Professional Documents

Culture Documents

Fassmer Freefall Lifeboats Type GAR (-T) 6.0 - 8.1 CFL (-T) 66 - 83 Manual

Fassmer Freefall Lifeboats Type GAR (-T) 6.0 - 8.1 CFL (-T) 66 - 83 Manual

Uploaded by

kayhan aytugOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fassmer Freefall Lifeboats Type GAR (-T) 6.0 - 8.1 CFL (-T) 66 - 83 Manual

Fassmer Freefall Lifeboats Type GAR (-T) 6.0 - 8.1 CFL (-T) 66 - 83 Manual

Uploaded by

kayhan aytugCopyright:

Available Formats

Operator’s Handbook for Fassmer

Freefall- Lifeboat Type

GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83 GB

20.0000-019.00.00.6

Fr. Fassmer GmbH & Co. KG

Industriestr. 2

D - 27804 Berne / Germany

Phone: +49 (0)4406 942-0 Fax: +49 (0)4406 942-100

Email: info@fassmer.de

Internet: www.fassmer.de

Art. no. 156336

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

Contents Page

1. Introduction .............................................................................................. 4

2. Brief construction description ................................................................... 5

3. Operation of Boat ...................................................................................... 7

3.1 Launching of the lifeboat ...................................................................... 7

3.2 Davit / Crane lowering of lifeboat ........................................................ 17

3.3 Other operating situations .................................................................. 17

3.3.1 Launching from a vessel moving ahead ....................................... 17

3.3.2 Launching into seaway ................................................................. 17

3.3.3 Towing .......................................................................................... 17

3.3.4 Capsizing ...................................................................................... 17

3.3.5 Injured person on stretcher ........................................................... 17

4. Recovery .................................................................................................. 18

5. Operation of Equipment ........................................................................... 21

5.1 Engine plant ........................................................................................ 21

5.1.1 SABB - Engine ............................................................................... 21

5.1.2 BUKH - Engine ............................................................................. 21

5.1.3 Nanni - Engine) ............................................................................. 22

5.1.4 Description of the engine plant ..................................................... 23

5.2 Rudder plant ....................................................................................... 24

5.3 Fuel tank ............................................................................................. 24

5.4 Electric plant ....................................................................................... 25

5.5 Lights .................................................................................................. 25

5.6 Water spray plant ................................................................................ 26

5.7 Self-contained air support system ...................................................... 27

5.8 Bailing ................................................................................................. 29

5.8.1 Manual bilge pump ....................................................................... 29

5.9 Rain water collection ........................................................................... 29

6. Release gear system ................................................................................ 30

Document 20.0000-019.00.00.6 Art. No. 156336 2 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

7. Simulated Launch .................................................................................... 31

7.1 Securing of boat during service or release test

without launching ................................................................................ 31

8. Launching ramp and lashing .................................................................... 32

9. Outfit and loose equipment ...................................................................... 33

10. Periodic servicing and inspection by crew ............................................. 34

10.1 WEEKLY and after every recovery of the boat into the davit ........... 35

10.2 MONTHLY ........................................................................................ 36

10.3 3-MONTHLY ..................................................................................... 37

11. Servicing, inspection, overhaul and testing by Fassmer-certified

service engineer ....................................................................................... 41

11.1 ANNUAL THOROUGH EXAMINATION ........................................... 41

11.2 EVERY 2 YEARS .............................................................................. 45

11.3 EVERY 5 YEARS .............................................................................. 46

11.4 EVERY 10 YEARS ............................................................................ 49

12. Maintenance ........................................................................................... 51

12.1 GRP-maintenance and repair ........................................................... 51

12.2 Engine plant maintenance ................................................................ 54

12.3 Electric plant maintenance ................................................................ 54

12.4 Doors and Hatches maintenance ..................................................... 56

12.5 Water spray plant maintenance ........................................................ 56

12.6 Self-contained air support system maintenance ............................... 57

12.7 Release gear system maintenance .................................................. 27

13. First installation ...................................................................................... 58

Document 20.0000-019.00.00.6 Art. No. 156336 3 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

1. Introduction

A Freefall-Lifeboat is carried for the protection of every person on board. It can,

however, only fulfil its task, if everyone on board is acquainted with the whole

lifeboat, its functions and operation.

Only ongoing practice brings reliability to the lifeboat and prevents handling

errors in a case of danger.

Equally important is the sound technical condition of the boat, which is ob-

tained through regular maintenance.

This instruction manual cannot, of course, be complete, nor can it unequivo-

cally cover all procedures or situations of danger that could arise during the

operation the boats.

Each user of the boat should familiarise himself with the boat before use and

before a situation of danger could arise.

This manual should help you accomplish this.

In the case of further questions, please forward your request to:

Fr. Fassmer GmbH & Co. KG

Industriestr. 2

D - 27804 Berne / Germany

Phone: +49 (0)4406 942-0

Fax: +49 (0)4406 942-100

Email: info@fassmer.de

www.fassmer.de

Quote your order number and build year, stamped on the Fassmer-lifeboat

plate and found behind the steering tower, or shipyard and build year of the

mother ship.

Note:

Additional detail manuals concerning engine, spare part lists,

drawings, certificates etc. can be found in the “Lifeboat Docu-

mentation” delivered with each boat, and found on the mother

ship.

Note:

This manual was established with consideration of:

- SOLAS 74, Chapter III, Edition 2004

- Resolution MSC.152(78)

- IMO MSC CIRC. 1206-MEASURES TO PREVENT ACCI-

DENTS WITH LIFEBOATS-(Consolidated Circ. from 1093

etc)

- MSC1-Circ. 1205-Guideline for Lifeboat System manuals

- GL-“Checklist for maintenance and inspection of safety

equipment” (2005)

- Lloyd’s Register “GUIDANCE NOTES FOR THE PREPERA-

TION OF A LIFEBOAT´S OPERATION INSTRUCTION &

MAINTENANCE MANUALS”

Document 20.0000-019.00.00.6 Art. No. 156336 4 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

2. Brief construction description:

The complete hull and canopy of the boat is produced in hand-Lay-up GRP

using a self-extinguishing laminate.

All scantlings meet the requirements of “Germanischer Lloyd” or respective

certifying authority.

The boat is of round bilge with a transom stern. It has a platform deck aft for

rescues and recovery by helicopter. The raised foredeck clears the sea well

and gives a large reserve buoyancy to the bow.

The boat has a complete inner shell built of glass-fibre reinforced polyester

(GRP) with single seats, floors and engine foundation.The area between inner

and outer shells is filled with foam (CFC-R11 free polyurethane) keeping the

boat buoyant even when damaged. A Locker forward below floor is used as

stowage room for inventory, provisions etc.

The boat is covered with an enclosed canopy, which contains towards the rear

a raised steering stand, closed with front and side windows.

To enter the boat comfortably from the aft deck, a large door is placed at the aft

bulkhead of the superstructure. An additional hatch forward on the superstruc-

ture makes it possible to operate the painter and sea anchor from inside.

All seats are installed with backrests and four-point safety belts.

An approved water-cooled marine diesel engine with indirect keel pipe cooling

is installed. The exhaust pipe is equipped with a silencer and is led outside

through a goose neck.

Only valid for tanker lifeboats:

Each tanker-lifeboat is equipped with a water spray plant which can be set into

operation by opening a sea water valve in the bottom of the boat in front of the

engine.

The sea water is distributed by an engine driven water spray pump through

pipes and hoses to spray nozzles on the outside surface of the lifeboat cover-

ing it completely with water.

This water shelter curtain around the boat enables it to drive through a fire on

the water surface without major damages to the boat. In addition the water

gives a cooling effect to the interior so that the inside temperature will not rise

significantly during a 10 minute period.

To be safe against fumes and toxious gazes created by the fire all air inlets

must be closed. Air supply for 10 minutes for crew and running engine is pro-

vided by an independent air supply system in the boat.

By opening air bottle and air plant valves compressed breathing air streams

into the boat creating a small overpressure inside to prevent entering of toxious

gazes.

For overall drawings refer to next page

Document 20.0000-019.00.00.6 Art. No. 156336 5 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

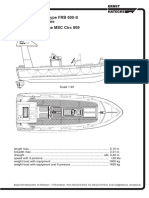

Overall drawing: (GAR 6.7 - 8.1 / CFL 66 - 83 boats)

Fig. 1

Document 20.0000-019.00.00.6 Art. No. 156336 6 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

3. Operation of Boat

Caution:

For drills follow the recommendations of IMO-MSC1.Circ 1206-

MEASURES TO PREVENT ACCIDENTS WITH LIFEBOATS, for

example:

Elements of the drill that may involve unnecessary risks need

special attention or may be excluded from the drill.

The launching of a boat with its full complement of persons is

an example of an element of a drill that may, depending on

the circumstances, involve an unnecessary risk. Such drills

should only be carried out if special precautions are ob-

served.

Before placing persons onboard a lifeboat, it is recom-

mended that the boat first be lowered and recovered without

persons onboard to ascertain that the arrangement functions

correctly. The boat should then be lowered into the water

with only the number of persons onboard necessary to oper-

ate the boat.

To prevent heaving wires or gripes from getting entangled,

proper release should be checked before launching the boat.

3.1 Launching of the lifeboat

The following description contains the general procedure for abandoning ship.

Circumstances may be unique onboard different vessels or the concerning

situation may require different action. The description is formed as a checklist,

which shall be used when required. (Items marked *S should be simulated

when carrying out drills)

1. When the abandon ship signal is given all those aboard, clothed head

to toe, with solid shoes, and carrying lifejackets must proceed to the mus-

ter station. The designated persons should bring a SART (Search and

Rescue Radar Transponder, *S), portable VHF radio (having verified its

operation) and additional fuel, water, clothing, blankets plus any other ad-

ditional equipment (*S) to the muster area. The assigned crew members

will then prepare the boat for launching:

2. Open side lashing plates by pulling rope on platform deck.

3. Disconnect the charging cable, if fitted.

(see overall drawing Fig. 1)

Charging plug

Document 20.0000-019.00.00.6 Art. No. 156336 7 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

4. Check if heaving wire long link(s) are disconnected from davit, resting in

the support, secured with belt (1).

5. Check if lifelines (1) are secured to canpoy

Fig. 2

6. Check if boat and launching ramp (Fig.3) are free of obstructions and

lashings.

Fig. 3

7. Ensuring release hook closure

Check that release hook rests at least 15mm onto stop pawl (1)

Document 20.0000-019.00.00.6 Art. No. 156336 8 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

8. Before opening the door

Remove release hook safety pin (1) from the release gear (1)

Put it into support at door and secure it (2)

1 2

SECURING FOR Open the door and secure it by placing the lower door handle

DOOR in its retainer.

TURN LOWER HANDLE

BEHIND DOOR STOPPER

9. Ensuring release handle closure

Check release handle (1) is secured with release handle safety pin (2)

1 2

10. Switch the battery change-over switch (1) to battery 1 or 2.

1

1+2

2

(see chapter 2, overall drawing Fig.1 or Fig.2)

OFF

Battery Battery

1 2

Battery change-over switch

WARNING: Use only Battery 1 or 2. Both together only in

emergency. Don´t switch off when engine is running.

Danger of generator damage!

Document 20.0000-019.00.00.6 Art. No. 156336 9 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

11. The engine should be regularly maintained and ready for starting, i.e.:

Fuel tank filled and uncontaminated

Fuel valve open

Diesel

Drive shaft greased

Batteries fully charged

Fuel valve If possible, examine before launching!

Only valid for tanker lifeboats:

Check additionally to above mentioned items:

Check sea water valve (1) in front of engine and spray pump

at the bottom is open, shown is the closed position

In USCG boats, a remote lever (2) to operate the sea water valve is

installed at the helmsman position

1 2

Open valves at all air bottles (1). USCG boats are equipped with two

air bottles and all other boats are equipped with three air bottles.

Check that the outlet valve (2) at the air supply control is closed

Check that the re-filling connection cap (3) is in place

and screwed down

Start air supply:

open valve

3 2

1

Document 20.0000-019.00.00.6 Art. No. 156336 10 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

12. The following actions are carried out by the crew on ship’s deck:

Ensure all additional equipment is given to the crewmen in the boat

Prepare the launching ramp, lashings etc. for launching according to

Launching instructions

When clear, contact the bridge and report “ready for boarding”.

The bridge will give the order to board and launch the boat.

Only valid for tanker lifeboats:

If there is a fire, smoke, or fumes to ensure constant water flow on the

whole surface, check additionally to the above mentioned items:

All parts outside the boat (ropes, fenders, dirt, etc)

have to be removed

Flushing connection for water spray plant have to be closed

13. Board lifeboat and take a seat filling farthest from the door first to ensure

all seats are used. Place arms under the shoulder straps and secure the

safety belt by connecting the square ring to the pelican hook. Close the

pelican hook and pull at the loose end of safety belt to tighten it. Always

use the same seat and adjust the belt for your body size:

Warning:

Danger of Injury:

Don’t wear rigid lifejackets during launching.

Put lifejacket on the knees during launching:

Use handgrips in front of your seat.

ES S ES S

PR PR

Press yourself into the seat by means of safety belt.

Press head tight against the head cushion during launching.

Close the aft door and hatches, if fitted

Only valid for tanker lifeboats:

If there is a fire, smoke, or fumes after boarding when doors and hatches

are closed, close additionally to the above mentioned item:

Close air flap in door

Close other openings and ventilations (if fitted)

Never:

Never close air flap without running air plant to avoid danger of

suffocations

Lack of fresh air will increase CO2-content inside the lifeboat.

This can result in uncontrolled sleeping followed by DEATH

Document 20.0000-019.00.00.6 Art. No. 156336 11 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

14. Control by helmsman before launching:

safety belts of all persons

closing of all hatches, door and openings

All loose items secured

water entry area free of obstructions.

Rudder on “straight-ahead”- position

Instruction by helmsman:

„PREPARE FOR LAUNCHING!“

15. Launching the boat (see instruction on next page)

Note:

Boat is designed to launch at max. +/- 10° trim and 20° list of

ship (30° for special ships). Launches in other conditions are not

covered by approval. Water depth in launching area should be

equal or more than boat’s length.

Document 20.0000-019.00.00.6 Art. No. 156336 12 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

Operation normal freefall release:

Warning:

Operation by Coxswain only

Faulty operation will drop the boat! Operation of release system

should only be carried out by the coxswain. Do not enter, launch

or hoist the boat before the correct positioning of the hook and

release handle are checked.

Note:

Ensure before freefall release

Everybody has taken seat and seat belts are fastened.

Entrance door is closed and water is free of barricades.

Take out release handle safety pin (1)

Close bypass valve (2)

By operating the release handle (3) app. 5 to 10 times the hydraulic

plunger (4) opens the stop pawl (5) until the release hook (6) is open

The boat slides down the launching ramp

3 1 2 4 6 5

Emergency freefall release:

Note:

If the hydraulic system doesn’t work the release system can be

opened manually.

Remove glass (1)

Open bypass valve (2)

Take out handle for emergency release (3) and screw in emergency re-

lease bolt (4) by turning it clockwise app. 20 turns until stop pawl (5) opens

the release hook (6)

The boat slides down the launching ramp

3 2 6 5

4 1

Document 20.0000-019.00.00.6 Art. No. 156336 13 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

Engine Control Lever 16. Starting the engine:

N (Neutral)

The engine will be either started with a turn-button (Fig. 4) or with

a push-button (Fig. 5 and Fig. 6)

F (Forward) R (Reverse)

Turn-button Sabb- engine):

Hold in red button when

Move the engine control lever to the neutral position. (1)

Turn the engine on at the switchboard (turn switch one step to the

setting speed control lever

to disengage propeller

right). (2)

Start the engine: turn switch to right end position and hold until en-

gine runs. (2) (for details refer to engine instructions)

Fig. 4

Push-button Bukh-engine):

Move the engine control lever to the neutral position. (1)

Switch to run position. (2)

Push the start button until engine runs (3)

(for details refer to engine instructions).

1 2

Fig. 5

Document 20.0000-019.00.00.6 Art. No. 156336 14 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

Push button Nanni-Engine:

Move the engine control lever to the neutral position (1)

Push the on/stop button once (a signal is sounding) (2)

Push the Heat/start button to middle position for heating the en-

gine.(3)

After at least 20 sec. push the Heat/Start button fully to start the en-

gine (for details refer to engine instruction (3)

1

3

Fig. 6

Only valid for tanker lifeboats:

If there is a fire, smoke, or fumes after engine starting or at the most

5 min. after closing ventilations:

Open outlet valve (1) at the air supply unit (The air supply in the air

bottles is good for 10 minutes maximum).

Document 20.0000-019.00.00.6 Art. No. 156336 15 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

Engine Control Lever 17. Sailing:

N (Neutral)

Push the engine control lever to the “Forward” position (F) and travel

away from the ship.

Weather permitting the door/hatch can stay open providing fresh air

F (Forward) R (Reverse)

inside

For further procedures refer to the “Survival Manual” which is stored

Hold in red button when

setting speed control lever

to disengage propeller

in the equipment box.

Stay at a safe distance from the ship and bring out the sea anchor.

Only valid for tanker lifeboats:

Driving through fire:

When boat is waterborne and is free of the ship:

Engage coupling and drive away immediately with full speed. (Only at

full speed full water coverage of surface is provided)

Take shortest way out of fire, i.e. drive against wind direction. If in

doubt use compass.

The air supply is sufficient for max. 10 minutes, i.e. one nat. mile at a

speed of 6 knots

Caution:

During fire do not touch metal fittings or screws which have con-

nections to outside the boat. They might be hot and cause inju-

ries.

When fire is passed or air bottles are empty (high pressure ma-

nometer about 10 bar):

Open air flap in aft door again

Stop water spray plant by closing sea water valve

(bypass valve remains open)

Never:

Never close air flap without running air plant to avoid danger of

suffocations

Lack of fresh air will increase CO2-content inside the lifeboat.

This can result in uncontrolled sleeping followed by DEATH

Document 20.0000-019.00.00.6 Art. No. 156336 16 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

3.2 Davit / Crane lowering of lifeboat (secondary launch)

If launching of the boat not possible (f.e. a person is seriously injured and can

not seated in seat) the lifeboat can be lowered into water by davit / crane.

For lowering of the boat refer to davit / crane instruction.

3.3 Other operating situations:

3.3.1 Launching from a vessel moving ahead:

All Freefall-Lifeboats are designed for launching with the vessel making head-

way of up to 5 knots or under the influence of a corresponding heavy current or

wind. If possible the ship’s propeller should be disengaged to minimise turbu-

lences behind the ship.

3.3.2 Launching into seaway:

It may be necessary to launch into rougher seas where the rise and fall of the

water level will cause severe motions and possibly damage the boat. Once

waterborne the boat will pitch and heave making immediate departure very

important. The following point can help in such a situation:

Choose a moment for launching where the boat enter a relatively even wa-

ter surface and not a breaking wave.

3.3.3 Towing:

Attach towing ropes and dock lines only on the draining hole of the release

hook or on the front hoisting fitting. If the boat itself is being towed, use front

hoisting fitting to attach the towing rope. The maximum towing speed for life

rafts is 3 kts, for the boat max. 5kts.

3.3.4 Capsizing:

Should the boat capsize with all hatches and doors closed it will re-right itself if

all persons have fastened their seat belts. Otherwise, the unbelted persons

have to move to one side of the boat in order to re-right the boat.

3.3.5 Injured person on stretcher:

A stretcher with an injured person can be stowed in forward part of the aisle,

with feet to forward end of boat, after the persons in adjacent seats nearby the

stretcher have taken place.

The Stretcher should be secured with suitable straps or ropes from stretcher to

safety belt fittings of adjacent seats.

Warning:

During freefall launching the injured person should be seated

and secured in a freefall seat. Otherwise there is danger of

life to this person.

If person is so seriously injured that it can not be seated in

freefall seat, davit launch instead of freefall launch is strongly

recommended.

Refer to chapter 3.2 Davit / crane lowering of lifeboat

Document 20.0000-019.00.00.6 Art. No. 156336 17 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

4. Recovery:

Caution:

Retrieval of Freefall-Lifeboats under seaway is extremely difficult.

Therefore, this is only recommended for action in harbours or in

very sheltered waters with the ship making no headway.

Max. 3 Persons are allowed to stay on board during heaving

Drive boat under davit / crane

Hang in lifting eye(s) into crane / davit hook(s) while standing on platform

deck.

Lift boat

Caution:

During heaving crew should be secured in their seats!

Caution:

When lifting the boat control that wires, chains or shackles are

straight and not turned and do not jam at boat parts like forward

hatch f.e.!

Ensure that side-lashing plates of launching ramp are open (hinged down)!

Return boat to launching ramp according to davit/crane instructions

Caution:

Boat to be lowered in such way that launching ramp has full con-

tact with all rollers before retaining chain takes load of the boat.

Lever forces might damage otherwise launching rail in roller

area.

Place retaining chain (1) into open release hook

Close release hook by lifting it and “arrest” the retaining chain

Open bypass valve by a second person

Ensure that the hydraulic plunger returns the stop pawl

to closed position.

Document 20.0000-019.00.00.6 Art. No. 156336 18 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

Mandatory:

Check that stop pawl has completely returned and release hook

lies about 15 mm on stop pawl. (1)

Note:

Insert release handle safety pin into release handle (1)

Bypass valve has to be open (2)

Caution:

The bypass valve of the hydraulic plunger has to be OPEN

CONSTANTLY, otherwise DANGER of unintended launching

Disconnect lifting eye(s) from davit/ crane, hang them into their holder(s)

and secure them with belt.

Close side lashings again by pulling and securing lashing plate wires.

Re- stow all loose equipment

Remove all parts, which do not belong to the boat equipment (portable

VHF, SART etc.)

Reconnect charging cable if any

Open drain plug drain bilge if necessary

Refill fuel and other consumed items

Rudder on “straight-ahead”- position

Every problem or damage experienced during the test should

Charging plug be settled immediately

Switch off battery switch when leaving the boat

Document 20.0000-019.00.00.6 Art. No. 156336 19 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

Close Door and insert release handle safety pin into release hook and se-

cure it (1).

Warning:

Always ensure that:

Release hook is closed correctly

Release hook safety pin is inserted to hook and secured

Only valid for tanker lifeboats:

If boat is in stowed position:

Flush water spray plant with fresh water and drain it

Open sea water valve to be prepared for next launch

Check if bypass valve of water spray plant is open

Refill air plant if necessary

Close valves on all air bottles

Caution:

At recovery take special care that spray nozzles are not dam-

aged by heaving equipment!

Document 20.0000-019.00.00.6 Art. No. 156336 20 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

5. Operation of Equipment:

5.1 Engine plant

5.1.1 SABB-Engine (Fig. 7)

5 7

Engine starting:

Move the engine control lever to the

neutral position. (1)

Turn the engine on at the switchboard

( turn switch one step to the right ) (2)

Start the engine: turn switch to right end position

and hold until engine runs. (2)

(for details refer to engine instructions)

Engine stopping:

Turn off the engine at the switchboard. (2)

1 6 2

Fig. 7

5.1.2 BUKH-Engine (Fig. 8) 5 7 2

Engine starting:

Move the engine control lever to the

neutral position (1).

Switch to run position (2)

Push the start button until engine runs (3)

(for details refer to engine instructions)

Engine stopping:

Push the stop button until the engine stops. (4)

Switch to off position (2)

1 4 3

6

Fig. 8

Document 20.0000-019.00.00.6 Art. No. 156336 21 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

5.1.3 Nanni-Engine (Fig. 9)

2 6 3

Engine starting:

Move the engine control lever to the

neutral position (1)

Push the on/stop button (2) (a signal is sounding

and the heating lamp goes on) (3)

Push the Heat/Start button (4) up to the middle for

heating the engine at least 20 sec. (3)

After at least 20 sec. push the Heat/Start button (4)

to start the engine (for details refer to engine instruc-

tion) (3)

Engine stopping:

Depress the on/stop (2) button until

the engine stops

1 4 5 7

Fig. 9

Note:

During sailing the boat the following alarm lights and sound might

occur, indicating engine problems:

Oil pressure (5)

Cooling water temperature (6)

Alternator (7)

In case of occurrence refer to engine manual

For tests or maintenance the engine can idle for about 5 minutes with the boat

out of the water.

Never:

NEVER turn the main battery switch OFF whilst the engine is

running. This can destroy the alternator.

Document 20.0000-019.00.00.6 Art. No. 156336 22 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

5.1.4 Discription of the engine plant

A water-cooled diesel engine with reverse gear is installed in the Fassmer free-

fall lifeboats. (Fig. 10)

Three different engine makers are in use: BUKH, SABB and Nanni.

Mandatory:

Quick shifting from full ahead to full astern may damage trans-

mission, circuits or engine. To avoid this, let the engine idle for

about 5 seconds before shifting.

All engines are fitted with a single circuit keel-pipe cooling.The cooling pipes

are situated below engine area alongside the keel. This cooling enables all

engines to run out of the water for five minutes (test run).

The cooling system is filled with anti-freeze fluid suitable down to -35°C.

A stainless steel shaft turns in greased bronze bearings, operating a bronce

propeller.

The exhaust system works without water injection.

Warning:

Exhaust temperatures can exceed 500°C. Do not touch any

components of the hot exhaust system.

If the insulation is wet the boat should be moored with open doors and hatches.

Run the engine at full speed with a disengaged propeller for about an hour. Try

to find the cause of the wet insulation and tighten any leakages.

Fig. 10

For maintenance refer to chapter 12.2 Engine plant maintenance

Document 20.0000-019.00.00.6 Art. No. 156336 23 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

5.2 Rudder plant

The rudder system (Fig. 11) consists of a steering device and a nozzle rudder

with shaft. A bowden wire connects them. Should a steering device fail, an

emergency tiller can be attached to the rudder stock. If the bowden wire is

blocked remove the bolt and safety ring.(Detail Z below)

Emergency tiller

disconnect steering for use

rudder stock

rudder stopper

emergency stock

Detail Z

self lubricating

plastic bearing

rudder nozzle

bowden wire

rudder shoe

Fig. 11

Mandatory:

When driving with hard rudder and high rpm forwards or back-

wards a strong force may be required to turn the steering wheel.

For this reason speed must be reduced for manoeuvring, or the

steering system may be damaged.

5.3 Fuel tank

The fuel tank is located aft on centre line. Its capacity is sufficient for 24 hours

engine operation at full speed.

The fuel capacity can be either checked on the tank level gauge at the fuel tank

or steering stand, (if fitted) or by inserting a measuring rod into the tank

(Fig.12).

Fig.12

Document 20.0000-019.00.00.6 Art. No. 156336 24 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

5.4 Electric plant

A 12VDC electrical system is installed.

For the wiring scheme refer to “Lifeboat documentation”.

The system will be activated with the battery switch (1): switch EITHER to

“BATT. 1” OR “BATT. 2” to keep the second battery as spare.

Position “BOTH” switches both batteries together for combined power: use

ONLY if one battery alone is not strong enough to start the engine

For maintenance refer to chapter 12.3. Electric plant maintenance

Never:

NEVER turn the main battery switch OFF whilst the engine is

running. This can destroy the alternator.

5.5 Lights

On the boat are one allround light outside and interior lights. With the electrical

light switches (Fig. 13) on the switchboard the following lights can be switched

on/off.

Switch 1: allround light

Switch 2: interior lights

2

1

Fig. 13

Document 20.0000-019.00.00.6 Art. No. 156336 25 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

5.6 Water spray plant:

Only valid for tanker lifeboats:

The tanker lifeboat is equipped with a water spray plant which can be set into

operation by opening a sea water valve in bottom of the boat in front of the

engine. (Fig. 14)

The sea water is distributed by an engine driven water spray pump through

pipes and hoses to spray nozzles on the outside surface of lifeboat covering it

completely with water. For nozzles arrangement refer to spray plant drawing in

“Lifeboat documentation”

This water shelter curtain around the boat enables it to drive through a fire on

the water surface without major damages to the boat. In addition the water

gives a cooling effect to the interior so that the temperature inside the boat will

not rise significantly during a 10 minute period.

The pump is permanently attached to the engine by a fixed coupling or by

means of vee-belts. It is therefore permanently running.

At the deepest point of the pump a hose is connected to a bypass valve at the

bottom.

Mandatory:

This bypass valve must always be open to prevent overheating

of running spray pump without sea water and to allow complete

self draining of water spray system.

A closed bypass valve can damage the pump or block it in case

of freezing. Close only in case of water entry.

Fig. 14

For maintenance information refer to Chapter 12.5

Document 20.0000-019.00.00.6 Art. No. 156336 26 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

5.7 Self-contained air support system:

Only valid for tanker lifeboats:

The system is to be used in case the boat has to drive through a fire on

the water surface or if toxious gazes are in the atmosphere.

The tanker-lifeboat is equipped with a self contained air support system stored

in 200 bar or in case of USCG boats 300 bar high pressure air bottles in the

bottom of the boat. The air bottles are connected to each other and to the air

distribution plant by high pressure hoses. Each air bottle has a shut off valve

at the bottle´s head.

The air distribution unit is installed within the reach of the helmsman. It consists

of an air pressure reducer, a filling connection with non- return valve and safety

cap to refill the plant, a stop valve, an air outlet with silencer and an high- and

low pressure manometers. Further an air flap and over- and under pressure

valves are installed in the air duct of the aft entrance door.

Operation:

To prepare the air plant for use all air bottle valves must be opened. The sys-

tem is now under pressure up to the stop valve which must still be closed (lever

transverse to pipes). Outlet of air at the filing connection is prevented by an

integrated non- return valve and an additional safety cap which must always be

fitted with exception of filling.

Additional doors, hatches, all other openings and the air flap in the aft door

must be closed to prevent loss of air supply to outside.

Two under pressure valves are integrated in this flap. They will open if danger-

ous under pressure occurs in the boat by engine operation or other reason

(rubber membrane moves upward).

Note:

This valves only prevent strong under pressure in the boat. They

are not sufficient to provide enough air supply for the occupants!

Never:

Never close air inlet without running air plant to avoid dan-

ger of suffocation.

Lack of fresh air will increase CO2-content inside the

lifeboat. This can result in uncontrolled sleeping fol-

lowed by DEATH!

When starting engine or latest 5 minutes after closing air flap plant must be set

into operation by turning stop valve lever for 90°. Air will now stream into air

reducer where the pressure and outcoming volume is reduced to an amount

which is sufficient to provide a small overpressure in the boat when the engine

is running at full speed. This overpressure prevents entry of toxious gazes from

outside through small leakages in the boat.

The volume is regulated at the air reducer by the boat yard by an air supply

test for each individual boat and sealed after setting.

Note:

DON’T OPEN SEAL AND CHANGE THIS SETTING

Document 20.0000-019.00.00.6 Art. No. 156336 27 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

The air stream out into boat through the silencer and distributes it into

the boat providing fresh and cold air for occupants and engine. The

outcoming pressure can be seen on the manometer behind the air re-

ducer, the normal range is between 1,5 and 4 bar.

The high pressure manometer shows the contents of the air bot-

tles, starting at 200 bar, in the case of USCG boats at 300 bar with

full bottles reducing to 0 bar within about 10 minutes, i.e. about

each 20 bar or in case of USCG boats 30 bar mean about 1 minute

of operation time!

Warning:

Due to expanding air all parts of air system will become very cold

and covered with ice!

DON’T TOUCH, DANGER OF FREEZING!

Although a spring loaded over pressure valve is located in the air duct

in the aft door to prevent uncomfortable over pressure:

Caution:

DON’T STOP ENGINE WHILE AIR PLANT IS IN OPERATION!

Caution:

DON’T FORGET TO RE- OPEN AIR FLAP AFTER AIR SUP-

PLY HAS STOPPED!

Document 20.0000-019.00.00.6 Art. No. 156336 28 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

5.8 Bailing

Water inside the boat will gather at the bilge. From there it can be bailed out

using the installed manual bilge pump (see chapter 5.8.1).

Water in other areas can be removed with a bailer.

To drain the air cases, at least one drain plug is fitted at deepest point outside

on the hull and inside at the canopy air cases.

AIR CASE DRAINING

5.8.1 Manual bilge pump

If water is in the bilge then:

connect the pump lever (1) into the socket (2)

move lever to bail out the water of the bilge

1

2

5.9 rain water collection

Rain water collection is used to increase the drinking water storage.

Rain water is collected by a gutter (1). It is guided to inside the boat by a valve

or hose. The rain water is to be stored in the drinking water cannister.

Mandatory:

To prevent that dirt and salt can get into the drinking water, the

valve should be stay closed for the first few minutes of raining.

Open the valve plug (3) only when it is raining, otherwise dirt and

salt could reach into the rain water collecting tank.

Document 20.0000-019.00.00.6 Art. No. 156336 29 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

6. Release gear system:

For operation refer to chapter 3 Operation of Boat item 15.

The GAR / CFL boats consist of a hydraulic gear system. The hydraulic gear

system is equipped with a release handle (1), hand-hydraulic release pump (2),

hydraulic oil tank (3), hydraulic hose (4) and the hydraulic plunger (5). The

hydraulic plunger is equipped with a return spring inside. If spring tension is no

more sufficient to return stop pawl totally it can be exchanged by opening aft

cap after draining hydraulic oil of piston.

Mandatory:

Check release hook for tender spots of chain. (1)

Grind smooth if there are any tender spots, otherwise hook

may not open!

Document 20.0000-019.00.00.6 Art. No. 156336 30 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

7. Simulated Launch

7.1 Securing of boat during service or release test without launching

Connect hoisting wires to crane or davit and pull them tight acc. to their in-

structions.

Secure boat additionally with applicable ropes or chains from shackle of

forward hoisting fitting downwards aft to launching ramp on both sides and/

or through drain cut- outs of release arrangement to ship side retaining de-

vice.

A special simulated launching kit is available as optional equipment This kit

allows the simulated launch more easy than the described above.

Caution:

Do not work or release the release arrangement without launch-

ing without having above securing tight. Release test without

launching WITH HELMSMAN ONLY

acc. to chapter 3.1

Document 20.0000-019.00.00.6 Art. No. 156336 31 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

8. Launching ramp and lashing:

The launching ramp consists of steel square pipes with welded rollers. The

rollers are made of polyamide and turn on stainless-steel axles. They are self-

lubricating. For damages on rollers: remove axle holder and pull out roller.

Lashings at the stern of the boat: The boat is connected to the launching

ramp with a connection link. As this connection link is going down at an angle

of 15° to the horizontal it prevents the boat jumping on the launching ramp in

heavy sea way. The bow of the boat is secured against jumping with one lash-

ing plate on each side. Additional lashings might be fitted. In this case applica-

ble extra signboards on the boat have to be observed.

During re-insetting of the boat by davit or crane, side lashing has to be opened

by pulling rope on platform deck.

Float free arrangement: If the ship should sink, the buoyancy of the complete

Lifeboat will act on the lashing plate, which will break by that load. The bow of

the boat will float free. After that, the retaining chain can slip off the lashing

bollard, which is open at the top, and the boat will float free.

Document 20.0000-019.00.00.6 Art. No. 156336 32 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

9. Outfit and loose equipment:

Loose equipment and provisions are stowed in the inventory case.

Water rations are provided in loose water canisters or in water tank(s).

Boat hooks are secured PS in the boat.

A rope ladder is also provided as part of the loose equipment. For boarding

from the water hang it onto the rowlock at the transom.

ROPE LADDER

ROPE LADDER

FITTING OF

RADAR REFLECTOR The radar reflector is found in the inventory case. After assembly, attach it

(Stored in inventory box)

to boat hook and fit it to one of the railing stanchions or the pipe fitting aft.

Secure the radar reflector with rope to a clamp.

Rope ladder is to knot at rope eye

railing and hoisting hook

Put boat hook into railing

or special support

A Compass is fixed installed close to helmsman position

Caution:

When stowed on steel ships a magnetic compass is permanently

influenced by the ship’s magnetic field and therefore, does not

display correctly! Even after leaving the ship this influence can

affect the compass for several weeks, or it may even have

caused permanent damage. A faulty compass can, therefore, not

be accepted as a guarantee.

Door and hatches: All entrances and doors can be opened from inside and

SECURING FOR

DOOR outside. The door is equipped with an integrated air vent.

Never:

NEVER close all air inlets to avoid danger of SUFFOCATION!

TURN LOWER HANDLE

BEHIND DOOR STOPPER

It is strongly recommended that entrances and hatches be opened as wide as

reasonable in the particular situation to provide fresh air inside. In this case life

jackets and seat belts must be worn.

Warning:

A lack of fresh air will increase the CO-content inside the lifeboat.

This can result in uncontrolled sleeping followed by DEATH!

Caution:

Before using a hatch/door, ensure that it is well secured in an

open position. A poorly secured hatch/door can cause injury.

Some hatches are fitted with self-stopping hinges instead of a

hatch-securing device. If they are loosened, the hinges can be

adjusted.

For maintenance information refer to Chapter 12.4

Document 20.0000-019.00.00.6 Art. No. 156336 33 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

10. Periodic servicing and inspection by crew

General safety precautions:

Inform Officer in duty when starting and finishing work on the lifeboat.

Ensure that the boat is safely secured to the davit, and that there is safe access to boat.

Never smoke inside a lifeboat.

Open doors and hatches for ventilation.

Do not touch any part of the release gear before special safety precautions have been taken

(i.e. A “hanging-off-pendant” fitted).

Do not the run engine for more than 5 minutes

Mandatory:

When CLEANING the boat, especially windows, plastic, retro- reflective tape and covered

aluminium DO NOT USE SOLVENTS OR SOLVENT BASED CLEANERS!

When flushing the boat with water hose:

NEVER direct hose towards engine exhaust outlet – water might enter into engine

and damage or destroy it.

NEVER use water hose inside of boat – parts or electric system might be damaged.

Water hose pressure might damage retro-reflective tape outside.

Note:

Maintenance and inspection is not restricted to the above mentioned items. Items and proce-

dures not listed need to be inspected and maintained according to good seamanship, so long

as they are not part of the service, which shall only be carried out by Fassmer-certified

service engineers (see Chapter 11 ).

Service Qualification level according to SOLAS III Reg. 20.11.2.2 and IMO MSC CIRC. 1206:

Weekly and monthly inspections and routine maintenance …

… may be done by the crewmembers under direct supervision of a senior ship’s officer, in accordance

with these instructions.

In case of annual service by Fassmer-certified lifeboat service engineers, the weekly and monthly inspec-

tions and routine maintenance part of the service shall be executed by the crew for training and instruction,

supervised by the service engineer.

All other inspections, servicing and repair …

… should be conducted by Fassmer’s representative or a person appropriately trained and certified by

Fassmer for the work to be done.

Reports and records

The following checklists should be correctly filled out and signed by the person who carries out the inspec-

tion and maintenance work and should also be signed by the company’s representative.

Mark checklist as following:

ok not ok: if item was checked / done and found to be in order

ok not ok: if item was NOT checked / done

if item was checked / done and found NOT to be in order, fault was NOT settled: in

ok not ok:

such case note the fault in the checklist.

if item was checked / done and found NOT to be in order, fault was SETTLED: in

ok not ok:

such case note the fault and kind of settlement in the checklist.

Records of inspections, servicing, repairs and maintenance should be updated and filed onboard the ship.

When repairs, thorough servicing and annual servicing are completed, a statement confirming that the life-

boat is fit for purpose should be issued by Fassmer’s representative.

Document 20.0000-019.00.00.6 Art. No. 156336 34 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

10.1 WEEKLY and after ever y recovery of the boat into the davits:

Note:

The following inspections and maintenance procedures (when required)have to be exe-

cuted during the WEEKLY INSPECTIONS of the life saving appliances acc. to SOLAS,

Chapter III, reg. 20.6.1!

Notes:

Lifeboat visual inspection

ok not ok

(SOLAS-requirement)

Start engine and idle it for about 5 min. En-

gage propeller ahead and astern, check ok not ok

engine circuits (SOLAS-requirement).

Check proper attachment of handrails and

ok not ok

grips.

Open door and hatches to ventilate for

ok not ok

approx. 2h.

Check working order of the steering system,

ok not ok

look for damages.

Release gear:

Check correct position of stop pawl ok not ok

Check correct position of release safety bolt ok not ok

Ensure that release handle in secured posi-

ok not ok

tion with safety bolt inserted

Only valid for tanker lifeboats:

Water spray plant:

Sea water- and bypass valve open, flushing

connection closed ok not ok

Self-contained air support system:

All valves and safety caps closed

Date Service engineer name (printed + signature) Boat no. Signature of company´s representative

Ship´s name:

Document 20.0000-019.00.00.6 Art. No. 156336 35 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

10.2 MONTHLY:

Note:

The following inspections and maintenance procedures (when required) should be car-

ried out during the MONTHLY INSPECTIONS acc. to SOLAS, Chapter III, reg. 20.7 (in

addition to above weekly inspections)

Notes:

Lifeboat abandon ship drill (at least one

boat launched and engine started) (SOLAS ok not ok

III/19.3.3-requirement)

Loose equipment complete and in good

ok not ok

condition (SOLAS III/20.7-requirement)

Check fuel level and top up if necessary. ok not ok

Date Service engineer name (printed + signature) Boat no. Signature of company´s representative

Ship´s name:

Document 20.0000-019.00.00.6 Art. No. 156336 36 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

10.3 3-MONTHLY (Items marked with „#“ also after every operation of the boat in the water)

Note:

The following checks and maintenance procedures (when required) should be carried out

EVERY 3 MONTHS during launching and sailing the lifeboats acc. to SOLAS, Chapter

III, reg. 19.3.3.3. (in addition to above weekly and monthly inspections)

Notes:

EACH Lifeboat launching and trial trip (SO-

ok not ok

LAS Chapter III, reg. 19.3.3.3-requirement)

Check pressure of fire extinguisher (if

ok not ok

gauge is fitted).

Check expiry date of fire extinguisher.

IF EXPIRED: arrange service and fitting of a ok not ok

new label by an authorised workshop!

Check expiry date of emergency signals.

ok not ok

IF EXPIRED: Replace!

Check expiry date of First aid kit.

IF EXPIRED: Replace or arrange inspection ok not ok

by authorised institution!

Check expiry date of emergency rations. ok not ok

IF EXPIRED: Replace

Replace drinking water (incl. Silver based

water disinfectant like Micropur or similar).

ok not ok

SEALED WATER RATIONS ONLY:

Check expiry date. IF EXPIRED: Replace!

# Drain bilge and clean bottom valve ok not ok

Open air case drain valves in bilge or at hull

and canopy air cases inside and close after ok not ok

draining.

Inspect working order of the bailing pump,

ok not ok

check for leakages, clean bailing hose inlet.

Check compass fitting and function

ok not ok

( see Caution chapter 9 )

Examine life lines and fittings ok not ok

Clean windows with mild soap and fresh

# ok not ok

water, NO SOLVENTS!

Inspect window wiper. ok not ok

Check retro reflective material, replace if

ok not ok

damaged.

Check all fittings, equipment etc. Clean,

ok not ok

grease or oil as applicable.

Clean the boat inside and out with mild

soap and fresh water. A wax and polish is

# ok not ok

recommended for the outside surfaces at

least once a year.

Check/grease doors and hatch sealing,

hinges and tightness, adjust door catches if ok not ok

necessary. ( see Chapter 12.4 )

Document 20.0000-019.00.00.6 Art. No. 156336 37 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

Check all screws and nuts are tight. Screws

can loosen with operation, vibration or sim-

ply from “setting” under load.

ok not ok

Pay special attention to the release system,

seat bolts, engine foundation and rudder

plant.

Check that exhaust pipe insulation is com-

ok not ok

plete and dry.

Check cooling water level. ok not ok

Check stern tube for leakages whilst ma-

# ok not ok

noeuvring.

Turn stern tube grease gun about 10 times

# after boat test or if leaking. Fill grease gun if ok not ok

empty.

If stern tube leaking continues, tighten stuff-

ok not ok

ing box.

Check propeller and mounting. ok not ok

Drain water from fuel tank. ok not ok

Check fuel lines for leakages. ok not ok

Check lights inside and out, and searchlight. ok not ok

Check batteries are charged. ok not ok

Check battery charging fuse (if fitted) is not

ok not ok

broken.

Inspect batteries. ( see chapter 12.3 ) ok not ok

Test the battery switch. CAUTION: DO NOT

SWITCH OFF WITH THE ENGINE RUN- ok not ok

NING!

®

Clean and apply Vaseline to the battery

charging socket (if fitted) and all free electri- ok not ok

cal connections.

Check working order of the engine

ok not ok

switchboard.

Inspect battery charger/solar generator (

ok not ok

to be cleaned!).

Hydraulic steering: Check pump oil level,

refill or vent if necessary. Check hydraulic ok not ok

system for leakages.

Check expiry date of torch batteries.

IF EXPIRED (or annually if no date is fitted): ok not ok

Replace!

Document 20.0000-019.00.00.6 Art. No. 156336 38 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

Launching ramp:

Check moveability of rollers, Clean and

grease if necessary. ok not ok

Replace damaged rollers

Check that side lashings are closed ok not ok

Check moveability of side lashings. Clean

ok not ok

and grease if necessary

Check correct position of aft

ok not ok

lashing / retaining chain

Release gear:

Check easygoing of all moveable parts ok not ok

Warning:

LEVER DROPS BOAT

ok not ok

Check only when boat is not

connected to release system!

Check hook for tender spots grind smooth if

ok not ok

necessary. Check chain

AFTER EACH LAUNCHING:

Flush hoisting hook with fresh water (but not ok not ok

more than monthly)

Mandatory:

If stop pawl does not return ok not ok

completely, replace return

spring in hydraulic plunger

Document 20.0000-019.00.00.6 Art. No. 156336 39 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

Only valid for tanker lifeboats:

Water spray plant:

Operate water spray plant, repair leakages ok not ok

Ensure correct function of all nozzles, clean

ok not ok

if necessary

Flush system with fresh water afterwards ok not ok

Self-contained air support system:

Check filling, refill if necessary ok not ok

Check pressure holding capability (leak-

ok not ok

ages)

Check function of reducer ok not ok

Check function of air flap ok not ok

Check function of overpressure valve

(check moveability of inner part by moving it ok not ok

with low force with finger)

Check under pressure valves (rubber mem-

brane undamaged and lying flat on bottom ok not ok

of valve)

Check air bottles and all fittings for major

ok not ok

corrosion

Note:

Replacement if necessary by

authorised personnel only

Date Service engineer name (printed + signature) Boat no. Signature of company´s representative

Ship´s name:

Document 20.0000-019.00.00.6 Art. No. 156336 40 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

11. Servicing, inspection, overhaul and testing by Fassmer-certified ser-

vice engineer

11.1 ANNUAL THOROUGH EXAMINATION:

Caution:

All work in this section is only allowed to be carried out by service engineers with

a valid Fassmer-“Certificate of Competence” and Fassmer-ID- card as “Authorized

Service Engineer” for Lifeboats!

Unauthorized manipulations to the lifeboat system void all guarantees and resolve

Fassmer of all responsibility!

Fassmer- service can only be ordered centralized at:

Fassmer Service GmbH & Co. KG

Industriestr. 2

D – 27804 Berne / Germany

Phone: +49 (0)4406 942-0, Fax: +49 (0)4406 942-100

Email: service@fassmer.de

Internet: www.fassmer.de

It is recommended to arrange certified release gear service together with lifeboat service

Remark: which is required at same intervals according to hook manual !

Note:

All general notes in the beginning of chapter 7 regarding safety precautions, service

qualification level and reports and records are also valid for this chapter!

These annual thorough examination MUST be carried out acc. to IMO-MSC/Circ. 1206

during the survey acc. to SOLAS, chapter. I, reg. 7 resp. 8.

Defects have to be solved and defective parts to be replaced. If this is not possible, such

defects have to be listed at the end of this list for quickest possible settlement.

Notes:

Launch EACH Lifeboat into water and exe-

ok not ok

cute trial trip.

SAFETY NOTE: For launching follow the

recommendations of IMO-MSC1/Circ. 1206/

Annex 2: “Guidance on Safety during aban-

don ship drills using lifeboats”, for example:

Before placing persons onboard a life-

boat, it is recommended that the boat

first be lowered and recovered without

persons on board to ascertain that the

arrangement functions correctly. The

boat should then be lowered into the wa-

ter with only the number of persons on

board necessary to operate the boat.

To prevent heaving wires or gripes from

getting entangled, proper release should

be checked before launching the boat.

Check all fittings, equipment etc. Clean,

ok not ok

grease or oil as applicable.

Document 20.0000-019.00.00.6 Art. No. 156336 41 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

Open air case drain valves in bilge or at hull

and canopy air cases inside, and close after

draining.

If greater amounts of water are regularly ok not ok

found in the air cases

Source the leakages and seal. Please

note that small amounts of water are normal

and no cause for complaint.

Check visibility through polycarbonate win-

ok not ok

dows. Replace, if blind!

Check all screws and nuts are tight. Screws

can loosen with operation, vibration or sim-

ply from “setting” under load. Pay special ok not ok

attention to the engine foundation, release

system, and rudder plant.

Check that exhaust pipe insulation is com-

plete and dry. Replace missing or damaged ok not ok

parts

Check exhaust line for leakages. ok not ok

Check cooling water level and system for

ok not ok

leakages

Check propeller shaft for bending etc. as the

ok not ok

shaft is turning slowly.

Check stern tube for leakages whilst ma-

noeuvring: tighten stuffing box gland or re- ok not ok

place packing if leaking.

Check propeller and mounting. Replace if

ok not ok

damaged.

Check batteries are charged.

ok not ok

( See Chapter 12.3 )

Drain water from fuel tank. If abnormal

amount of water is in fuel: ok not ok

check the reason and settle it.

Check fuel lines for leakages and repair if

ok not ok

leaking.

Check lights inside and out, and searchlight.

ok not ok

Replace bulbs and lights as necessary.

Replace bulb of outside position indicating

light after 12 hours of use ONLY AGAINST

ORIGINAL BULB SUPPLIED BY FASSMER

ok not ok

(requirement from lamp supplier and his

approval authority. Fassmer- order no.

576283)

Check moving parts, fastenings and the

ok not ok

safety belt itself.

Repair or replace loose and damaged seat

ok not ok

cushions (if fitted).

If fitted inspect the electric bilge pump func-

ok not ok

tion and floater switch by lifting it.

Document 20.0000-019.00.00.6 Art. No. 156336 42 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

Inspect battery charger/ solar generator (

ok not ok

to be cleaned!).

Hydraulic Steering: Check pump oil level,

refill or vent if necessary. Check hydraulic ok not ok

system for leakages.

Check all canopy air cases visually for tight-

ok not ok

ness. Seal or repair as necessary.

Engine and gear box see engine manual. ok not ok

Check inside the fuel tank: If a solid residue

is present, remove the residue and clean the ok not ok

tank.

Check elastic engine bearings for damages ok not ok

Check connection of engine control wires.

Tighten screws and secure with Loctite, if ok not ok

necessary.

Release gear: Refer to separate instruction

ok not ok

manual!

Check steering owden wire. ok not ok

Winch brake test done? If a dynamic winch

brake test with the EMPTY BOAT is exe-

cuted acc. MSC/Circ 1093/3.1 for davit ser-

vice, the complete boat, especially all re-

lease gear connections to the boat, bolts,

nuts, surrounding laminate, elastic seams

etc. shall be carefully examined AFTER this

test to detect any possible damages, loose ok not ok

bolts, cracks or other to the system:

Every damage has to be repaired by CER-

TIFIED service engineer. Depending on

amount of damage, davit brake test and

examination may have to be repeated after

repair.

Broken elastic seams have to be renewed.

Warning:

No person shall be in the boat

during a dynamic winch brake

test. A system failure can drop

the boat and KILL YOU or

cause serious injuries

Document 20.0000-019.00.00.6 Art. No. 156336 43 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

Only valid for tanker lifeboats:

Water spray plant:

Check all hoses for damages especially at

ok not ok

connections, replace if necessary

Clean and degrease boat surface ok not ok

Mandatory:

Don’t polish or wax the boat

because this disturbs water

coverage

Self-contained air support system:

Execute self-contained air support system

test acc. to operation described in Chapter 3

Check:

Function of air reducer (smooth and con-

stant air outcome)

Small overpressure in cabin (rubbers of un-

der pressure valve closed or barometer in ok not ok

cabin rising for max. 20 mbar, then over

pressure valve must open)

Cabin for air leakages (person outside to

hear or feel outblowing air)

Afterwards refill air bottles

Date Service engineer name (printed + signature) Boat no. Signature of company´s representative

Ship´s name:

Document 20.0000-019.00.00.6 Art. No. 156336 44 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

11.2 EVERY 2 YEARS: applicable not applicable

Note:

In addition to the annually thorough examinations the following items have to be

checked/serviced every two years:

Notes:

Replace window wiper blade. ok not ok

Replace stuffing box packing. ok not ok

Date Service engineer name (printed + signature) Boat no. Signature of company´s representative

Ship´s name:

Document 20.0000-019.00.00.6 Art. No. 156336 45 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

11.3 EVERY 5 YEARS: applicable not applicable

Note:

In addition to the annually / and 2- years thorough examinations the following items have

to be checked/ serviced every five years:

Notes:

Replace retro reflective material. ok not ok

Replace the rubber membrane and non-

ok not ok

return valves of the bailing pump.

Replace all rubber ropes. ok not ok

Inspect/renew all elastic sealing outside with

ok not ok

MS-Polymer.

Replace all bulbs of inside lamps and

ok not ok

searchlight.

Replace bulb of outside position indicating

light ONLY AGAINST ORIGINAL BULB

SUPPLIED BY FASSMER (requirement ok not ok

from lamp supplier and his approval author-

ity. Fassmer-order no. 576283).

Replace position indicating light cover out-

ok not ok

side (damaged by UV-radiation).

Replace main batteries – use ORIGINAL

ok not ok

GEL-TYPE BATTERIES ONLY!

Dynamic overload davit winch brake test

done in spite of safety recommendation

below? If a dynamic winch brake test with

the BOAT LOADED TO 110% LOAD is exe-

cuted acc. MSC1/Circ 1206, Annex 1/3.2 for

davit service, the complete boat, especially

all release gear connections to the boat,

bolts, nuts, surrounding laminate, elastic

seams etc. shall be carefully examined AF-

TER this test to detect any possible dam- ok not ok

ages, loose bolts, cracks or other damages:

Every damage has to be repaired by CER-

TIFIED service engineer. Depending on

amount of damage, a 110% release gear

overload test (refer to release gear manual)

and examination may have to be repeated

after repair.

Broken elastic seams have to be renewed.

Document 20.0000-019.00.00.6 Art. No. 156336 46 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

Caution:

IMPORTANT SAFETY REC-

OMMENDATION: The five-

yearly dynamic overload davit

winch brake test should be

executed with a PROOF

LOAD and NOT with the boat

(revised SOLAS III/Reg.

20.11.1.3 in Res.

MSC.152(78))

Reason: The forces occurring

during such test can not be

predicted but are usually be-

tween 2 and 3 times the

weight of the fully loaded boat,

sometimes maybe even

higher! This might cause un-

detectable damages in lifeboat

GRP structures which might

lead to later failure when in

use with persons!

Also davit brake failure during

this test will lead to serious

damages to the boat.

FASSMER THEREFORE

REJECTS ANY RESPONSI-

BILITY FOR DAMAGES OC-

CURRED TO THE BOAT

DUE TO USE OF THE BOAT

FOR DYNAMIC OVERLOAD

DAVIT WINCH BRAKE TEST.

Warning:

NO person shall be in the boat

during a dynamic winch brake

test. A system failure can drop

the boat and KILL YOU or

cause serious injuries!

Replace return spring in hydraulic plunger ok not ok

Document 20.0000-019.00.00.6 Art. No. 156336 47 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

Only valid for tanker lifeboats:

Self-contained air support system:

Air bottle over pressure test in authorised

workshop and new certification by applicable

ok not ok

authority or exchange of bottles against

newly certified ones

High pressure hoses over pressure test

with 1,5x nominal pressure= 300 bar, in

case of USCG boats 450 bar in authorised ok not ok

workshop or exchange of hoses against new

ones.

Self-contained air support system over pres-

sure test with 1,5x nominal

pressure= 300 bar, in case of USCG boats

ok not ok

450 bar

Replace of membrane and service in author-

ised workshop or replace by new one.

Date Service engineer name (printed + signature) Boat no. Signature of company´s representative

Ship´s name:

Document 20.0000-019.00.00.6 Art. No. 156336 48 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

11.4 EVERY 10 YEARS: applicable not applicable

Note:

In addition to the annually/ 2-years and 5- years thorough examinations the following

items have to be checked/ serviced every ten years: (In addition to above annually and 2

Years and 5 Years thorough examinations)

Notes:

If fitted replace the electric bilge pump and

ok not ok

floater switch.

Replace all gaskets in doors and hatches ok not ok

Replace all rope installed outside of boat:

ok not ok

lifelines, fender cushion lashings etc.

Replace exhaust gas piping and insulation. ok not ok

Replace fuel hoses between engine and

ok not ok

tank.

Replace elastic engine bearings for dam-

ok not ok

ages.

If fitted: replace battery charger resp. solar

ok not ok

charging panel and regulator.

Replace steering bowden wire resp. hydrau-

ok not ok

lic hoses for hydraulic steering.

Date Service engineer name (printed + signature) Boat no. Signature of company´s representative

Ship´s name:

Document 20.0000-019.00.00.6 Art. No. 156336 49 Mod. 6 (MSC1205) Lange/WZ 22.04.2010

Operator’s Handbook for

Fassmer Freefall-Lifeboats type GAR(-T) 6.0 - 8.1 / CFL(-T) 66 - 83

This is to confirm that the Freefall lifeboat has been thorough examined and is "FIT FOR PUR-

POSE". The next annual inspection to be latest 12 months after the date below. Following de-

fects (in addition to notes in above check list) have been eliminated/parts were replaced:

This is to confirm that the Freefall lifeboat has been thorough examined and will be "FIT FOR

PURPOSE" AFTER SETTLEMENT OF FOLLOWING DEFECTS. The next annual inspection to