Professional Documents

Culture Documents

Torque Table Guidelines For A325 M-8.8 and A490 M - 10.9 by Newton Lab

Uploaded by

Knowledge we shareOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Torque Table Guidelines For A325 M-8.8 and A490 M - 10.9 by Newton Lab

Uploaded by

Knowledge we shareCopyright:

Available Formats

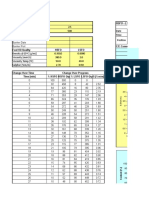

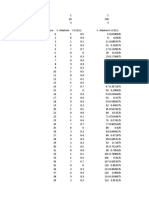

Pre-load and Tightening torques (Metric coarse thread)

Property Class 4.6 4.8 5.6 5.8 6.8 8.8 9.8 10.9 12.9/12.9

Pre-load (MPa) 225 310 280 380 440 d≤16=580 650 830 970

d>16=600

Coefficient of

Size friction

Bolt Torque Specs in Newton Meters (Nm)

0.08 ~ 0.1 2~3 3~4 3 4~5 4~5 6~7 6~10 8~10 9~12

M6x1.0 0.125 3 5 4 6 7 9 10 13 15

0.140 4 5 5 6 7 10 11 14 16

0.08 ~ 0.1 5~7 7~9 7~8 9~11 10~13 14~17 15~19 19~24 23~28

M8x1.25 0.125 8 11 10 14 16 21 24 30 36

0.140 9 13 11 16 18 24 27 34 40

0.08 ~ 0.1 10~13 14~18 13~16 18~22 20~26 27~34 30~38 39~48 45~56

M10x1.5 0.125 16 22 20 28 32 42 47 60 70

0.140 18 25 23 31 36 47 53 67 79

0.08 ~ 0.1 18~23 25~31 23~18 31~38 36~45 47~59 53~66 67~84 79~98

M12x1.75 0.125 28 39 35 48 56 73 82 105 123

0.140 32 44 40 54 62 82 92 118 137

0.08 ~ 0.1 29~36 40~50 36~45 49~61 57~71 75~93 84~105 107~134 125~156

M14x2.0 0.125 45 62 56 76 89 117 131 167 195

0.140 51 70 63 86 99 131 147 187 219

0.08 ~ 0.1 45~57 62~78 56~70 76~95 88~111 117~146 131~163 167~208 195~244

M16x2.0 0.125 71 97 88 119 138 182 204 261 305

0.140 79 109 98 134 155 204 229 292 341

0.08 ~ 0.1 62~78 86~107 77~97 105~131 122~152 166~207 180~225 229~287 268~335

M18x2.5 0.125 97 134 121 164 190 259 281 359 419

0.140 109 150 135 184 213 290 314 402 469

0.08 ~ 0.1 88~110 122~152 110~137 149~186 172~216 235~294 255~319 325~407 380~475

M20x2.5 0.125 138 190 172 233 270 368 398 508 594

0.140 154 213 192 261 302 412 446 569 665

0.08 ~ 0.1 120~150 165~207 149~187 203~253 235~293 320~400 347~433 443~553 517~647

M22x2.5 0.125 187 258 233 317 367 500 542 692 808

0.140 210 289 261 355 411 560 607 775 905

0.08 ~ 0.1 152~191 210~263 190~237 258~322 298~373 407~508 441~551 563~703 657~822

M24x3.0 0.125 238 328 297 402 466 635 688 879 1027

0.140 267 368 332 451 522 712 771 984 1150

0.08 ~ 0.1 223~279 307~384 278~347 377~471 436~545 595~744 644~806 823~1029 962~1202

M27x3.0 0.125 349 480 434 589 682 929 1007 1286 1503

0.140 390 538 486 659 763 1041 1128 1440 1683

0.08 ~ 0.1 303~379 417~522 377~471 512~640 592~741 808~1010 875~1094 1118~1397 1306~1633

M30x3.5 0.125 473 652 589 799 926 1262 1367 1746 2041

0.140 530 730 660 895 1037 1414 1532 1956 2286

0.08 ~ 0.1 412~515 568~710 513~641 696~870 806~1008 1099~1374 1191~1489 1521~1901 1777~2221

M33x3.5 0.125 644 887 802 1088 1260 1718 1861 2376 2777

0.140 721 994 898 1218 1411 1924 2084 2661 3110

0.08 ~ 0.1 529~662 729~912 659~824 894~1118 1035~1294 1412~1765 1529~1912 1953~2441 2282~2853

M36x4.0 0.125 827 1140 1029 1397 1618 2206 2390 3051 3566

0.140 926 1276 1153 1565 1812 2471 2676 3418 3994

Remark: The preloads stated in the table result in 90% utilization of the yield Rei (ISO 898-1).

The tightening torques are calculated from formula T = k x F x d.

Assumes coefficient of friction to be 0.14 for dry, 0.125 for plain and 0.08 ~ 0.1 for lubricated nut and bolt.

The above information is for guidance only and is correct to the best of our knowledge. 1 Nm = 0.737562 lb-ft.

The customer must satisfy themselves with the performance of the fastener and validity of the data.

The manufacturer will not be held responsible for any failure that may occur from the use of this information.

863/4 ถ.ประช ร ร .10510, 863/4 Pracharuamchai Road, Sai Kong Din Tai, Khlong Sam Wa, Bangkok 10510 Tel: +66-2-049-1400, +66-2-049-1401 Mobile: +66-8-6325-1530

www.newtonlab.co.th

You might also like

- Government Publications: Key PapersFrom EverandGovernment Publications: Key PapersBernard M. FryNo ratings yet

- Bolt Torque Table Guidelines by Newton LabDocument1 pageBolt Torque Table Guidelines by Newton LabKnowledge we shareNo ratings yet

- Torque Table Guidelines by Newton LabDocument1 pageTorque Table Guidelines by Newton LabKnowledge we shareNo ratings yet

- Collared Eye BoltsDocument1 pageCollared Eye BoltsKevin MorrisNo ratings yet

- Jl. Pendidikan, 27 Malaingkedi, Kota Sorong, Telp (0951) 328775 Faks (0951) 326162Document13 pagesJl. Pendidikan, 27 Malaingkedi, Kota Sorong, Telp (0951) 328775 Faks (0951) 326162era watiNo ratings yet

- Pseudo First Order KinetikDocument5 pagesPseudo First Order Kinetikmaulida rahmiNo ratings yet

- Alloy Shackles: (Meets The Performance Requirements of RR-C-271 & EN13889)Document1 pageAlloy Shackles: (Meets The Performance Requirements of RR-C-271 & EN13889)iyan supriadiNo ratings yet

- Perhitungan BasoooDocument6 pagesPerhitungan Basoooteguh aditya NNo ratings yet

- Yc/s Yp/s Ysp/s Ym/s Yc/s (Prom)Document16 pagesYc/s Yp/s Ysp/s Ym/s Yc/s (Prom)S G.No ratings yet

- Lampiran CDocument40 pagesLampiran CShinta Arvinda P. WulandariNo ratings yet

- SCZ/SKZ Cold Formed Steel Sheet PileDocument2 pagesSCZ/SKZ Cold Formed Steel Sheet PileLuis Valdivieso VidalNo ratings yet

- Elapsed Time (T) Observati On Number Hydrometer READING (Upper Meniscus) Rh-1000Document12 pagesElapsed Time (T) Observati On Number Hydrometer READING (Upper Meniscus) Rh-1000SamwailNo ratings yet

- T AttenuatorDocument2 pagesT Attenuatoribrahim aNo ratings yet

- Topo GeneralDocument1 pageTopo GeneralcarlosNo ratings yet

- Praktikum Tanah Alfa 1Document42 pagesPraktikum Tanah Alfa 1calon youtubersNo ratings yet

- PartyyyyDocument6 pagesPartyyyyMOH KHASAN AL FARUQ FARUQNo ratings yet

- Session 9Document9 pagesSession 9KhushbooNo ratings yet

- S1 TK Ui: 100 UI Wulan 2 SM (MN, 2x3) 1: Tof Ms Es+ BPI 1.28e7 AreaDocument1 pageS1 TK Ui: 100 UI Wulan 2 SM (MN, 2x3) 1: Tof Ms Es+ BPI 1.28e7 AreaWulanNo ratings yet

- MaDocument5 pagesMaLino HuaracalloNo ratings yet

- Universidad Nacional de Cajamarca "Facultad de Ingenieria" E.A.P "Ingenieria de Minas"Document1 pageUniversidad Nacional de Cajamarca "Facultad de Ingenieria" E.A.P "Ingenieria de Minas"carlosNo ratings yet

- UntitledDocument5 pagesUntitledAhmad FadillahNo ratings yet

- Lab4 Report: Knife Edge Follower and Cam (Base Radius RB 11.33)Document6 pagesLab4 Report: Knife Edge Follower and Cam (Base Radius RB 11.33)Mayuri GedamNo ratings yet

- LSFO Calculator: 2.5 FO System Capacity (Liters) 500 Date Time Position FO Consumption (M /HR)Document8 pagesLSFO Calculator: 2.5 FO System Capacity (Liters) 500 Date Time Position FO Consumption (M /HR)dharmawanNo ratings yet

- Graph of X Vs X 2Document4 pagesGraph of X Vs X 2Akash SonawaneNo ratings yet

- LC-02 RebarDocument1 pageLC-02 RebarRafikNo ratings yet

- Cable Sizing & Voltage Drop Calc Rev 1Document58 pagesCable Sizing & Voltage Drop Calc Rev 1MohamedNo ratings yet

- Tablas CachetonasDocument5 pagesTablas Cachetonasvnc5t5djq5No ratings yet

- Tabel Pengamatan Eksperimen Interferometer Fabry-PerotDocument3 pagesTabel Pengamatan Eksperimen Interferometer Fabry-Perotmaul ataNo ratings yet

- Distancia (x) θDocument2 pagesDistancia (x) θLIZBETH VELAZQUEZ GONZALEZNo ratings yet

- Upper Atbara Dam Grain Size Distribution Curve T.P # 2: Clay Sand Gravel SiltDocument14 pagesUpper Atbara Dam Grain Size Distribution Curve T.P # 2: Clay Sand Gravel Siltabdallah abdurhman aliNo ratings yet

- Optical Splitter RatioDocument11 pagesOptical Splitter RatioAlbert AloepchaNo ratings yet

- Tugas Terstruktur Farmakokinetik Klinik - 1Document3 pagesTugas Terstruktur Farmakokinetik Klinik - 1Fazar Malik novendra putraNo ratings yet

- Assessment 6-Stat20023Document2 pagesAssessment 6-Stat20023Mhervin BisisNo ratings yet

- Regression ResubmitDocument7 pagesRegression Resubmitapi-3729749No ratings yet

- Pardon Supervision 2017Document1 pagePardon Supervision 2017Kakal D'GreatNo ratings yet

- Fenomenos LabDocument8 pagesFenomenos LabJoelAnguianoNo ratings yet

- Conductores de Cobre para Bobinados de Trafos Y Motores de InduccionDocument2 pagesConductores de Cobre para Bobinados de Trafos Y Motores de InduccionNelson Lopez CuestasNo ratings yet

- Dimension Report of Back Frame and Front ChannelDocument1 pageDimension Report of Back Frame and Front ChannelIntern1 SpectomsNo ratings yet

- BS2871 Table yDocument5 pagesBS2871 Table yNILESH SHAHNo ratings yet

- Jarak (KM) Top (KM) Bottom (KM) Selisih Kontras Densitas (g/cm3)Document13 pagesJarak (KM) Top (KM) Bottom (KM) Selisih Kontras Densitas (g/cm3)sigit edhiNo ratings yet

- Jarak (KM) Top (KM) Bottom (KM) Selisih Kontras Densitas (g/cm3)Document13 pagesJarak (KM) Top (KM) Bottom (KM) Selisih Kontras Densitas (g/cm3)sigit edhiNo ratings yet

- Indicator Marking Details For 2''Document3 pagesIndicator Marking Details For 2''Gaurang PandyaNo ratings yet

- Vdo SensorsDocument5 pagesVdo SensorsAbdul KhaliqNo ratings yet

- Products: Blue Strand Class 6x36 Steel CoreDocument1 pageProducts: Blue Strand Class 6x36 Steel Coreindra smiNo ratings yet

- 1 Examen ParcialDocument4 pages1 Examen ParcialDarwin Aima CruzNo ratings yet

- Dasar Karakteristik MaterialDocument13 pagesDasar Karakteristik Materialkhusnul nurhidayatiNo ratings yet

- Pounds To Kilograms Conversion ChartDocument1 pagePounds To Kilograms Conversion ChartNick MomrikNo ratings yet

- No N/10s N/10s Frekuensi (N/10 S) (F) Pobs P (M) : Grafik Watak Statistik Radiasi NuklirDocument5 pagesNo N/10s N/10s Frekuensi (N/10 S) (F) Pobs P (M) : Grafik Watak Statistik Radiasi NuklirMaria DANo ratings yet

- Aine 2Document4 pagesAine 2IrahNo ratings yet

- Service DataDocument12 pagesService DataGianni DaBolognaNo ratings yet

- Hubungan Antara Massa Beban Dan Perpanjangan PegasDocument6 pagesHubungan Antara Massa Beban Dan Perpanjangan PegasPramita Rimba CahyaniNo ratings yet

- Hubungan Antara Massa Beban Dan Perpanjangan PegasDocument6 pagesHubungan Antara Massa Beban Dan Perpanjangan PegasPramita Rimba CahyaniNo ratings yet

- Catalogo MaflexmetDocument10 pagesCatalogo MaflexmetRodrigo RamirezNo ratings yet

- Nº de Orden Numero de Puñados Cantidad Que Se Extrejo Distribucion NormalDocument8 pagesNº de Orden Numero de Puñados Cantidad Que Se Extrejo Distribucion NormalFabrizio Buscando QuennNo ratings yet

- Torque Values For EPDM-GasketsDocument1 pageTorque Values For EPDM-GasketsfaizanAkhtarNo ratings yet

- Rated Motor Currents: Rated Currents of Three-Phase Motors (Approximate Figures For Squirrel-Cage Motors)Document1 pageRated Motor Currents: Rated Currents of Three-Phase Motors (Approximate Figures For Squirrel-Cage Motors)Csaba VargaNo ratings yet

- Datos Variables AleatoriasDocument322 pagesDatos Variables AleatoriasCristian HernandezNo ratings yet

- Sample Size Required Per Group When Using The T Test To Compare Means of Continuous VariablesDocument11 pagesSample Size Required Per Group When Using The T Test To Compare Means of Continuous VariablesOneng IfayaniNo ratings yet

- Undersize & Oversize Cumulative Analysis: Particle SizeDocument2 pagesUndersize & Oversize Cumulative Analysis: Particle SizeJohn NathanNo ratings yet

- FisdasDocument6 pagesFisdasVivin Revina MelianaNo ratings yet