Professional Documents

Culture Documents

Comecer (Bbst-Series) Ien

Uploaded by

Fernando OliveiraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Comecer (Bbst-Series) Ien

Uploaded by

Fernando OliveiraCopyright:

Available Formats

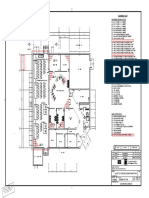

BBST SERIES

SHIELDED ISOLATORS FOR DISPENSING

Modular design and flexible configuration

Work chamber with air quality complying with

Class A “At rest” (EEC-cGMP) and equipped with

laminar flow over the entire area

Product extraction system in shielded container by

means of specific drawer

Dose calibrator compartment equipped with

pneumatic system to move the vial in the well

Shielded chambers under constant negative pressure

The series of BBST shielded cells is a Features and Benefits

family of Class A isolators equipped --Possibility of installing material in- --Air outlet filtration system made with

with laminar flow on the entire main troduction chamber (airlock) with air active carbon filtering cartridge

chamber. They can house automatic quality complying with Class B ’’At --7” touch-screen operator panel to

modules or fractioning systems in rest’’ (EEC-cGMP) and equipped with check and trace the critical param-

sterile conditions and in observance of handling gloves eters of the machine both in “at rest”

cGMP regulations. --Possibility of installing waste com- or “in operation” mode

The BBST series is specifically designed partment with air quality complying --Tele-pliers on special ball bearings for

for filling, calibrating and fractioning op- with Class B “At rest” (EEC-cGMP) high sensitivity and precision-move-

erations on vials/syringes. The equip- --Possibility of installing a product ex- ment handling

ment is ideal for small/medium produc- traction system equipped with “Pass- --Possibility of installing a Geiger-Muller

tions of vials and, upon express request, through dose calibrator” probe to detect radioactivity inside the

for small productions of syringes. --Possibility of setting up connection synthesis and dispensing cell and

The cell guarantees maximum protec- and integration with COMECER auto- door interlock management

tion for the operator against ionising ra- matic dispensers --Possibility of installing ventilation iso-

diation through complete shielding, the --Shielded and hinged front doors lation valves and connection to hydro-

air seal between the chambers and the --Chambers tightness ensured by inflat- gen peroxide solution generators (AVC

use of tele-pliers. These characteristics, able gasket system, placed on the pe- LIGHT) for the dispensing chamber

along with the integrated tools such as rimeter of the openings and the material introduction chamber

the COMECER automatic dispensers, --Filtration system to generate laminar --Possibility of installing automatic leak

make it particularly suitable for radio- flow in the Class A chamber, made tests system on the dispensing cham-

pharmaceutical dose preparation, in ac- with ULPA U15 absolute filtering car- ber and material introduction cham-

cordance with cGMP regulations. tridge ber

--Filtration system for Class B cham-

bers with HEPA H14 absolute filtering

cartridge

NUCLEAR MEDICINE SHIELDED HOT CELLS

Equipment lines

The machine is available in different equipment lines to fulfil the requirements of any production centre.

WITH PASS THROUGH

SYRINGE DISPENSER

SYRINGE DISPENSER

SYRINGE DISPENSER

WITH SOLID WASTE

DOSE CALIBRATOR

BBST-PC VIAL AND

BBST-PC VIAL AND

BBST-PC VIAL AND

AND SOLID WASTE

DISPENSER BASIC

DISPENSER WITH

Models

BBST COMPACT

BBST-PC VIAL

BBST-PC VIAL

SOLID WASTE

Main equipment

Side pharmaceutical pre-chamber for materials introduction - S S S S S

Solid waste compartment - - S - S S

Dose calibrator S S S S S S

Pass through dose calibrator - - - - - S

Smart Geiger (internal environmental monitoring system) O O O O O O

Automatic Bubble Point Test S S S S S S

Drawing System

Drawing System for vials S S S - - -

Drawing System for vials and syringes - - - S S -

Drawing System for vials and syringes with

- - - - - S

integrated pass through calibrator

Final product extraction position

Front Drawing System drawer opening S S S S S S

Rear Drawing System drawer opening O O O O O O

Side Drawing System drawer opening - - - - - O

Dispenser set-up

GET dispensing system set-up O O O O O O

TIMOTHEO LT dispensing system set-up O O O O O O

ARGO dispensing system set-up O O O O O O

S= Standard; O= Option; R= Configurable when placing order

Technical data

Support frame material Carbon steel treated with epoxy paints

External casing material AISI 304 - Scotch-BriteTM

Working chamber material AISI 316L - Mirror-Bright

Lead purity Title Pb 98% + Sb 2%

Electrical panel protection rating IP 54

Shielding (Pb) mm 75

Shielded glass window dimensions mm 200 x 200 (w x h)

Weight kg from 5700 to 8100

Working chamber internal dimensions mm 594 x 587 x 662 (w x d x h)

Internal pre-chamber dimensions (if applicable) mm 559 x 742 x 499 (w x d x h)

External dimensions with pre-chamber mm 1680 x 1090 x 2400 (w x d x h)

External dimensions without pre-chamber mm 1060 x 1090 x 2400 (w x d x h)

Ventilation and Filters

Air classification: Class “A” with laminar flow (LAF) on the entire area

Air inlet: F9 pre-filter and U15 absolute filter

Dispensing chamber

Air outlet: active carbon filter

Air flow rate: 100 m³/h

2016-12 | All rights reserved | DS_BBST-SERIES_R6_ENG

Air classification: Class “B”

Air inlet: H14 absolute filter

Pre-chamber for materials introduction (if applicable)

Air outlet: H14 absolute filter

Air flow rate: 20 m³/h

Air classification: Class “B”

Air inlet: H14 absolute filter

Drawing System for vials/syringes

Air outlet: active carbon filter

Air flow rate: 10 m³/h

Air classification: Class “B”

Air inlet: H14 absolute filter

Solid Waste Compartment (if applicable)

Air outlet: active carbon filter

Air flow rate: 10 m³/h

BBST SERIES - SHIELDED ISOLATORS FOR DISPENSING

COMECER S.p.A. Via Maestri del Lavoro 90

4801 Castel Bolognese (RA) Italy T +39 0546 6537 F +39 0546 653

comecer@comecer.com www.comecer.com http://www.comecer.com/bbst

aP rt of COMECERGROUP

You might also like

- Combi: Packaged Pretreatment System For Sewage and Septage ReceivingDocument2 pagesCombi: Packaged Pretreatment System For Sewage and Septage Receivinglifemillion2847No ratings yet

- Pouch Li-Ion Cell Pilot Assembly LineDocument3 pagesPouch Li-Ion Cell Pilot Assembly Linevenugopalan srinivasan100% (1)

- HED Broschuere Giessharz-Isolierung enDocument7 pagesHED Broschuere Giessharz-Isolierung enAbhinav KumarNo ratings yet

- BOGE Compressed Air Filters: Maximum Energy SavingsDocument2 pagesBOGE Compressed Air Filters: Maximum Energy SavingsRUN GONo ratings yet

- 205 en Cyclone-Separator 20200403Document2 pages205 en Cyclone-Separator 20200403Abid HameedNo ratings yet

- Elgin Hydrocyclone Cut Sheet 2019Document1 pageElgin Hydrocyclone Cut Sheet 2019Andrew GoadNo ratings yet

- 205 - EN - Cyclone - Separator - 2Document2 pages205 - EN - Cyclone - Separator - 2Nguyễn ĐứcNo ratings yet

- Inline Powder Wetting-YstralDocument3 pagesInline Powder Wetting-Ystralpsvel123No ratings yet

- CUOBOGASDocument4 pagesCUOBOGASDiego Fernando Pedroza UribeNo ratings yet

- Rocks / Aggregates: Bulk Density and Voids MeasuresDocument4 pagesRocks / Aggregates: Bulk Density and Voids Measuresshinichi saikoNo ratings yet

- CSM-CV Single and Multistage PumpsDocument20 pagesCSM-CV Single and Multistage PumpsNavinNo ratings yet

- KIRK KSEP Separator Internals 2012Document5 pagesKIRK KSEP Separator Internals 2012TesisAyF ProyectoNo ratings yet

- MCCB Distribution Panel CatalogueDocument12 pagesMCCB Distribution Panel CatalogueAbdul BasithNo ratings yet

- Seprador de MaterialesDocument2 pagesSeprador de MaterialesJulio CNo ratings yet

- Sea Pixel: Electronic SortingDocument8 pagesSea Pixel: Electronic SortingAna VioletaNo ratings yet

- Amtronic Smartronic en DataDocument6 pagesAmtronic Smartronic en DatahtorresnajeraNo ratings yet

- Corrugated Plate Separator (CPS) ForDocument2 pagesCorrugated Plate Separator (CPS) Formib_ajayNo ratings yet

- P-325E Copper Tube ProductionDocument24 pagesP-325E Copper Tube ProductionThilagam Manie RathinaNo ratings yet

- DottBonapace Suppository BP-2 BP-10Document3 pagesDottBonapace Suppository BP-2 BP-10diegoh_silvaNo ratings yet

- Minilec MBAS0600 Alarm AnnunciatorsDocument10 pagesMinilec MBAS0600 Alarm Annunciatorssourav_v2004No ratings yet

- Definition of Instrumentation in Process FieldDocument6 pagesDefinition of Instrumentation in Process FieldJehangir PhoneNo ratings yet

- MEP - Preform - UkDocument5 pagesMEP - Preform - UkLuiz HenriqueNo ratings yet

- ACAF Fire Suppression BrochureDocument4 pagesACAF Fire Suppression Brochure1029384765qazwsxNo ratings yet

- Johnson Control Sabroe A-Frame VSD PanelDocument2 pagesJohnson Control Sabroe A-Frame VSD PanelMuhammad AzriNo ratings yet

- Ammonium Sulfate ProductionDocument2 pagesAmmonium Sulfate Productionsinggih0% (1)

- Wildlife and Asset Protection: Selection GuideDocument3 pagesWildlife and Asset Protection: Selection GuideGiovany Vargas QuirozNo ratings yet

- Atcs CatalogueDocument9 pagesAtcs CatalogueAnderson SNo ratings yet

- V V-D DO OS SC C: Wavefront Sculpture TechnologyDocument4 pagesV V-D DO OS SC C: Wavefront Sculpture TechnologyTC Sinan ÜzenliNo ratings yet

- FCI 08-ProductBrochureDocument16 pagesFCI 08-ProductBrochurepardan aksaniNo ratings yet

- Bar Handling Machines and Systems: Knca - The Master of Master Binding MachinesDocument8 pagesBar Handling Machines and Systems: Knca - The Master of Master Binding Machinesbbcsteeltech LtdNo ratings yet

- NDJ Drip Eng 160914Document48 pagesNDJ Drip Eng 160914CARLOS EDUARDONo ratings yet

- SBB-HFF en 0522 EditDocument4 pagesSBB-HFF en 0522 Editeng2sckioNo ratings yet

- WCFX-E Series 60Hz: Water Cooled Rotary Screw Water Chillers Cooling Capacity: 70 To 990 TR (246 To 3482 KW)Document36 pagesWCFX-E Series 60Hz: Water Cooled Rotary Screw Water Chillers Cooling Capacity: 70 To 990 TR (246 To 3482 KW)Linder Rimac HuillcaNo ratings yet

- EagleBurgmann - TSA6 Barrier - Buffer Fluid System - ENDocument5 pagesEagleBurgmann - TSA6 Barrier - Buffer Fluid System - ENJavier PerezNo ratings yet

- Automatic Filler AFS Modular 2014Document4 pagesAutomatic Filler AFS Modular 2014mhafizanNo ratings yet

- Tube Settler Systems: Solutions For Enhanced SedimentationDocument8 pagesTube Settler Systems: Solutions For Enhanced SedimentationAbd RahmanNo ratings yet

- A Frame VSD Panel - PUBL 7797 - 2023 - ENDocument2 pagesA Frame VSD Panel - PUBL 7797 - 2023 - ENMuhammad AzriNo ratings yet

- Viscosystem Avs eDocument9 pagesViscosystem Avs eMohammed OuikhalfanNo ratings yet

- Cougar XT Compact Rev4Document6 pagesCougar XT Compact Rev4Alfonso RamosNo ratings yet

- Cartridge Mechanical Seals Series "C"Document6 pagesCartridge Mechanical Seals Series "C"dmitosNo ratings yet

- VP2100 ConfigurationDocument2 pagesVP2100 ConfigurationLuz Stella Calixto GomezNo ratings yet

- Bulk Storage Transfer Equipment PsDocument1 pageBulk Storage Transfer Equipment Psalvaro netoNo ratings yet

- LINTEC LEP Warm Mix Asphalt System En16Document3 pagesLINTEC LEP Warm Mix Asphalt System En1628g8stj2cjNo ratings yet

- Instrument Technical Room: PDC PDC 1600 800Document1 pageInstrument Technical Room: PDC PDC 1600 800ENGNo ratings yet

- Vib ScannerDocument76 pagesVib ScannerJunior BalabarcaNo ratings yet

- Dunham BushDocument36 pagesDunham BushhjmmNo ratings yet

- Isobar Chassis CatalogueDocument12 pagesIsobar Chassis CatalogueHeri MunirNo ratings yet

- Y0524 SB ScrubbersDocument4 pagesY0524 SB ScrubbersDHAVALESH AMNo ratings yet

- Aw/Vw Series: Weighing SystemsDocument5 pagesAw/Vw Series: Weighing SystemsWawan DevNo ratings yet

- C SeriesDocument12 pagesC Series杰森林No ratings yet

- Dunham Bush WCFX E R134ADocument11 pagesDunham Bush WCFX E R134AManuel Guardia AraujoNo ratings yet

- Baker 2Document8 pagesBaker 2William EvansNo ratings yet

- 01 Dieffenbacher THDF - DSDocument26 pages01 Dieffenbacher THDF - DSLong Đặng HoàngNo ratings yet

- Kurzkatalog Bilz Vibration Technology Ag 2020 enDocument8 pagesKurzkatalog Bilz Vibration Technology Ag 2020 enfp8872hvbrNo ratings yet

- Tor 31Document1 pageTor 31carlitoNo ratings yet

- Vdocuments - MX - Aseptomag Double Chamber Valve Type DK PDFDocument3 pagesVdocuments - MX - Aseptomag Double Chamber Valve Type DK PDFĐivềphía Mặt TrờiNo ratings yet

- Astec Nomad enDocument9 pagesAstec Nomad enWily Wayer100% (1)

- Sanic Sediment Cartridges: Filter Cartridges With Antimicrobial TechnologyDocument3 pagesSanic Sediment Cartridges: Filter Cartridges With Antimicrobial TechnologyGle YoyojimijiNo ratings yet

- سعدیDocument26 pagesسعدیkimia.ghanadian.1999No ratings yet

- Msds of Spray Dried LactoseDocument8 pagesMsds of Spray Dried LactoseAnandaNo ratings yet

- Indian Income Tax Return Acknowledgement 2021-22: Assessment YearDocument1 pageIndian Income Tax Return Acknowledgement 2021-22: Assessment YearPrateek GuptaNo ratings yet

- Yellow Book (Analysis of Rate)Document161 pagesYellow Book (Analysis of Rate)antt phweNo ratings yet

- Gastrulation in BirdsDocument20 pagesGastrulation in Birdskashif manzoor75% (4)

- Strategic Plans of Microfinance FirmDocument23 pagesStrategic Plans of Microfinance FirmAnatol PaladeNo ratings yet

- Tanaka Ecs 3301/3351 Owners ManualDocument20 pagesTanaka Ecs 3301/3351 Owners ManualΝικολαος ΕλληναςNo ratings yet

- Langmatz Polycarbonate Manholes and Underground Distribution Systems - enDocument6 pagesLangmatz Polycarbonate Manholes and Underground Distribution Systems - endhandiwaNo ratings yet

- How To Read A Prescription Drug LabelDocument3 pagesHow To Read A Prescription Drug LabelJefriyanto Saud100% (2)

- PAS Lesson PlanDocument2 pagesPAS Lesson PlanMahesh SinghNo ratings yet

- Iso Astm 52701-13 PDFDocument10 pagesIso Astm 52701-13 PDFAhmed LabibNo ratings yet

- Pocket Dermatology Sara Hylwa, Elisabeth Hurliman, Jing Liu EtcDocument542 pagesPocket Dermatology Sara Hylwa, Elisabeth Hurliman, Jing Liu EtcMuhammad Ahmad bin makruf syammaku100% (1)

- Hydrostatic Test CertificateDocument2 pagesHydrostatic Test CertificateSulistyo Adi33% (3)

- Medicinal PlantsDocument82 pagesMedicinal PlantsPapa KingNo ratings yet

- A Study of An Improved Overhead Crane Wheel Flange Lubrication SystemDocument5 pagesA Study of An Improved Overhead Crane Wheel Flange Lubrication SystemYasser TawfikNo ratings yet

- Gray Hat Hacking The Ethical Hackers Handbook Sixth Edition Daniel Regalado Full ChapterDocument51 pagesGray Hat Hacking The Ethical Hackers Handbook Sixth Edition Daniel Regalado Full Chaptereugene.poremski145100% (5)

- Wage BoardDocument10 pagesWage BoardDaniel PeterNo ratings yet

- Inverter TrainerDocument2 pagesInverter TrainerBudhi PrasetiyoNo ratings yet

- Principles of ChromatographyDocument8 pagesPrinciples of ChromatographylordniklausNo ratings yet

- Molusco ContagiosoDocument12 pagesMolusco ContagiosoEduardo Medeiros Tabosa PinheiroNo ratings yet

- Alternative Sexual Identities ExpressionDocument180 pagesAlternative Sexual Identities ExpressionHarmoniq777No ratings yet

- 33 - Tunnel Fire Safety StrategyDocument68 pages33 - Tunnel Fire Safety StrategyLo WongNo ratings yet

- Progress Report - MC&T - WK - 34Document3 pagesProgress Report - MC&T - WK - 34sellitt ngNo ratings yet

- AC Rectifier Bulk Capacitor Selection With Analysis+SPICE (Walker) PDFDocument5 pagesAC Rectifier Bulk Capacitor Selection With Analysis+SPICE (Walker) PDFjazbo8No ratings yet

- Input Data Sheet For E-Class Record: Region Division School Name School Id School YearDocument18 pagesInput Data Sheet For E-Class Record: Region Division School Name School Id School YearRonie DacubaNo ratings yet

- 110S 5Document33 pages110S 5Amit JainNo ratings yet

- Separation Agreement Template 04Document5 pagesSeparation Agreement Template 04rob De MayoNo ratings yet

- Hirschman 1982 Hedonic Consumption Emerging Concepts Methods and Propositio PDFDocument11 pagesHirschman 1982 Hedonic Consumption Emerging Concepts Methods and Propositio PDFMichael Alexandre Ramos BravoNo ratings yet

- Epekto NG Paninigarilyo Sa Kabataan ThesisDocument5 pagesEpekto NG Paninigarilyo Sa Kabataan ThesisWriteMyPaperCollegeWichitaFalls100% (1)

- Tarnished Queen - Nicole FoxDocument396 pagesTarnished Queen - Nicole Foxyourmom33% (3)