Professional Documents

Culture Documents

NA9800000

Uploaded by

Noe floresCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NA9800000

Uploaded by

Noe floresCopyright:

Available Formats

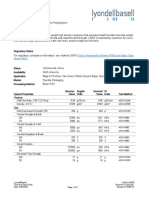

Technical Data Sheet

Petrothene NA980000

Low Density Polyethylene

Product Description

Petrothene NA980000 is a low density homopolymer resin selected by customers for use in shrink packaging,

bundling, pallet wrap and heavy-duty liner applications. NA980000 is also selected by customers for use in blow

molding squeeze bottles and other specialty applications. Excellent bubble stability, melt strength, impact and

shrinkage are key attributes of NA980000.

Regulatory Status

For regulatory compliance information, see Petrothene NA980000 Product Stewardship Bulletin (PSB) and

Safety Data Sheet (SDS).

Status Commercial: Active

Availability North America

Application Agriculture Film; Bags & Pouches; Bottles and Vials; Bottles For Consumer Goods;

Bottles for Industrial Use; Can Liners; Clear Containers; Film Wrap; Food Packaging

Film; Heavy Duty Packaging; Liner Film; Opaque Containers; Shrink Film; Specialty

Film; Textile Packaging Film

Market Flexible Packaging; Rigid Packaging

Processing Method Blown Film; Extrusion Blow Molding

Nominal English Nominal SI

Typical Properties Value Units Value Units Test Method

Physical

Melt Flow Rate, (190 °C/2.16 kg) 0.25 g/10 min 0.25 g/10 min ASTM D1238

Base Resin Density, (23 °C) 0.920 g/cm³ 0.920 g/cm³ ASTM D1505

Product Density, (23 °C) 0.920 g/cm³ 0.920 g/cm³ ASTM D1505

Mechanical

Tensile Strength at Break 2600 psi 17.9 MPa ASTM D638

Tensile Strength at Yield 1420 psi 9.79 MPa ASTM D638

Tensile Elongation at Break 700 % 700 % ASTM D638

Tensile Elongation at Yield 100 % 100 % ASTM D638

Film

Dart Drop Impact Strength, F50 180 g 180 g ASTM D1709

Tensile Strength at Break

MD 3000 psi 20.7 MPa ASTM D882

TD 2800 psi 19.3 MPa ASTM D882

Tensile Elongation at Break

MD 310 % 310 % ASTM D882

TD 430 % 430 % ASTM D882

1% Secant Modulus

MD 30000 psi 207 MPa ASTM D882

TD 35000 psi 241 MPa ASTM D882

Hardness

Shore Hardness, (Shore D) 45 45 ASTM D2240

Thermal

LyondellBasell Petrothene NA980000

Technical Data Sheet Recipient Tracking #:

Date: 4/13/2023 Page 1 of 2 Request #: 4311596

Vicat Softening Temperature 199 °F 93 °C ASTM D1525

Low Temperature Brittleness, Fཥའ -103 °F -75 °C ASTM D746

Additive

Slip None None LYB Method

Antiblock None None LYB Method

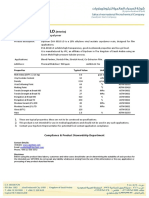

Water Vapor

Transmission

Product Rate Antiblock

Product Density(g/cm³) (g/m²/day) (ppm)

NA980000 0.920 Not Available None

NA983085 0.922 10 4000

Notes

Data obtained from 1.25 mil (32 micron) film produced on a blown film line with a 8" (203 mm) die, 350°F

(177°C) melt temperature, 2:1 BUR, 0.025" die gap at 150 lbs/hr.

These are typical property values not to be construed as specification limits.

Processing Techniques

Specific recommendations for resin type and processing conditions can only be made when the end use,

required properties and fabrication equipment are known.

Company Information

For further information regarding the LyondellBasell company, please visit http://www.lyb.com/.

© LyondellBasell Industries Holdings, B.V. 2018

Disclaimer

Information in this document is accurate to the best of our knowledge at the date of publication. The document is

designed to provide users general information for safe handling, use, processing, storage, transportation,

disposal and release and does not constitute any warranty or quality specification, either express or implied,

including any warranty of merchantability or fitness for any particular purpose. Users shall determine whether the

product is suitable for their use and can be used safely and legally.

In addition to any prohibitions of use specifically noted in this document, LyondellBasell may further prohibit or

restrict the sale of its products into certain applications. For further information, please contact a LyondellBasell

representative.

Trademarks

The Trademark referenced within the product name is owned or used by the LyondellBasell family of companies.

LyondellBasell Petrothene NA980000

Technical Data Sheet Recipient Tracking #:

Date: 4/13/2023 Page 2 of 2 Request #: 4311596

You might also like

- Technical Data SheetDocument2 pagesTechnical Data SheetLeductoan LeNo ratings yet

- LLGA1810Document2 pagesLLGA1810KAKI BELANGNo ratings yet

- Lldpe Petrothene Ga502-024Document2 pagesLldpe Petrothene Ga502-024Noe floresNo ratings yet

- Technical Data Sheet 2021-09-09 05 - 27 - 06Document2 pagesTechnical Data Sheet 2021-09-09 05 - 27 - 06AnderssonNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetEndayenew MollaNo ratings yet

- Petrothene: Technical Data SheetDocument2 pagesPetrothene: Technical Data SheetJaime222No ratings yet

- Petrothene: Technical Data SheetDocument3 pagesPetrothene: Technical Data SheetEli DelgadoNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetihscribedNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetingindjorimaNo ratings yet

- Bapolene 200fDocument2 pagesBapolene 200fDiana SarmientoNo ratings yet

- Product DatasheetDocument1 pageProduct Datasheetأبو أميرNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetIVANCHUNo ratings yet

- Dow Elite 5401G TDSDocument3 pagesDow Elite 5401G TDSAli RazuNo ratings yet

- Technical Data Sheet - ASTM PDFDocument2 pagesTechnical Data Sheet - ASTM PDFnielNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data Sheetnadaelbeltagy4No ratings yet

- Technical Data Sheet - ASTMDocument2 pagesTechnical Data Sheet - ASTMvinayaknttfNo ratings yet

- DoW LDPE 2685GDocument4 pagesDoW LDPE 2685Gtariquekhan143No ratings yet

- Hdpe Alathon H5520 EquistarDocument2 pagesHdpe Alathon H5520 EquistarEric Mahonri PereidaNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetIVANCHUNo ratings yet

- PEADM5372Document2 pagesPEADM5372nicolas yoris marcoglieseNo ratings yet

- Caring Formula High Flow Glass Filled PA6Document3 pagesCaring Formula High Flow Glass Filled PA6ratz23695No ratings yet

- Technical Data Sheet - Original Hoop MaterialDocument2 pagesTechnical Data Sheet - Original Hoop MaterialMichelle Kozmik JirakNo ratings yet

- DOW™ Butene 1220P: Polyethylene ResinDocument1 pageDOW™ Butene 1220P: Polyethylene Resinvantuan17792No ratings yet

- Elite NG 5401BDocument3 pagesElite NG 5401BAbdo WalidNo ratings yet

- High Density Polyethylene Grade Used in Injection Molding Melt Index: 62 Density: 0.942Document2 pagesHigh Density Polyethylene Grade Used in Injection Molding Melt Index: 62 Density: 0.942Phung LucNo ratings yet

- Sabic® Ldpe Hp0322Nn: Low Density PolyethyleneDocument2 pagesSabic® Ldpe Hp0322Nn: Low Density PolyethyleneGabriela Lopez MunozNo ratings yet

- 3812 ExceedDocument2 pages3812 ExceedJimmys GothiqueNo ratings yet

- Lldpe - Sabic® Lldpe - 118NJ PDFDocument2 pagesLldpe - Sabic® Lldpe - 118NJ PDFNilay TanrıverNo ratings yet

- Sabicr Ldpe Hp4023wnDocument2 pagesSabicr Ldpe Hp4023wnFarah bennourNo ratings yet

- LG Chem TDS SP988 EnglishDocument1 pageLG Chem TDS SP988 EnglishSérgio BarbosaNo ratings yet

- TDS EVA 0818 LO - InterimDocument1 pageTDS EVA 0818 LO - InterimAnas AbdoNo ratings yet

- HDPE Product Data SheetDocument2 pagesHDPE Product Data SheetingindjorimaNo ratings yet

- Alathon®: ApplicationsDocument2 pagesAlathon®: ApplicationsCarlos Revilla FloresNo ratings yet

- Lldpe - LL7410D PDSDocument1 pageLldpe - LL7410D PDSchinchotarngNo ratings yet

- Microthene: Technical Data SheetDocument2 pagesMicrothene: Technical Data SheetJaime222No ratings yet

- ELITE 5401G: Blown Film ResinDocument2 pagesELITE 5401G: Blown Film ResinEndayenew MollaNo ratings yet

- High Density Polyethylene (HDPE Injection) : Technical Data SheetDocument1 pageHigh Density Polyethylene (HDPE Injection) : Technical Data SheetEleannys GarciasNo ratings yet

- High Performance Stretch Film ResinDocument3 pagesHigh Performance Stretch Film Resinujang sukartaNo ratings yet

- Exxonmobil™ Hdpe Hta 108: High Density Polyethylene ResinDocument2 pagesExxonmobil™ Hdpe Hta 108: High Density Polyethylene ResinCristian RodriguezNo ratings yet

- Pei 0270 RTP 2183Document2 pagesPei 0270 RTP 2183Vincent NguyenNo ratings yet

- Total PPR 7238 Polypropylene Random Copolymer Blow MoldingDocument1 pageTotal PPR 7238 Polypropylene Random Copolymer Blow Moldingquanghoang10986No ratings yet

- TDS Emeraude Ldpe Lf2021e - V 2.3Document1 pageTDS Emeraude Ldpe Lf2021e - V 2.3Gabriela Lopez MunozNo ratings yet

- Sabic Hdpe B5429: High Density PolyethyleneDocument2 pagesSabic Hdpe B5429: High Density Polyethylenegetasew altasebNo ratings yet

- Exceed™ XP 8318MJ: Performance PolymerDocument2 pagesExceed™ XP 8318MJ: Performance PolymerMaram YasserNo ratings yet

- Adflex Q100FDocument2 pagesAdflex Q100FAna Maria MuresanNo ratings yet

- TDS - LD 2023 CC PDFDocument1 pageTDS - LD 2023 CC PDFYasir SiddiquiNo ratings yet

- Marlex D139 Polyethylene: Nominal Resin Properties English SI MethodDocument1 pageMarlex D139 Polyethylene: Nominal Resin Properties English SI MethodGabriela Lopez MunozNo ratings yet

- SABIC® LDPE - HP2023JN - Global - Technical - Data - SheetDocument2 pagesSABIC® LDPE - HP2023JN - Global - Technical - Data - SheetSarvesh SinghNo ratings yet

- Durastar DS1910HFDocument2 pagesDurastar DS1910HFEvelyn SigoliNo ratings yet

- CEFOR™ 1221P: Linear Low Density Polyethylene ResinDocument3 pagesCEFOR™ 1221P: Linear Low Density Polyethylene ResincuppycuppycupNo ratings yet

- Unival™ Dmdg-6200 NT 7: High Density Polyethylene ResinDocument3 pagesUnival™ Dmdg-6200 NT 7: High Density Polyethylene Resinyesenia flores rosadoNo ratings yet

- SABIC® LDPE - HP2022NN - Global - Technical - Data - SheetDocument2 pagesSABIC® LDPE - HP2022NN - Global - Technical - Data - Sheetselman gürbüzNo ratings yet

- TKC 2007N NA 82V TITAN Technical Data SheetDocument1 pageTKC 2007N NA 82V TITAN Technical Data SheetEduardo MazariegosNo ratings yet

- LLDPE - Lotrene Q1018N PDFDocument2 pagesLLDPE - Lotrene Q1018N PDFNilay TanrıverNo ratings yet

- Sabic Lldpe 118Wsj: Linear Low Density PolyethyleneDocument2 pagesSabic Lldpe 118Wsj: Linear Low Density PolyethyleneFahad MohamedNo ratings yet

- ELITE™ AT 6111: Enhanced Polyethylene ResinDocument3 pagesELITE™ AT 6111: Enhanced Polyethylene ResinRoberto De Mesa PNo ratings yet

- Q2018 Series: Linear Low Density Polyethylene (LLDPE)Document2 pagesQ2018 Series: Linear Low Density Polyethylene (LLDPE)lyesNo ratings yet

- Q1018 Series: Linear Low Density Polyethylene (LLDPE)Document2 pagesQ1018 Series: Linear Low Density Polyethylene (LLDPE)lyesNo ratings yet

- Sigmacover™ 456: Product Data SheetDocument6 pagesSigmacover™ 456: Product Data SheetscottNo ratings yet

- Dayton Close Coupled Centrifugal Pumps OIPM PDFDocument48 pagesDayton Close Coupled Centrifugal Pumps OIPM PDFstepa79No ratings yet

- TerraMaster End User License & Warranty Agreement - enDocument9 pagesTerraMaster End User License & Warranty Agreement - enfelix_scribdNo ratings yet

- Michem® Guard 349: Technical Data SheetDocument3 pagesMichem® Guard 349: Technical Data Sheetsriatul2006No ratings yet

- Hi! Let's Get Started.: 4-Series S431/S433/S435Document16 pagesHi! Let's Get Started.: 4-Series S431/S433/S435Juan Sanchez GarciaNo ratings yet

- IEEE Recommended Practice For Sizing Nickel-Cadmium Batteries For Stationary ApplicationsDocument7 pagesIEEE Recommended Practice For Sizing Nickel-Cadmium Batteries For Stationary ApplicationssathyasonyNo ratings yet

- Basic Service Manual: MototrboDocument102 pagesBasic Service Manual: MototrboAlex GomezNo ratings yet

- Lincoln ER CuNiDocument2 pagesLincoln ER CuNiLuis DuarteNo ratings yet

- MSCI ESG Ratings Methodology - Exec Summary 2019Document16 pagesMSCI ESG Ratings Methodology - Exec Summary 2019anon_244626589100% (1)

- RFLIB Chapter 4Document12 pagesRFLIB Chapter 4CJ Tin100% (1)

- M101 99Document91 pagesM101 99Rolando MorochoNo ratings yet

- Lexmark C734n, C734dn, C734dnw, C736n, C736dn, CS736dn Service ManualDocument470 pagesLexmark C734n, C734dn, C734dnw, C736n, C736dn, CS736dn Service ManualJoan Manuel Sánchez Gómez100% (1)

- 317 Art. 1561 Obligations of The Vendor Conditions and Warranties 318 Sales Art. 1561Document9 pages317 Art. 1561 Obligations of The Vendor Conditions and Warranties 318 Sales Art. 1561elaineNo ratings yet

- Sale of Goods Act 1930Document33 pagesSale of Goods Act 1930Tannu RadhaNo ratings yet

- Manual L 850c IrelDocument66 pagesManual L 850c IrelLabinot KutllovciNo ratings yet

- Best Practices For Tensorrt PerformanceDocument20 pagesBest Practices For Tensorrt PerformanceacabaNo ratings yet

- OpenDSS ManualDocument214 pagesOpenDSS ManualDavis MontenegroNo ratings yet

- Contract of Sale, Agency and Credit TransactionDocument24 pagesContract of Sale, Agency and Credit TransactionJovy Sobrevilla DimpoNo ratings yet

- EZVIZ Camera - Guide Démarrage RapideDocument34 pagesEZVIZ Camera - Guide Démarrage Rapiderom1486No ratings yet

- Sales Contract Conditions, Warranties and Eviction LiabilityDocument28 pagesSales Contract Conditions, Warranties and Eviction Liabilitymmc_clinicNo ratings yet

- LC-2 ManualDocument13 pagesLC-2 ManualSeaBass2013No ratings yet

- Bolt-Down Instructions: Coffre-Fort de Sécurité Manuel Du PropriétaireDocument4 pagesBolt-Down Instructions: Coffre-Fort de Sécurité Manuel Du PropriétaireAgustin Martinez HernandezNo ratings yet

- Carvaan GO warranty detailsDocument4 pagesCarvaan GO warranty detailsAshm-ashu SharmaNo ratings yet

- IR1025 Series Basic Op GuideDocument327 pagesIR1025 Series Basic Op GuideenzureNo ratings yet

- Ieee 1018-04Document38 pagesIeee 1018-04Jose Antonio EstofaneroNo ratings yet

- Directv Blue or Black Remote Control ManualDocument32 pagesDirectv Blue or Black Remote Control ManualJose Luis ValenciaNo ratings yet

- Ashley Furniture Industries, Inc. Arcadia, Wisconsin 54612Document4 pagesAshley Furniture Industries, Inc. Arcadia, Wisconsin 54612picfixerNo ratings yet

- PowerFlex 70 - 700 Drive - Parameters To Configure Dynamic Braking ResistorDocument2 pagesPowerFlex 70 - 700 Drive - Parameters To Configure Dynamic Braking ResistorHenrique MartinatoNo ratings yet

- SAW Flux StorageDocument2 pagesSAW Flux StorageTrung Tinh HoNo ratings yet

- Bunn Thermofresh ManualDocument14 pagesBunn Thermofresh ManualBornToSparkle100% (1)