Professional Documents

Culture Documents

OA 7630 Permalux High Gloss Enamel Product Data: (Exterior/Interior

Uploaded by

7981Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

OA 7630 Permalux High Gloss Enamel Product Data: (Exterior/Interior

Uploaded by

7981Copyright:

Available Formats

OA 7630

Permalux High Gloss Enamel

Product Data (Exterior/Interior)

Description

Physical Data

This is a high quality Alkyd Enamel Paint with an attractive gloss

appearance. It is fully washable and resistant to soaps, Volume Solids .................. 47.85% (ASTM D 2697)

detergents and aliphatic hydro carbons. Good colour retention (Varies slightly according to colour)

and weather resistance makes it ideal for interior or exterior use.

Suitable for new or maintenance applications. Permalux is a truly Finish ............................... Gloss

versatile top coat.

Colour .............................. As per colour card

Recommended uses Spreading rate

@ 25 microns DFT........... 19.14 m2 /Lt

Permalux can be applied on all suitably prepared and primed

surfaces. Timber, metal, plaster and cementitious substrates. It Drying time:

can be used in aggressive areas such as bathrooms, Kitchens, To Touch ...................... 2 hours

laundries as well as sensitive areas such as nurseries or To re-coat..................... 16 hours

bedrooms.

Depending on ambient temperature &

surface conditions.

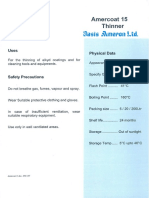

Principal Properties : Thinners ........................... AM 15, White Spirit or

similar

1. Good covering power

2. Ease of application Flash Point ....................... 38ºC

3. Full washability

4. Good levelling & drying properties

5. Provides long term protection in aggressive environments. Application method .......... Brush,Spray/Roller

6. Resists steam and condensation.

7. Good colour retention. Packing size ..................... 18 Ltr/ US Gallon

8. Lead free

Shelf life ........................... 12 months

Application methods : Brush ,Roller & Spray

Dilute with AM 15 (or similar) only as required to achieve good Storage ............................ Out of sun light

workability or an even spray pattern.

Storage Temp .................. 5ºC upto 40ºC

Surface Preparation :

Note : Allow for application losses. ie.

Substrates to be properly primed and prepared. Existing paints conditions, surface irregularity, surface porosity

to be sound. Clean and degrease surfaces to remove all types of and application method.

contamination. De-dust after smoothing or sand papering.

Volume solids is measured in accordance with ASTM-

D-2697. Slight variations may occur due to colour and

testing variances.

pg181000.doc - PD 1/97

You might also like

- 2018 Federal Income Tax Return PDFDocument8 pages2018 Federal Income Tax Return PDFBrandon BachNo ratings yet

- Printing Ink and Overprint Varnish Formulations, 2nd EditionFrom EverandPrinting Ink and Overprint Varnish Formulations, 2nd EditionRating: 3 out of 5 stars3/5 (2)

- Thermal Destruction of Microorganisms in 38 CharactersDocument6 pagesThermal Destruction of Microorganisms in 38 CharactersRobin TanNo ratings yet

- Water-Based Paint Formulations, Vol. 3From EverandWater-Based Paint Formulations, Vol. 3Rating: 4.5 out of 5 stars4.5/5 (6)

- Manual de Reparacion TXV75Document16 pagesManual de Reparacion TXV75Ovh MaquinariasNo ratings yet

- Product Data: Hempel'S 15asgDocument2 pagesProduct Data: Hempel'S 15asgwahyu0% (1)

- Sds d201 Diatro - Lyse-Diff v4.1Document7 pagesSds d201 Diatro - Lyse-Diff v4.1Fauzia BudimanNo ratings yet

- SES Amercoat Dimetcote 9Document4 pagesSES Amercoat Dimetcote 9kamalkashNo ratings yet

- Working at Height PolicyDocument7 pagesWorking at Height PolicyAniekan AkpaidiokNo ratings yet

- Plastipak PresentationDocument28 pagesPlastipak Presentationapi-608970005No ratings yet

- Dimecote 9 Inorganic Zinc Silicate CoatingDocument4 pagesDimecote 9 Inorganic Zinc Silicate Coatingabdulgafoor54No ratings yet

- Aminacid MetabolismDocument84 pagesAminacid MetabolismAaronJose100% (1)

- Outgassing Properties of Vacuum MaterialsDocument47 pagesOutgassing Properties of Vacuum Materialsmax8086No ratings yet

- 5.1 Sumatane HSDocument4 pages5.1 Sumatane HSjnu6mnju6njNo ratings yet

- OA 7855 Permalux Semi Gloss Enamel Product Data: (Exterior/InteriorDocument1 pageOA 7855 Permalux Semi Gloss Enamel Product Data: (Exterior/Interior7981No ratings yet

- Permastic Vinyl Acrylic EmulsionDocument1 pagePermastic Vinyl Acrylic EmulsionCynthia MillerNo ratings yet

- OA 6543 Permagloss Acrylic Emulsion Product Data: (Exterior/InteriorDocument1 pageOA 6543 Permagloss Acrylic Emulsion Product Data: (Exterior/Interior7981No ratings yet

- OA 9010 Road Marking Paint White Product Data: (Exterior/InteriorDocument1 pageOA 9010 Road Marking Paint White Product Data: (Exterior/Interior7981No ratings yet

- OA 9550 Road Marking Paint Yellow Product Data: (Exterior/InteriorDocument1 pageOA 9550 Road Marking Paint Yellow Product Data: (Exterior/Interior7981No ratings yet

- Oasis Ameron 3587 Latex Primer Sealer Product DataDocument1 pageOasis Ameron 3587 Latex Primer Sealer Product Data7981No ratings yet

- MP 2269Document1 pageMP 2269Muneer KonajeNo ratings yet

- Amercoat 450S: Physical DataDocument2 pagesAmercoat 450S: Physical DataKhaled bouhlelNo ratings yet

- Amercoat 68 BSDocument4 pagesAmercoat 68 BSStephen Francis BothelloNo ratings yet

- PN450X PDSDocument4 pagesPN450X PDSPeshteenNo ratings yet

- OA 3957 Red Oxide Primer Product Data: (Exterior/InteriorDocument1 pageOA 3957 Red Oxide Primer Product Data: (Exterior/InteriortshawkyNo ratings yet

- Amercoat 56E Polyamide Epoxy High Solids Tank LiningDocument4 pagesAmercoat 56E Polyamide Epoxy High Solids Tank LiningMuhammad MustahsinNo ratings yet

- Amertex 2269 MP Texture Product Data: (Exterior/InteriorDocument1 pageAmertex 2269 MP Texture Product Data: (Exterior/InteriortshawkyNo ratings yet

- Nu-Klad 114A: Epoxy Filler Compound Product Data/ Application InstructionsDocument4 pagesNu-Klad 114A: Epoxy Filler Compound Product Data/ Application InstructionsCad AutocadNo ratings yet

- Amercoat 391PC: Solvent Free Epoxy Product Data/ Application InstructionsDocument4 pagesAmercoat 391PC: Solvent Free Epoxy Product Data/ Application InstructionsAchraf BoudayaNo ratings yet

- Ameron PN220GDocument4 pagesAmeron PN220GLalit Bom MallaNo ratings yet

- The Paint System: Primer Intermediate CoatsDocument5 pagesThe Paint System: Primer Intermediate CoatsJerome ChuaNo ratings yet

- DS385Document4 pagesDS385gabriel habibNo ratings yet

- Ureprime HS2 TDDocument2 pagesUreprime HS2 TDFredy Xavier DomínguezNo ratings yet

- Amercoat 878: Physical DataDocument2 pagesAmercoat 878: Physical Dataabdulgafoor54No ratings yet

- Amercoat 4801 Glass Flake Vinyl EsterDocument4 pagesAmercoat 4801 Glass Flake Vinyl Esterilyasmd7No ratings yet

- Zinfos 340 Ws Brushing and SprayingDocument2 pagesZinfos 340 Ws Brushing and SprayingjNo ratings yet

- Amercoat 450E: Product Data/ Application InstructionsDocument4 pagesAmercoat 450E: Product Data/ Application Instructions전상문No ratings yet

- Control of The Mat Gloss BalanceDocument3 pagesControl of The Mat Gloss Balancejulio100% (1)

- PN78HBCDocument4 pagesPN78HBCLassadNo ratings yet

- 45881Document3 pages45881amachmouchiNo ratings yet

- Stonclad GR Product DataDocument2 pagesStonclad GR Product DataAnonymous aii1ilNo ratings yet

- 3rd-Temadur 20Document2 pages3rd-Temadur 20Erikas KulpinasNo ratings yet

- Plasite 9133 Product Data SheetDocument3 pagesPlasite 9133 Product Data SheetChris StroudNo ratings yet

- Hempadur Fast Dry 17410 En-GbDocument2 pagesHempadur Fast Dry 17410 En-GbTrịnh Minh KhoaNo ratings yet

- Hempadur Primer 15300Document2 pagesHempadur Primer 15300anto081287No ratings yet

- 0866 Sigmadur - Finish - High - Gloss PDFDocument2 pages0866 Sigmadur - Finish - High - Gloss PDFImtiyaz KhanNo ratings yet

- 050-I0E-028 - Chapter 5 Trouble Shooting Rev.2Document8 pages050-I0E-028 - Chapter 5 Trouble Shooting Rev.2cengiz kutukcuNo ratings yet

- Hempadur Mastic 45880: Page 1 of 2 Issued: January 2010Document2 pagesHempadur Mastic 45880: Page 1 of 2 Issued: January 2010daimaheshNo ratings yet

- PN325 PDSDocument4 pagesPN325 PDSPeshteenNo ratings yet

- Rubber Seam Compound: RC 2200 Is A Unique Rubber Compound That Provides Extremely Effective ForDocument1 pageRubber Seam Compound: RC 2200 Is A Unique Rubber Compound That Provides Extremely Effective Foriman awdNo ratings yet

- Poxeecote-D: High - Build Epoxy CoatingDocument2 pagesPoxeecote-D: High - Build Epoxy CoatingSibgathullahNo ratings yet

- PDS Hempadur 45883Document2 pagesPDS Hempadur 45883Fredy Xavier DomínguezNo ratings yet

- Hempadur Mastic 45881-12170Document3 pagesHempadur Mastic 45881-12170Bang OchimNo ratings yet

- Paint Specification HamadourDocument2 pagesPaint Specification HamadourAbdul Majid LodhiNo ratings yet

- National PaintsPure Epoxy Powder CoatingDocument2 pagesNational PaintsPure Epoxy Powder CoatingMariaAshrafNo ratings yet

- IONYX T2AMicrobial Data SheetDocument5 pagesIONYX T2AMicrobial Data SheetCristian Alejandro Cardenas VillegasNo ratings yet

- WL0060Document2 pagesWL0060KARLA NUÑEZNo ratings yet

- REHAU Relazzo Pardoseala Terasa Pe PicioruseDocument16 pagesREHAU Relazzo Pardoseala Terasa Pe PicioruseAlexandru CeteaNo ratings yet

- OA 3961 Zinc Phosphate Primer Product Data: (Exterior / Interior)Document1 pageOA 3961 Zinc Phosphate Primer Product Data: (Exterior / Interior)tshawkyNo ratings yet

- OA 9564 Red Oxide - F.D. Product Data: Alkyd PrimerDocument1 pageOA 9564 Red Oxide - F.D. Product Data: Alkyd PrimertshawkyNo ratings yet

- Plasite 4310 PDS 1-06Document2 pagesPlasite 4310 PDS 1-06Gerardo FloresNo ratings yet

- Amerlock 2C: Fast Drying High Solids Epoxy Product Data/ Application InstructionsDocument4 pagesAmerlock 2C: Fast Drying High Solids Epoxy Product Data/ Application InstructionsTony KhouryNo ratings yet

- APCS-26T HempelDocument5 pagesAPCS-26T HempelarjunmohananNo ratings yet

- ENGUARD Gelcoatguide 09 03Document12 pagesENGUARD Gelcoatguide 09 03Milu OberoiNo ratings yet

- PDS Hempaprime Multi 500 Winter en-GBDocument2 pagesPDS Hempaprime Multi 500 Winter en-GBFreddyNo ratings yet

- Product Data Sheet: Topaz SG Enamel 524MEDocument2 pagesProduct Data Sheet: Topaz SG Enamel 524METejinder KumarNo ratings yet

- Carboguard 635: Selection & Specification DataDocument5 pagesCarboguard 635: Selection & Specification DataPrakashNo ratings yet

- Hempadur Mastic 45880 & 45881Document2 pagesHempadur Mastic 45880 & 45881Syarif Irwanto100% (1)

- Am 2213Document4 pagesAm 22137981No ratings yet

- Am 65Document1 pageAm 657981No ratings yet

- Am 15Document1 pageAm 157981No ratings yet

- Am 9 HFDocument1 pageAm 9 HF7981No ratings yet

- Oasis Ameron 3587 Latex Primer Sealer Product DataDocument1 pageOasis Ameron 3587 Latex Primer Sealer Product Data7981No ratings yet

- D & C G T G N A. R E S P A, NY 12242: Esign Onstruction Roup HE Overnor Elson Ockefeller Mpire Tate Laza LbanyDocument18 pagesD & C G T G N A. R E S P A, NY 12242: Esign Onstruction Roup HE Overnor Elson Ockefeller Mpire Tate Laza LbanyAlexNo ratings yet

- Quotes by Clarissa Pinkola Estés (Author of Women Who Run With The Wolves)Document1 pageQuotes by Clarissa Pinkola Estés (Author of Women Who Run With The Wolves)Nes GillNo ratings yet

- State-wise list of 376 approved cold chain projectsDocument45 pagesState-wise list of 376 approved cold chain projectsUsha Hasini VelagapudiNo ratings yet

- Fire Safety in Public BuildingDocument48 pagesFire Safety in Public BuildingSamirsinh ParmarNo ratings yet

- Electrical Isolation Work PermitDocument2 pagesElectrical Isolation Work PermitGreg GenoveNo ratings yet

- PN Junction Formation and Barrier PotentialDocument9 pagesPN Junction Formation and Barrier PotentialchristlllNo ratings yet

- Lab Report P2 A1 - IDocument19 pagesLab Report P2 A1 - Inzirh 01No ratings yet

- 2) Coa-Vitamin-Dsm-Lot # XW91707139-146 PDFDocument16 pages2) Coa-Vitamin-Dsm-Lot # XW91707139-146 PDFNaeem AnjumNo ratings yet

- Bone Tumours and MalignanciesDocument55 pagesBone Tumours and MalignanciesFreeburn SimunchembuNo ratings yet

- Complete Dummy's Guide to a Diffusion Pumped Vacuum SystemDocument4 pagesComplete Dummy's Guide to a Diffusion Pumped Vacuum Systemjokerbuddy01No ratings yet

- Klubermatic Lubricant DispensersDocument13 pagesKlubermatic Lubricant Dispenserstatankise100% (1)

- Amidoxime Vanadium U Da Çekiyor SıkıntısıDocument7 pagesAmidoxime Vanadium U Da Çekiyor SıkıntısıMelike AltayNo ratings yet

- Mental Health Lesson on Identity, Grief, Anxiety, OCD, Schizophrenia, and Eating DisordersDocument2 pagesMental Health Lesson on Identity, Grief, Anxiety, OCD, Schizophrenia, and Eating DisordersKaya S75% (4)

- Shortened Dental Arch ConceptDocument3 pagesShortened Dental Arch ConceptVivek ShankarNo ratings yet

- Experiment # 04: Short-Circuit Test of Single Phase TransformerDocument5 pagesExperiment # 04: Short-Circuit Test of Single Phase TransformerNasir Ali / Lab Engineer, Electrical Engineering DepartmentNo ratings yet

- Noise DetectorDocument19 pagesNoise DetectorPlaban Pratim BhuyanNo ratings yet

- Premium detergent market insights and Nirma case studyDocument32 pagesPremium detergent market insights and Nirma case studyBhavya ShahNo ratings yet

- Sub-Zero Icing Your Testicles For Increased Male Performance - MyBioHack Unlock Your Maximus PotentialDocument7 pagesSub-Zero Icing Your Testicles For Increased Male Performance - MyBioHack Unlock Your Maximus PotentialfortnitediscordbgweeNo ratings yet

- Nichita Stanescu - The Poet of Loneliness and LossDocument28 pagesNichita Stanescu - The Poet of Loneliness and LossEmanuelaCiocanNo ratings yet

- Admin, 085 - 799 - Ivan Master Worung - GalleyDocument5 pagesAdmin, 085 - 799 - Ivan Master Worung - GalleyM Ali AdrianNo ratings yet

- Cases Digest on Adoption, Guardianship and Related LawsDocument2 pagesCases Digest on Adoption, Guardianship and Related LawsGillian BrionesNo ratings yet

- Install Panel WallDocument10 pagesInstall Panel WallLuis PalaciosNo ratings yet