Professional Documents

Culture Documents

Haldex - Truck Air Brake Troubleshooting Guide

Uploaded by

HILLCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Haldex - Truck Air Brake Troubleshooting Guide

Uploaded by

HILLCopyright:

Available Formats

Truck Commercial Vehicle Systems

Haldex Brake Products Corporation Haldex Limited

Troubleshooting 10707 N.W. Airworld Drive

Kansas City, MO 64153 -1215

Phone: (816) 891- 2470

525 Southgate Drive, Unit 1

Guelph, Ontario CANADA N1G 3W6

Phone: (519) 826- 7723

Guide Fax: (816) 801-4198 Fax: (519) 826-9497

22 22

21

21

17

18b

16

18a

16

21

21

22 22

20

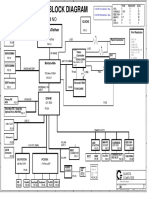

COMPLAINT/REMEDY COMPLAINT/REMEDY COMPLAINT/REMEDY COMPLAINT/REMEDY

1 COMPRESSOR 7 SINGLE CHECK VALVE 15 SPRING PARKING BRAKE (SERVICE ONLY 21 ABS INLINE VALVES

■ PUMPS BEYOND “CUT-OUT” ■ ALLOW BLEED BACK TO SUPPLY RESERVOIR

◆ Check gauge. ◆ Periodic Test: bleed supply reservoir and observe gauges. Check valves SERVICE CHAMBER SIDE OF SPRING ■ FOR COMPLETE TROUBLESHOOTING INFORMATION REFER TO LITERATURE

◆ Check governor.

◆ Be certain it pressurizes unloader port when above “cut-out”.

should maintain rear and front reservoir pressure. BRAKE) PIECES MODAL POWER TK-2 INSTALLATION & SERVICE MANUAL (L30022)

◆ Replace it if results are negative.

■ AND/OR ABS DIAGNOSTIC TROUBLESHOOTING GUIDE (L20293)

◆ Check unloader/plungers. Lube, kit or change head. PARK BRAKE DRAGS OR WON’T RELEASE

■ WON’T PUMP AIR

◆ Check gauge.

8 PRIMARY & SECONDARY RESERVOIR ◆ Check for: Improper adjustment, restriction or broken line. Diaphragm

failure. System pressure too low. Improper manual release. Broken 22 ABS SENSORS & EXCITER RINGS

■ EXCESS OIL/WATER

◆ Check compressor drive. return spring (spring side). Quick release of relay malfunction. Broken ■ FOR COMPLETE TROUBLESHOOTING INFORMATION REFER TO LITERATURE

◆ Drain as required. power spring.

◆ Check inlet valves and plungers. If stuck, leak will be evident at intake ◆ Check automatic drain valve on wet tank for proper operation (See #5). PIECES MODAL POWER TK-2 INSTALLATION & SERVICE MANUAL (L30022)

when unloaded. Install unloader kit, head kit or head assembly. ◆ Replace entire unit or piggy-back emergency section.

■ SLUGGISH PARK APPLICATION AND/OR ABS DIAGNOSTIC TROUBLESHOOTING GUIDE (L20293)

■ SLOW PRESSURE BUILD-UP

◆ Check gauge.

9 AIR GAUGE ◆ Check for: Diaphragm failure. Improper manual release. Broken power spring.

■ INCORRECT READING

◆ Check compressor drive. ■ LEAKS WHEN PRESSURIZED FOR PARK BRAKE RELEASE

◆ Calibrate or replace.

◆ Check intake for restriction. ◆ Check for: Ruptured spring side diaphragm. Push rod seal leakage (may be

◆ Check discharge line for restriction. evident at # 14 relay valve).

◆ Check unloader function. Lube or kit. 10 DUAL SYSTEM FOOT BRAKE VALVE ■ SERVICE CHAMBER MALFUNCTION NOTE: FOR FURTHER TECHNICAL ASSISTANCE CONTACT YOUR

◆ Check inlet and exhaust valves. Leak will be evident at intake when ■ LEAKS AT EXHAUST WITH ALL BRAKES RELEASED ◆ See #12 service brake chamber.

unloaded. Kit or exchange head. ◆ Check anti-compound double check valve # 16. HALDEX DISTRIBUTOR, YOUR LOCAL HALDEX SALES

■ PUMPS EXCESSIVE OIL ◆ Check #18a and 18b for back flow into service control line. PROFESSIONAL, OR CALL (800) 643-2374 AND ASK FOR A

◆ Check oil return for restriction, kink or loop. ■ CAUTION: CHOCK WHEELS - Repair and replace items as necessary. 16 QUICK RELEASE AND DOUBLE CHECK TECHNICAL ADVISOR.

◆ Check for gasket sealant obstructing drain.

◆ Check for undersize return line (1/2” minimum).

■ LEAKS AT EXHAUST WITH FOOT BRAKE APPLIED VALVE COMBINATION

◆ Foot valve defective. Repair or replace.

◆ Check for fitting restricting drain. ■ FOOT VALVE EXHAUST LEAK PARK BRAKES RELEASED YELLOW DASH

■ LEAKS AT EXHAUST WITH ALL PARK BRAKES SET IN PARK POSITION

◆ Check for intake vacuum (20” water maximum). CONTROL VALVE EXHAUST LEAK IN PARK POSITION AND SERVICE

◆ Check for excessive engine crankcase pressure (poor engine ventilation). AND FOOT BRAKE RELEASED BRAKES APPLIED

◆ Check compressor ring wear. Exchange for service unit. ◆ Foot valve defective. Repair or replace. ◆ Check anti-compound double check valve portion for feedback to foot

or dash control valve. Repair or replace.

2 WET TANK

■ EXCESS OIL ACCUMULATION

◆ See PUMPS EXCESSIVE OIL (above). 17 STOP LIGHT SWITCH

■ EXCESS WATER ACCUMULATION 11 QUICK RELEASE VALVE ■ LEAKS

◆ Drain daily. Install automatic drain on wet tank. ■ LEAKS AT EXHAUST PORT WITH ALL BRAKES RELEASED

■ ◆ Check and replace #18b if back flow occurs into service delivery line. ◆ Replace.

DAMAGED WET TANK

■ ■ FAILS TO SIGNAL A GOOD BULB THROUGH SOUND WIRING AT 3-6 P.S.I.

◆ Replace. LEAKS WHEN SERVICE BRAKES ARE APPLIED

◆ Repair or replace. ◆ Replace.

3 LOW PRESSURE INDICATOR SWITCH

■ BUZZER OR LIGHT INOPERABLE. 12 SERVICE BRAKE CHAMBER 18a INVERSION RELAY VALVE WITH THE LOSS

◆ Check ground and wiring on switch and buzzer/light. ■

◆ Replace switch or buzzer/light.

LEAKS

◆ Replace diaphragm.

OF REAR SERVICE BRAKES, APPLICATION

■ WON’T OPERATE AT PRESSURES BELOW 60 P.S.I. ◆ Cage park brake. 18b OF SPRING BRAKE BY USING THE

◆ Check dash gauge for accuracy. ◆ Reset clamps.

◆ Replace switch or buzzer/light. ◆ Adjust brakes. EMERGENCY SECTION SHOULD BE

■ WITH SERVICE BRAKES AVAILABLE ALONG WITH FRONT

4 SAFETY VALVE APPLIED STROKE IS AT OR

BEYOND MAXIMUM LIMIT OF: SERVICE BRAKE BY APPLYING FOOT

■ ”POPS” OFF EXCESSIVELY. ◆ Type 9

◆ Check system pressure. ◆ Type 12

1 3/8”

1 3/8”

VALVE

◆ Valve operating properly in venting at 140/150 P.S.I. ◆ Type 16 1 3/4” ■ Periodically test by bleeding rear service tank and observing front brake and

◆ Check unloader/governor. ◆ Type 20 1 3/4” rear spring brake application upon depressing foot pedal. Repair or replace,

■ ”POPS” OFF AT LESS THAN 140 P.S.I. ◆ Type 24 1 3/4”

if after checking piping is not functioning properly.

◆ Replace. ◆ Type 30 2”

■ LEAKS

■ ■ SLUGGISH APPLICATION OR

LEAKS ◆ Repair or replace.

◆ Replace. RELEASE

◆ Check basic brake.

■ WON’T FUNCTION ◆ Check for air line restriction/leak.

◆ Periodic Test: remove and test above 150 P.S.I. with shop air. ◆ Align linkage.

◆ Replace if non-functional. ◆ Check chamber return spring. 19 BARRIER WHEEL OIL SEALS

◆ Adjust brakes. Angle should approach 90° on application (NOT SHOWN IN SCHEMATIC)

5 DRAIN VALVES - MANUAL ◆ Check for improper chamber or obstruction.

■ ■ OIL LEAK

LEAKS

◆ Replace. ◆ Check for proper glazing of the sealing lip.

13 BRAKE ADJUSTER ◆ Check serrations on O.D. and I.D. to see that sealing surfaces are dry. If

5 DRAIN VALVES - AUTOMATIC ■ SLEEVE WILL NOT DEPRESS

◆ Clean and lubricate or replace with unit dimensionally same.

wet, this could denote the leakage path.

■ WON’T DRAIN ◆ Check area between positioning pads. If wet, suspect seal leak.

■ ADJUSTING SHAFT WILL NOT TURN

◆ Repair or replace. ◆ Check seal for possible damage incurred during installation.

◆ Replace with unit dimensionally same.

■ WON’T DRAIN IN COLD WEATHER ■ CRACKED HOUSING ◆ Check hub bore and spindle surfaces for imperfections or irregularities.

◆ Replace with heated unit.

◆ Check spring brake anti-compound system. ◆ Check to see that proper seal has been installed for the particular

■ LEAKS - MALFUNCTIONS ◆ Check air chamber size. Replace if larger than original size. axle application.

◆ Repair or replace. ◆ Check direction of travel for proper position of hex nut (Shown Under #12).

◆ Periodic Test: with system pressure stabilized (compressor unloaded) ◆ Hex nut must face away from chamber for uni-directional brake adjuster.

no leak evident at discharge port - make several foot brake applications

to reduce wet tank pressure. Moisture should drain from discharge port.

■ WORN CLEVIS PIN BUSHING

◆ Replace bushing.

20 AIR DRYER

■ AIR LEAKING CONSTANTLY FROM PURGE VALVE

6 GOVERNOR ◆ Purge valve seal damaged. Replace.

■ FLUTTERS 14 RELAY VALVE ◆ Purge valve frozen.

■ LEAKS AT EXHAUST PORT WITH ALL BRAKES RELEASED

◆ Check gauge. ■

◆ Check seal in spring brake for back flow of spring “hold-off” pressure HEATER INOPERATIVE

◆ Check unloader line size (5/16” x 5’ maximum).

◆ Check air actuated accessory. Is the air volume requirement greater through service port to open exhaust on valve. Replace #15 Spring ◆ Blown fuse. Check fuse and replace with 8 - 10 amp fuse.

than governor capacity? Parking Brake. ◆ Broken wires or poor connections. Repair or replace wiring to heater.

■

◆ Check for plugged governor reservoir line.

◆ Repair, adjust or replace governor.

WON'T PASS AIR TO UNLOADER TO “CUT-OUT” COMPRESSOR

◆ Check and replace #18b if back flow occurs into service delivery line.

◆ Check reservoir port for evidence of contamination, check supply lines

for rusty fittings or carbon deposits. Repair or replace.

■ SLOW WET TANK BUILD-UP

◆ Filter and or desiccant plugged. Service air dryer.

www.haldex.com

■ LEAKS AT EXHAUST PORT WITH SERVICE BRAKES APPLIED

◆ Check governor reservoir line.

◆ Repair or replace. ◆ Exhaust valve not seating properly. Repair or replace.

L60038 US Rev 10/08 5M CUT

You might also like

- Em-2006-Mep-Eom-Mt-Sd-Plb-110-1 FF Plan-01 Enlarged Water Supply LayoutDocument1 pageEm-2006-Mep-Eom-Mt-Sd-Plb-110-1 FF Plan-01 Enlarged Water Supply LayoutshreeNo ratings yet

- Site Development Plan: Option 2 (Warehouse)Document1 pageSite Development Plan: Option 2 (Warehouse)JHENDIE ASTRANo ratings yet

- Academic Year Calendar-Ipad X HDocument1 pageAcademic Year Calendar-Ipad X HAdunwit TiampaeNo ratings yet

- sisEB48f374479loader g2444Document1 pagesisEB48f374479loader g2444marsh2002No ratings yet

- C AreaDocument1 pageC AreaSamar FathyNo ratings yet

- ALL-T Parts ListDocument9 pagesALL-T Parts ListDBKNo ratings yet

- Cambay - Jamdoli D.C.Document5 pagesCambay - Jamdoli D.C.Sunil PatelNo ratings yet

- Achievement Progress Chart Training Activity MatrixDocument3 pagesAchievement Progress Chart Training Activity Matrixkelvsgarcia22No ratings yet

- Airport Diagram: 10266 BedfordDocument1 pageAirport Diagram: 10266 BedfordThomas Chiu-yNo ratings yet

- Asa Branca FÁ para Sax Alto MibDocument1 pageAsa Branca FÁ para Sax Alto MibMiguel HenriqueNo ratings yet

- Building Edgar The Club PDFDocument1 pageBuilding Edgar The Club PDFJeff Sanchez PalacinNo ratings yet

- Hitesh Patil - Staircase DetailDocument1 pageHitesh Patil - Staircase DetailHitesh PatilNo ratings yet

- Layout HXC GFDocument1 pageLayout HXC GFVray MozeartNo ratings yet

- Screenshot 2022-09-06 at 11.16.17 PMDocument1 pageScreenshot 2022-09-06 at 11.16.17 PMAmeerudeen SalamNo ratings yet

- Rolling Acres PlazaDocument1 pageRolling Acres Plazaapi-302974836No ratings yet

- TV service manual circuit diagrams and schematicsDocument6 pagesTV service manual circuit diagrams and schematicsAndré LeftNo ratings yet

- I Mohan Varma 14BMA0035: Bench ViseDocument2 pagesI Mohan Varma 14BMA0035: Bench ViseVishnu TejaNo ratings yet

- CLMetalDocument45 pagesCLMetalLuisa Fernanda CaicedoNo ratings yet

- Pompa Grease Trap 166,2 LPM @22 MDocument5 pagesPompa Grease Trap 166,2 LPM @22 MAndreas B KresnawanNo ratings yet

- OptionsDocument6 pagesOptionsMD ŠTĕvēNo ratings yet

- Sagapò OttavinoDocument2 pagesSagapò OttavinoTommasoNo ratings yet

- Coating Area 189 SQ.M: Spaceera Hanger PlanDocument1 pageCoating Area 189 SQ.M: Spaceera Hanger PlanSrajeshKNo ratings yet

- All Over The WorldDocument1 pageAll Over The WorldJhon Vilegas GarciaNo ratings yet

- Autodesk educational product documentDocument1 pageAutodesk educational product documentDavie MolateNo ratings yet

- STYLE 2775 Product Bronco Hydrant Support: Parts List SheetDocument2 pagesSTYLE 2775 Product Bronco Hydrant Support: Parts List SheetFarmaceuticaNo ratings yet

- Zone L Sector 23Document1 pageZone L Sector 23atul singhNo ratings yet

- CP Network Map 2020Document2 pagesCP Network Map 2020EmelineNo ratings yet

- August Osage County v2013bDocument1 pageAugust Osage County v2013bapi-245236637No ratings yet

- Gems Estates 1 & Gems Estates 2Document39 pagesGems Estates 1 & Gems Estates 2Vikas PamnaniNo ratings yet

- (149039-111) - Dress - Kit - GP25 - Axis - 1-3 - (S, L, U) Empty - Hose - BDocument1 page(149039-111) - Dress - Kit - GP25 - Axis - 1-3 - (S, L, U) Empty - Hose - Bamir sfaihiNo ratings yet

- Land Scape 1Document1 pageLand Scape 1Ardit ValishtaNo ratings yet

- GCLB PDFDocument6 pagesGCLB PDFMiguel Angel MartinNo ratings yet

- 3i-Want-Ot-Break-Free - QueenDocument4 pages3i-Want-Ot-Break-Free - QueenELEAZAR JESUS MOLINA ROJASNo ratings yet

- Peça Xadrez Cavalo PDFDocument1 pagePeça Xadrez Cavalo PDFRobert ScheerNo ratings yet

- 446B Backhoe Loader Electrical System: Machine Harness Connector and Component LocationsDocument2 pages446B Backhoe Loader Electrical System: Machine Harness Connector and Component LocationsOsvaldo67% (3)

- 101 Znja072 01i (Ni-77215) r1Document27 pages101 Znja072 01i (Ni-77215) r1atifNo ratings yet

- Technische Oefeningen, FluitDocument1 pageTechnische Oefeningen, FluitchristiaankortesNo ratings yet

- Ground Floor Plan: Cinema Museum Noida Sector-33ADocument1 pageGround Floor Plan: Cinema Museum Noida Sector-33ASUDARSHAN KUMARNo ratings yet

- Mini Catalogo Cabine PDFDocument80 pagesMini Catalogo Cabine PDFWilas Borges DiasNo ratings yet

- Patient complaint and treatment scheduleDocument1 pagePatient complaint and treatment scheduleRiyan saputraNo ratings yet

- Tambahan KerjaDocument1 pageTambahan KerjaRiyan saputraNo ratings yet

- Siteplan Mutiara CibinongDocument1 pageSiteplan Mutiara CibinongRizky RamadhanNo ratings yet

- Angel de Luz - Tercera VozDocument1 pageAngel de Luz - Tercera VozBryan Geovanni Rivera CordovaNo ratings yet

- Parts List: NXC125K (4C61)Document125 pagesParts List: NXC125K (4C61)林辰叡No ratings yet

- 6 Nos. Truss Reqd. As Drn. Mkd. Tr3: Erection Mkd. Item NO. Section Length Erection Mkd. Item NO. Section LengthDocument1 page6 Nos. Truss Reqd. As Drn. Mkd. Tr3: Erection Mkd. Item NO. Section Length Erection Mkd. Item NO. Section LengthMridupaban DuttaNo ratings yet

- 2500kVA ASML - SketchDocument1 page2500kVA ASML - SketchKhalid RafiqueNo ratings yet

- Explosiondrawing R081 01Document1 pageExplosiondrawing R081 01lax inkoNo ratings yet

- DD 311 DS 311 DL 311: SandvikDocument1 pageDD 311 DS 311 DL 311: SandvikBernabe Ruben Alayo RamosNo ratings yet

- MF WongDocument3 pagesMF WongNilanjana SenguptaNo ratings yet

- Options: CatalogueDocument6 pagesOptions: CatalogueMahmøud SaaêdNo ratings yet

- Acer TM800x Quanta ZI6Document43 pagesAcer TM800x Quanta ZI6DeadMikeNo ratings yet

- Articulacion 745CDocument2 pagesArticulacion 745CAngel ContrerasNo ratings yet

- Metal DSDSDSG: ComposerDocument1 pageMetal DSDSDSG: ComposerNormanNo ratings yet

- Btoc Tc-Roa Revised1Document1 pageBtoc Tc-Roa Revised1Mannie VasquezNo ratings yet

- Casa Proyectos11Document1 pageCasa Proyectos11pamelaNo ratings yet

- Route & Profile Design For FQS Substation ESP Feed.2-Rev.0Document3 pagesRoute & Profile Design For FQS Substation ESP Feed.2-Rev.0Hassan H AlshokyNo ratings yet

- Progress Chart SampleDocument3 pagesProgress Chart SampleAce Anthony Figueroa CaroNo ratings yet

- Wide-Leg Trousers: WWW - Lovesewingmag.co - UkDocument29 pagesWide-Leg Trousers: WWW - Lovesewingmag.co - Ukนันท์ปภัทร์ จิ้วเลี่ยนNo ratings yet

- One Bold Move a Day: Meaningful Actions Women Can Take to Fulfill Their Leadership and Career PotentialFrom EverandOne Bold Move a Day: Meaningful Actions Women Can Take to Fulfill Their Leadership and Career PotentialNo ratings yet

- Fill Your Glass With Gold-When It's Half-Full or Even Completely ShatteredFrom EverandFill Your Glass With Gold-When It's Half-Full or Even Completely ShatteredNo ratings yet

- Mack MP8 Camshaft Bearing Housing Replacement BulletinDocument6 pagesMack MP8 Camshaft Bearing Housing Replacement BulletinHamilton MirandaNo ratings yet

- 821F 921F Op's Manual PDFDocument340 pages821F 921F Op's Manual PDFchiromaq chiromaq100% (1)

- N14 Parts Catalog PDFDocument114 pagesN14 Parts Catalog PDFManuais De Catálogos Jose Carlos100% (15)

- Wabco™ - C - and D-Version HABS Replacement PCDocument8 pagesWabco™ - C - and D-Version HABS Replacement PCHILLNo ratings yet

- Applied ElectricityDocument111 pagesApplied ElectricityYusif Ishaq Muhammad NazirNo ratings yet

- Qdoc - Tips - Gy6 Engine Service ManualDocument39 pagesQdoc - Tips - Gy6 Engine Service ManualAislan ScaravattoNo ratings yet

- Science 7 Q3Document30 pagesScience 7 Q3MARIZA MAPALONo ratings yet

- Physics: Rapid Crash CourseDocument16 pagesPhysics: Rapid Crash CourseHudsun HornetNo ratings yet

- 7build Your Own Mud BatteryDocument3 pages7build Your Own Mud BatterySKNo ratings yet

- 9400 Thermostat Manual - 110-1039Document11 pages9400 Thermostat Manual - 110-1039andrewh3No ratings yet

- WALA Case StudyDocument6 pagesWALA Case StudyPandji AhmadNo ratings yet

- Digital Resistance Meter - Innova I63CDocument1 pageDigital Resistance Meter - Innova I63CSourabh ChoudharyNo ratings yet

- IPM FNA41560T2 Tarjeta Samsung NeveraDocument15 pagesIPM FNA41560T2 Tarjeta Samsung Neverafredy guevara oNo ratings yet

- Heavy Duty Flyer CatalogDocument7 pagesHeavy Duty Flyer CatalogJessie BechaydaNo ratings yet

- Nema Ics 18 M C C: Otor Ontrol EntersDocument26 pagesNema Ics 18 M C C: Otor Ontrol EntersHesham badawyNo ratings yet

- NPRA Gasoline Q&A (1990-2010)Document292 pagesNPRA Gasoline Q&A (1990-2010)VijayakumarNarasimhanNo ratings yet

- Propeller Owner's Manual: and LogbookDocument176 pagesPropeller Owner's Manual: and LogbookThania Karina Flores Carvajal.No ratings yet

- Ignition System: Tech A Tech BDocument8 pagesIgnition System: Tech A Tech BHiếuNo ratings yet

- LG 1.4 Four Main Branches of Engineering - Electrical Engineering Chemical EngineeringDocument9 pagesLG 1.4 Four Main Branches of Engineering - Electrical Engineering Chemical EngineeringReav Andrei MartelinoNo ratings yet

- About Spark PlugsDocument9 pagesAbout Spark PlugsfadiharmoushNo ratings yet

- Fire Fighting Panel Design SummaryDocument52 pagesFire Fighting Panel Design SummarySuvendu Sekhar SabatNo ratings yet

- Desalination Plants Around the WorldDocument10 pagesDesalination Plants Around the WorldHelena KimNo ratings yet

- Apl Iit DelhiDocument1,215 pagesApl Iit DelhiManral SaurabhNo ratings yet

- Solution Manual The Physics of Vibrations and Waves 6th Edition PainDocument10 pagesSolution Manual The Physics of Vibrations and Waves 6th Edition PainS Devika Sajeev100% (3)

- Gpe EpeDocument15 pagesGpe EpeMiles BarrozoNo ratings yet

- Database FanyDocument35 pagesDatabase Fanyimam17No ratings yet

- Sci 8 Q1 W3 FinalDocument4 pagesSci 8 Q1 W3 FinalShiela Belandres MendozaNo ratings yet

- Especificaciones Ups YorksDocument4 pagesEspecificaciones Ups Yorksluisgerardogonzalez8No ratings yet

- PPR-2663 Flashover Performance MVLCDocument5 pagesPPR-2663 Flashover Performance MVLCHaris ZaimovicNo ratings yet

- Cambridge Assessment International Education: Combined Science 0653/42 March 2018Document9 pagesCambridge Assessment International Education: Combined Science 0653/42 March 2018equakeroatsNo ratings yet

- LSA 50.2 - 4 POLES: AlternatorsDocument24 pagesLSA 50.2 - 4 POLES: Alternators02031989No ratings yet

- HydraulicsDocument234 pagesHydraulicsChristine CastroNo ratings yet

- AnsaldoEnergia SYNCHRONOUSCONDENSERS 20220622Document6 pagesAnsaldoEnergia SYNCHRONOUSCONDENSERS 20220622rotimi olalekan fataiNo ratings yet

- Arch 001 Architectural Design 01 Introduction of Design Ar, Ryan BakingDocument12 pagesArch 001 Architectural Design 01 Introduction of Design Ar, Ryan BakingZendrick EspartinezNo ratings yet