Professional Documents

Culture Documents

OSHA Const Ind Fact Sheet 3681-1

Uploaded by

fabioOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

OSHA Const Ind Fact Sheet 3681-1

Uploaded by

fabioCopyright:

Available Formats

FactSheet

OSHA’s Crystalline Silica Rule:

Construction

OSHA is issuing two standards to protect workers from exposure to respirable

crystalline silica—one for construction, and the other for general industry and

maritime—in order to allow employers to tailor solutions to the specific conditions

in their workplaces.

Who is affected by the construction The construction standard does not apply where

standard? exposures will remain low under any foreseeable

About two million construction workers are conditions; for example, when only performing

exposed to respirable crystalline silica in over tasks such as mixing mortar; pouring concrete

600,000 workplaces. OSHA estimates that more footers, slab foundation and foundation walls;

than 840,000 of these workers are exposed to and removing concrete formwork.

silica levels that exceed the new permissible

exposure limit (PEL). What does the standard require?

The standard requires employers to limit worker

Exposure to respirable crystalline silica can exposures to respirable crystalline silica and to

cause silicosis, lung cancer, other respiratory take other steps to protect workers.

diseases, and kidney disease. Exposure can occur

during common construction tasks such as using The standard provides flexible alternatives,

masonry saws, grinders, drills, jackhammers especially useful for small employers. Employers

and handheld powered chipping tools; operating can either use a control method laid out in Table 1

vehicle-mounted drilling rigs; milling; operating of the construction standard, or they can measure

crushing machines; and using heavy equipment workers’ exposure to silica and independently

for demolition or certain other tasks. decide which dust controls work best to limit

exposures to the PEL in their workplaces.

Regardless of which exposure control method is

used, all construction employers covered by the

standard are required to:

• Establish and implement a written exposure

control plan that identifies tasks that involve

exposure and methods used to protect workers,

including procedures to restrict access to work

areas where high exposures may occur.

• Designate a competent person to implement

the written exposure control plan.

• Restrict housekeeping practices that expose

workers to silica where feasible alternatives

are available.

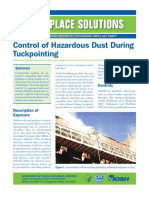

Photo: NIOSH

• Offer medical exams – including chest X-rays

and lung function tests – every three years for

workers who are required by the standard to

Without dust controls, using a handheld power saw to cut concrete

can expose workers to high levels of respirable crystalline silica. wear a respirator for 30 or more days per year.

• Train workers on work operations that result In this example, if a worker uses the saw

in silica exposure and ways to limit exposure. outdoors for four hours or less per day, no

• Keep records of workers’ silica exposure and respirator would be needed. If a worker uses the

medical exams. saw for more than four hours per day or any time

indoors, he or she would need to use a respirator

What is Table 1? with an assigned protection factor (APF) of at

Table 1 matches common construction tasks with least 10. In this case, a NIOSH-certified filtering

dust control methods, so employers know exactly facepiece respirator that covers the nose and

what they need to do to limit worker exposures mouth (sometimes referred to as a dust mask)

to silica. The dust control measures listed in the could be used. If a worker needs to use a

table include methods known to be effective, like respirator on 30 or more days a year, he or she

using water to keep dust from getting into the would need to be offered a medical exam.

air or using ventilation to capture dust. In some

operations, respirators may also be needed. Alternative exposure control methods

Employers who do not use control methods on

Employers who follow Table 1 correctly are not

Table 1 must:

required to measure workers’ exposure to silica

and are not subject to the PEL. • Measure the amount of silica that workers are

exposed to if it may be at or above an action

Table 1 Example: Handheld Power Saws level of 25 μg/m3 (micrograms of silica per

If workers are sawing silica-containing materials, cubic meter of air), averaged over an eight-

they can use a saw with a built-in system that hour day.

applies water to the saw blade. The water limits • Protect workers from respirable crystalline

the amount of respirable crystalline silica that silica exposures above the permissible

gets into the air. exposure limit of 50 μg/m3, averaged over an

eight-hour day.

Table 1: Specified Exposure Control Methods • Use dust controls to protect workers from

When Working with Materials Containing silica exposures above the PEL.

Crystalline Silica • Provide respirators to workers when dust

controls cannot limit exposures to the PEL.

Equipment/ Engineering and Required

Task Work Practice Respiratory When are employers required to comply

Control Methods Protection with the standard?

and Minimum

Assigned Construction employers must comply with all

Protection requirements of the standard by June 23, 2017,

Factor (APF)

except requirements for laboratory evaluation of

exposure samples, which begin on June 23, 2018.

≤ 4 hrs/ > 4 hrs/

shift shift

Additional information

Handheld Use saw equipped Additional information on OSHA’s silica rule can

power saws with integrated be found at www.osha.gov/silica.

(any blade water delivery

diameter) system that OSHA can provide extensive help through a variety

continuously feeds of programs, including technical assistance about

water to the blade.

effective safety and health programs, workplace

Operate and consultations, and training and education.

maintain tool in

accordance with OSHA’s On-site Consultation Program offers free

manufacturer’s

instructions to and confidential occupational safety and health

minimize dust services to small and medium-sized businesses in

emissions. all states and several territories across the country,

• When used with priority given to high-hazard worksites.

outdoors. None APF 10 On-site consultation services are separate from

• When used

indoors or in an enforcement and do not result in penalties or

enclosed area. APF 10 APF 10 citations. Consultants from state agencies or

universities work with employers to identify

workplace hazards, provide advice on compliance For more information on this and other health-

with OSHA standards, and assist in establishing related issues impacting workers, to report an

and improving safety and health management emergency, fatality, inpatient hospitalization, or to

systems. To locate the OSHA On-site Consultation file a confidential complaint, contact your nearest

Program nearest you, call 1-800-321-OSHA (6742) OSHA office, visit www.osha.gov, or call OSHA at

or visit www.osha.gov/dcsp/smallbusiness. 1-800-321-OSHA (6742), TTY 1-877-889-5627.

This is one in a series of informational fact sheets highlighting OSHA programs, policies or

standards. It does not impose any new compliance requirements. For a comprehensive list of

compliance requirements of OSHA standards or regulations, refer to Title 29 of the Code of Federal

Regulations. This information will be made available to sensory-impaired individuals upon request.

The voice phone is (202) 693-1999; teletypewriter (TTY) number: (877) 889-5627.

DSG FS-3681 03/2016

You might also like

- A Guide in Practical Psychrometrics for Students and EngineersFrom EverandA Guide in Practical Psychrometrics for Students and EngineersNo ratings yet

- Rec 2 - HHRA - UPL.A19519.HHRA Situation Report.11 Nov 2021Document54 pagesRec 2 - HHRA - UPL.A19519.HHRA Situation Report.11 Nov 2021Leila DouganNo ratings yet

- Risk Assessment-Maintance of Tanks, VesselsDocument5 pagesRisk Assessment-Maintance of Tanks, VesselsKono Nor AtanNo ratings yet

- Dam Safety Guidelines - December 2018Document209 pagesDam Safety Guidelines - December 2018PRAPATSORN CHOMSREENo ratings yet

- OSHA's Asbestos Standard For The Construction IndustryDocument80 pagesOSHA's Asbestos Standard For The Construction IndustrySuhaib SghaireenNo ratings yet

- CV RkiDocument5 pagesCV Rkidynamic2004No ratings yet

- Isogifran 125-7 M Msds Rev11 enDocument8 pagesIsogifran 125-7 M Msds Rev11 enHéctor FabiánNo ratings yet

- Local Order Regarding The Dubai Municipality Occupational Health CardDocument34 pagesLocal Order Regarding The Dubai Municipality Occupational Health CardAl Nuhasi0% (1)

- IG2 Mohamed HassanienDocument30 pagesIG2 Mohamed HassanienAyman ElHapashy0% (1)

- Information Sheet: Crystalline Silica DustDocument2 pagesInformation Sheet: Crystalline Silica DustIoana UrsanNo ratings yet

- Advanced Water Injection for Low Permeability Reservoirs: Theory and PracticeFrom EverandAdvanced Water Injection for Low Permeability Reservoirs: Theory and PracticeRating: 4 out of 5 stars4/5 (2)

- Occupational Health HazardsDocument9 pagesOccupational Health HazardsAswin Magesh100% (1)

- Basic Account Work Level 2Document61 pagesBasic Account Work Level 2AreguNo ratings yet

- CodeofPractice ControlofDampnessinBuildings Jan2023Document20 pagesCodeofPractice ControlofDampnessinBuildings Jan2023Adam ClutterbuckNo ratings yet

- Crystalline Silica Dust 2Document2 pagesCrystalline Silica Dust 2Serdal SözüneerNo ratings yet

- Pipeline Systems PIP PLSC0011 Trenching and Excavation For PipelinesDocument26 pagesPipeline Systems PIP PLSC0011 Trenching and Excavation For PipelinesAbimelech SalasNo ratings yet

- Intensification of Sorption Processes: Active and Passive MechanismsFrom EverandIntensification of Sorption Processes: Active and Passive MechanismsNo ratings yet

- Lead Compliance PlanDocument12 pagesLead Compliance PlanArsalan Ahmed SheikhNo ratings yet

- Factsheet: Osha'S Respirable Crystalline Silica Standard For ConstructionDocument2 pagesFactsheet: Osha'S Respirable Crystalline Silica Standard For ConstructionNurshahanimNo ratings yet

- B3365 OSHA Silica Sand Rule Compliance Workbook With ChecklistDocument12 pagesB3365 OSHA Silica Sand Rule Compliance Workbook With ChecklistZeckNo ratings yet

- Exposure Control Plan For Chip Hammering and Jackhammering: Protecting Workers When Chipping or Jackhammering ConcreteDocument6 pagesExposure Control Plan For Chip Hammering and Jackhammering: Protecting Workers When Chipping or Jackhammering Concreteritika5656No ratings yet

- Silica Safety Training PresentationDocument36 pagesSilica Safety Training PresentationJonathan FerueloNo ratings yet

- Osha 3902Document101 pagesOsha 3902Derecho Laboral IndividualNo ratings yet

- WSBC Developing A Silica ECPDocument25 pagesWSBC Developing A Silica ECPKarhysNo ratings yet

- Cis36 - SilicaDocument4 pagesCis36 - SilicaIlgar KarimovNo ratings yet

- OSHA3929Document2 pagesOSHA3929Herminio Román MoralesNo ratings yet

- Silica Toolbox Talk: Exposure Control Plan Work PracticesDocument1 pageSilica Toolbox Talk: Exposure Control Plan Work PracticesDivyang TrivediNo ratings yet

- OSHA Exposure To Respirable Crystalline Silica Technical Bulletin 080717Document2 pagesOSHA Exposure To Respirable Crystalline Silica Technical Bulletin 080717Tanmay GorNo ratings yet

- Osha Silica 2018Document79 pagesOsha Silica 2018Maria PinedaNo ratings yet

- Information Sheet: Crystalline Silica DustDocument2 pagesInformation Sheet: Crystalline Silica DustMohamad Hidayat Zainul MasriNo ratings yet

- APB Risk & Safety - COVIDSafe Principles For Businesses - COVIDSafe Plan Requirements 02102020Document4 pagesAPB Risk & Safety - COVIDSafe Principles For Businesses - COVIDSafe Plan Requirements 02102020Adam BarnesNo ratings yet

- NR 18 Controlling Silica Exposure in ConstructionDocument72 pagesNR 18 Controlling Silica Exposure in ConstructionCPSSTNo ratings yet

- OSHA's Asbestos Standard For The Construction IndustryDocument80 pagesOSHA's Asbestos Standard For The Construction Industrykenlavie1No ratings yet

- APB Risk & Safety - COVIDSafe Principles For Businesses - COVIDSafe Plan Requirements 25092020Document4 pagesAPB Risk & Safety - COVIDSafe Principles For Businesses - COVIDSafe Plan Requirements 25092020Adam BarnesNo ratings yet

- Industrial Hygiene 2 PresentationDocument19 pagesIndustrial Hygiene 2 PresentationYashini DussoyeNo ratings yet

- OSHA's Asbestos Standard For The Construction IndustryDocument75 pagesOSHA's Asbestos Standard For The Construction IndustryminingnovaNo ratings yet

- Lead and SilicaDocument11 pagesLead and SilicayawarhassanNo ratings yet

- Control of Hazardous Dust During Tuckpointing: ControlsDocument4 pagesControl of Hazardous Dust During Tuckpointing: ControlsMarkNo ratings yet

- OSHA's Asbestos Standard For The Construction Industry: Institute Safety ManagementDocument80 pagesOSHA's Asbestos Standard For The Construction Industry: Institute Safety Managementmalik jahanNo ratings yet

- Worksafe Bulletin: Carbon Monoxide Exposure During Film ShootsDocument3 pagesWorksafe Bulletin: Carbon Monoxide Exposure During Film ShootsBuddho BuddhaNo ratings yet

- Bricklayer Fact SheetDocument2 pagesBricklayer Fact SheetMarkNo ratings yet

- Estates Development and Projects: Dust PolicyDocument6 pagesEstates Development and Projects: Dust PolicyNay Win MaungNo ratings yet

- Protection of BreathingDocument2 pagesProtection of BreathingMostafaAboElkhirNo ratings yet

- IPA Guidance Chapter9Document36 pagesIPA Guidance Chapter9Rebecca SchroederNo ratings yet

- Ref. Monitoring-Exposure-To-Welding-Fume-V5Document4 pagesRef. Monitoring-Exposure-To-Welding-Fume-V5Sunil SEHSNo ratings yet

- Construction Exhibit Air QualityDocument3 pagesConstruction Exhibit Air QualityMarvin ParaynoNo ratings yet

- Labotary Safety Guidence: 1.1 Elements of The Laboratory StandardDocument21 pagesLabotary Safety Guidence: 1.1 Elements of The Laboratory Standardroyroy0093No ratings yet

- BLTN 03Document5 pagesBLTN 03saji84No ratings yet

- Silica Factsheet - TBADocument2 pagesSilica Factsheet - TBABrett RobertsNo ratings yet

- Safeguard: Dangerous SubstancesDocument2 pagesSafeguard: Dangerous Substancesreza rashadNo ratings yet

- BF CMT Silic ShowDocument15 pagesBF CMT Silic ShowIoana UrsanNo ratings yet

- HSE Information Sheet: Industrial Radiography - Managing Radiation RisksDocument5 pagesHSE Information Sheet: Industrial Radiography - Managing Radiation RiskserskdNo ratings yet

- PS Confined Space 19072023Document3 pagesPS Confined Space 19072023Gustavo DucaNo ratings yet

- IR Ampling Nalysis: Neha Patel Associate Professor Civil Engineering Department B.V.M.Engineering CollegeDocument13 pagesIR Ampling Nalysis: Neha Patel Associate Professor Civil Engineering Department B.V.M.Engineering CollegeNeha PatelNo ratings yet

- Workplace Exposure Standards For Airborne ContaminantsDocument42 pagesWorkplace Exposure Standards For Airborne ContaminantsYunlaNo ratings yet

- Workplace Exposure Standards For Airborne ContaminantsDocument43 pagesWorkplace Exposure Standards For Airborne Contaminantshitman1363No ratings yet

- OSHA's Asbestos Standard For The Construction IndustryDocument80 pagesOSHA's Asbestos Standard For The Construction Industrychan49No ratings yet

- Osha3507 PDFDocument2 pagesOsha3507 PDFSwarg VibhaNo ratings yet

- Fume Controls GuideDocument6 pagesFume Controls Guidereview20No ratings yet

- Module 13 - Introduction To Industrial Hygiene (2 Hours)Document24 pagesModule 13 - Introduction To Industrial Hygiene (2 Hours)memey grepo ramosNo ratings yet

- CN6 Cutting Blocks, Paving and Kerbstones With A Cut-Off SawDocument4 pagesCN6 Cutting Blocks, Paving and Kerbstones With A Cut-Off SawAntónio PereiraNo ratings yet

- Guideline For Prevention of HazeDocument8 pagesGuideline For Prevention of Hazenazrul nazriNo ratings yet

- Section III.2015Document10 pagesSection III.2015Etibar AliyevNo ratings yet

- CN4 Crushing and Screening Demolition MaterialDocument4 pagesCN4 Crushing and Screening Demolition MaterialAntónio PereiraNo ratings yet

- Occupational Hygiene Procedure - Sew19Document19 pagesOccupational Hygiene Procedure - Sew19abdulla kasimNo ratings yet

- ISBN Safe Work Method Statements 2022 03Document8 pagesISBN Safe Work Method Statements 2022 03Tamo Kim ChowNo ratings yet

- BojalejeniraresovuveDocument2 pagesBojalejeniraresovuveShah MuzzamilNo ratings yet

- MODULE COC 1 (ADCEPS) A PDFDocument314 pagesMODULE COC 1 (ADCEPS) A PDFMarlon A. AranasNo ratings yet

- Chap 006Document23 pagesChap 006Larmaine FajardoNo ratings yet

- Hoja de Seguridad - DynoMix WR (Inglés)Document10 pagesHoja de Seguridad - DynoMix WR (Inglés)Pedro Ramos PAchecoNo ratings yet

- Material Safety Data Sheet: 1. Chemical Product / Company InformationDocument5 pagesMaterial Safety Data Sheet: 1. Chemical Product / Company InformationM.FAIZAN ARSHADNo ratings yet

- Ems AuditDocument3 pagesEms AuditVenkata SattiRajuNo ratings yet

- As Tle9 M5Document6 pagesAs Tle9 M5Erl CasiñoNo ratings yet

- Need of Health & Safety in Social WorkplaceDocument20 pagesNeed of Health & Safety in Social WorkplaceOnline Dissertation WritingNo ratings yet

- Take 5 Safety InspectionDocument2 pagesTake 5 Safety Inspectionkmohamedkeita906No ratings yet

- Lightning Powder - Synperonic A9Document3 pagesLightning Powder - Synperonic A9Rahul TadeNo ratings yet

- Alignment Between Lean Principles and Practices and Worker Safety BehaviorDocument10 pagesAlignment Between Lean Principles and Practices and Worker Safety BehaviorPandi AnNo ratings yet

- Research and Comply With Regulatory RequirementsDocument30 pagesResearch and Comply With Regulatory RequirementsPandi WritingsNo ratings yet

- Mill Operators Manual 96-8200 Rev C English May 2015Document420 pagesMill Operators Manual 96-8200 Rev C English May 2015LuisNo ratings yet

- Case Study No 1Document9 pagesCase Study No 1Sparsh ShukalNo ratings yet

- Sample SWMSDocument4 pagesSample SWMSJuma KavesuNo ratings yet

- Sanskrit EssaysDocument4 pagesSanskrit Essaysafibzfwdkaesyf100% (2)

- 01 Nival Tech MEP Consultants Profile Jan 201Document22 pages01 Nival Tech MEP Consultants Profile Jan 201NagiahTNo ratings yet

- Construction Regulations, 2003Document31 pagesConstruction Regulations, 2003Mercedes Cano MeseguerNo ratings yet

- PUASAR031 Undertake An Urban Search and Rescue Category 2 Rescue TechnicianDocument6 pagesPUASAR031 Undertake An Urban Search and Rescue Category 2 Rescue TechnicianbayyrNo ratings yet

- Alphaplus® 1-Butene: Safety Data SheetDocument12 pagesAlphaplus® 1-Butene: Safety Data SheetlyesNo ratings yet

- Historical Background Meaning Definition Nature Objectives Scope Importance Parties To Industrial Relation ApproachesDocument17 pagesHistorical Background Meaning Definition Nature Objectives Scope Importance Parties To Industrial Relation Approachesnivedita patilNo ratings yet

- Lista de Precios Division Medica: Stock Number DescripciónDocument3 pagesLista de Precios Division Medica: Stock Number DescripciónVito TCNo ratings yet

- Checklist ILODocument12 pagesChecklist ILORyan AliNo ratings yet

- Sikadur® 752 Comp. ADocument9 pagesSikadur® 752 Comp. Aashley.susalumNo ratings yet