Professional Documents

Culture Documents

HDPE Product Data Sheet

Uploaded by

ingindjorimaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HDPE Product Data Sheet

Uploaded by

ingindjorimaCopyright:

Available Formats

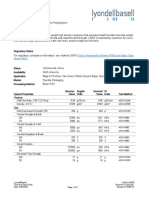

PRODUCT DATA SHEET

HDPE HDPE HDPE HDPE HDPE HDPE HDPE HDPE HDPE HDPE HDPE

Technical support: Sales office:

High Density Polyethylene Sasol Chemicals Sasol Chemicals

North America LLC North America LLC

12120 Wickchester Lane 12120 Wickchester Lane

Houston, TX 77079 Houston, TX 77079

Telephone: (281) 588 3000

HD5208 FLX Email:

PolymersTechnical@us.sasol.com

Email:

PolymersSales@us.sasol.com

Date of issue February 01, 2019 www.sasol.com

High Load Melt Index: 9.0 g/10min Density: 0.952 g/cm³

Features Potential Applications Additives

• High molecular weight hexene copolymer • Thin films for trash can liners, t-shirt • Antioxidant

HDPE with a bimodal molecular weight bags, merchandise bags, produce bags

distribution. and roll stock.

• Excellent draw-down for thin films. • Thick film for multi use applications.

• Bubble stability for high rates.

• Good balance of stiffness and toughness.

Typical properties (not to be construed as specifications) Value (English) Value (SI) Method

Melt Index (190°C/2.16kg) 0.057 g/10min 0.057 g/10min ASTM D1238

Resin

Properties High Load Melt Index (190°C/21.6 kg load) 9.0 g/10min 9.0 g/10min ASTM D1238

Density 0.952 g/cm³ 0.952 g/cm³ ASTM D4883

Tensile Strength at Yield MD 4500 psi 31 MPa ASTM D882

Tensile Strength at Yield TD 3900 psi 27 MPa ASTM D882

Tensile Strength at Break MD 11000 psi 76 MPa ASTM D882

Tensile Strength at Break TD 7000 psi 48 MPa ASTM D882

Elongation at Break MD >250 % >250 % ASTM D882

Physical Elongation at Break TD >350 % >350 % ASTM D882

Properties

1% Secant Modulus MD 112000 psi 772 MPa ASTM D882

1% Secant Modulus TD 139000 psi 958 MPa ASTM D882

Dart Drop Impact 350 g 350 g ASTM D1709

Elmendorf Tear MD 37 g 37 g ASTM 1922

Elmendorf Tear TD 83 g 83 g ASTM 1922

HOU-TDS-HD5208FL, Issue Date: February 01, 2019 1

HDPE HDPE HDPE HDPE HDPE HDPE HDPE HDPE HDPE HDPE HDPE

Handling

Workers should be protected from the possibility of skin or eye contact with molten polymer. Safety glasses are suggested as

a minimal protection to prevent possible mechanical or thermal injury to the eyes. Fabrication areas should be ventilated to

carry away fumes or vapours.

Storage

As ultraviolet light may cause a change in the material, all resins should be protected from direct sunlight during storage.

Combustibility

Polyethylene resins will burn when supplied adequate heat and oxygen. They should be handled and stored away from

contact with direct flames and/or other ignition sources. In burning, polyethylene resins contribute high heat and may generate

a dense black smoke. Fires can be extinguished by conventional means with water and water mist preferred. In enclosed

areas, fire fighters should be provided with self contained breathing apparatus.

Conveying

Conveying equipment should be designed to prevent accumulation of fines and dust particles that are contained in all

polyethylene resins. These fines and dust particles can, under certain conditions, pose an explosion hazard. We recommend

that the conveying system used:

1. be equipped with adequate filters

2. is operated and maintained in such a manner to ensure no leaks develop

3. that adequate grounding exists at all times

It is further recommended that good housekeeping is practiced throughout the facility.

This publication contains information provided in good faith and is indicative, based on Sasol’s current knowledge on the subject. No guarantee or warranty is intended or implied. We

reserve the right to make changes as a result of technological progress or development. Any information, including suggestions for use of products, should not preclude

experimental testing and verification, to ensure the suitability of a product for each specific application. Users must also abide by local and international laws and obtain all necessary

permits when required to do so. Prior to handling a hazardous product, consult it’s safety data sheet. In case of questions or queries, please contact Sasol through our customer

service channels. All products purchased from Sasol Chemicals are subject to the terms and conditions as set out in the contract, order confirmation and/or bill of lading.

HOU-TDS-HD5208FL, Issue Date: February 01, 2019 2

You might also like

- Example 1-Special Moment FramesDocument16 pagesExample 1-Special Moment FramestoshicrystalNo ratings yet

- Bottles, Preforms and Closures: A Design Guide for PET PackagingFrom EverandBottles, Preforms and Closures: A Design Guide for PET PackagingRating: 4.5 out of 5 stars4.5/5 (3)

- GRP and Buildings: A Design Guide for Architects and EngineersFrom EverandGRP and Buildings: A Design Guide for Architects and EngineersNo ratings yet

- Composite Engineering MaterialsDocument69 pagesComposite Engineering MaterialsvialmaNo ratings yet

- En 10297-1-2003Document46 pagesEn 10297-1-2003Mircea VladNo ratings yet

- Temperature Effect On ConcreteDocument8 pagesTemperature Effect On ConcreteArif AliNo ratings yet

- Refrigeration and Air Conditioning - Jordan-PriesterDocument532 pagesRefrigeration and Air Conditioning - Jordan-PriesterJuan Jerez67% (3)

- Muscat International Airport plaster specificationDocument23 pagesMuscat International Airport plaster specificationDiana Alexandra Comaromi0% (1)

- Astm d4065 PDFDocument7 pagesAstm d4065 PDFradziNo ratings yet

- Benchmarks in AbaqusDocument1,738 pagesBenchmarks in AbaqusAnonymous LcR6ykPBTNo ratings yet

- WSS M2P180 DDocument12 pagesWSS M2P180 DJuan Angel DechimaNo ratings yet

- Short Circuit CalculationDocument57 pagesShort Circuit CalculationBrenda Naranjo MorenoNo ratings yet

- Marlex D139 Polyethylene: Nominal Resin Properties English SI MethodDocument1 pageMarlex D139 Polyethylene: Nominal Resin Properties English SI MethodGabriela Lopez MunozNo ratings yet

- Hdpe HD 7845.30Document2 pagesHdpe HD 7845.30Cristian RodriguezNo ratings yet

- Chevron_Phillips_Marlex_D139Document1 pageChevron_Phillips_Marlex_D139AthonioMourinhoNo ratings yet

- Exxonmobil™ Lldpe Ll1001Xbu: Linear Low Density Polyethylene ResinDocument2 pagesExxonmobil™ Lldpe Ll1001Xbu: Linear Low Density Polyethylene ResinchinchotarngNo ratings yet

- NA9800000Document2 pagesNA9800000Noe floresNo ratings yet

- Exxonmobil™ Hdpe Hta 108: High Density Polyethylene ResinDocument2 pagesExxonmobil™ Hdpe Hta 108: High Density Polyethylene ResinCristian RodriguezNo ratings yet

- D139FKDocument1 pageD139FKsonhungdoanNo ratings yet

- Product DatasheetDocument1 pageProduct Datasheetأبو أميرNo ratings yet

- TDS Pe 200 SF5007Document2 pagesTDS Pe 200 SF5007Oktaviandri SaputraNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetLeductoan LeNo ratings yet

- Hdpe H5604FDocument2 pagesHdpe H5604Fakankshas06No ratings yet

- Taisox 7350Document1 pageTaisox 7350Retno ElakadesciNo ratings yet

- Elite NG 5401BDocument3 pagesElite NG 5401BAbdo WalidNo ratings yet

- TDS Emeraude Ldpe Lf2021e - V 2.3Document1 pageTDS Emeraude Ldpe Lf2021e - V 2.3Gabriela Lopez MunozNo ratings yet

- TDS SCGC PP P348S Rev Mar2022Document3 pagesTDS SCGC PP P348S Rev Mar2022y.s.6saputroNo ratings yet

- Product Data Sheet for SCGC PP P303SDocument3 pagesProduct Data Sheet for SCGC PP P303Sy.s.6saputroNo ratings yet

- Marlex TRB-115 PolyethyleneDocument1 pageMarlex TRB-115 PolyethyleneSeyfullah Akan KarapaçaNo ratings yet

- 3812 ExceedDocument2 pages3812 ExceedJimmys GothiqueNo ratings yet

- Mpact D143: Metallocene Linear Low Density PolyethyleneDocument1 pageMpact D143: Metallocene Linear Low Density PolyethyleneJulio GarcíaNo ratings yet

- Exceed 1012HA PDFDocument2 pagesExceed 1012HA PDFEdgar CascoNo ratings yet

- enDocument2 pagesenabdelmoumene djafer beyNo ratings yet

- LLDPE Film Product Data SheetDocument2 pagesLLDPE Film Product Data SheetManufaktur Sinar JoyoboyoNo ratings yet

- Exceed 1012MK PDFDocument2 pagesExceed 1012MK PDFEdgar CascoNo ratings yet

- TDS Pe 008 Up4806hDocument2 pagesTDS Pe 008 Up4806hariefNo ratings yet

- Alathon®: ApplicationsDocument2 pagesAlathon®: ApplicationsCarlos Revilla FloresNo ratings yet

- Tds DGDX 6097 Astm ButeneDocument2 pagesTds DGDX 6097 Astm ButeneLakshay UniplarNo ratings yet

- PEADM5372Document2 pagesPEADM5372nicolas yoris marcoglieseNo ratings yet

- Tricolene HDF10952: High Density Polyethylene ResinDocument1 pageTricolene HDF10952: High Density Polyethylene ResinLFCV5No ratings yet

- SABIC® SUPEER™ - VM006 PROVISIONAL DATA SHEET - Global - Technical - Data - SheetDocument2 pagesSABIC® SUPEER™ - VM006 PROVISIONAL DATA SHEET - Global - Technical - Data - SheetAna Maria MuresanNo ratings yet

- LLGA1810Document2 pagesLLGA1810KAKI BELANGNo ratings yet

- Low Density Polyethylene: DescriptionDocument2 pagesLow Density Polyethylene: DescriptionlyesNo ratings yet

- TDS DGDZ 6097 ASTM HexeneDocument2 pagesTDS DGDZ 6097 ASTM HexenegauravmishraanalystNo ratings yet

- PP Trilene Hi10hoDocument2 pagesPP Trilene Hi10hoLaili AzkiyahNo ratings yet

- 1661ff33-51be - ZA - LF2103 Film - EN-ZADocument2 pages1661ff33-51be - ZA - LF2103 Film - EN-ZApepeNo ratings yet

- TDS Pe 100 Ub5206h 02 PDFDocument2 pagesTDS Pe 100 Ub5206h 02 PDFOktaviandri SaputraNo ratings yet

- TDS Pe 100 Ub5206h 01 PDFDocument2 pagesTDS Pe 100 Ub5206h 01 PDFOktaviandri SaputraNo ratings yet

- LDPE C2923 - Con AditivosDocument1 pageLDPE C2923 - Con Aditivosedinson100% (1)

- Low Density Polyethylene: DescriptionDocument2 pagesLow Density Polyethylene: DescriptionlyesNo ratings yet

- Polymer Production Capacity Projections for 2009Document27 pagesPolymer Production Capacity Projections for 2009al-maaliNo ratings yet

- Exceed™ 1018KB: Metallocene Polyethylene ResinDocument2 pagesExceed™ 1018KB: Metallocene Polyethylene ResinHafiani HichamNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetihscribedNo ratings yet

- Technical Data Sheet 2021-09-09 05 - 27 - 06Document2 pagesTechnical Data Sheet 2021-09-09 05 - 27 - 06AnderssonNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetEndayenew MollaNo ratings yet

- Lldpe Ga564189Document3 pagesLldpe Ga564189xy2zjgNo ratings yet

- Petrothene: Technical Data SheetDocument3 pagesPetrothene: Technical Data SheetEli DelgadoNo ratings yet

- At-N70 NC006 Tds-En - 071049Document2 pagesAt-N70 NC006 Tds-En - 071049Thunder StromNo ratings yet

- High Density Polyethylene Grade Used in Injection Molding Melt Index: 62 Density: 0.942Document2 pagesHigh Density Polyethylene Grade Used in Injection Molding Melt Index: 62 Density: 0.942Phung LucNo ratings yet

- Low Density Polyethylene: DescriptionDocument2 pagesLow Density Polyethylene: DescriptionlyesNo ratings yet

- TDS Pe 201 Sf5008eDocument2 pagesTDS Pe 201 Sf5008eOktaviandri SaputraNo ratings yet

- Hdpe Alathon H5520 EquistarDocument2 pagesHdpe Alathon H5520 EquistarEric Mahonri PereidaNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetingindjorimaNo ratings yet

- HD7000F High Density Polyethylene Film GradeDocument2 pagesHD7000F High Density Polyethylene Film GradePhuoc TranNo ratings yet

- Taisox 8001Document2 pagesTaisox 8001Le Minh TuanNo ratings yet

- Exceed 3518Document2 pagesExceed 3518Jimmys GothiqueNo ratings yet

- Exceed 3518Document2 pagesExceed 3518Amin PanNo ratings yet

- Low Density Polyethylene: DescriptionDocument2 pagesLow Density Polyethylene: DescriptionlyesNo ratings yet

- 02 Bab IiDocument2 pages02 Bab IiariefNo ratings yet

- HD5208 FL: Safety Data SheetDocument9 pagesHD5208 FL: Safety Data SheetingindjorimaNo ratings yet

- Mpg-85842 Thank You Millenium (29+16) 53cm C 48 Rojo 485-c Cn1000Document1 pageMpg-85842 Thank You Millenium (29+16) 53cm C 48 Rojo 485-c Cn1000ingindjorimaNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetingindjorimaNo ratings yet

- HDPE Product Data SheetDocument2 pagesHDPE Product Data SheetingindjorimaNo ratings yet

- HDPE Product Data SheetDocument2 pagesHDPE Product Data SheetingindjorimaNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetingindjorimaNo ratings yet

- HDPE Product Data SheetDocument2 pagesHDPE Product Data SheetingindjorimaNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetingindjorimaNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetingindjorimaNo ratings yet

- HD5208 FL: Safety Data SheetDocument9 pagesHD5208 FL: Safety Data SheetingindjorimaNo ratings yet

- PlasticsBrochure WB1280B 0913 LoresDocument40 pagesPlasticsBrochure WB1280B 0913 LoresingindjorimaNo ratings yet

- Elvax 460Document3 pagesElvax 460ingindjorimaNo ratings yet

- IPS E-Max CADDocument30 pagesIPS E-Max CADZé Miguel100% (1)

- Structural Design of Buried Corrugated Polyethylene Pipes: R. K. M. EDocument9 pagesStructural Design of Buried Corrugated Polyethylene Pipes: R. K. M. EElvi PapajNo ratings yet

- Zeta Tray Icms 3Document13 pagesZeta Tray Icms 3Sebin KvNo ratings yet

- Advanced Ceramics - The New Frontier in Modern-Day Technology: Part IDocument9 pagesAdvanced Ceramics - The New Frontier in Modern-Day Technology: Part IAbdi EphremNo ratings yet

- 3M 5386Document2 pages3M 5386monkey1929No ratings yet

- Stirling Engine Project ReportDocument39 pagesStirling Engine Project Reportapi-328800450100% (2)

- Roofing ShinglesDocument4 pagesRoofing ShinglesFaizal HaziziNo ratings yet

- Evaporative Air Cooler ManualDocument10 pagesEvaporative Air Cooler Manualinnovates1No ratings yet

- CATALOGUE AHU DDW C 50 MMDocument11 pagesCATALOGUE AHU DDW C 50 MMGeorge H. Gutierrez, PECSANo ratings yet

- Remmers Kiesol C - Horizontal Barrier: Quick and Easy Injection Due To Its Cream ConsistenceDocument4 pagesRemmers Kiesol C - Horizontal Barrier: Quick and Easy Injection Due To Its Cream ConsistenceAjayNo ratings yet

- TFP338 12 2019Document4 pagesTFP338 12 2019pippoNo ratings yet

- Fresh Intellivent Mechanical Ventilation SystemDocument4 pagesFresh Intellivent Mechanical Ventilation Systemandrewnacho22No ratings yet

- 414CC3 Excel Template Prelim Shell and Tube Heat Exchanger Design Si UnitsDocument3 pages414CC3 Excel Template Prelim Shell and Tube Heat Exchanger Design Si UnitsGuruh Mehra MulyanaNo ratings yet

- The Phases of MatterDocument6 pagesThe Phases of MatterbettynogpoNo ratings yet

- Rezumate AllDocument116 pagesRezumate AllraduonoNo ratings yet

- Brazier LoadsDocument12 pagesBrazier LoadsManoj ManoharanNo ratings yet

- PIPING SYSTEMS ARRANGEMENTDocument19 pagesPIPING SYSTEMS ARRANGEMENTNur SalimNo ratings yet

- Engineering Properties of PolypropyleneDocument2 pagesEngineering Properties of Polypropylenesimonorr17No ratings yet

- Wrought Alloys for Orthodontic ApplicationsDocument33 pagesWrought Alloys for Orthodontic ApplicationsKanjiMasroorNo ratings yet

- Home Experiment For Measuring The Latent Heat of IceDocument2 pagesHome Experiment For Measuring The Latent Heat of IcechlronaldNo ratings yet