Professional Documents

Culture Documents

Pur 1964 en 221128

Uploaded by

SitiMaesarohOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pur 1964 en 221128

Uploaded by

SitiMaesarohCopyright:

Available Formats

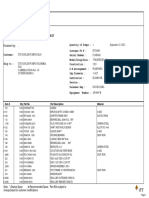

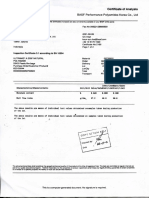

Akzo Nobel Vietnam Ltd.

Production Information

PUR 1964

PUR 1964 is a one-component polyurethane adhesive for wood.

1964 is used for doors, windows, house elements, furniture, wooden floors and wood/metal or wood/hard

plastics bonds. Well suited for difficult-to-glue materials and for bonding wood with high moisture contents,

even at low temperatures.

1964 is tested and approved by Treteknisk in Norway according to EN 204, Class D4.

This product conforms to JAIA-013408 F☆☆☆☆.

Product Specification

1964

Product Isocyanate MDI based prepolymer

Delivery Form Liquid

Colour Brown

Viscosity 2000 to 3500 mPas (Brookfield LVT sp. 4, 20 rpm, 25°C)

pH NA

Storage life 20°C 30°C

12 months 12 months

Sealed packaging at 20°C.

Storage Condition

Should not be exposed to temperatures below 5°C or above 30°C.

Formaldehyde

The adhesive contains no formaldehyde, and will not contribute to emission.

Info

Density 1140 kg/m³

This product conforms to JAIA-013408 F☆☆☆☆.

Approvals

EN 204 Class D4

Gluing operation instruction

The adhesive cures by reacting with water and practice show that the moisture

Moisture contents contents of the wood should be 8 – 22%. All our tests were made on wood with

water content of 10 – 12%.

Preparation of Materials must be clean and free of grease. Wood must be freshly planned.

materials Plastics and metals should be sanded and degreased.

Assembly time

Open: Maximum 10 - 15 minutes.

at 20°C, 65 % RH, 200

g/m² and 12% moisture Closed: Minimum 5 to maximum 60 minutes.

content of wood.

Contact Information

Akzo Nobel Vietnam Ltd.

Amata Industrial Zone T + 84 251 3936 390 Date: 11/28/2022

Bien Hoa City, Dong Nai Province F + 84 251 3936 386 Replaces: 11/23/2020

Vietnam www.akzonobel.com Reason for changes: Change of legal entity

1

Akzo Nobel Vietnam Ltd.

Glue amount 100 - 300 g/m² for single-sided or double-sided application.

In general the pressing time will depend on the glue amount, the temperature,

Pressing time, the relative humidity (RH) and the moisture content of the wood.

general After 48 hours, the adhesive has finished curing.

The adhesive joint obtains full water resistance after approx. 7 days at 20°C.

Pressing time MC (moisture content of wood) RH (air humidity) Time

guideline at 20°C 12% 65% 4 – 6 hours

Pressure 4 - 8 kg/cm²

Machinery

The adhesive is applied by manual roller, ribbon spreader or nozzle and can

Applicator be pumped. For small tasks, the adhesive is applied directly from the plastic

container.

Handling and HSE info

Adhesive on skin is removed with water and soap.

Tools are cleaned with Cleaning Liquid 4453, before the adhesive is cured.

Cleaning

Dried adhesive on tools is removed mechanically.

Release agent 4454 can be used for presses.

Good working hygiene should be observed. The adhesive contains isocyanate,

which reacts with the moisture of the skin.

Handling

Always use gloves and goggles when handling the product.

Provide good ventilation, especially when using a hot press.

Normally not to be considered as hazardous waste. Leave residues to cool

before sending it off for disposal.

Waste handling

– of the products

NOTE: There might be national and/or local regulatory differences, therefore always keep a

dialogue w the local authorities.

Health and Safety For more information see the respective SDS.

Legal clause

The information is based on laboratory tests and practical experience. It is introductory and intended to

help the user find the most suitable method of working. Since the user's production conditions are beyond

our control, we cannot be held responsible for the results of the work which is affected by local

circumstances. In each particular case testing and continuous control are recommended.

Contact Information

Akzo Nobel Vietnam Ltd.

Amata Industrial Zone T + 84 251 3936 390 Date: 11/28/2022

Bien Hoa City, Dong Nai Province F + 84 251 3936 386 Replaces: 11/23/2020

Vietnam www.akzonobel.com Reason for changes: Change of legal entity

2

You might also like

- Aw0028 TDS enDocument2 pagesAw0028 TDS enSaqib NawazNo ratings yet

- Pva Bonding Agent ADocument2 pagesPva Bonding Agent ANovaArieNo ratings yet

- Antifouling SeaomegaDocument3 pagesAntifouling SeaomegaRidwan BaharumNo ratings yet

- TDS SAFEGUARD EnglishDocument4 pagesTDS SAFEGUARD EnglishthirdNo ratings yet

- Penguard Primer: Technical DataDocument4 pagesPenguard Primer: Technical DataRohit KambleNo ratings yet

- Yeolcoat QT6612 Heat Resistant Paint Product DescriptionDocument2 pagesYeolcoat QT6612 Heat Resistant Paint Product DescriptionTrịnh Minh KhoaNo ratings yet

- GORI 34 Outdoor Deck StainDocument3 pagesGORI 34 Outdoor Deck StainAjith SomaratneNo ratings yet

- Penguard HB 2005 PDFDocument4 pagesPenguard HB 2005 PDFMuthuKumarNo ratings yet

- 54 Betek-Pva-Tutkal Tds GBDocument2 pages54 Betek-Pva-Tutkal Tds GBJayant SethiNo ratings yet

- Tds Tasnee LD 0222nDocument2 pagesTds Tasnee LD 0222nNoman Abu-FarhaNo ratings yet

- Super Glue: Glue For Indoor School UseDocument2 pagesSuper Glue: Glue For Indoor School UseAlvaroNo ratings yet

- Sikafloor - 290 PrimerDocument4 pagesSikafloor - 290 PrimerMaha MuflehNo ratings yet

- Tds - Penguard HB - English (GB) - Issued.24.06.2005Document4 pagesTds - Penguard HB - English (GB) - Issued.24.06.2005BNo ratings yet

- Simacover EP Unicoat 2401-00: Product Data SheetDocument3 pagesSimacover EP Unicoat 2401-00: Product Data SheetParan baenNo ratings yet

- Jotashield Colourxtreme SilkDocument3 pagesJotashield Colourxtreme Silkمحمد عزتNo ratings yet

- Pds Simathane Gloss 9-1Document2 pagesPds Simathane Gloss 9-1Aulia RahmahNo ratings yet

- TDS-PENGUARD HB-EnglishDocument4 pagesTDS-PENGUARD HB-EnglishthirdNo ratings yet

- PROTODUR 303.0 enDocument2 pagesPROTODUR 303.0 enNovingroupNo ratings yet

- TDS U7294 UV Roller Clear Adhesion Sealer For GlassDocument3 pagesTDS U7294 UV Roller Clear Adhesion Sealer For GlassWilliam SalimNo ratings yet

- Technical Data Sheet Mekol-1413-GDocument1 pageTechnical Data Sheet Mekol-1413-Ggrigory-1No ratings yet

- Besealed Water Swellable PasteDocument2 pagesBesealed Water Swellable PasteJosé Luis CampelloNo ratings yet

- Xylan 80-018-g6706 Black - BeDocument2 pagesXylan 80-018-g6706 Black - BeSYED MAZHARNo ratings yet

- 13X44 10130DSC13X44 Gori 44+ TDS (En) #3105Document3 pages13X44 10130DSC13X44 Gori 44+ TDS (En) #3105Ajith SomaratneNo ratings yet

- Kanseal Pu.Document4 pagesKanseal Pu.Sunny SinghNo ratings yet

- Antifouling SeaaluDocument3 pagesAntifouling SeaaluRidwan BaharumNo ratings yet

- Acrylic Plaster PrimerDocument3 pagesAcrylic Plaster Primerapi-302611547No ratings yet

- Chemtech 340Document3 pagesChemtech 340pardissNo ratings yet

- KCC - DATASHEET - Komarine Anti-Rust Oil RV490 - EngDocument2 pagesKCC - DATASHEET - Komarine Anti-Rust Oil RV490 - EngNguyen1987 TrungNo ratings yet

- TDS JOTATHANE EnglishDocument3 pagesTDS JOTATHANE EnglishthirdNo ratings yet

- TDS-ANTIFOULING SARGASSO-EnglishDocument3 pagesTDS-ANTIFOULING SARGASSO-EnglishthirdNo ratings yet

- Silicone U - TDSDocument2 pagesSilicone U - TDShadeer youns0% (1)

- TDS Majestic True Beauty and CareDocument4 pagesTDS Majestic True Beauty and Carephan tuan datNo ratings yet

- Jotacote UniversalDocument4 pagesJotacote UniversalRidwan BaharumNo ratings yet

- Sealant Used by BHEL For Turbine Bearing Housing Parting PlanesDocument3 pagesSealant Used by BHEL For Turbine Bearing Housing Parting PlanesProject Sales CorpNo ratings yet

- TDS MARATHON EnglishDocument4 pagesTDS MARATHON EnglishthirdNo ratings yet

- RF-9801 Lamination Adhesive For Soft PackageDocument4 pagesRF-9801 Lamination Adhesive For Soft PackageWasif AzimNo ratings yet

- TDS - Penguard Midcoat Mio 80Document4 pagesTDS - Penguard Midcoat Mio 80GunarsyahNo ratings yet

- Araldite Kit K134: Araldite Kit K134 Part A 100 PBW Araldite Kit K134 Part B 40 PBWDocument5 pagesAraldite Kit K134: Araldite Kit K134 Part A 100 PBW Araldite Kit K134 Part B 40 PBWVaibhav GuptaNo ratings yet

- DUFILLDocument3 pagesDUFILLvelmurug_balaNo ratings yet

- Sikagard®-62: Product Data SheetDocument4 pagesSikagard®-62: Product Data Sheetantonsugiarto20_7049No ratings yet

- Jotashield Colourxtreme MattDocument4 pagesJotashield Colourxtreme Mattمحمد عزتNo ratings yet

- TDS-ANODESHIELD ICCP-EnglishDocument4 pagesTDS-ANODESHIELD ICCP-EnglishthirdNo ratings yet

- Antifouling Seaquantum PlusDocument3 pagesAntifouling Seaquantum PlusMoh. Emil SyamsudinNo ratings yet

- Fineset 2119R - H Single Component Thixotropic Epoxy ResinDocument3 pagesFineset 2119R - H Single Component Thixotropic Epoxy ResinBabyboy2010No ratings yet

- Epoxy Topcoat Technical DataDocument4 pagesEpoxy Topcoat Technical DatathirdNo ratings yet

- Protopren 103 SprayDocument1 pageProtopren 103 SprayNovingroupNo ratings yet

- Tankguard Holding Primer: Technical DataDocument4 pagesTankguard Holding Primer: Technical DataTra ThanhNo ratings yet

- Submarine Filler - English (Uk) - Issued.06.12.2007Document4 pagesSubmarine Filler - English (Uk) - Issued.06.12.2007Mohamed FaragNo ratings yet

- FlexicreteDocument3 pagesFlexicreteapi-302611547No ratings yet

- Jotashield Alkali Resistant PrimerDocument3 pagesJotashield Alkali Resistant PrimerRaviyanantham RishabananthanNo ratings yet

- Bitushield: Field of ApplicationDocument2 pagesBitushield: Field of ApplicationFandy SipataNo ratings yet

- Majestic True Beauty Sheen PDFDocument3 pagesMajestic True Beauty Sheen PDFBilher SihombingNo ratings yet

- Polyfoam SS45Document71 pagesPolyfoam SS45BavishNo ratings yet

- Spesifikasi Cat JotunDocument3 pagesSpesifikasi Cat JotunTeknoGayaNo ratings yet

- Anti Carbonation PaintDocument24 pagesAnti Carbonation PaintAnonymous KeVnZt2ynBNo ratings yet

- Antifouling Seaquantum ClassicDocument3 pagesAntifouling Seaquantum ClassicRidwan BaharumNo ratings yet

- Penguard SpecialDocument3 pagesPenguard SpecialAbay OchNo ratings yet

- Sikagard 403 W PdsDocument3 pagesSikagard 403 W PdsPRERAKNo ratings yet

- Family Handyman Handy Hints, Volume 2From EverandFamily Handyman Handy Hints, Volume 2Family HandymanNo ratings yet

- Creative Resin: Easy techniques for contemporary resin artFrom EverandCreative Resin: Easy techniques for contemporary resin artNo ratings yet

- UK Modern Slavery Statement 2023 PublishedDocument17 pagesUK Modern Slavery Statement 2023 PublishedSitiMaesarohNo ratings yet

- Chapter 3 DiscriminationDocument1 pageChapter 3 DiscriminationSitiMaesarohNo ratings yet

- ISO 9001 2008 Internal Audit and Gap AnaDocument7 pagesISO 9001 2008 Internal Audit and Gap AnaSitiMaesarohNo ratings yet

- Appendix H Social Impact Management PlanDocument24 pagesAppendix H Social Impact Management PlanSitiMaesarohNo ratings yet

- 20191113-Philips-Fluorescent-T8-Lamps-Bis33602 TLDocument8 pages20191113-Philips-Fluorescent-T8-Lamps-Bis33602 TLSitiMaesarohNo ratings yet

- D KokdpaneDocument3 pagesD KokdpaneSitiMaesarohNo ratings yet

- Schedule Survey Customr Satisfaction - 20152Document2 pagesSchedule Survey Customr Satisfaction - 20152SitiMaesarohNo ratings yet

- Rumus LoginDocument1 pageRumus LoginSitiMaesarohNo ratings yet

- Asian CatalogueDocument18 pagesAsian CatalogueAvinash GuptaNo ratings yet

- Steel Sections (China)Document33 pagesSteel Sections (China)Ragesh KarimbilNo ratings yet

- Latihan Soal - 231121-CBTDocument6 pagesLatihan Soal - 231121-CBTsitepu1223No ratings yet

- Tds Protite Fibreglas Clear Casting ResinDocument2 pagesTds Protite Fibreglas Clear Casting ResinLinton EckertNo ratings yet

- 1 MAGKOR - K - Zement - ISO - ENDocument1 page1 MAGKOR - K - Zement - ISO - ENValyJaraFariasNo ratings yet

- Basic 5Document21 pagesBasic 5yousab creator2No ratings yet

- Schematic Diagram of Casting MouldDocument25 pagesSchematic Diagram of Casting MouldvigneshNo ratings yet

- 2K PU SF PrimerDocument2 pages2K PU SF PrimerVajbayee elangovanNo ratings yet

- Ridderman OilDocument2 pagesRidderman OilLEANA JAN CANDOLETANo ratings yet

- IACS Rec-69-Rev2-Oct-2020-Ul (NDT)Document21 pagesIACS Rec-69-Rev2-Oct-2020-Ul (NDT)Al aminNo ratings yet

- Wmould Products CatalogDocument698 pagesWmould Products CatalogMarco SabellaNo ratings yet

- RT22-09-09 01Document2 pagesRT22-09-09 01cristhian.sebastian.12No ratings yet

- List of Explosion Proof EquipmentDocument75 pagesList of Explosion Proof EquipmentsandeepNo ratings yet

- 3651 TDS - eDocument3 pages3651 TDS - eDavidNo ratings yet

- Temperature Dependant Properties of Excothermic Riser SleevesDocument4 pagesTemperature Dependant Properties of Excothermic Riser SleevesCorneNo ratings yet

- 4.36. Millsheet COUPLER 6P MINI F 32671-KYZ - 9010-Y1 Housing (66 Nylon)Document7 pages4.36. Millsheet COUPLER 6P MINI F 32671-KYZ - 9010-Y1 Housing (66 Nylon)Rizki Eka SiswantoNo ratings yet

- SM Presentation Group 2 FinalDocument25 pagesSM Presentation Group 2 FinalSANJAI CTTNo ratings yet

- OA 7630 Permalux High Gloss Enamel Product Data: (Exterior/InteriorDocument1 pageOA 7630 Permalux High Gloss Enamel Product Data: (Exterior/Interior7981No ratings yet

- Structural SteelDocument17 pagesStructural SteelliNo ratings yet

- Lean Process of Zero Waste Management With Dynamic System and Cost-Benefit Analysis in Bandung CityDocument9 pagesLean Process of Zero Waste Management With Dynamic System and Cost-Benefit Analysis in Bandung CityVITA SARASINo ratings yet

- Internship Diary/Daily Log: Department of Mechanical Engineering Haldia Institute of TechnologyDocument1 pageInternship Diary/Daily Log: Department of Mechanical Engineering Haldia Institute of TechnologyShresth SanskarNo ratings yet

- 3D Printing Construction TechnologyDocument16 pages3D Printing Construction TechnologySunilNo ratings yet

- Bomba Maag PiñonesDocument2 pagesBomba Maag Piñonesalexander villanuevaNo ratings yet

- PackingSlip 42602133Document2 pagesPackingSlip 42602133Zbyněk SyptákNo ratings yet

- Tan Quiz 3Document2 pagesTan Quiz 3Bryan TanNo ratings yet

- Clariant Brochure Colorants For The Paint Industry 201703 enDocument36 pagesClariant Brochure Colorants For The Paint Industry 201703 enYohanes DitoNo ratings yet

- Welded Connection-1Document23 pagesWelded Connection-1Ynah Marie BoragayNo ratings yet

- Thermofoil 730Document2 pagesThermofoil 730szejye.unionNo ratings yet

- Metacut 302Document6 pagesMetacut 302sơn trần vănNo ratings yet

- 01-Lambdo Autolubricadas CadenasDocument28 pages01-Lambdo Autolubricadas CadenasUlises DrebesNo ratings yet