100% found this document useful (1 vote)

756 views50 pagesWell Integrity Management System

The document is a presentation on Well Integrity Management Systems (WIMS) throughout the well lifecycle given by Mahmoud Farag Radwan, the Subsurface & Integrity Operations Dept. Head at AMAL Petroleum Company. It discusses well integrity definitions, why it is important, examples of well integrity failures, standards, critical requirements, barriers, annulus pressure management, and a WIMS workflow. The presentation provides an overview of key concepts in well integrity and managing well integrity through the use of a WIMS.

Uploaded by

nappyCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

756 views50 pagesWell Integrity Management System

The document is a presentation on Well Integrity Management Systems (WIMS) throughout the well lifecycle given by Mahmoud Farag Radwan, the Subsurface & Integrity Operations Dept. Head at AMAL Petroleum Company. It discusses well integrity definitions, why it is important, examples of well integrity failures, standards, critical requirements, barriers, annulus pressure management, and a WIMS workflow. The presentation provides an overview of key concepts in well integrity and managing well integrity through the use of a WIMS.

Uploaded by

nappyCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- Introduction: Introduces the Well Integrity Management System course and the goal of proper well lifecycle management.

- Short Biography & Publications: Presents the professional background and notable publications of the instructor, Mahmoud Farag Radwan.

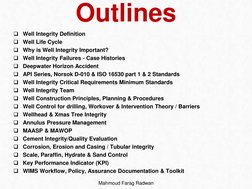

- Outlines: Lists the main topics covered in the Well Integrity Management System course, including definitions, life cycle, and standards.

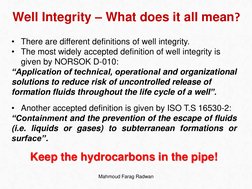

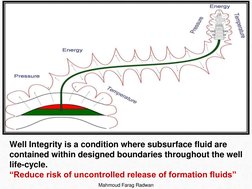

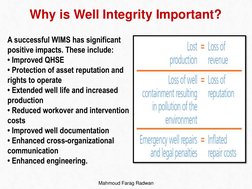

- Well Integrity - Definitions and Importance: Explains well integrity definitions and its critical role in maintaining operational safety and efficiency.

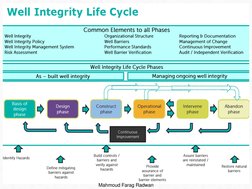

- Well Integrity Life Cycle: Describes the phases of well integrity management, from design to abandonment.

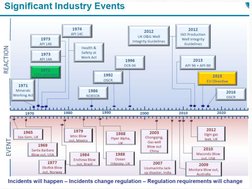

- Significant Industry Events: Illustrates key historical events that influenced industry regulations and practices for well integrity.

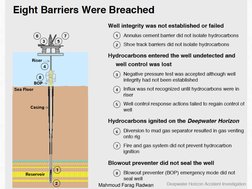

- Deepwater Horizon Case Study: Analyzes the Deepwater Horizon disaster, focusing on breached barriers and response improvements.

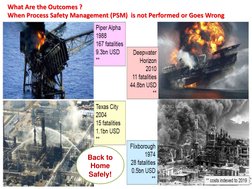

- Failure Assessment: Assesses the economic considerations and strategies for preventing well integrity failures.

- Barrier Standard: Outlines the critical requirements for maintaining barriers to ensure well safety.

- Roles and Responsibilities: Defines roles within well integrity management, focusing on coordination and accountability.

- Well Control Theory: Discusses the theories and classifications of barriers essential for well control operations.

- Permanent Well Barrier Definition: Details characteristics of permanent well barriers according to NORSOK standards.

- Wellhead API Trim Guide: Guide to API standards for wellhead components and configurations.

- Leak Rate Criteria: Details criteria for evaluating acceptable leak rates in well integrity assessments.

- Types of Annular Pressures: Explains the different types of annular pressures encountered in well operations.

- Prevention Methods: Highlights preventive practices in well construction and integrity management.

- Cement Job Guidelines: Provides guidelines for executing effective cement jobs to ensure well integrity.

- Cement Quality/Integrity Evaluation: Discusses methodologies for evaluating cement quality and assessing well integrity.

- Ultrasonic Measurements: Covers advanced ultrasonic measurement techniques in well integrity diagnostics.

- MAASP and MAWOP: Explains Maximum Allowable Annulus Surface Pressure and Wellhead Operating Pressure considerations.

- Management of Change (MOC): Addresses the importance of change management in maintaining effective well integrity.

- Downhole Corrosion Mechanisms: Explores various corrosion mechanisms encountered in downhole environments.

- Plugging and Abandonment (P&A): Discusses strategies and regulations for properly plugging and abandoning wells.

- WIMS Workflow: Outlines the workflow and action items within the Well Integrity Management System.

- Well Integrity KPI Definition: Defines key performance indicators for assessing well integrity and operational success.