Professional Documents

Culture Documents

Design and Simulation Studies On An Esp System IJERTV10IS080182

Uploaded by

Alfurjani AbubakrOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design and Simulation Studies On An Esp System IJERTV10IS080182

Uploaded by

Alfurjani AbubakrCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/354207487

Design and Simulation Studies on An ESP System

Article in International Journal of Engineering Research · August 2021

DOI: 10.17577/IJERTV10IS080182

CITATIONS READS

0 94

4 authors, including:

Sreenivas Matla

Jawaharlal Nehru Technological University, Kakinada

7 PUBLICATIONS 4 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

MANUFACTURE OF GUANIDINE HCL AND GUANIDINE NITRATE View project

Simulation Studies on Effect of Parameters on to the Matrix Acidizing View project

All content following this page was uploaded by Sreenivas Matla on 30 August 2021.

The user has requested enhancement of the downloaded file.

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 10 Issue 08, August-2021

Design and Simulation Studies on An ESP System

Dasari Venkata Manoj Sreenivas Matla

Department of Petroleum Engg & Petrochemical Department of Petroleum Engg & Petrochemical

Engineering Engineering

JNTUK, Kakinada, Andhra Pradesh, India JNTUK, Kakinada, Andhra Pradesh, India

Pampana Anil Kumar Koppisetti Srinivasa Rao

Department of Petroleum Engg & Petrochemical Department of Petroleum Engg & Petrochemical

Engineering Engineering

JNTUK, Kakinada, Andhra Pradesh, India JNTUK, Kakinada, Andhra Pradesh, India

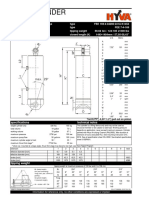

Abstract - Artificial lift methods are used for the Components:

enhancement of productivity from oil wells. These methods are The components of an ESP System can be categorized into

implemented in oil wells whose energy from the reservoir is surface and downhole components are listed [2]: a). Surface

insufficient to lift the fluids to the surface. In this study about Components: Transformers, Motor controllers, Junction box,

Electrical submersible pump and its design & simulation in

PROSPER software. It is one of the important type of artificial

Well Head. b). Downhole Components: Electrical Cable,

lift methods, which is used to lower the producing bottom hole Cable Protectors, Pumps, Gas Separator, Seal section, Motor,

pressure on the formation to obtain a higher production rate Pump intake, Drain valve, Check valve. The ESP System

from the well. It is an efficient and reliable method for lifting along with its components labelled is shown in Fig.1.0.

moderate to high volumes of fluids from wellbores. PROSPER is Working Principle of ESP System:

a well performance, design and optimization computer software Electrical Submersible Pumps are the vertical alignment of

for modelling most types of well configurations. This study centrifugal pumps in the borehole which accelerates the

major focuses on the design and simulation of an ESP system for velocity of fluids by impellers. The kinetic energy produced

wells having different productivity index using the PROSPER by the impellers is converted into pressure energy by the

software.

diffuser and pumps the fluid. An Electrical Submersible Pump

Keywords: Artificial lift methods, Electrical submersible pump, is a multi-stage stacked centrifugal pump whose stages are

PROSPER software, Well performance. determined by bottom hole pressure and desired flow rate. The

arrangement of each stage of an ESP System consists of an

I. INTRODUCTION impeller and diffuser. When the fluid enters the impeller of the

The artificial lift system of a well resembles the human first stage, it centrifuges the liquid radially outward and

heart which pumps the high volumes of reservoir fluids to the increases the velocity of the fluid. Now the fluid enters the

surface in low producing wells. These methods are employed diffuser from the sharp edges of the impeller where the kinetic

in oil wells whose energy from the reservoir is insufficient to energy of the fluid is converted into pressure energy. The

lift the fluids to the surface. Most of the producing wells in the pressure gained by the fluid in the first stage and enters the

world nearly 90 % are presently working on the artificial lift next stage where the pressure is increased slightly than the

system from early stages. Among the available artificial lift first stage. As the stages are increase, the pressures are gaining

methods, the electrical submersible pump (ESP) system is incrementally in each stage to desired discharge pressure and

very effective in wells with low bottom hole pressure, low gas designed head of the pump [1].

to oil ratio, low bubble point pressure, high water cut, and

deviated wells [1].

Electrical Submersible Pump System

History and origin:

A Russian engineer named Armais Arutunoff in 1911

invented an electric motor that can be worked on the water.

By the addition of a drill and centrifugal pump to the motor,

he invented an electrical submersible pump. Later he

improves the system and invented the Russian Electrical

Dynamo of Arutunoff for which Schlumberger is currently

acting as a service provider [1].

Some of the ESP System Service Providers are listed:

Schlumberger- REDA, Weatherford, Baker Hughes- Figure 1.0: ESP System and its components

Centrilift, Wood Group ESP, ALNAS.

IJERTV10IS080182 www.ijert.org 384

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 10 Issue 08, August-2021

Advantages, Disadvantages, and Industrial applications of choose Electrical Submersible Pump for artificial lift

ESP system: method.

The major advantages of an ESP system [3,4,5]: • Enter the PVT parameters in the PVT input data

• Capable of pumping high viscous crude oils to the window and match data with correlations to get the

surface. least deviation.

• It can be applied to well having low bottom hole • After matching PVT data, input reservoir operating

pressure. parameters in the IPR window to develop the inflow

• ESP System has a low tendency of scale forming performance relation (IPR) curve and determine the

operating conditions. absolute open flow.

• It has a capacity to produce high volumes of fluids up • Enter deviation survey data, downhole equipment

to 18,000 barrels/day to surface. data, surface equipment data, (if available) and

• High efficiency and low operating costs. geothermal gradient data in their respective windows.

The major disadvantages of an ESP system [3,4]: • Enter desirable design parameters and calculate the

output design parameters and generate a plot based on

• It can take high repair and maintenance costs. output design parameters.

• It is not applicable to high GOR producing wells. • From the plot generated, choose the optimum

• The efficiency of the motor is reduced in sand operating design of ESP System.

producing wells and sand producing wells will cause

mechanical repairs to wells. We consider two wells having different productivity index

wells (i.e. High and Low) for the design of the ESP System.

• ESP System installation is very critical in highly

deviated and dogleg severity wells. Design of ESP System for low productivity index of a well:

• Special equipment is needed for the repair of the ESP

The following table 1 delineates the reservoir and fluid

system in deviated wells.

input data for the PROSPER software to design the ESP

• It is not applicable to the high temperature and deep

System for the low productivity index of a well.

wells.

The Industrial applications of an ESP system [3, 4, 5]: Table 1: Reservoir and Fluid Input Data

• High productive index wells. Reservoir and Fluid Input Data

Reservoir pressure 3200 psi

• Offshore wells. Bubble point pressure 1500 psi

• Mostly deviated and horizontal wells. Reservoir Temperature 1800F

• ESP is also used for the dewatering purpose of the GOR 300 scf/stb

wells. Water cut 75 %

Economic analysis of an ESP system: Oil API 320API

Gas specific gravity 0.7

The better economic evaluation of an ESP System is Water salinity 80000 ppm

carried out through the PROSPER software and Oil FVF 1.2 bbl/stb

production can be forecasted in different scenarios for 5-6 Oil viscosity 0.31 cp

years. ESP generates higher gross profits because it Productivity index 2 stb/day. psi

produces high potentials of reservoir fluids. On other hand

it can also have high operating expenses due to high water After giving the reservoir and fluid input data to the

cuts and the replacement of failed pumps. software, inflow performance relation (IPR) curve is

generated and the absolute open flow (AOF) of the well is

II. DESIGN AND SIMULATION STUDIES ON ESP determined. The Fig. 2.0. Illustrates the IPR curve for low

SYSTEM USING THE PROSPER SOFTWARE productivity index well with AOF.

PROSPER is a production optimization software used

to models the well completions configuration and design

artificial lift methods. It predicts the reservoir fluid

properties as a function of temperature and pressure. It

simulates the optimized results for the particular artificial

lift method based on input data. PROSPER distinctive

matching options that tune PVT, multi-phase flow

correlations and IPR to match measured field information.

It is accustomed style and optimize well completions as

well as multi-lateral, multi-layer and horizontal wells,

conduit and pipeline sizes [6,7,8].

Stepwise Procedure for Design of ESP System Using

PROSPER Software

• First click on file option and select the new file.

• Now in the system summary, water and oil with Black Figure 2.0: IPR curve of a low productivity index well

Oil model options are chosen for fluid description and

IJERTV10IS080182 www.ijert.org 385

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 10 Issue 08, August-2021

According to the absolute open flow rate, give the Design of ESP System for high productivity index of a

desirable design parameters to software as shown in table 2 well:

and generate calculated output design of ESP System as The following table 5 below represents the reservoir

shown in table 3. and fluid input data for the PROSPER software to design ESP

Table 2: Input Design Data System for low productivity index of a well.

Input data

Pump depth(measured) 5500 ft Table 5: Reservoir and Fluid Input Data

Operating frequency 60 Hz

Maximum pump outside diameter 6 in Reservoir and Fluid Input Data

Length of cable 7000 ft Reservoir pressure 5500 psig

Design rate 5300 stb/day Bubble point pressure 3500 psi

Water cut 75% Reservoir Temperature 2500F

Top node pressure 300 psig GOR 500 scf/stb

Water cut 50 %

Table 3: Calculated Design Data Oil API 32o API

Gas specific gravity 0.72

Calculated Design Data Water salinity 75000 ppm

Pump Intake Pressure 11.33 psig Oil FVF 1.42 bbl/stb

Pump Intake Rate 53911.2 Rb/Day Oil viscosity 0.5 cp

Free GOR Entering Pump 298.6 scf/STB Productivity index 6.5 stb/day. psi

Pump Discharge Pressure 2498.9 psig

Pump Discharge Rate 5626.7 Rb/Day

Total GOR Above Pump 300 scf/STB After giving the reservoir and fluid input data to the

Average Downhole Rate 6946 Rb/Day software, an inflow performance relation (IPR) curve is

Head Required 7417.6 ft generated and the absolute open flow (AOF) of the well is

Pump Inlet Temperature 174.460F determined. The figure 4 delineates the IPR curve for the

high productivity index well with AOF.

On the basis calculated design data, select the better

downhole equipment like pump, motor and electrical cable

for well having low productivity index (PI = 2) available in

the software. For the selected equipment generate optimum

output results are presented in table 4 and the design plot of a

ESP system as shown in Fig. 3. 0. From the plot generated

the best efficiency and better operating conditions of system.

Table 4: Results for selected Equipment

Results

Number of Stages 341

Power Required 459.79 HP

Pump Efficiency 63.812 %

Pump Outlet Temperature 186.59 0 F

Current Used 116.48 amps

Motor Efficiency 82.83 %

Power Generated 459.79 HP

Figure 4: IPR Curve for high productivity index well

Motor Speed 3438.53 rpm

Voltage Drop along Cable 303.75 volts

Voltage Required at Surface 2778.75 volts

Based on the absolute open flow rate, give the desirable

design parameters to software as shown in table 6 and

generate calculated output design of ESP System as show in

table 7.

Table 6: Input Design Data

Input data

Pump depth(measured) 12200 ft

Operating frequency 60 Hz

Maximum pump outside diameter 6 in

Length of cable 13400 ft

Design rate 13000 stb/day

Water cut 50 %

Top node pressure 350 psig

Table 7: Calculated Design Data

Calculated Design Data

Pump Intake Pressure 3209.97 psig

Pump Intake Rate 15319.9 Rb/Day

Free GOR Entering Pump 52.73 scf/STB

Pump Discharge Pressure 4575.05 psig

Figure 4: ESP Design plot for low productivity index well Pump Discharge Rate 15036.3 Rb/Day

IJERTV10IS080182 www.ijert.org 386

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 10 Issue 08, August-2021

Total GOR Above Pump 500 scf/STB Table 9: Comparison of results of two wells

Average Downhole Rate 15122.5 Rb/Day

Head Required 3676.2 ft High

Low Productivity

Pump Inlet Temperature 174.460F Parameters Productivity

Index Well

Index Well

Pump setting depth Low High

Based on calculated design data, select the better Design Rate Low (5300 High (13000

downhole equipment like the pump, motor, and electrical STB/Day) STB/Day)

cable for well having high productivity index (PI = 6.5) Water cut High (75 %) Low (50%)

available in the software. For the selected equipment generate Pump Intake Pressure Low High

Pump Intake Rate High Low

optimum output results are shown in table 8 and the ESP

Pump discharge Rate Low High

Design plot as depicts in figure 5. From the plot generated the Head Required High Low

efficiency and better operating conditions are determined. Number of Stages High Low

Pump efficiency Low High

Table 8: Results for selected Equipment Voltage Drop along Cable Low High

Results

Number of Stages 66 III. CONCULSION

Power Required 508.28 HP From the Design of ESP Systems of two wells, we studied

Pump Efficiency 69.235 % that a greater number of stages of pumping and high head is

Pump Outlet Temperature 253.41 0 F required for low productive well, due to these factors the

Current Used 112.42 amps

pump efficiency is decreased. More over Pump intake

Motor Efficiency 82.83 %

Power Generated 508.79 HP pressure and Pump discharge pressure are decreased because

Motor Speed 3441.53 rpm of its low producing rates. The same conditions are vice versa

Voltage Drop along Cable 509.07 volts for high productive wells.

Voltage Required at Surface 3344.07 volts

IV. ACKNOWLEDGMENT

I would prefer to specific my profound sense of feeling to

guide Mr, P. Anil Kumar, Asst. Professor, Department of

Petroleum Engineering and Petrochemical Engineering,

JNTUK, Kakinada, for his or her skillful steerage, timely

suggestions and encouragement in finishing this paper.

V. REFERENCES

[1] Rick Van Flatern, Electrical Submersible Pumps the Defining Series,

Senior Edition, 2014.

[2] Matthew Amao, Lecture notes on Electrical Submersible Pumping

(ESP) Systems, 2014.

[3] Quartz School for Well Site Supervisors, Module 12: Well

Completions / Section 2: The Completion String & Accessories,

2004.

[4] Abdelhady A, Gomaa S, Ramzi H, Hisham H, Galal A and

Abdelfattah A, Electrical Submersible Pump Design in Vertical Oil

Wells, Petroleum & Petrochemical Engineering Journal ISSN: 2578-

Figure 5: ESP Design plot for high productivity index well 4846, 2020.

[5] Boyun Guo, William C. Lyons, Ali Ghalambor, Petroleum

Production Engineering A Computer Assisted Approach Elsevier

Comparison between the High Productivity and Low Science & Technology Books, 2007.

Productivity Index of Wells: [6] Petroleum Experts IPM PROSPER Version 11.5, User Manual, 2015.

The following table 9 represents comparison of results of [7] Knut Undheim Stanghelle, Evaluation of artificial lift methods on

low productivity index well and high productivity index well the Gyda field, Master thesis, 2009.

[8] Imran A. Hullio*, Sarfraz A. Jokhio, Khalil Rehman Memon, Sohail

which are taken as case studies. Nawab and Khair Jan Baloch, Design and Economic Evaluation of

the ESP and Gas Lift on the Dead Oil Well International Journal of

Current Engineering and Technology,2018.

IJERTV10IS080182 www.ijert.org 387

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

View publication stats

You might also like

- Computational Flow Modeling for Chemical Reactor EngineeringFrom EverandComputational Flow Modeling for Chemical Reactor EngineeringRating: 3 out of 5 stars3/5 (3)

- Design and Simulation Studies On ESP SystemDocument4 pagesDesign and Simulation Studies On ESP SystemJay PatelNo ratings yet

- Operator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowFrom EverandOperator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowRating: 2 out of 5 stars2/5 (1)

- Paper51548 1553Document7 pagesPaper51548 1553ShakerMahmoodNo ratings yet

- Sucker-Rod Pumping Handbook: Production Engineering Fundamentals and Long-Stroke Rod PumpingFrom EverandSucker-Rod Pumping Handbook: Production Engineering Fundamentals and Long-Stroke Rod PumpingRating: 5 out of 5 stars5/5 (9)

- Paper51548 1553Document7 pagesPaper51548 1553darshanNo ratings yet

- Operating Parameters of Electrical Submersible Pump Simulation Using Excel®Document7 pagesOperating Parameters of Electrical Submersible Pump Simulation Using Excel®Martin SaputraNo ratings yet

- Ijert Ijert: Design and Flow Through CFD Analysis of Enclosed ImpellerDocument8 pagesIjert Ijert: Design and Flow Through CFD Analysis of Enclosed ImpellerguganesannnNo ratings yet

- Prosper SoftwareDocument6 pagesProsper Softwarebharath35kumar0% (1)

- Electrical Submersiblepumps PDFDocument51 pagesElectrical Submersiblepumps PDFRadu Chibzui100% (1)

- Design and CFD Analysis of Centrifugal Pump IJERTCONV9IS10007Document5 pagesDesign and CFD Analysis of Centrifugal Pump IJERTCONV9IS10007muhammad faisalNo ratings yet

- Intelligent Wells and Fields What'S New in Artificial Lift Nocs Growing and Evolving Deepwater Drilling AdvancesDocument4 pagesIntelligent Wells and Fields What'S New in Artificial Lift Nocs Growing and Evolving Deepwater Drilling Advanceslepro brunelNo ratings yet

- Research ProposalDocument7 pagesResearch ProposalKrystal 查尔斯No ratings yet

- Thermodynamic Analysis of Two-Phase Ejector As ExpansionDocument11 pagesThermodynamic Analysis of Two-Phase Ejector As ExpansionPurwono F. SutopoNo ratings yet

- Design and Analysis of Centrifugal Pump Impeller Using CFD Analysis IJERTCONV5IS07017Document6 pagesDesign and Analysis of Centrifugal Pump Impeller Using CFD Analysis IJERTCONV5IS07017VSNo ratings yet

- A Neural Network Model For Electric PDFDocument6 pagesA Neural Network Model For Electric PDFR Adhitya ArNo ratings yet

- Posterrr TekproDocument1 pagePosterrr TekproFanya PangauNo ratings yet

- Development of An Electronic Fuel Injection System For A 4-Stroke Locomotive Diesel EngineDocument8 pagesDevelopment of An Electronic Fuel Injection System For A 4-Stroke Locomotive Diesel EngineSinh Viên ITNo ratings yet

- Materials Selectionfor Dynamic Variable Geometry Turbocharger Flow Control ApplicationDocument21 pagesMaterials Selectionfor Dynamic Variable Geometry Turbocharger Flow Control ApplicationTed ddyNo ratings yet

- Feasibility of A Thrust Control Mechanism by Regulating The Flow at The EngineDocument9 pagesFeasibility of A Thrust Control Mechanism by Regulating The Flow at The EngineIJRASETPublicationsNo ratings yet

- ReviewPaper WO QuillbotDocument9 pagesReviewPaper WO QuillbotHet PatelNo ratings yet

- Application Engineering: Reda Esp System ComponentsDocument4 pagesApplication Engineering: Reda Esp System Componentselsayed amerNo ratings yet

- Paper Tekpro Ii - Kelompok 8-DikonversiDocument6 pagesPaper Tekpro Ii - Kelompok 8-DikonversiSilvi AmaliaNo ratings yet

- Gujarat Technological University: Ac Motor ControllerDocument17 pagesGujarat Technological University: Ac Motor ControllerEngineers worldNo ratings yet

- SahebBedi High Powered Rocket Using Non Pyro Recovery SystemDocument13 pagesSahebBedi High Powered Rocket Using Non Pyro Recovery SystemSaheb BediNo ratings yet

- Modelling, Fabrication & Analysis of Pelton Turbine For Different Head and MaterialsDocument18 pagesModelling, Fabrication & Analysis of Pelton Turbine For Different Head and MaterialsDurga prasadNo ratings yet

- Oil Testing DeviceDocument3 pagesOil Testing DeviceJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- Head and Efficiency Prediction Methods For Centrifugal Pumps2 PDFDocument9 pagesHead and Efficiency Prediction Methods For Centrifugal Pumps2 PDFSimon TudorNo ratings yet

- Ernesto Ndjoli Article 2Document7 pagesErnesto Ndjoli Article 2ernesto ndjoli rokuNo ratings yet

- CFD Analysis For Estimation of Efficiency of Low-Pressure Steam TurbineDocument4 pagesCFD Analysis For Estimation of Efficiency of Low-Pressure Steam TurbineaminardakaniNo ratings yet

- Obtimum Design of Esp in Well No. (C-233) : Sarir FieldDocument3 pagesObtimum Design of Esp in Well No. (C-233) : Sarir FieldخالدNo ratings yet

- Background of The StudyDocument14 pagesBackground of The StudyJm DaguimolNo ratings yet

- CFD Analysis On Ejector Cooling System With Variable Throat GeometryDocument6 pagesCFD Analysis On Ejector Cooling System With Variable Throat GeometryijripublishersNo ratings yet

- Design of IPM Synchronous Motor For Gearless Elevator ApplicationsDocument7 pagesDesign of IPM Synchronous Motor For Gearless Elevator Applicationsرجل من الزمن الجميلNo ratings yet

- Computational Fluid Flow AnalysisDocument6 pagesComputational Fluid Flow AnalysisRiddhesh PatelNo ratings yet

- Spe 206265 MsDocument14 pagesSpe 206265 MsAlfonso RamosNo ratings yet

- Solar InteligentDocument37 pagesSolar InteligentPrekshitha NNo ratings yet

- Vibration Analysis of Distributor Pipe System and Base Structure IJERTCONV5IS02004Document5 pagesVibration Analysis of Distributor Pipe System and Base Structure IJERTCONV5IS02004ach .bustomi arifNo ratings yet

- Iut JournalDocument20 pagesIut JournalRong GuoNo ratings yet

- Design-Based Performance Evaluation of Two-Winding Capacitor Self-Excited Single-Phase Induction GeneratorDocument9 pagesDesign-Based Performance Evaluation of Two-Winding Capacitor Self-Excited Single-Phase Induction Generatordedi sanatraNo ratings yet

- SPE-177990-MS Electric Submersible Pump Installation and Commissioning - Challenges and Lesson Learned From Field DevelopmentDocument17 pagesSPE-177990-MS Electric Submersible Pump Installation and Commissioning - Challenges and Lesson Learned From Field Developmentmahmoud korieshNo ratings yet

- Virtul Engine Managment SimulatorDocument15 pagesVirtul Engine Managment SimulatorTiếngHátĐêmNo ratings yet

- Prssurised Flushing SystemDocument19 pagesPrssurised Flushing SystemjeiohkotaNo ratings yet

- Common Header Line For Pump TestingDocument8 pagesCommon Header Line For Pump TestingNovesa NurgirisiaNo ratings yet

- Thermal Modelling and Optimization of Low-Grade Waste Heat Driven Ejector Refrigeration System Incorporating A Direct Ejector ModelDocument25 pagesThermal Modelling and Optimization of Low-Grade Waste Heat Driven Ejector Refrigeration System Incorporating A Direct Ejector ModelAhmad AnsariNo ratings yet

- Engine ControlDocument15 pagesEngine ControlDhammikaNo ratings yet

- Adaptive Cooling and Spindle Condition Monitoring System: Guided By: Dr. B. Giriraj R. No. 07MI31Document28 pagesAdaptive Cooling and Spindle Condition Monitoring System: Guided By: Dr. B. Giriraj R. No. 07MI31arunnicalNo ratings yet

- Rod Less Pump OptimizationDocument15 pagesRod Less Pump OptimizationAvanish ChaubeyNo ratings yet

- Theoretical Modelling and Experimental Validation of Combustion in DI Diesel Engine by Using Diesel - RKDocument5 pagesTheoretical Modelling and Experimental Validation of Combustion in DI Diesel Engine by Using Diesel - RKmoath farrajNo ratings yet

- 1 PBDocument20 pages1 PBMuhammad ShahidNo ratings yet

- D1.8 Optimised Radial Turbine DesignDocument28 pagesD1.8 Optimised Radial Turbine Designedwin flores mamaniNo ratings yet

- Experimental Design and Analysis of Pump As TurbinDocument12 pagesExperimental Design and Analysis of Pump As TurbinSebastián Alexander Flores OroscoNo ratings yet

- A Review of Model Based Optimization of Production SystemsDocument7 pagesA Review of Model Based Optimization of Production SystemsTrevorNo ratings yet

- Study On The Effects of Variation of Fuel Injection Pressure On Single Cylinder Diesel EngineDocument5 pagesStudy On The Effects of Variation of Fuel Injection Pressure On Single Cylinder Diesel EngineAngel FajmNo ratings yet

- Cavitation Performance Improvement of An Industrial Cryogenic Centrifugal Pump by Implementing Variable Pitch InducerDocument12 pagesCavitation Performance Improvement of An Industrial Cryogenic Centrifugal Pump by Implementing Variable Pitch InducerKOWSHIK 4310No ratings yet

- Centrifugal PumpDocument3 pagesCentrifugal PumpJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- Energy, Exergy and Simulation Analysis of Steam Driven High Pressure Pumps of Cogeneration PlantsDocument8 pagesEnergy, Exergy and Simulation Analysis of Steam Driven High Pressure Pumps of Cogeneration PlantsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Review Paper On New Automotive Camless EngineDocument4 pagesReview Paper On New Automotive Camless EngineEditor IJTSRDNo ratings yet

- Vibration Analysis To Estimate Turbocharger Speed Fluctuation in Diesel EnginesDocument8 pagesVibration Analysis To Estimate Turbocharger Speed Fluctuation in Diesel Enginesachraf zegnaniNo ratings yet

- Ijmerr 52e00b22d2840Document9 pagesIjmerr 52e00b22d2840Natan Dos SantosNo ratings yet

- Parts Print - Aspx BookId 888&ModelIdDocument2 pagesParts Print - Aspx BookId 888&ModelIdPlaneacion MantenimientoNo ratings yet

- Zd320使用说明书(en)Document116 pagesZd320使用说明书(en)मुकेश कुमार झा100% (1)

- Answer All Questions. Each Question Carries 2 Marks.: Sixth Semester B.Tech Degree ExaminationDocument3 pagesAnswer All Questions. Each Question Carries 2 Marks.: Sixth Semester B.Tech Degree ExaminationKrishna YadavNo ratings yet

- Thermodynamics: S T H G S T H G S T G H C T H G K Mol KJ Mol JK K Mol KJ Mol KJ Mol KJ HCL NaohDocument5 pagesThermodynamics: S T H G S T H G S T G H C T H G K Mol KJ Mol JK K Mol KJ Mol KJ Mol KJ HCL NaohSam Illuminaughtyy KayNo ratings yet

- Ammonia P-H ChartDocument1 pageAmmonia P-H Chartalimkali86% (7)

- Step by Step Methods For WRC 107 and WRC 297 Checking in Caesar IIDocument7 pagesStep by Step Methods For WRC 107 and WRC 297 Checking in Caesar IIaap1No ratings yet

- Soil CharacterizationDocument20 pagesSoil CharacterizationSajjad AnwarNo ratings yet

- Presentation Ssi DynaPumpDocument23 pagesPresentation Ssi DynaPumpMohamed GhareebNo ratings yet

- Eurocode 4 Seminar Composite Structures Composite Slabs With Profiled Steel SheetingDocument23 pagesEurocode 4 Seminar Composite Structures Composite Slabs With Profiled Steel Sheetingjplezp100% (1)

- Konica C&H Machine Parts List 24-10-2011Document45 pagesKonica C&H Machine Parts List 24-10-2011CésarMarinNo ratings yet

- Cilindro HidraulicoDocument1 pageCilindro HidraulicoEnrique Escobar LozanoNo ratings yet

- Induction NotesDocument15 pagesInduction NotesKartikNo ratings yet

- Nippon Piston RingsDocument26 pagesNippon Piston Ringsadam_nell_1No ratings yet

- Kinetic Model of Gases: Section 1.3 of Atkins, 6th Ed. Section 24.1 of Atkins, 7th Ed. Section 21.1 of Atkins, 8th EdDocument18 pagesKinetic Model of Gases: Section 1.3 of Atkins, 6th Ed. Section 24.1 of Atkins, 7th Ed. Section 21.1 of Atkins, 8th EdJerome JavierNo ratings yet

- Weforma 19 LDS PDFDocument19 pagesWeforma 19 LDS PDFsatheez3251No ratings yet

- Iso 21013 4 2012 en PDFDocument8 pagesIso 21013 4 2012 en PDFds14me001 SvnitNo ratings yet

- Shell and Tube Heat ExhangerDocument28 pagesShell and Tube Heat ExhangerAmoluck BhatiaNo ratings yet

- TDI Turbo T100-CS 1 Product SheetDocument1 pageTDI Turbo T100-CS 1 Product Sheetandistwn99No ratings yet

- Series: Direct Solenoid and Solenoid Pilot Operated ValvesDocument8 pagesSeries: Direct Solenoid and Solenoid Pilot Operated ValvesSAUL OSPINONo ratings yet

- State-Space Linear Systems: ExercisesDocument9 pagesState-Space Linear Systems: ExercisesYoshua Diaz0% (1)

- Item# Decsription Uom Material MasterDocument3 pagesItem# Decsription Uom Material MasterPARAG GANDHINo ratings yet

- Grundfosliterature 3979032 PDFDocument110 pagesGrundfosliterature 3979032 PDFIslam FawzyNo ratings yet

- Aloris CatalogDocument31 pagesAloris CatalogErich KeaneNo ratings yet

- Back Hoe ExcavatorDocument4 pagesBack Hoe ExcavatorLemi Chala BeyeneNo ratings yet

- Physics Notes AJk 9th Class Chap6Document3 pagesPhysics Notes AJk 9th Class Chap6Khizer Tariq QureshiNo ratings yet

- 777D.Schematic ElectricDocument2 pages777D.Schematic ElectricDedeNo ratings yet

- Computers & Fluids: James Chen, Chunlei Liang, James D. LeeDocument9 pagesComputers & Fluids: James Chen, Chunlei Liang, James D. Leeisele1977No ratings yet

- Elgin Hydrocyclone Cut Sheet 2019Document1 pageElgin Hydrocyclone Cut Sheet 2019Andrew GoadNo ratings yet

- YZJ2015-2223-SED 轴接地 - FinalDocument18 pagesYZJ2015-2223-SED 轴接地 - Finalmarine ShanghaiNo ratings yet

- Deltalab - Introduction EX1100 - enDocument7 pagesDeltalab - Introduction EX1100 - enPetre TachitaNo ratings yet