Professional Documents

Culture Documents

As 2205.2.2 - 2003 (R2018)

As 2205.2.2 - 2003 (R2018)

Uploaded by

jesonelite0 ratings0% found this document useful (0 votes)

68 views9 pagesOriginal Title

AS 2205.2.2_2003 (R2018)

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

68 views9 pagesAs 2205.2.2 - 2003 (R2018)

As 2205.2.2 - 2003 (R2018)

Uploaded by

jesoneliteCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 9

AS 2205.2.2--200Reconfirmed}2018-03-16

STANDARDS AUSTRALIA

RECONFIRMATION

OF

AS 2205.2.2—2003

Methods for destructive testing of welds in metal

Method 2. veld-metal tensile test

RECONFIRMATION NOTICE

Major stakeholders of this publication have reviewed the content of this publication and

in accordance with Standards Australia procedures for reconfirmation, it has been

determined that the publication is still valid and does not require change.

Certain documents referenced in the publication may have been amended since the

original date of publication. Users are advised to ensure that they are using the latest

versions of such documents as appropriate, unless advised otherwise in this

Reconfirmation Notice

Approved for reconfirmation in accordance with Standards Australia procedures for

reconfirmation on 12 January 2018.

NoTEs

ze'sozz sv

' AS 2205.2.2—2003

Reconfirmed 2018

Australian Standard™

Methods for destructive testing of welds in metal

Method 2.2: All-weld-metal tensile test

PREFACE,

This Standard was prepared by the Standards Australia Committee WD-006, Testing of

Welds, to supersede AS 2205.2.2—1997.

The objective of this edition is to update the Standard and include editorial changes in

accordance with current Standards Australia editorial policy

METHOD.

1 SCOPE

This Standard sets out a method for all-weld-metal tensile testing of deposited weld metal

2 REFERENCED DOCUMENTS

‘The following documents are referred to in this Standard:

AS

1391 Methods for tensile testing of metals

1553 Covered electrodes for welding

1553.2 Part 2: Low and intermediate alloy steel electrodes for manual metal-are welding

of carbon steels and low and intermediate alloy steels

1858 Electrodes and fluxes for submerged-are welding

1858.1 Part I: Carbon steels and carbon-manganese steels

2203 Cored electrodes for are-welding

Part I: Ferritic steel electrodes

Methods for destructive testing of welds in metal

Method 1: General requirements for tests

ASINZS

1553 Covered electrodes for welding

1553.1 Part 1: Low carbon steel electrodes for manual metal-are welding of carbon steels

and carbon-manganese steels

2717 Welding—Blectrodes—Gas metal are

2717.1 Part I: Ferritic steel electrodes

3. PRINCIPLE

An all-weld-metal test specimen taken from a weld in which the weld metal has been

deposited under specified conditions is subjected to uniaxial tension. The tensile strength is

then determined.

© Standards Australia ® Standards Australia

AS 2205,

2003 2

4 PREPARATION OF TEST SPECIMEN

The test specimen shall be prepared in accordance with the requirements of AS 2208.1 and

the following:

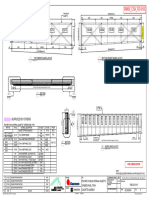

(a) It shall be cut from the weld metal as illustrated in Figure Ia),

(6) It shall be of the maximum attainable diameter conforming to the dimensional

requirements for proportional circular section test pieces specified in AS 1391, unless

specifically required otherwise (see Note to Item (c) below).

Where it is not possible to obtain a complete test specimen from the joint, it is

permissible to add extra weld metal at the locations shown in Figure 1(a). The weld

should be checked by etching the test piece before final machining, so as to ensure

that the test specimen is correctly located (see Figure 1(a))

(©) Where required for the qualification of welding consumables, it shall be in

accordance with the dimensions of Figure I(b).

NOTE: The dimensions of the specimen illustrated in Figure I(b) comply with the

requirements of International (ISO), British and Australian Standards for welding

consumables and Ship Classification Societies Unified Rules for Welding Consumables, and

require a different angle of weld preparation from that shown in Figure I(a) (see

ASINZS 1553.1, AS 1553.2, AS 1858.1, AS 2203.1 or AS/NZS 2717.1)

(d) Where the material thickness exceeds 70 mm, two specimens shall be taken, one

above the other.

5 PROCEDURE

The procedure shall be in accordance with AS 1391, using any convenient straining rate in

accordance with AS 1391 or, if applicable, the straining rate specified in the application

Standard,

6 REPORTING OF RESULTS

The test results shall be reported as follows:

(a) Identification of this and any relevant application Standards, (i.e., “AS 2205.

weld-metal tensile test and ...

(b) Identification of test specimens by any markings (e.g... ‘Specimen A’).

(©) Type of test specimen (e.g., as illustrated in Figure I(a) or 1(b)).

(4) Type of material and, if known, Standard number and grade.

(©) Dimensions of test specimen and minimum original cross-secti

(Any special feature of the test specimen before testing (e,

imperfection).

(2) Any heat treatment applied to the test specimen before testing

(h) Whether extra weld metal was added in accordance with Clause 4(b).

(i) Temperature of test, if not carried out at ambient temperature

Alle

nal area,

any visible

(Maximum straining rate applied, yield strength or proof stress as appropriate,

elongation and reduction of area, where applicable.

(k)- Maximum fore.

() Calculated tensile strength

(m) Location of failure, only required if outside the central third of the gauge length.

(n) Any special feature of the fracture surface (e.g., presence and type of any defects).

(0) Compliance or otherwise with the application Standard, if applicable

www standards.com.au © Standards Australia

3 AS 2205.2.2—2003

To suit required Added weld metal

[number of specimens | if necessary

Limits of added weld metal

(a) Location of test specimen in @ welded joint

To suit testing

machine grips

with 12min

60_min_paraliel length

Ip) Test specimen for qualification of welding consumables

NOTE: Parallel lengths of the specimens to be taken entirely from the deposited weld metal.

DIMENSIONS IN MILLIMETRES

FIGURE 1 TEST SPECIMEN

ww standards.com au © Standards Australia

NoTEs

Notes

This Australian Standard was prepared by Committee WD-006, Testing of Welds. It was approved on behalf ofthe Council of Standards

Australia on 7 March 2003 and published on 27 March 2003.

The following are represented on Committee WD-006:

‘Austalian Railway Association

AUSTROADS.

Bureau of Steel Manufacturers of Australia

National Association of Testing Authorities Australia,

‘Welding Technology Instat oF Austalia

Keeping Standards up-to-date

Standards are living documents which reflect progress in science, technology’ and systems, To maintain their curteney, all Standards are

periodically reviewed, and new editions are published. Between eilions, amendments mas be issued. Standards may also be withdraw. It

‘Simportant that readers assure themselves they ate sing a current Standard, which should include any amendments which may have beet

Published since the Standard was purchased,

Detaled information about Standards can be found by visiting the Standards Aus

the relevant Standard inthe on-line eataloghs

Altematively, the printed Catalogue provides information current at 1 January each year, and the monthly magazine, The Australian

Standard, hiss full isting of revisions and amendments published each month.

ia Web site at www:standards.com.au

looking up

Originated as AS 8301 21971

Previous edition AS 2205,22—1997,

Fourth edition 2003,

This Standard was issued in draft form for comment as DR 02621.

COPYRIGHT

© Standards Australia International

Allrghts are reserved. No part of this work may be reproduced or copied in any form or by any means,

‘or mechsnical, including photocopying, without the writen permission of the publisher.

Published by Standards Australia International Lid

‘GPO Box $420, Sydney, NSW 2001, Australia,

SBN 07397 5137 7 Printed in Australia

lectronic

This page has been left intentionally blank.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- ANSI ISEA Z87.1 - 2020 - American National Standard Occupational and Educational Personal Eye and Face Protection Devices - UnlockedDocument67 pagesANSI ISEA Z87.1 - 2020 - American National Standard Occupational and Educational Personal Eye and Face Protection Devices - Unlockedjesonelite100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- 0301e - 2023-2 - Welding Inspector Application GuideDocument17 pages0301e - 2023-2 - Welding Inspector Application GuidejesoneliteNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- As 2205.2.3 - 2003 (R2018)Document9 pagesAs 2205.2.3 - 2003 (R2018)jesoneliteNo ratings yet

- As 2205.3.2 - 2003Document5 pagesAs 2205.3.2 - 2003jesoneliteNo ratings yet

- Fab-Cs-61141 - FDocument1 pageFab-Cs-61141 - FjesoneliteNo ratings yet

- Structural Design CheatsheetDocument32 pagesStructural Design CheatsheetjesoneliteNo ratings yet

- 12 Manufacturing, Assembly and TestingDocument30 pages12 Manufacturing, Assembly and TestingjesoneliteNo ratings yet

- Iso TR 17671-5 - 2004Document14 pagesIso TR 17671-5 - 2004jesoneliteNo ratings yet

- Stud Welding - A First LookDocument16 pagesStud Welding - A First LookjesoneliteNo ratings yet

- BS en Iso 9606-3 - 1999Document30 pagesBS en Iso 9606-3 - 1999jesoneliteNo ratings yet

- Iso 3452-5 - 2008Document12 pagesIso 3452-5 - 2008jesonelite100% (1)

- Iso 5576 - 1997Document39 pagesIso 5576 - 1997jesoneliteNo ratings yet

- As 2205.2.1 - 2003 (R2018)Document9 pagesAs 2205.2.1 - 2003 (R2018)jesoneliteNo ratings yet

- Welding Defects 3Document39 pagesWelding Defects 3jesonelite100% (1)

- BS en Iso 9606-5 - 2000Document26 pagesBS en Iso 9606-5 - 2000jesoneliteNo ratings yet

- Welder's Guide To Contact CD Welding - IMAGE Industries - UnlockedDocument13 pagesWelder's Guide To Contact CD Welding - IMAGE Industries - UnlockedjesoneliteNo ratings yet

- 1261481.220502 - Annals 2022 2 17Document5 pages1261481.220502 - Annals 2022 2 17jesoneliteNo ratings yet

- Stud WeldingDocument10 pagesStud WeldingjesoneliteNo ratings yet

- Iso TR 25901-3 - 2016Document38 pagesIso TR 25901-3 - 2016jesoneliteNo ratings yet

- ACR Magenta Book Part 1 Rev. 2 - Recommended Practice For Use of Horizontal Safety Systems in RoofworkDocument29 pagesACR Magenta Book Part 1 Rev. 2 - Recommended Practice For Use of Horizontal Safety Systems in RoofworkjesoneliteNo ratings yet

- Seams Membranes:: Tape-Bonded Comparison Tape-Bonded andDocument76 pagesSeams Membranes:: Tape-Bonded Comparison Tape-Bonded andjesoneliteNo ratings yet

- BS en Iso 3834-3 - 2021Document16 pagesBS en Iso 3834-3 - 2021jesonelite100% (2)

- ACR IS5 - Glass Specification in Flat RooflightsDocument4 pagesACR IS5 - Glass Specification in Flat RooflightsjesoneliteNo ratings yet

- BS EN 10210 (Part 2) - 2006Document34 pagesBS EN 10210 (Part 2) - 2006jesoneliteNo ratings yet

- AAMA 100-07 - Standard Practice For The Installation of Windows With Flanges or Mounting Fins in Wood Frame ConstructionDocument13 pagesAAMA 100-07 - Standard Practice For The Installation of Windows With Flanges or Mounting Fins in Wood Frame ConstructionjesoneliteNo ratings yet

- ACR Blue Book Rev. 2 - Recommended Best Practice For Use of Safety Nets For RoofworkDocument17 pagesACR Blue Book Rev. 2 - Recommended Best Practice For Use of Safety Nets For RoofworkjesoneliteNo ratings yet

- ACR Green Book Rev. 3 - Guidance Note For Safe Working On Fragile Roofs or Roofs With Fragile ElementsDocument25 pagesACR Green Book Rev. 3 - Guidance Note For Safe Working On Fragile Roofs or Roofs With Fragile ElementsjesoneliteNo ratings yet

- BS en 13411-7 (2006) + A1 (2008)Document24 pagesBS en 13411-7 (2006) + A1 (2008)jesoneliteNo ratings yet

- ACR Black Book Rev. 3 - Guidance Note For Competence & General Fitness Requirements To Work On RoofsDocument9 pagesACR Black Book Rev. 3 - Guidance Note For Competence & General Fitness Requirements To Work On RoofsjesoneliteNo ratings yet

- BS en 13411-6 (2004) + A1 (2008)Document28 pagesBS en 13411-6 (2004) + A1 (2008)jesonelite100% (1)