100% found this document useful (1 vote)

1K views15 pagesWelding Table Project

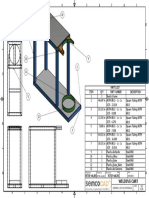

This document describes a trade project submitted for the Craft Certificate in Mechanical Engineering (Welding & Fabrication Option). The project involved designing and building a welding table. The table consists of metal rods, bars, sheet metal, and an insulator. The rods conduct welding electrodes, the bars form the frame, and the sheet metal and insulator provide surfaces for welding and storing electrodes. The project aims to provide welders with more work space compared to traditional tables. The welding table was tested and found to work efficiently for its purpose. Some challenges in the project included delays obtaining materials.

Uploaded by

Kheri MohdCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

1K views15 pagesWelding Table Project

This document describes a trade project submitted for the Craft Certificate in Mechanical Engineering (Welding & Fabrication Option). The project involved designing and building a welding table. The table consists of metal rods, bars, sheet metal, and an insulator. The rods conduct welding electrodes, the bars form the frame, and the sheet metal and insulator provide surfaces for welding and storing electrodes. The project aims to provide welders with more work space compared to traditional tables. The welding table was tested and found to work efficiently for its purpose. Some challenges in the project included delays obtaining materials.

Uploaded by

Kheri MohdCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- Introduction: Presents the main parts and challenges associated with welding tables, including objectives and justifications for the project.

- Background: Describes the historical evolution and desired improvements in welding tables for enhanced efficiency.

- Literature Review: Analyzes existing research on welding tables and their applications in mechanical systems to draw effective solutions.

- Methodology: Outlines the method of data collection and the roles of different materials like rods, bars, sheet metals in the design process.