Professional Documents

Culture Documents

TERERICE

TERERICE

Uploaded by

sita0 ratings0% found this document useful (0 votes)

8 views3 pagesterace

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentterace

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views3 pagesTERERICE

TERERICE

Uploaded by

sitaterace

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 3

Operation, Installation & Maintenance Manual

Te eat)

Self-Operating Temperature Regulators

Model 91400 Shown

Indicating and Non-indicating

[5 TRERICE

Series 97000

i-Operating Regulators Operation, installation & Maintenance Manual

PRINCIPLES OF OPERATION OF THE REGULATOR

The Trerice Series 91000 Temperature Regulator operates on tho vapor pressure principle. The thermally se

bulb of the instrument contains a fluid thal creates a vapor which increases or decreases in pressure as the se

bulb temperature increases or decreases, This vapor prossure is transmitted hydraulically to the bellows which,

‘opposed by the adjusting (return) spring, actuates the valve controling the floys in proportion to the sensed

mperature at the bulb, Raising of lowering the adjusting screw will chango the comprossion of the sprin

the bollows, thus raising or lowering the control temperature. For tho most sensitive operation a nominal range

should be selected thal contains the desired control point in the uppor 1/3 of the nominal range. The vapor pressur

response is greater per unit of temperature change in the uppor portion of the nominal range. All TRERICE

temperature requiators (with the exception of tho 91600 “Safely: Type") are equipped with an ovor-range feature which

allows the bulb to be healed 100°F abovo the nominal range without damaging the temperature sensing system,

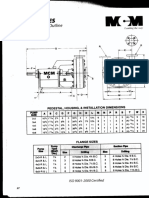

IDENTIFYING YOUR UNIT - 91000 & 91400 Actuators

Single Seat, ln-To-ose Wes

‘DoutleSea,l-o-Clse Ves

——_________} bouaie Set, tr-to-tpen tes Single Seat Dal Themmoeter Range

Rang tate Noval Range ‘Av May Yale {n-To-Open Vales |W! St0t ony)

ror tei A100 oer aS toDe un W weit Fac

oz’ 10 ta90'F & $10 30°C WoW 8 PO" wwE Ni Fac

os avtansts o'tese | soto nF & v0 oAs 0° 10 80F & 10 Fac

os sow MoT 6 1'rm8 | TOW IE& Ay"t0 60'S to 05'F & 2) OF aC

os Ty to 6st & PS to TOG | 19910 160

F& B0"t0 (010 to A0F & 40 bo 168 &

os 9st & ate 90's | 160"I0 190 8 TOI BOS 18010 1957F & 50 os" t0 109 F AC

oT 16°F & s9°t0 W0-C | 190" 2105 & orto ToC | TS8eto OF & 8! rasta FAC

Foe 38" 10 AAO'F & 70°10 120°C | 10°10 75°F 8 100" 120% Ww7IS'F & 6010 100" | TSS" to AAC

R10 200° 10 780°F & 99°10 109°C | 2151927 & 120" Tae 102657 & 19010 120° | 7On"19 280 AC

at P7y"to9'F 10°10 199°C | 77S" I0 STO & 198" 0 155 280F RPO IMO | PAH aIVFAC

Riz Pe9" to a70°F &175° 0 185°C | 305" 10.965 & 155° to 185 (MSF 819610165 786" toa AC

ans 95" 10 490'F 84S" I0915'C | 3H to HIF A 18H" 0 218% e196 Pasta ar AG

oy 0 10 A00-F 81881079916 | ATU Io AONE & 710" to 77 te708C | ate AMT AC

“Not cecommonded or single seated values

STANDARD RANGES

91600 Safety-Type Actuators

ange Wominal Range

cade and Recarmended Working Span

at ovr & S70

rez Sy toBD By to?

Res 6s ta90F & 20toanC

Ree & my tome

es 20

Reo & 60

Rot 190'to7 D&B

ee 708:10970F & 9

Reo D1s¢t0 250% & 100

Ros oreo & 110

R06 270't0300"T & 139

ISTRERICE Page

Series 91000 ators ‘Operation, instal

‘Sel Operating Reg jon & Maintenance Manual

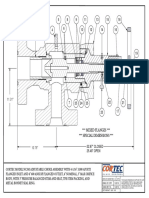

INSTALLATION

Deciding the LOCATION for the Regulator

gulator should be installed in an accessible location on horizontal piping. Possible damage from moving

parts, splashing of corrosivo liquids, vibration, heat, fluid pulsations, otc., should be considered in deciding the

location, Similar considration should also be given to the conneciing tubing and bulb. The tubing for the

special purpose “Small Bulb" option (9" long) should be located whore the temperature is at least 20°F cooler

than the control point.

REGULATOR Installat

A strainer should be installed just ahead of the regulator to protect the valve from dirt, scale or foreign

‘matter which could interfere with the seating of the valve. A three valve by-pass installed around the

regulator will facilitate removal for service.

v

wil

STEAM INLET o pe PRacese|

1100 Sertos 91400

Stralnor Sattoperating

Regulator

NOTE: ACTUAL BYPASS

Witton above

PROCESS LINE.

Blow out all pipe lines thoroughly to eliminate all foreign material from the system. Pipe thread compound

should be applied only on external or male pipe threads (not on the union nut threads). Install the regulator

ina vertical position with the flow direction through thie valve corresponding to the flow arrow cast on the

valve body. Tighten taiipieces of unions on piping first and then tighten both valve union nuts

simultaneously.

Positioning the Indicator

The Model 91400 Self-Operaling Regulator contains an integral dial thermometer that can be rotated 330)

about the vertical ax's for best readability. To prevent thermal system damage, a rotation stop is bull in,

If the stop prevents a propor viewing angle from being achieved, rotate the thermometer in the oppostt

direction, This thermometer can also be tilled up or down for maximum readabilily._ Io tit, laasen the

clovis screw/nut, tit thermometer to desired angle and re-tighten the clevis screw/nul combinatior

LGTRERICE Pages

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- C236385 WithakerDocument2 pagesC236385 WithakersitaNo ratings yet

- FLEXICHEVRON-Mist-Eliminators Type VIIIDocument12 pagesFLEXICHEVRON-Mist-Eliminators Type VIIIsitaNo ratings yet

- BOTIL Cement RetainerDocument1 pageBOTIL Cement RetainersitaNo ratings yet

- DetronicDocument217 pagesDetronicsitaNo ratings yet

- Penta (OleDocument4 pagesPenta (OlesitaNo ratings yet

- Flexteral HoseDocument56 pagesFlexteral HosesitaNo ratings yet

- BOR 165 (3500 A 82) Cable ProtectorDocument1 pageBOR 165 (3500 A 82) Cable ProtectorsitaNo ratings yet

- Red SkinDocument1 pageRed SkinsitaNo ratings yet

- Dodge Quantis Gear Box BrochureDocument12 pagesDodge Quantis Gear Box BrochuresitaNo ratings yet

- Check Valve 13701Document1 pageCheck Valve 13701sitaNo ratings yet

- Star Pump PDFDocument2 pagesStar Pump PDFsitaNo ratings yet

- CAm TECH AgentDocument1 pageCAm TECH AgentsitaNo ratings yet

- 178 SeriesDocument1 page178 SeriessitaNo ratings yet

- Advanced Rock Properties (Core Lab)Document3 pagesAdvanced Rock Properties (Core Lab)sitaNo ratings yet

- Part and Lists Drawing Page 5Document1 pagePart and Lists Drawing Page 5sitaNo ratings yet

- N BridgingDocument1 pageN BridgingsitaNo ratings yet

- Edited CatalogDocument8 pagesEdited CatalogsitaNo ratings yet

- For KevinDocument6 pagesFor KevinsitaNo ratings yet

- Team Oil ToolsDocument54 pagesTeam Oil ToolssitaNo ratings yet

- Spareparts ListDocument5 pagesSpareparts ListsitaNo ratings yet

- Sling ShackelDocument1 pageSling ShackelsitaNo ratings yet

- NC3M 4 1-16 3K X 4 600 Ansi RF 3 Trim Spec Dims 11.31 X 10.75Document1 pageNC3M 4 1-16 3K X 4 600 Ansi RF 3 Trim Spec Dims 11.31 X 10.75sitaNo ratings yet

- ABB AMD Motor BrochureDocument4 pagesABB AMD Motor BrochuresitaNo ratings yet

- Goosneck VentDocument3 pagesGoosneck VentsitaNo ratings yet

- MSDS Lead Acetate TapeDocument9 pagesMSDS Lead Acetate TapesitaNo ratings yet

- Original Messag1Document1 pageOriginal Messag1sitaNo ratings yet

- Westco Thortle Cylinder AssyDocument1 pageWestco Thortle Cylinder AssysitaNo ratings yet

- General Product Catalogue SmallDocument88 pagesGeneral Product Catalogue SmallsitaNo ratings yet

- Vogt BrochureDocument1 pageVogt BrochuresitaNo ratings yet

- Watson PackerDocument2 pagesWatson PackersitaNo ratings yet