Professional Documents

Culture Documents

A3 Report Muhammad Raditya Wicaksana

Uploaded by

Raditya Wicak0 ratings0% found this document useful (0 votes)

32 views1 page1. The document discusses reducing breakdowns of graphir crankshaft sizes in engine production at Toyota Motor Manufacturing Indonesia.

2. It found that head grafir has the most problematic parts, accounting for 39% of breakdowns.

3. The root causes of issues were analyzed to be related to factors like employees, materials, machines, methods, and the environment. Countermeasures will be developed and evaluated to address the problems.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1. The document discusses reducing breakdowns of graphir crankshaft sizes in engine production at Toyota Motor Manufacturing Indonesia.

2. It found that head grafir has the most problematic parts, accounting for 39% of breakdowns.

3. The root causes of issues were analyzed to be related to factors like employees, materials, machines, methods, and the environment. Countermeasures will be developed and evaluated to address the problems.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

32 views1 pageA3 Report Muhammad Raditya Wicaksana

Uploaded by

Raditya Wicak1. The document discusses reducing breakdowns of graphir crankshaft sizes in engine production at Toyota Motor Manufacturing Indonesia.

2. It found that head grafir has the most problematic parts, accounting for 39% of breakdowns.

3. The root causes of issues were analyzed to be related to factors like employees, materials, machines, methods, and the environment. Countermeasures will be developed and evaluated to address the problems.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 1

Acknowledge Approved Checked Prepared

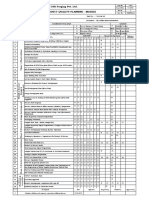

PT Toyota Motor Manufacturing Indonesia A3 Report

Engine Production Division

Maintenance Department Reduce Cokotai in Graphir Cr. Size Engine

Tagor J. D. A. Kohar D. Indra P. M. Raditya W.

VI. Schedule Activity

I. Introduction May June July

Personal Data No. Item Activity

1. Name : Muhammad Raditya Wicaksana W2 W3 W4 W1 W2 W3 W4 W1 W2 W3 W4

2. NIM : 2440086193 1 Collecting Data

3. Division : Engine Production Sunter 2 Genba

4. Department : Maintenance 3 Define Problem

5. Status : Internship

4 Analyze root cause

5 Design Solution

II. Background 6

7

8

*Graphic 1 Average All Line April 2022 *Graphic 2 . Cyl. Block Engine Breakdown *Pie Chart Graphir Cr.Size

- March 2023 Part Breakdown

60

1200

50 HEAD V. Develop Countermeasure

1000 40 15% GRAFIR

800 30

39% JIG Problem Countermeasure Safety Quality Productivity Cost Environment Priority

20 15%

600 10

400 0 CONTROL

GRAFIR ISPS IWB IMI IBR ISPS ITS ISP ISP ISPS PANEL

200 CR.SIZE 031 026 045 024 032 015 095 088 029

0 DETECTOR

Cyl. Crank Cyl. Cam Assy Case Duration 30%

Block Shaft Head Shaft

Head Grafir has the most problem part that need to investigate

Case Duration

III. Clarify and Breakdown Problem

By where By what

Ideal State: Head Grafir

Head Graphir Vibration

Smooth Production 13 Case

Gap: Jig Clamp Belt

10 Case Lepas Pneumatic

Vibration System

Control Panel Baut Graphir VII. See Countermeasure Through

5 Case Patah

Current Situation

…. Out of … breakdown by Detector Connector I/O

graphir 5 Case kendor

IV. Analyze the Root Cause

Target Setting VIII. Evaluation

Man Material Machine Method Environment

*check tanoko,

employee has

enough skill

You might also like

- Master - KaizenDocument15 pagesMaster - KaizenNagarajan100% (1)

- Gm-Afr-hseq-201 Guide To Cleaning and Degassing Underground Tanks For Ne...Document26 pagesGm-Afr-hseq-201 Guide To Cleaning and Degassing Underground Tanks For Ne...Ahmed FodaNo ratings yet

- Por, Et and DTR New DryDocument33 pagesPor, Et and DTR New DrymscontrowareNo ratings yet

- B - 22 - 2011-En (Size 3 and 5 and 7)Document11 pagesB - 22 - 2011-En (Size 3 and 5 and 7)Asa ReidNo ratings yet

- Intership Reports Azgard Nine Limited Muzaffar GardDocument44 pagesIntership Reports Azgard Nine Limited Muzaffar GardAsad AliNo ratings yet

- A3 CompleteDocument2 pagesA3 Complete2k18.russia.world.cupNo ratings yet

- Fmea Synthesis: Name FunctionDocument11 pagesFmea Synthesis: Name FunctionFida GhanmiNo ratings yet

- ExP Class NotesDocument38 pagesExP Class NotesEltonNo ratings yet

- 2021 Salaries and Benefits Survey Report - Final ReportDocument178 pages2021 Salaries and Benefits Survey Report - Final ReportRoderick GanzonNo ratings yet

- FRVT 1N Report 2022 12 18Document239 pagesFRVT 1N Report 2022 12 18Haroldo MedeirosNo ratings yet

- Yashpatil Industrial ReportDocument20 pagesYashpatil Industrial ReportS K.No ratings yet

- Table of Content: Structural Calculation Skid Frame Filter 1 of 12Document12 pagesTable of Content: Structural Calculation Skid Frame Filter 1 of 12Ridho ZiskaNo ratings yet

- Hexagon Socket Head Screw M8X43mmDocument1 pageHexagon Socket Head Screw M8X43mmCbh FastenersNo ratings yet

- ID Task Mode Printing DN Task Name DurationDocument2 pagesID Task Mode Printing DN Task Name DurationmatejNo ratings yet

- Hang FireDocument95 pagesHang FireCarlos Andrey Henao RincónNo ratings yet

- APQP Timing Plan SampleDocument3 pagesAPQP Timing Plan SampleDhananjay Patil75% (4)

- Painting ProcedureDocument62 pagesPainting Proceduretuan mai vanNo ratings yet

- Mal MSHE C194 Side Discoloration IR 2019.03.28 Rev.01Document11 pagesMal MSHE C194 Side Discoloration IR 2019.03.28 Rev.01mohd irshahrezal muhamad rasidiNo ratings yet

- Jungleworks ProposalDocument29 pagesJungleworks ProposalTushar GuptaNo ratings yet

- B 09 2006 04 Eng 20.04.2016Document10 pagesB 09 2006 04 Eng 20.04.2016yumalinNo ratings yet

- Wedding Planner SystemDocument1 pageWedding Planner Systemriyaa.jha29No ratings yet

- Problem Identification and Corective ActionDocument3 pagesProblem Identification and Corective ActionAnne CiamiezNo ratings yet

- ICAP Practice KIt Business Management & Startegy PDFDocument199 pagesICAP Practice KIt Business Management & Startegy PDFSajid Saeed Azfar0% (1)

- Proposal For Facade Repair Work, Mill Building Phase.1Document1 pageProposal For Facade Repair Work, Mill Building Phase.1fernando gultomNo ratings yet

- Improvement Projects Identification: YearDocument3 pagesImprovement Projects Identification: Yearbetapark solutionNo ratings yet

- Apqp Matrix UpdatedDocument2 pagesApqp Matrix Updatedabhishek100% (1)

- SM-R350 Esquematico Completo Anibal Garcia IrepairDocument7 pagesSM-R350 Esquematico Completo Anibal Garcia IrepairCris CellNo ratings yet

- Bhubaneswar: Brand Image of Yamaha & Its CompetitorsDocument90 pagesBhubaneswar: Brand Image of Yamaha & Its CompetitorsDurga RathNo ratings yet

- 8D - One Page 8-D Report Rev 007 Duplicate PKG ID-UNITDocument7 pages8D - One Page 8-D Report Rev 007 Duplicate PKG ID-UNITEdgar LopezNo ratings yet

- Aashto Codes2Document109 pagesAashto Codes2CE22D505 Neetu G KumarNo ratings yet

- Abra CottonDocument28 pagesAbra CottondhruvrealtyNo ratings yet

- Spring Lock Washer B8 - IS 3063 Phosphate Coated ...Document1 pageSpring Lock Washer B8 - IS 3063 Phosphate Coated ...Cbh FastenersNo ratings yet

- Fa2402 003 02Document1 pageFa2402 003 02hoangluyen1201No ratings yet

- Placements 2017 18Document7 pagesPlacements 2017 18Shreyash TaoriNo ratings yet

- Bluebird Digital Marketing StrategyDocument24 pagesBluebird Digital Marketing StrategyDesiree StiernstamNo ratings yet

- HangfireDocument112 pagesHangfirekhol nayokNo ratings yet

- Glazline Project - Schematic - 16-07-2022Document38 pagesGlazline Project - Schematic - 16-07-2022Ajit Pratap SinghNo ratings yet

- Kaizen Sheet: Kaizen Theme: Kaizen IdeaDocument1 pageKaizen Sheet: Kaizen Theme: Kaizen IdeaAnkurNo ratings yet

- PL HU Bicaj KM OraDocument2 pagesPL HU Bicaj KM OraZsolt VNo ratings yet

- FMT - Qa.014 Capa FormatDocument2 pagesFMT - Qa.014 Capa Formatnishantpriya1104No ratings yet

- Amanueal Jib Crane (Keg Palletizer)Document67 pagesAmanueal Jib Crane (Keg Palletizer)mengstuhagos1223No ratings yet

- FS Mina JustaDocument247 pagesFS Mina JustaLeo PalNo ratings yet

- 21-01-19 JSS PROGRESS WA500-3 PT. Adimitra Baratama NusantaraDocument25 pages21-01-19 JSS PROGRESS WA500-3 PT. Adimitra Baratama Nusantarabigar bernadhusNo ratings yet

- Progress Skid EnclosureDocument2 pagesProgress Skid EnclosureFirzaNo ratings yet

- 409686-02-V6-D ESIA For NMIA Volume VI - Revised Draft - 20211130Document61 pages409686-02-V6-D ESIA For NMIA Volume VI - Revised Draft - 20211130Ramon Jose Arandia SarmientoNo ratings yet

- SPARKDocument49 pagesSPARKBibhudutta MishraNo ratings yet

- State of The Agri-Fishery Credit in The PhilippinesDocument24 pagesState of The Agri-Fishery Credit in The PhilippinesRonel Dimaya CañaNo ratings yet

- MC Soldering PressDocument10 pagesMC Soldering PressPT Sumber Insan Nawasena IndonesiaNo ratings yet

- Probe42.in: Ms Biotech Private LimitedDocument33 pagesProbe42.in: Ms Biotech Private LimitedSriram ReddyNo ratings yet

- 2W PPFR Export Tracking Sheet 2018-2019Document5 pages2W PPFR Export Tracking Sheet 2018-2019MaelEdwardAritonangNo ratings yet

- IQWQ-CE1091-VPNDT-00-2564 - A PMI ProcedureDocument5 pagesIQWQ-CE1091-VPNDT-00-2564 - A PMI Procedurejacksonbello34No ratings yet

- A REPORT On Front Page Satnam (3 Files Merged)Document85 pagesA REPORT On Front Page Satnam (3 Files Merged)Damodar SharmaNo ratings yet

- Example Project Three Line PDFDocument6 pagesExample Project Three Line PDFerfan fatahiNo ratings yet

- Sad Pertt ChartDocument1 pageSad Pertt ChartTony TeezyNo ratings yet

- Paint Manufacturing Feasibility StudyDocument45 pagesPaint Manufacturing Feasibility StudyOlufemi Moyegun100% (4)

- MKTG FinalDocument34 pagesMKTG Finalapi-242082997No ratings yet

- Compal Kiue0 La-5191pDocument43 pagesCompal Kiue0 La-5191pحسن علي نوفلNo ratings yet

- New Staff Training Mech. Eng - DanielDocument2 pagesNew Staff Training Mech. Eng - DanielDaniel Garnando KristianNo ratings yet

- Monica Burton - EaterDocument2 pagesMonica Burton - Eaterapi-520025735No ratings yet

- Accounting Theory Construction Dr. Zaroni UMN, Serpong, 5 September 2020Document32 pagesAccounting Theory Construction Dr. Zaroni UMN, Serpong, 5 September 2020Rickie FebriadyNo ratings yet

- Digests PALEDocument11 pagesDigests PALEInter_vivosNo ratings yet

- Communication & Control Software For UTD2000 - 3000 Series Oscilloscopes User Manual V1.0Document28 pagesCommunication & Control Software For UTD2000 - 3000 Series Oscilloscopes User Manual V1.0Damir MiletaNo ratings yet

- Reyes Vs HRET GR 221103Document20 pagesReyes Vs HRET GR 221103Di JoyaNo ratings yet

- SlowPoke ReactorDocument10 pagesSlowPoke Reactorakashdad100% (1)

- NCLT and NclatDocument144 pagesNCLT and NclatPratyush mishraNo ratings yet

- Rovio Manual (For v5.00 Firmware) PDFDocument68 pagesRovio Manual (For v5.00 Firmware) PDFTamyLedesmaRicoNo ratings yet

- DBA Strategy Roadmap (Amazon)Document28 pagesDBA Strategy Roadmap (Amazon)Muhammad Sajid SaeedNo ratings yet

- Create RDP Using Digital OceanDocument3 pagesCreate RDP Using Digital OceanZay Min HtetNo ratings yet

- Advance Transportation Management Technologies (Abridged)Document326 pagesAdvance Transportation Management Technologies (Abridged)Pablo Chan100% (1)

- Knowledge Work & Human CapitalDocument2 pagesKnowledge Work & Human Capitalchandnioptom100% (2)

- 7900 - 9900 Service Manual - Rev.H PDFDocument522 pages7900 - 9900 Service Manual - Rev.H PDFTodd DoyleNo ratings yet

- Management Information Systems, 10/eDocument22 pagesManagement Information Systems, 10/eEko Nur HidayatNo ratings yet

- Skill Developmetn Instituter Project RepotDocument7 pagesSkill Developmetn Instituter Project RepotPriyotosh DasNo ratings yet

- Max17126b PDFDocument34 pagesMax17126b PDFedvanps100% (2)

- Due Date Telephone Number Amount Payable: Summary of Charges Usage History (6 Months)Document5 pagesDue Date Telephone Number Amount Payable: Summary of Charges Usage History (6 Months)GEO MERINNo ratings yet

- B - 01 - TDD-LTE Protocol and InterfaceDocument31 pagesB - 01 - TDD-LTE Protocol and Interfaceaslam_326580186No ratings yet

- Chapter 1Document10 pagesChapter 1dipeshscribdNo ratings yet

- Nota Amalan Iktisas 3 C4382Document34 pagesNota Amalan Iktisas 3 C4382Sharifah NadzehaNo ratings yet

- Applying Organizational Routines in Understanding Organizational ChangeDocument17 pagesApplying Organizational Routines in Understanding Organizational ChangeJack000123No ratings yet

- Undergraduate Curriculum Vitae: PublicationsDocument1 pageUndergraduate Curriculum Vitae: PublicationsMuhammad Zaim EmbongNo ratings yet

- Dr. Ram Manohar Lohiya National Law University, Lucknow 2016-2017Document25 pagesDr. Ram Manohar Lohiya National Law University, Lucknow 2016-2017vaishali kardam100% (1)

- Fabric EJDocument20 pagesFabric EJOctama RizkyNo ratings yet

- Flight International 13 November 2018Document52 pagesFlight International 13 November 2018Adrian BistreanuNo ratings yet

- الحلل السندسية في الأخبار التونسيةDocument381 pagesالحلل السندسية في الأخبار التونسيةchohra khaledNo ratings yet

- CCTV System Installation ChecklistDocument5 pagesCCTV System Installation ChecklistAlvin Badz100% (1)

- BD Ompost and AmaranthasDocument11 pagesBD Ompost and AmaranthasNarasimha MurthyNo ratings yet

- Director Manager Operations Pharmacy in Los Angeles CA Resume Philip HoDocument2 pagesDirector Manager Operations Pharmacy in Los Angeles CA Resume Philip HoPhilipHo2No ratings yet

- LNG SummitDocument19 pagesLNG SummitRoozbeh PNo ratings yet