 30oC as shown on Table 5. There was also no significant

difference in the activity of this enzyme at 40oC and 45oC however the values dropped to

about half of the values obtained at 30oC and 35oC.

Mannanase produced by Trichoderma spp. had optimum activity at pH 5 while its activity

was least at pH 8. The activity of this enzyme started to drop pH 5 until it was least at pH8,

the activity of this enzyme at pH 7 was not significantly different from its activity at pH 8 as

shown on Table 6. In this work, A.niger produced a mannanase with optimum activity of

0.435U/ml also at pH 5 while its activity was lowest at pH 7.

Adesina, et al., 2013: ajrc.journal@gmail.com

American Journal of Research Communication www.usa-journals.com

Table 2: β- Mannanase activities of Isolates on Different Incubation Periods in

stationary and agitated flasks

Mannanase activities (U/ml) of isolates on Different Incubation Period (Days)

(Stationary flasks) (Agitated flasks)

ISOLATES Day2S Day 4S Day 6S Day 2A Day 4A Day 6A

Trichoderma 0.263+0.002a 0.259+0.002a 0.066+0.001b 0.074+0.002b 0.473+0.003a 0.081+0.002b

sp.

A. niger 0.075+0.001c 0.143+0.002b 0.325+0.002a 0.054+0;002c 0.427+0.002a 0.172+0.002b

Each value is the mean of triplicate results + standard mean error. KEY: 2S, 4S, 6S= Cultures in Stationary flasks. 2A, 4A,

6A= Cultures in agitated flasks. Means with different superscript within the same row are significantly different (p<0.05).

Table 3: Total Protein released by isolates into fermentation medium in stationary and

agitated flasks

ISOLATES Protein content(mg/ml) on Different Incubation Period (Days)

(Stationary flasks) (Agitated flasks)

Day2S Day 4S Day 6S Day 2A Day 4A Day 6A

Trichoderma 0.694+0.002b 0.244+0.002c 0.946+0.002a 0.707+0.003b 1.158+0.002a 0.392+0.001c

sp.

A. niger 0.269+0.002c 0.871+0.002b 0.945+0.002a 0.882+0.002c 1.067+0.002b 1.296+0.002a

Each value is the mean of triplicate results + standard mean error. Means with different superscript within the same row are

significantly different (p<0.05). KEY: 2S, 4S, 6S= Cultures in Stationary flasks. 2A, 4A, 6A= Cultures in agitated flasks

Table 4: Specific β - Mannanase Activity of Isolates on different Days of Incubation in

stationary and agitated flasks

ISOLATES Specific mannanase activity of isolates (U/mg) on Different Incubation Days

(Stationary flasks) (Agitated flasks)

Day2S Day 4S Day 6S Day 2A Day 4A Day 6A

Trichoderma 0.373+0.001 1.066+0.002 0.070+0.002 0.112+0.001 0.411+0.002 0.466+0.001a

b a c c b

sp.

Aspergillus 0.276+0.002b 0.165+0.002c 0.345+0.002a 0.063+0.002c 0.402+0.004a 0.134+0.002b

niger

Each value is the mean of triplicate results + standard mean error. Means with different superscript within the same row are

significantly different (p<0.05). KEY: 2S, 4S, 6S= Cultures in Stationary flasks. 2A, 4A, 6A= Cultures in agitated flasks

Table 5: Optimum temperature of β - Mannanase produced by isolates

Isolates Mannanase activities(U/ml) of isolates at Different Temperatures(oC)

30 35 40 45 50

Trichoderma sp. 0.411+0.007a 0.358+0.001b 0.134+0.009c 0.072+0.010d 0.398+0.003a

A.niger 0.573+0.027a 0.522+0.020a 0.279+0.009b 0.278+0.009b 0.162+0.006c

Each value is the mean of triplicate results + mean error. Means with different superscript within the same row are

significantly different (p<0.05).

Adesina, et al., 2013: ajrc.journal@gmail.com

American Journal of Research Communication www.usa-journals.com

Table 6: Optimum pH of β -Mannanase produced by isolates

Isolates Mannanase activities(U/ml) of isolates at Different pH

3 4 5 6 7 8

Trichoderma 0.288+0.003b 0.230+0.009c 0.418+0.007a 0.113+0.00e 0.191+0.003d 0.104+0.003e

sp.

A.niger 0.245+0.001c 0.228+0.003d 0.435+0.001a 0.339+0.001b 0.112+0.001e 0.154+0.001d

Each value is the mean of triplicate results + mean error. Means with different superscript within the same row are

significantly different (p<0.05).

DISCUSSION

Growing interest in potential application of beta 1, 4 - mannanase in various industries has

triggered increasing research towards biochemical characterisation of these enzymes.

Consequently beta mannanases of fungal and bacterial sources have been characterized

(Ferreira and Filho, 2004).

Two of the isolates obtained from the decaying wood samples, namely Trichoderma spp. and

Aspergillus niger had relatively high mannanase activity. This is in correlation with other

researchers who have used Aspergillus niger and Trichoderma sp. in the production of

various enzymatic and non-enzymatic bioproteins such as mannanase, glucanase and

cellulases (Pentilla et al., 1998; Viikari et al., 1998; Fadel 2001; Immanuel et al., 2007).

Hemicellulloses are one of the most abundant polymers in nature and one of the very

important enzyme for the digestion of this component is β-mannanase enzyme. It hydrolyzes

mannan yielding mannotriose and mannobiose (Stalbrand et al., 1993). The screening result

showed that Trichoderma sp. showed the highest mannanase activity followed by A.niger

cultures. The results showed that A. niger and Trichoderma spp. obtained in this work can

produce β-mannanase enzyme when cultured in medium containing locust bean gum as sole

carbon source. Extracellular proteins with significant mannanase activity were obtained from

the cultures( Tables 2,3 and 4). Most species of Trichoderma and A. niger are notable

producers of extracellular enzymes including important plant cell-wall hydrolyzing enzymes

such as mannanases (de Vries and Visser, 2001). The protein levels and mannanase activities

of the crude enzyme preparations however differed significantly.

The lowest protein released by Trichoderma spp. in agitated flasks was on the 6th day of

incubation while for stationary was on the fourth day. This is the basis for the high specific

mannanase activity obtained for this isolate on these days (Table 4). However for A.niger, the

specific mannanase activity of this isolate was highest on the 6th day and 4th day for stationary

and agitated flasks respectively which happens not to be the days lowest protein levels were

recorded for this isolate (Table 4).

The cultures in agitated flasks were observed to have higher mannanase activity and protein

content than those in static flasks. This may be attributed to the oxygen limitation that could

be a serious problem in the shaken culture due to the highly non-Newtonian medium caused

by the filamentous growth of each of the isolates (Grobwindhager et al., 1999).

The β - mannanase produced by Trichoderma spp. in this study has maximum activity at 30

°C and 50 °C as shown in Table 5. These peaks may indicate that this isolate secreted two or

more distinct β - mannanase into their environment. Viikari et al. (1993) reported that

Adesina, et al., 2013: ajrc.journal@gmail.com

American Journal of Research Communication www.usa-journals.com

mannanases were usually secreted into the culture fluid as multiple enzyme form. Gübitz et

al. (1996) also reported two mannanases from Sclerotium rolfsii which had optimum

temperature between 72 °C and 74 °C. The optimum temperature obtained for mannanase by

A. niger falls within the range for mesophilic fungi. The activity of β - mannanase by

Trichoderma spp. and A. niger was highest at pH 5 (Table 6) and remain more active to

around neutral pH region. The β -mannanases reported so far exhibit acidic to neutral pH

optima just like this isolates and temperature optima between 40oC and 70oC (Stalbrand et al.,

1993; Puchart et al., 2004), The pH optimum (pH 5) obtained for these β - mannanases was

similar to those of fungal β -mannanases that usually lie between pH 3 – 5.5 (Stalbrand et al.,

1993; Christgau et al., 1994; Ademark et al., 1998; Sachslehner and Haltrich, 1999; Siti

Norita et al., 2010). However, it was lower than those reported for bacterial β - mannanases

which have pH optima close to neutral pH (Viikari et al., 1993). Recently, a β - mannanase

produced by Scopulariopsis candida was reported to be most active at pH 6 (Mudau and

Setati, 2008).

CONCLUSSION

Degrading wood and wood shavings are abundantly available as waste in our environment.

This work shows that easily grown fungal isolates – Trichoderma spp and A. niger from

degrading wood could be used to produce mannanases which are of great industrial

importance. The obtained mannanases of the fungal isolates had optimum temperatures and

pH that lied within the range previously reported for fungal mannanases.

REFERENCES

Abd-Aziz S, Ong LGA, Hassan MA, Karim MIA. 2008. Process Parameters Optimisation of

Mannanase Production from Aspergillus niger FTCC 5003 Using Palm Kernel Cake as

Carbon Source. Asian Journal of Biochemistry, 3: 297-307.

Ademark P, Varga A, Medve J, Harjunpaa V, Drakenberg T, Tjerneld F, Stalbrand H. 1998.

Softwood hemicellulose-degrading enzymes from Aspergillus niger: purification and

properties of a beta-mannanase. J Biotechnol., 63(3):199–210.

Araujo A, Ward OW. 1991. Studies on the galactomannan-degrading enzymes produced by

Sporotrichum cellulophilum. J. Ind. Microbiol., 8: 229-236.

Arisan-Atac I, Hodits R, Kristufek D, Kubicek CP. 1993. Purification, and characterization of

a β-mannanase of Trichoderma reesei C-30. Applied Microbiology and Biotechnology.,

39(1):58–62.

Belitz HD, Grosch W. 1987. Enzymes. In Food Chemistry Hadziev DT (ed). Springer verlag

Berline; 73-127.

Buckeridge MS, dos Santos HP, Tine MAS. 2000. Mobilisation of storage cell wall

polysaccharides in seeds. Plant Physiol. Biochem., 38: 141– 156.

Christgau S, Kofod LV, Halkier T, Andersen LN, Hockauf M, Dörreich K, Dalboge H,

Kauppinen S. 1996. Pectin methyl esterase from Aspergillus aculeatus: expression cloning in

yeast and characterization of the recombinant enzyme. Biochem J., 319:705–712.

Adesina, et al., 2013: ajrc.journal@gmail.com

American Journal of Research Communication www.usa-journals.com

Civas AR, Eberhard PL, Petek F. 1984. Glycosidases induced in Aspergillus tamarii. J.

Biochem., 219: 857-863.

Cuevas WA, Kantelinen A, Tanner P, Bodie B, Leskinen S.1996. Purification and

characterization of novel mannanases used in pulp bleaching. In Biotechnology in the Pulp

and Paper Industry, Srebotnik, E. and K. Mesner (eds). Facultas-Universitätsverlag; Vienna,

Austria: 123 - 126.

De Vries RP, Visser J. 2001. Aspergillus enzymes involved in degradation of plant cell wall

polysaccharides. Micobiol Mol. Biol. Rev., 65: 497-522.

Domsch KI, Gam W, Anderson TH. 1980. Compedium of soil fungi. U.K. (1st edn).

Academic Press: London.

Downie B, Hilhorst WM, Bewley JD. 1994. A new assay for quantifying endo-beta-

mannanase activity using congo red dye. Phytochemistry 36: 829-835.

El-Naggar MY, El-Aassar SA, Youssef AS, El-Sersy NA Beltagy EA. 2006. Extracellular β-

mannanase production by the immobilization of the locally isolated Aspergillus niger. Int. J.

Agri. Biol., 8: 57-62.

Fadel M. 2001. High level xylanase production from sorghum flour by a new isolate of

Trichoderma harzianum cultivated under solid state fementation. Annals of Microbiol.,

51:61-78.

Ferreira HM, Filho EXF. 2004. Purification and characterization of a β - mannanase from

Trichoderma harzianum strain T4. Carbohydr. Polym., 57: 23-29.

Francoise M, Ghakis C, Dupont C, Morosoli R, Kluepfel D. 1996. Improved production of

mannanase by Streptomyces lividans . Appl. Environ. Microbiol., 62: 4656-4658.

Grobwindhager C, Sachslehner A, Nidetzky B, Haltrich D. 1999. Endo-β-1,4-D-mannanase is

efficiently produced by Sclerotium (Athelia) rolfsii under derepressed conditions. J.

Biotechnol., 67: 189-203.

Gubitz GM, Hayn M, Urbanz G, Steiner W. 1996. Purification and properties of an acidic β-

mannanase from Sclerotium rolfsii. J. Biotechnol., 45(2): 165-172.

Immanuel G, Bhgavath CMA, Raj PI, Esakkiraj P, Palavaesan I. 2007. Production and

partial purification of cellulose by Aspergillus niger and Aspergillus fumigatus in Coir wastes

and sawdusts. The internet J. Microbiology, 3(1): 2-12.

Kiffer E, Morelet M. 2000. The Deuteromycetes. Mitosporic Fungi Classification and

Generic Keys. Science Publishers Inc: U.S.A.; 273 – 285.

Krishna C. 2005. Solid State Fermentation systems – An overview. Critical Reviews in

Biotechnol., 25(1,2):1-30.

Lahtinen T, Kristoo P, Paloheimo M. 1995. Mannanases in Softwood Kraft Pulp Bleaching,

Sixth International Conference on Biotechnology in the pulp and paper Industry, June 1995,

Vienna, Austria Abstract;11.

Lee RC, Hrmova M, Burton RA, Lahnstein J, Fincher GB, 2003. Bifunctional family 3

glycoside hydrolases from Barley with α-L-Arabinofuranosidase and β-D-xylosidase activity

Adesina, et al., 2013: ajrc.journal@gmail.com

American Journal of Research Communication www.usa-journals.com

characterization, primary structures and COOH-terminal processing. J.Biol.Chem. 278:5377-

5388.

Lowry OH, Rosebrough NH, Farr AL, Randall RJ. 1951. Protein measurement with the folin

phenol reagent. J. Biol. Chem., 193: 265-75.

Miller GL. 1959. Use of dinitrosalicylic acid reagent for determination of reducing sugar.

Anal. Chem., 31: 426-428.

Mudau MM1, Setati, ME. 2008. Partial purification and characterization of endo-b-1,4-

mannanases from Scopulariopsis candida strains isolated from solar salterns. Afr. J.

Biotechnol., 7(13): 2279-2285.

Penttilla M, 1998. Heterologous protein production in Trichoderma. In Trichoderma &

Gliocladium, Harman GE, Kubicek CP (ed). Taylor & Francis Ltd.: London; 365-382.

Puchart V, Vrsanská M, Svoboda P, Pohl J, Ogel ZB, Biely P. (2004). Purification and

characterization of two forms of endo-β-1,4-mannanase from a thermotolerant fungus,

Aspergillus fumigatus IMI 385708 (formerly Thermomyces lanuginosus IMI 158749)

Biochimica et Biophysica Acta, 1674(3):239–250.

Sachslehner A, Foidl G, Foidi N, Gubitz G, Haltrich D. 2000. Hydrolysis of isolated coffee

mannan and coffee extract by mannanases of Sclrotium rolfsii. J. Biotechnol., 80: 127- 134.

Sae –Lee, N, 2007. The production of fungal mannanase, cellulose and xylanase using Palm

Kernel meal as a substrate. Walailak. J. Sci. Tech., 4(1): 67-82.

Saha BC. 2003. Purification and properties of an extracellular β-xylosidase from a newly

isolated F. proliferatum in Bioresource Technol., 90(1): 33-38.

Schäfer T, Kirk O, Borchert TV, Fuglsang CC, Pedersen S, Salmon S, Olsen HS,

Deinhammer R, Lund H. 2002. Enzymes for technical applications. In Biopolymers,

Fahnestock SR, Steinbüchel SR (ed). Wiley VCH Pub.; 377-437.

Siti Norita M, Rosfariza M, Ariff AB. 2010. Evaluation of the activities of concentrated

crude mannan-degrading enzymes produced by Aspergillus niger. Malaysian J. of Microbiol.

6(2):171-180.

Stalbrand H, Siika-aho M, Viikari L. 1993. Purification and characterisation of two b-

mannanases from Trichoderma reesei. J. Biotechnol., 29: 229- 242.

Timell TE. 1967. Recent progress in the chemistry of wood hemicelluloses.Wood Sci.

Technol., 1: 45–70.

Viikari L, Pere A, Suurnakki A, Oksanen T, Buchert J. 1998. Use of cellulases in pulp and

paper applications. In Carbohydrases from Trichoderma reesei and other microorganisms:

Structure, Biochemistry, Genetics and Applications, Claeyssens M, Nerinckx W, Piens K

(ed). Royal Soceity Of Chemistry: Cambridge; 219: 245-254.

Willey JM, Sherwood LM, Woolverton CJ. 2008. Prescott, Harley, and Klein’s

Microbiology. (7thed). McGraw Hill companies Inc.; 627-632.

Adesina, et al., 2013: ajrc.journal@gmail.com

American Journal of Research Communication www.usa-journals.com

Wong KKY, Saddler JN. 1993. Applications of hemicellulases in the food, feed, pulp and

paper industries. In Hemicellulose and Hemicellulases, Coughlan MP, Hazlewood GP (ed).

Portland Press: London, England; 127-143.

Wu G, Bryant MM, Voitle RA, Roland DA. 2005. Effects of β-mannanase in corn-soy diets

on commercial leghorns in second-cycle hens. Poultry Sci., 84: 894-897.

Adesina, et al., 2013: ajrc.journal@gmail.com

You might also like

- Grade 10 Terms and DefinitionsDocument11 pagesGrade 10 Terms and Definitionskhotso100% (6)

- Hydrocarbons Chapter 13 ReviewDocument70 pagesHydrocarbons Chapter 13 ReviewGururaj Vasisth100% (3)

- Gamsat Chemistry Sample QuestionsDocument6 pagesGamsat Chemistry Sample QuestionsM S Rahman100% (1)

- Earth and Science PointersDocument3 pagesEarth and Science PointersDominico Jr Pojas TanNo ratings yet

- General Piping Design: Document No. Rev.: A BMR-PIP-DBS-ST-0001 Page 1 of 20Document20 pagesGeneral Piping Design: Document No. Rev.: A BMR-PIP-DBS-ST-0001 Page 1 of 20Agus SupriadiNo ratings yet

- Production of Animal Feed Concentrates From Sour Sop and Pineapple Peels Using Solid State Fermentation.Document5 pagesProduction of Animal Feed Concentrates From Sour Sop and Pineapple Peels Using Solid State Fermentation.Gregory Kalona100% (1)

- Starter Cultures in Food ProductionFrom EverandStarter Cultures in Food ProductionBarbara SperanzaNo ratings yet

- FES Aspergillus 5Document9 pagesFES Aspergillus 5Alexis RodriguezNo ratings yet

- Paper 16Document6 pagesPaper 16Sorin LazarNo ratings yet

- Production of Amylase Enzyme From Mangrove Fungal Isolates: African Journal of BiotechnologyDocument9 pagesProduction of Amylase Enzyme From Mangrove Fungal Isolates: African Journal of BiotechnologyAliyah SajaNo ratings yet

- BioRes 08-1-0250 Hariharan N Opt Lignin Peroxidase SSF Pineapple Leaf 3060Document22 pagesBioRes 08-1-0250 Hariharan N Opt Lignin Peroxidase SSF Pineapple Leaf 3060Hildan H GNo ratings yet

- 2891 6404 1 PBDocument8 pages2891 6404 1 PBIsworo RukmiNo ratings yet

- Seed starches as pharmaceutical sourcesDocument6 pagesSeed starches as pharmaceutical sourcesChem EngNo ratings yet

- Journal Type (Thesis)Document12 pagesJournal Type (Thesis)api-19649313No ratings yet

- Supported By: Sample Collection and PreparationDocument5 pagesSupported By: Sample Collection and Preparationmoses richardNo ratings yet

- Cellulolytic Fruits Wastes: A Potential Support For Enzyme Assisted Protein ProductionDocument9 pagesCellulolytic Fruits Wastes: A Potential Support For Enzyme Assisted Protein ProductionkesavarajNo ratings yet

- Jurnal Acara 1Document6 pagesJurnal Acara 1dinaserevinaNo ratings yet

- Journal Type (Thesis)Document12 pagesJournal Type (Thesis)api-19649313No ratings yet

- Aspergillus FlavusDocument6 pagesAspergillus FlavusFebri ShaarawyNo ratings yet

- Isolation, Identification and Characterisation of The Dominant Microorganisms of Kule Naoto: The Maasai Traditional Fermented Milk in KenyaDocument10 pagesIsolation, Identification and Characterisation of The Dominant Microorganisms of Kule Naoto: The Maasai Traditional Fermented Milk in KenyaVivek MokanNo ratings yet

- Ajol File Journals - 413 - Articles - 203082 - Submission - Proof - 203082 4921 508128 1 10 20210126Document12 pagesAjol File Journals - 413 - Articles - 203082 - Submission - Proof - 203082 4921 508128 1 10 20210126iqra sadiqNo ratings yet

- B9387CC3447Document5 pagesB9387CC3447cemz5No ratings yet

- MAB - 2018 A PDFDocument6 pagesMAB - 2018 A PDFAmriNo ratings yet

- ISFAS 2012-SukirahDocument4 pagesISFAS 2012-SukirahSukirah Abdul RahmanNo ratings yet

- Biodegradation of Agricultural Wastes (Rice Straw and Sorghum Stalk) Into Substrates of Utilizable Products Using White Rot FungusDocument7 pagesBiodegradation of Agricultural Wastes (Rice Straw and Sorghum Stalk) Into Substrates of Utilizable Products Using White Rot FungusInes HrastinskiNo ratings yet

- Isolation and Characterization of Starter Culture From Spontaneous Fermentation of SourdoughDocument4 pagesIsolation and Characterization of Starter Culture From Spontaneous Fermentation of SourdoughHusna AdilaNo ratings yet

- Article1380180775 - Oyeleke and OduwoleDocument4 pagesArticle1380180775 - Oyeleke and Oduwoleaditi_joshee419No ratings yet

- Solid State Fermentation of Aspergillus Oryzae For Glucoamylase Production On Agro ResiduesDocument10 pagesSolid State Fermentation of Aspergillus Oryzae For Glucoamylase Production On Agro ResiduesArlunandaAdhiarthaNo ratings yet

- Research ArticleDocument4 pagesResearch ArticleMusfeera KhanNo ratings yet

- Amylase and Xylanase Production by Soil FungiDocument3 pagesAmylase and Xylanase Production by Soil FungiSubhadra JhaNo ratings yet

- Banana Waste As Substrate For A-Amylase Production by Bacillus Subtilis (CBTK 106) Under Solid-State FermentationDocument6 pagesBanana Waste As Substrate For A-Amylase Production by Bacillus Subtilis (CBTK 106) Under Solid-State FermentationAlejandro Murillo V.No ratings yet

- Bacillus Licheniformis BT5.9 Isolated From Changar Hot SpringDocument14 pagesBacillus Licheniformis BT5.9 Isolated From Changar Hot SpringAleivi PérezNo ratings yet

- Aspergillus Oryzae Extract Improve Bromegrass Degradation With Rumen BateriaDocument6 pagesAspergillus Oryzae Extract Improve Bromegrass Degradation With Rumen BateriaAndres BelalcazarNo ratings yet

- Growth Response of Activities ofDocument6 pagesGrowth Response of Activities ofSbenmohamedNo ratings yet

- Measurement of β-glucan and other nutritional characteristics in distinct strains of AgaricusDocument7 pagesMeasurement of β-glucan and other nutritional characteristics in distinct strains of AgaricusDaniela ChalarcaNo ratings yet

- El Uso de Pectinasa para Tratamiendo de Jugo de Manzana y Mora AzulDocument7 pagesEl Uso de Pectinasa para Tratamiendo de Jugo de Manzana y Mora AzulLaura RDNo ratings yet

- Optimized Solid State Fermentation Medium Enhances The Multienzymes Production From Penicillium Citrinum and AspergillusDocument15 pagesOptimized Solid State Fermentation Medium Enhances The Multienzymes Production From Penicillium Citrinum and AspergillusSerafín Pérez ContrerasNo ratings yet

- Production and application of amylases from Rhizopus for glucose syrupDocument9 pagesProduction and application of amylases from Rhizopus for glucose syrupbarbarahNo ratings yet

- Digestive Amylase Activity in Wheat Bug StagesDocument8 pagesDigestive Amylase Activity in Wheat Bug Stagespharmacologist786No ratings yet

- Stenochlaena Palustri 02Document8 pagesStenochlaena Palustri 02donny sophandiNo ratings yet

- 128925-Article Text-349303-1-10-20160120Document9 pages128925-Article Text-349303-1-10-20160120Richard Ivan Medina HoyosNo ratings yet

- Chenodium QuinoaDocument8 pagesChenodium QuinoaЛуизАпазаТ.No ratings yet

- Sci - HubDocument7 pagesSci - HubVõ Hữu Hồng ChiNo ratings yet

- Application of A Statistical DesignDocument8 pagesApplication of A Statistical DesignTheophile IZERENo ratings yet

- Comparative Prod of Amylase Enzyme From RhizopusDocument4 pagesComparative Prod of Amylase Enzyme From RhizopusIsworo RukmiNo ratings yet

- Chemical Composition, Physicochemical and Functional Properties of Custard Apple (Annona Squmosa) Seed Flours and Protein IsolateDocument5 pagesChemical Composition, Physicochemical and Functional Properties of Custard Apple (Annona Squmosa) Seed Flours and Protein IsolateInnovative Research PublicationsNo ratings yet

- Honey CropDocument6 pagesHoney CropashatjhangNo ratings yet

- Salawu 2011Document7 pagesSalawu 2011Eti ApriyantiNo ratings yet

- Pectin From Ripe Peels of Mango CultivarsDocument10 pagesPectin From Ripe Peels of Mango CultivarsIsabel Tacunan CastilloNo ratings yet

- Nicanor 2005 PDFDocument9 pagesNicanor 2005 PDFLorenaNo ratings yet

- Biradar Et Al 2016 - BiologiaDocument9 pagesBiradar Et Al 2016 - BiologiaRahul KhandareNo ratings yet

- Production and Optimization of Xylanase and α-Amylase from Non-Saccharomyces Yeasts (Pichia membranifaciens)Document10 pagesProduction and Optimization of Xylanase and α-Amylase from Non-Saccharomyces Yeasts (Pichia membranifaciens)Jefri Nur HidayatNo ratings yet

- Production and Optimization of Xylanase and α-Amylase from Non-Saccharomyces Yeasts (Pichia membranifaciens)Document10 pagesProduction and Optimization of Xylanase and α-Amylase from Non-Saccharomyces Yeasts (Pichia membranifaciens)Jefri Nur HidayatNo ratings yet

- Canaliculata (Ampullariidae) : Oxicity of Barringtonia Racemosa (L.) Kernel Extract On PomaceaDocument5 pagesCanaliculata (Ampullariidae) : Oxicity of Barringtonia Racemosa (L.) Kernel Extract On PomaceaDarmansyah YasinNo ratings yet

- Phytochemical Analysis and Cytotoxicity Studies of Curcuma Amada Rhizomes in BHK-21 CellsDocument7 pagesPhytochemical Analysis and Cytotoxicity Studies of Curcuma Amada Rhizomes in BHK-21 CellsJessica ClarkNo ratings yet

- Via Suspension Cultures of Banana (Musa SPP.) : Highly Efficient Somatic Embryogenesis and Plant RegenerationDocument12 pagesVia Suspension Cultures of Banana (Musa SPP.) : Highly Efficient Somatic Embryogenesis and Plant Regenerationth_kiranNo ratings yet

- Decolourization of Azo Dye Methyl Red byDocument7 pagesDecolourization of Azo Dye Methyl Red byEvelyn NathaliaNo ratings yet

- Amylase Activity of Starch Degrading BacDocument13 pagesAmylase Activity of Starch Degrading BacRaisya RagilNo ratings yet

- RS - Volume 9 - Issue 4 - Pages 378-391Document14 pagesRS - Volume 9 - Issue 4 - Pages 378-391samirNo ratings yet

- Optimization of Culture Condition in The Production of Bioenzymes by Bacteria Isolated From Poultry Waste in Sokoto State, NigeriaDocument8 pagesOptimization of Culture Condition in The Production of Bioenzymes by Bacteria Isolated From Poultry Waste in Sokoto State, NigeriaUMYU Journal of Microbiology Research (UJMR)No ratings yet

- Bio Tech - IJBTR - Determination of Tropane Alkaloids in - Ayman Amin - EgyptDocument10 pagesBio Tech - IJBTR - Determination of Tropane Alkaloids in - Ayman Amin - EgyptTJPRC PublicationsNo ratings yet

- Abstract 7 12Document6 pagesAbstract 7 12Nikita RizkyNo ratings yet

- 225 2017-CJFSDocument8 pages225 2017-CJFSYuliet SusantoNo ratings yet

- In Vitro Propagation of Stevia rebaudianaDocument11 pagesIn Vitro Propagation of Stevia rebaudianahenry72No ratings yet

- Modern Alkaloids: Structure, Isolation, Synthesis, and BiologyFrom EverandModern Alkaloids: Structure, Isolation, Synthesis, and BiologyErnesto FattorussoNo ratings yet

- Test For Hydrocarbons: Laboratory Activity CHEM 525Document39 pagesTest For Hydrocarbons: Laboratory Activity CHEM 525Jherby TeodoroNo ratings yet

- Zinc Sulfate Oral SolutionDocument1 pageZinc Sulfate Oral SolutionKasidit SornchaiNo ratings yet

- THIRD YEAR QUESTION 2015 Calcutta UniversityDocument4 pagesTHIRD YEAR QUESTION 2015 Calcutta UniversityUshnish RoyNo ratings yet

- HPLC Columns For Carbohydrates: Product SpecificationDocument2 pagesHPLC Columns For Carbohydrates: Product SpecificationSandip BasuNo ratings yet

- Earth Science Lecture 2 V.2Document39 pagesEarth Science Lecture 2 V.2MieNo ratings yet

- Acidity in TeaDocument17 pagesAcidity in TeaRukmani 1011No ratings yet

- Halogens (Group VIIA) PresentationDocument12 pagesHalogens (Group VIIA) PresentationPatrick RegidorNo ratings yet

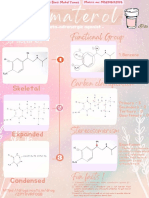

- Cimaterol Functional Groups and Carbon ClassificationDocument1 pageCimaterol Functional Groups and Carbon ClassificationHanny Mohd Yunus100% (1)

- PWD S.R. 2016-17 - KalaburagiDocument429 pagesPWD S.R. 2016-17 - KalaburagiKiran Rathod RitesNo ratings yet

- Preservation and Conservation TechniquesDocument20 pagesPreservation and Conservation TechniquesNur AthifahNo ratings yet

- Determining The Susceptibility of Stainless Steels and Related Nickel-Chromium-Iron Alloys To Stress-Corrosion Cracking in Polythionic AcidsDocument3 pagesDetermining The Susceptibility of Stainless Steels and Related Nickel-Chromium-Iron Alloys To Stress-Corrosion Cracking in Polythionic AcidsClaudio Di GioseffoNo ratings yet

- Industrial Training Performed at Piramal Pharma Solutions, Mahad, Dist-RaigadDocument32 pagesIndustrial Training Performed at Piramal Pharma Solutions, Mahad, Dist-RaigadChandan A. Wagh100% (1)

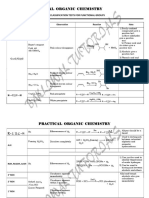

- Practical Organic Chemistry Classification TestsDocument19 pagesPractical Organic Chemistry Classification TestsJonathan ParkerNo ratings yet

- EU4 D2 M4 Inspection in Composites PDFDocument20 pagesEU4 D2 M4 Inspection in Composites PDFaerorenNo ratings yet

- The Punjab School Teaching Material of Class VIII Chapter 1 Human Organ Systems Q.no.1Document12 pagesThe Punjab School Teaching Material of Class VIII Chapter 1 Human Organ Systems Q.no.1Qulb e AbbasNo ratings yet

- CBSE Class 10 Science MCQ Bank Term IDocument48 pagesCBSE Class 10 Science MCQ Bank Term IAtharva Bhokare100% (1)

- Reactions of Carboxylic Acids and Its DerivativesDocument40 pagesReactions of Carboxylic Acids and Its DerivativesRoger ReyesNo ratings yet

- Utilization of Ecofriendly Self-Cleaning Concrete Using Zinc Oxide and Polypropylene FibreDocument3 pagesUtilization of Ecofriendly Self-Cleaning Concrete Using Zinc Oxide and Polypropylene FibreUmesha KempegowdaNo ratings yet

- MPHARM QA 1Y 2S 202T Pharm - ValidationDocument562 pagesMPHARM QA 1Y 2S 202T Pharm - Validationhosein bagheriNo ratings yet

- Life Cycle Assessment of Fertilizer Manufacturing and Impacts (39Document31 pagesLife Cycle Assessment of Fertilizer Manufacturing and Impacts (39Vijay SinghNo ratings yet

- 2022 Hilti Product Catalogue Firestop PDFDocument32 pages2022 Hilti Product Catalogue Firestop PDFecjr consNo ratings yet

- Requirements for Polymer MaterialsDocument4 pagesRequirements for Polymer MaterialsadrianNo ratings yet

- Development of An Internationally Competitive Australian Saffron IndustryDocument37 pagesDevelopment of An Internationally Competitive Australian Saffron IndustryNemanja NikolicNo ratings yet

- Spe 200369 PaDocument13 pagesSpe 200369 PaYousif IraqiNo ratings yet

- Energy Analysis of The Steel Making IndustryDocument7 pagesEnergy Analysis of The Steel Making Industrymrshami7754No ratings yet