Professional Documents

Culture Documents

Kadanwari Well Integrity Program

Uploaded by

salmanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kadanwari Well Integrity Program

Uploaded by

salmanCopyright:

Available Formats

Kadanwari WI Page 1

eni Pakistan Ltd

Development Onshore Well

WEOP/ Reservoir Well Integrity Program REV

Kadanwari Well Integrity (K-01, K-09 & K-31)

Development Well

Tajjal Block

Onshore Pakistan

August, 2020

Kanwal Shahid

Prepared

Graduate Completion Engineer

Imran Khurshid

Sr. Drilling & Completion Engineer

Reviewed

Hammad Attaullah

D&C Engineering Coordinator

Abdelaziz Kurd

Concurred

Wells & Operations Manager

Matteo Turco

Approved

Technical Manager

This document is CONFIDENTIAL and Company’s property.

It shall not be shown to Third Parties or used for purposes other than those for which it was transmitted.

Page 2 of 28

Kadanwari WI Development Onshore Well

eni Pakistan Ltd

WEOP/ Reservoir Well Integrity Program REV

INDEX

1.0 SAFETY, HSE POLICY AND HSE MANAGEMENT:..............................................4

2.0 OBJECTIVE:............................................................................................................ 4

3.0 GENERAL GUIDELINES.........................................................................................5

4.0 APPLICABLE DOCUMENTS..................................................................................6

5.0 OUTLINE PROGRAM:.............................................................................................7

6.0 DETAILED JOB PROCEDURE:..............................................................................8

FIGURES

Wellhead sketches/picture of K-01, K-09 and K-31

APPENDICES:

1. Safety Meetings

2. Last well integrity test reports

3. Well Integrity Certificate

4. Surface Well Testing Layout

5. Emergency Response plan

6. Emergency Contact Numbers

ATTACHMENT:

1. Schlumberger Surface well testing Hazard Analysis and Risk Control

This document is CONFIDENTIAL and Company’s property.

It shall not be shown to Third Parties or used for purposes other than those for which it was transmitted.

Page 3 of 28

Kadanwari WI Development Onshore Well

eni Pakistan Ltd

WEOP/ Reservoir Well Integrity Program REV

1.0 Safety, HSE policy and HSE Management:

Hold safety meeting prior to start of operations with all the company & services personnel.

Appropriate lighting system will be arranged to enable the crew to conduct operations safely

during the night.

HSE Policy:

The HSE policy of Eni Pakistan governs all business activities to manage HSE risks

associated with them. This policy outlines company’s commitment towards HSE ensuring that

there is no harm or injury to any person or damage to the environment that may arise due to

its business activity.

To make sure that HSE policy is complied, an HSE Integrated Management System is in

place that describes the standards and guidelines for safe operations.

HSE Management:

In order to safely conduct this job, following steps will be taken that are derived from Eni

Pakistan HSE Integrated Management System.

1. Development and implementation of HSE Guidelines for Contractors to carry out this

job.

2. Carry out HSE risk assessment prior to activity start-up. This HSE risk assessment

will be qualitative based on pre-defined risk assessment matrix. The mitigation

measures arising from this risk assessment will be agreed among the group and

implemented.

3. Strong HSE communication among the site personnel will be important to make sure

that all risks associated to the activity and their controls are well understood. This

communication will be evident through

a. Tool box talks will be carried out prior to start of each activity.

b. Daily HSE meetings by all site company and contractor personnel.

2.0 Objective:

The objectives this activity is to bleed off shut-in pressure of these wells by flaring the gas and

see wells’ response to exclude them from well integrity checks

This document is CONFIDENTIAL and Company’s property.

It shall not be shown to Third Parties or used for purposes other than those for which it was transmitted.

Page 4 of 28

Kadanwari WI Development Onshore Well

eni Pakistan Ltd

WEOP/ Reservoir Well Integrity Program REV

3.0 General Guidelines

Perform medical evacuation drill prior to any activity on the location

Perform Greasing of X-mass tree Gate Valves prior to the job

Eni representative to witness and check all equipment original certificates on location

Ensure proper PTW system is in place

Perform PJSM with all involved personnel to explain ENI risk assessment. ENI HSE

and operation representative must be present.

Standard emergency kit (including spill kit, Fire Extinguishers etc.) to be available on

location as per standard practice.

Ensure availability of at least two (02) SCABA sets on location.

Proper Lighting arrangements in case of night activity

Display Emergency Contact Details, Emergency Action Plan on location

In general, apply all the necessary precautions for a specific tool or an operation

This document is CONFIDENTIAL and Company’s property.

It shall not be shown to Third Parties or used for purposes other than those for which it was transmitted.

Page 5 of 28

Kadanwari WI Development Onshore Well

eni Pakistan Ltd

WEOP/ Reservoir Well Integrity Program REV

4.0 APPLICABLE DOCUMENTS

Well Control Manual STAP P-1-M-25007 Rev. A dated 03-12-2014

Well Test Procedures Manual STAP P-1-M-7130 Rev. 01 Dated 01-01-2005

ENI E&P Well Maintenance Procedure STAP-G-1-M-26527 dated 01-01-2016.

Well Integrity Management Procedures for Production and Injection Wells STAP-P-1-

MG-26526 Rev. 01 dated 01-01-2016

Best Practices for Drilling Completion and Production Optimization Activities P-1-M-

20742 dated 16-02-2012

Well Maintenance Procedure STAP-M1-MG-26527 Rev. 3 Dated 15-06-2018

Hydrogen Sulphide (H2S) Well Operations Procedures STAP-P-1-MG-26511 Rev. 01

dated 21-03-2016

This document is CONFIDENTIAL and Company’s property.

It shall not be shown to Third Parties or used for purposes other than those for which it was transmitted.

Page 6 of 28

Kadanwari WI Development Onshore Well

eni Pakistan Ltd

WEOP/ Reservoir Well Integrity Program REV

5.0 Outline Program:

Kadanwari-01

Mobilize equipment and resources to wellsite

R/up lubricator and remove BPV from tubing hanger profile

Spot and R/up surface well testing and H2S monitoring

Perform SSSV inflow test

Open the well gradually towards the flare pit

Continue flaring until SIWHP becomes 0

Shut-in the well and observe for increase in pressure

R/up lubricator, install BPV

R/D well testing, Handover the well to production department

Move to K-09

Kadanwari-09

Mobilize equipment and resources to wellsite

Spot and R/up surface well testing and H2S monitoring

Perform SSSV Inflow test

Open the well gradually towards the flare pit

Continue flaring until SIWHP becomes 0

Shut-in the well and observe for increase in pressure

R/D well testing, Handover the well to production department

Move to K-31

Kadanwari-31

Mobilize equipment and resources to wellsite

R/up lubricator and remove BPV from tubing hanger profile

Spot and R/up surface well testing and H2S monitoring

Perform SSSV inflow test

Open the well gradually towards the flare pit

Continue flaring until SIWHP becomes 0

Shut-in the well and observe for increase in pressure

R/up lubricator, install BPV

R/D well testing, Handover the well to production department

Release all the services

This document is CONFIDENTIAL and Company’s property.

It shall not be shown to Third Parties or used for purposes other than those for which it was transmitted.

Page 7 of 28

Kadanwari WI Development Onshore Well

eni Pakistan Ltd

WEOP/ Reservoir Well Integrity Program REV

6.0 Detailed Job Procedure:

Kadanwari-01

Note: Eni Representative to check and verify all equipment’s original certification on

location.

1. Mobilize Schlumberger Well Testing equipment, Cameron Lubricator, Hydraulic crane and

other resources to wellsite.

2. Hold pre-operation safety meeting with all the concerned personnel available on the

location and brief their responsibilities for operations and safety awareness. All the support

personnel should stay away from wellhead.

3. Offload, spot Schlumberger sacrificial choke manifold and related equipment as per

Appendix-4. Meanwhile R/up H2S monitoring setup.

4. Make-up flare lines and connect with downstream of sacrificial choke manifold. Hook-up

upstream of choke manifold with SSV.

5. Connect SSV with remote emergency shut-down stations and function test the same.

6. Secure all surface flow lines with slings / chains.

7. Shut-in the well. Record & Report shut-in wellhead pressure.

8. Make sure that all X-Mass Tree valves are closed. (Swab Valve, LMV, KWV, FWV).

Note: X-Mass tree FWV is 5-1/8” 10K

9. Remove pressure gauge and open needle valve on the tree cap to bleed any pressure

trapped below the tree cap.

10. Remove Tree Cap. R/U Cameron lubricator on top of X-mass tree.

11. Open UMV, LMV & Swab valve. Pressure test Cameron lubricator against SIWHP for 15

min. Bleed off pressure.

12. Lock-open UM actuator valve by installing mechanical hold-open device.

13. Gradually RIH lubricator rod with BPV removing tool. Latch the tool with BPV and equalize

pressure using BPV poppet valve. Remove BPV from tubing hanger profile.

14. Close all X-mass tree gate valves and R/D Lubricator

15. Perform inflow test of TRSCSSV at 50% SIWHP. Prepare and submit integrity certificates

per Appendix-3. If shut-in pressure is less than 500 psi, bleed off pressure to 90% and

perform SSSV inflow test.

Note: In case of positive inflow test. Report to Karachi Office for way forward.

16. Hook up the X-Mass Tree FWV to Schlumberger well testing choke manifold.

17. Open the well and pressure test all surface equipment against SIWHP

18. Divert the well to flare pit and flare the gas until SIWHP reach to 0 psi

This document is CONFIDENTIAL and Company’s property.

It shall not be shown to Third Parties or used for purposes other than those for which it was transmitted.

Page 8 of 28

Kadanwari WI Development Onshore Well

eni Pakistan Ltd

WEOP/ Reservoir Well Integrity Program REV

19. Shut-in the well from FWV and observe for increase in shut-in wellhead pressure for one

hour. Report the same

20. R/U Cameron lubricator on top of X-mass tree.

21. Open UMV, LMV & Swab valve. Gradually RIH lubricator rod with BPV and install it in

tubing hanger profile.

22. Bleed off pressure above BPV and check BPV integrity. R/D lubricator.

23. Install needle valve and pressure gauge above Tree Cap.

24. Load back equipment; perform housekeeping and handover the well to Production

Department.

25. Mobilize all resources to K-09.

26. Perform housekeeping and handover the well to production department.

Kadanwari-09

Note: Eni Representative to check and verify all equipment’s original certification on

location.

27. Mobilize Schlumberger Well Testing equipment, Hydraulic crane and other resources to

wellsite.

28. Hold pre-operation safety meeting with all the concerned personnel available on the

location and brief their responsibilities for operations and safety awareness. All the support

personnel should stay away from wellhead.

29. Offload, spot Schlumberger sacrificial choke manifold and related equipment as per

Appendix-4. Meanwhile R/up H2S monitoring setup.

30. Make-up flare lines and connect with downstream of sacrificial choke manifold. Hook-up

upstream of choke manifold with SSV.

31. Connect SSV with remote emergency shut-down stations and function test the same.

32. Secure all surface flow lines with slings / chains.

33. Shut-in the well. Record & Report shut-in wellhead pressure.

34. Make sure that all X-Mass Tree valves are closed. (Swab Valve, LMV, KWV, FWV).

Note: X-Mass tree FWV is 5-1/8” 5K

35. Perform inflow test of TRSCSSV at 50% SIWHP. Prepare and submit integrity certificates

per Appendix-3. If shut-in pressure is less than 500 psi, bleed off pressure to 90% and

perform SSSV inflow test.

Note: In case of positive inflow test. Report to Karachi Office for way forward.

36. Hook up the X-Mass Tree FWV to Schlumberger well testing choke manifold.

37. Open the well and pressure test all surface equipment against SIWHP

This document is CONFIDENTIAL and Company’s property.

It shall not be shown to Third Parties or used for purposes other than those for which it was transmitted.

Page 9 of 28

Kadanwari WI Development Onshore Well

eni Pakistan Ltd

WEOP/ Reservoir Well Integrity Program REV

38. Divert the well to flare pit and flare the gas until SIWHP reach to 0 psi

39. Shut-in the well from FWV and observe for increase in shut-in wellhead pressure for 1 hour.

Report the same

40. Load back equipment; perform housekeeping and handover the well to Production

Department.

41. Mobilize all resources to K-31

42. Perform housekeeping and handover the well to production department.

Kadanwari-31

Note: Eni Representative to check and verify all equipment’s original certification on

location.

43. Mobilize Schlumberger Well Testing equipment, Cameron Lubricator, Hydraulic crane and

other resources to wellsite.

44. Hold pre-operation safety meeting with all the concerned personnel available on the

location and brief their responsibilities for operations and safety awareness. All the support

personnel should stay away from wellhead.

45. Offload, spot Schlumberger sacrificial choke manifold and related equipment as per

Appendix-4. Meanwhile R/up H2S monitoring setup.

46. Make-up flare lines and connect with downstream of sacrificial choke manifold. Hook-up

upstream of choke manifold with SSV.

47. Connect SSV with remote emergency shut-down stations and function test the same.

48. Secure all surface flow lines with slings / chains.

49. Shut-in the well. Record & Report shut-in wellhead pressure.

50. Make sure that all X-Mass Tree valves are closed. (Swab Valve, LMV, KWV, FWV).

Note: X-Mass tree FWV is 5-1/8” 10K, KWV is 4-1/16” 10K

51. Remove pressure gauge and open needle valve on the tree cap to bleed any pressure

trapped below the tree cap.

52. Remove Tree Cap. R/U Cameron lubricator on top of X-mass tree.

53. Open UMV, LMV & Swab valve. Pressure test Cameron lubricator against SIWHP for 15

min. Bleed off pressure.

54. Lock-open UM actuator valve by installing mechanical hold-open device.

55. Gradually RIH lubricator rod with BPV removing tool. Latch the tool with BPV and equalize

pressure using BPV poppet valve. Remove BPV from tubing hanger profile.

56. Close all X-mass tree gate valves and R/D Lubricator

This document is CONFIDENTIAL and Company’s property.

It shall not be shown to Third Parties or used for purposes other than those for which it was transmitted.

Page 10 of 28

Kadanwari WI Development Onshore Well

eni Pakistan Ltd

WEOP/ Reservoir Well Integrity Program REV

57. Perform inflow test of TRSCSSV at 50% SIWHP. Prepare and submit integrity certificates

per Appendix-3. If shut-in pressure is less than 500 psi, bleed off pressure to 90% and

perform SSSV inflow test.

Note: In case of positive inflow test. Report to Karachi Office for way forward.

58. Hook up the X-Mass Tree FWV/KWV to Schlumberger well testing choke manifold.

59. Open the well and pressure test all surface equipment against SIWHP

60. Divert the well to flare pit and flare the gas until SIWHP reach to 0 psi

61. Shut-in the well from FWV and observe for increase in shut-in wellhead pressure for 1 hour.

Report the same

62. R/U Cameron lubricator on top of X-mass tree.

63. Open UMV, LMV & Swab valve. Gradually RIH lubricator rod with BPV and install it in

tubing hanger profile.

64. Bleed off pressure above BPV and check BPV integrity. R/D lubricator.

65. Install needle valve and pressure gauge above Tree Cap.

66. Load back equipment; perform housekeeping and handover the well to Production

Department.

67. Release all the services

68. Perform housekeeping and handover the well to production department.

This document is CONFIDENTIAL and Company’s property.

It shall not be shown to Third Parties or used for purposes other than those for which it was transmitted.

Page 11 of 28

Kadanwari WI Development Onshore Well

eni Pakistan Ltd

WEOP/ Reservoir Well Integrity Program REV

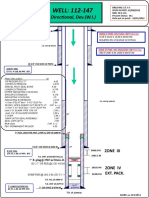

Figure – Well Head

Kadanwari-01

This document is CONFIDENTIAL and Company’s property.

It shall not be shown to Third Parties or used for purposes other than those for which it was transmitted.

Page 12 of 28

Kadanwari WI Development Onshore Well

eni Pakistan Ltd

WEOP/ Reservoir Well Integrity Program REV

This document is CONFIDENTIAL and Company’s property.

It shall not be shown to Third Parties or used for purposes other than those for which it was transmitted.

Page 13 of 28

Kadanwari WI Development Onshore Well

eni Pakistan Ltd

WEOP/ Reservoir Well Integrity Program REV

Kadanwari-09

Kadanwari-31

This document is CONFIDENTIAL and Company’s property.

It shall not be shown to Third Parties or used for purposes other than those for which it was transmitted.

Page 14 of 28

Kadanwari WI Development Onshore Well

eni Pakistan Ltd

WEOP/ Reservoir Well Integrity Program REV

This document is CONFIDENTIAL and Company’s property.

It shall not be shown to Third Parties or used for purposes other than those for which it was transmitted.

Page 15 of 28

Kadanwari WI Development Onshore Well

eni Pakistan Ltd

WEOP/ Reservoir Well Integrity Program REV

Appendix-1

SAFETY MEETINGS - AWARENESS

BRIEFINGS

A. Pre Operational

A full safety meeting will be held prior to the commencement of all operations.

B. Agenda

The procedures contained in this program should form the basis of the agenda for this

meeting. However, this may be supplemented by any topic that the concerned personnel

may think relevant. Representative from the service company should present an overview of

This document is CONFIDENTIAL and Company’s property.

It shall not be shown to Third Parties or used for purposes other than those for which it was transmitted.

Page 16 of 28

Kadanwari WI Development Onshore Well

eni Pakistan Ltd

WEOP/ Reservoir Well Integrity Program REV

his function and highlight any points of safety or general awareness. The Eni Pakistan Job

supervisor should clearly outline the following:

Chain of Command

Roles and Responsibilities of all key personnel

Proper lines of communication

Awareness briefing on Security issues related to Eni Pakistan.

Briefing on environment protection and standards.

C. Attendance

These meetings should be attended by all services personnel and representatives on

location.

D. Tool Box Meetings

Tool Box type safety meetings will be convened at any stage during the operations, when it is

deemed that special attention to forthcoming operations is required. The Eni Pakistan Job

supervisor will coordinate these meetings.

The meetings will also address and re-enforce standard safety procedures such as driving,

lifting equipment, crane operations etc.

Concerns or general comments and recommendations on safety issues are welcomed from

any member taking part in the regular tool box safety meeting.

Ensure that this section SAFETY / RESPONSIBILITIES / MEETINGS is thoroughly read

and understood by the all personnel who are part of the operations:

All operations shall be in accordance with the safety and environmental requirements

specified in ENI completion and well intervention manual STAP-P-1-M-7120.

E. Responsibilities

If a conflict arises between Eni or Service Company procedures, which are not covered by

documentation agreed by both parties, the issue shall be resolved by management from

involved parties (i.e. Eni, Service Companies), and the proposed course of action shall be

approved by the Eni Well Intervention Job Supervisor and Drilling Engineering Manager.

If a non-standard operation is required (i.e. one that is not covered in existing Eni or

Service Company procedures), an on-site risk assessment must be carried out and

recorded through a set of written instructions agreed by all relevant parties.

The Eni Senior Operations Supervisor has the ultimate responsibility for the health and

safety of all persons at the well site and for the good practice and security of the site. In his

absence, a competent alternate will be identified, usually the Well Services Contractors

Supervisor or designate on location.

The Eni Well Intervention Supervisor reports directly to the Drilling & Wells Manager in

Karachi.

This document is CONFIDENTIAL and Company’s property.

It shall not be shown to Third Parties or used for purposes other than those for which it was transmitted.

Page 17 of 28

Kadanwari WI Development Onshore Well

eni Pakistan Ltd

WEOP/ Reservoir Well Integrity Program REV

This document is CONFIDENTIAL and Company’s property.

It shall not be shown to Third Parties or used for purposes other than those for which it was transmitted.

Page 18 of 28

Kadanwari WI Development Onshore Well

eni Pakistan Ltd

WEOP/ Reservoir Well Integrity Program REV

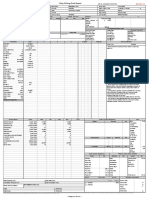

Appendix 2

LAST WELL INTEGRITY TEST REPORTS

ENI Pakistan Limited RIGLESS Operation

Daily Report

Well Name: Report No. Start Date: Report Date: Days on Location:

Kadanwari-01 1 18-Dec-2019 18-Dec-2019 01

Drilling Rig: Eni Supervisor: Contractors P.O.B Daily Cost $:

Rigless Adnan Hafeez Cameron Cum Cost $:

TIME (From – To) Hrs:min Description of Operations

Obtain PTW authorizations meanwhile mobilize equipment to location.

09:00 – 09:30 00:30

Arrive on location K-01.

Conduct TBT. Close LMV and bled off tree pressure to 0 psi.

Monitor pressure build up for half an hour. OK.

09:30 – 10:30 01:00

Tight FWV flange to stop leak. Open LMV, Observe 1200 psi in the tree.

Check for leak points. No leak detected.

Close LMV and bleed off tree pressure to 0 psi. Offload Equipment & rig

10:30 – 12:30 02:00 up Cameron lubricator on wellhead meanwhile M/U SSSV control line

connection with enerpac pump and open SSSV.

Lower down polish rod and engage BPV, equalize pressure & Record

SIWHP= 4600 psi. Close SSSV, bleed off pressure above flapper and

conduct test as below:

12:30 – 14:30 02:00 Initial Pressure after bleed off = 2000 psi

Final Pressure = 4000 psi

Test duration = 30 minutes

Bleed off pressure above flapper to 500 psi and try to remove BPV from

profile. No Success.

Unscrew the retrieving tool and pull the polish rod inside the lubricator.

Bleed of pressure above BPV to 100 psi & Perform inflow test against BPV

as below:

14:30 – 16:30 02:00 Initial Pressure after bleed off = 100 psi

Final Pressure = 100 psi

Test duration = 30 minutes

Closed LMV and bleed off tree pressure to 0 psi.

R/d Cameron lubricator.

Perform housekeeping and leave location.

This document is CONFIDENTIAL and Company’s property.

It shall not be shown to Third Parties or used for purposes other than those for which it was transmitted.

Page 19 of 28

Kadanwari WI Development Onshore Well

eni Pakistan Ltd

WEOP/ Reservoir Well Integrity Program REV

ENI Pakistan Limited RIGLESS Operation

Daily Report

Well Name: Report No. Start Date: Report Date: Days on Location:

Kadanwari-09 1 13-Dec-2019 13-Dec-2019 01

Drilling Rig: Eni Supervisor: Contractors P.O.B Daily Cost $:

Rigless Adnan Hafeez Cum Cost $:

TIME (From – To) Hrs:min Description of Operations

16:00 – 16:30 00:30 Obtain PTW authorization and arrive on location.

Record SIWHP= 450 psi. Close SSSV, bleed off pressure above

flapper and conduct test as below:

Initial Pressure after bleed off = 200 psi

Final Pressure = 450 psi

16:30 – 17:30 01:00 Test duration = 04 minutes

Meanwhile monitor annulus pressure in wellhead sections as:

Section A= 0 psi

Section B= 0 psi

Perform housekeeping and leave location.

This document is CONFIDENTIAL and Company’s property.

It shall not be shown to Third Parties or used for purposes other than those for which it was transmitted.

Page 20 of 28

Kadanwari WI Development Onshore Well

eni Pakistan Ltd

WEOP/ Reservoir Well Integrity Program REV

ENI Pakistan Limited RIGLESS Operation

Daily Report

Well Name: Report No. Start Date: Report Date: Days on Location:

Kadanwari-31 1 13-June-2019 13-June-2019

Drilling Rig: Eni Supervisor: Contractors P.O.B Daily Cost $:

Umar Rasheed/

Rigless Cum Cost $:

M. Mubasher

TIME (From –

Hrs: min Description of Operations

To)

Obtain PTW authorization meanwhile mobilizes equipment on location.

07:00 – 08:30 01:30

Arrive on K-31 location.

Conduct TBT. Offload equipment and R/U Cameron lubricator on

08:30 – 10:00 01:30 wellhead meanwhile M/U SSSV control line connection with enerpac

pump and open same.

Lower down polish rod and engage BPV. Equalize pressure and observe

600 psi on surface. Remove BPV from profile. Close SSSV and bleed

10:00 – 13:30 03:30 pressure above to 200 psi. Observe SSSV not holding pressure. Cycle SSSV

3 times and test again and found SSSV not holding pressure. Re-install

BPV and R/D Cameron lubricator from wellhead.

Load back all equipment. Perform housekeeping. Secure x-mass tree and

13:30 – 14:30 01:00

left location.

This document is CONFIDENTIAL and Company’s property.

It shall not be shown to Third Parties or used for purposes other than those for which it was transmitted.

Page 21 of 28

Kadanwari WI Development Onshore Well

eni Pakistan Ltd

WEOP/ Reservoir Well Integrity Program REV

Appendix 3

WELL INTEGRITY CERTIFICATE

WELL INTEGRITY CERTIFICATE Test Date:

Eni Pakistan Ltd.

Well Integrity is defined as the application of technical, operational and organizational solutions to reduce the risk of

uncontrolled release of formation fluids to atmosphere or subsurface layers, throughout the life cycle of a well.

General Information

Well Name

Test Equipment

Serial & Part Numbers

Equipment Specification

Test Pressure

Hold Period

Eni Drilling Supervisor

Contractor Representative

Purpose of Testing

Acceptance Criteria

As per clause F.1.6.3 of ISO 10423, the hydrostatic test at room temperature is passed if no visible leakage occurs

during

the specified pressure hold periods of the test. The pressure change observed on the pressure measuring device

during

the hold period shall be less than 5% of the test pressure or 3.45 MPa (500psi), whichever is less.

Note: Hold period is one hour.

Observation (If Any)

Statement

This equipment qualifies the above mentioned criteria.

Eni Drilling Supervisor Contractor Representative

Drilling & Completion Superintendent

This document is CONFIDENTIAL and Company’s property.

It shall not be shown to Third Parties or used for purposes other than those for which it was transmitted.

Page 22 of 28

Kadanwari WI Development Onshore Well

eni Pakistan Ltd

WEOP/ Reservoir Well Integrity Program REV

Appendix-4

This document is CONFIDENTIAL and Company’s property.

It shall not be shown to Third Parties or used for purposes other than those for which it was transmitted.

Page 23 of 28

Kadanwari WI Development Onshore Well

eni Pakistan Ltd

WEOP/ Reservoir Well Integrity Program REV

Appendix-5

EMERGENCY RESPONSE PLAN

This document is CONFIDENTIAL and Company’s property.

It shall not be shown to Third Parties or used for purposes other than those for which it was transmitted.

Page 24 of 28

Kadanwari WI Development Onshore Well

eni Pakistan Ltd

WEOP/ Reservoir Well Integrity Program REV

This document is CONFIDENTIAL and Company’s property.

It shall not be shown to Third Parties or used for purposes other than those for which it was transmitted.

Page 25 of 28

Kadanwari WI Development Onshore Well

eni Pakistan Ltd

WEOP/ Reservoir Well Integrity Program REV

This document is CONFIDENTIAL and Company’s property.

It shall not be shown to Third Parties or used for purposes other than those for which it was transmitted.

Page 26 of 28

Kadanwari WI Development Onshore Well

eni Pakistan Ltd

WEOP/ Reservoir Well Integrity Program REV

This document is CONFIDENTIAL and Company’s property.

It shall not be shown to Third Parties or used for purposes other than those for which it was transmitted.

Page 27 of 28

Kadanwari WI Development Onshore Well

eni Pakistan Ltd

WEOP/ Reservoir Well Integrity Program REV

This document is CONFIDENTIAL and Company’s property.

It shall not be shown to Third Parties or used for purposes other than those for which it was transmitted.

Page 28 of 28

K-24 DIR C Development Onshore Well

eni Pakistan Ltd

WEOP/ Reservoir Wellbore Cleanout Program REV

Appendix-6

Emergency Contact Numbers

Operational Contacts

Eni Pakistan Limited (Operations Department)

Names Designation e–mail Office Phone Mobile Fax no.

+92(0)21 5838491

Matteo Turco Technical Manager Matteo.Turco@eni.com +92(0)21 35828101 0333-4900230

+92(0)21 5838452

Abdelaziz Kurd Well Operations Manager Abdelaziz.Kurd@eni.com +92(0)21 35828103 0333-4900285 As above

Drilling & Completion

Hammad Attaullah Hammad.Attaullah@eni.com +92(0)21 35828108 0333-4900286 As above

Engineering Coordinator

Sr. Drilling and Completion

Imran Khurshid Imran.khurshid@eni.com +92(0)21 -35828166 0333-4900296 As above

Engineer

Jacopo Tontodonati

Drilling Superintendent enipak.drilling-spt@eni.com +92(0)21 35828131 0333-6900178 As above

Eni Pakistan Limited (Reservoir Department)

Muhammad Amjad Reservoir Manager Muhammad.Amjad@eni.com +92(0)21 35828310 0333-4900275 As above

Abrar Ahmed Sr. Reservoir Engineer Abrar.Ahmed@eni.com +92(0)21 35828414 0333-4900279 As above

Emergency Contacts

Kadanwari Resident Manager 0321 8202704 / 0321-8202706

HSE Manager 0333-4900319

Logistic Manager 0333-4900244

Company Doctor 0333-6900146

Karachi Radio Room +92(0)21 35838401 / 0333-4900444

This document is CONFIDENTIAL and Company’s property.

It shall not be shown to Third Parties or used for purposes other than those for which it was transmitted.

You might also like

- Max Pull On Drill StringDocument1 pageMax Pull On Drill StringMuhammad ShahrukhNo ratings yet

- BP Shell Chevron Conocophillips Marathon Total Schlumberger Imperial College, London Heriot Watt University, Edinburgh (Anywhere in Article)Document42 pagesBP Shell Chevron Conocophillips Marathon Total Schlumberger Imperial College, London Heriot Watt University, Edinburgh (Anywhere in Article)Doppler KenzoNo ratings yet

- Avg Downhole Losses: 4 BBLS/HR.: G.P.C Daily Drilling Report Att. Eastern Desert Rig Heading: 206°Document1 pageAvg Downhole Losses: 4 BBLS/HR.: G.P.C Daily Drilling Report Att. Eastern Desert Rig Heading: 206°Mahmoud Ahmed Ali AbdelrazikNo ratings yet

- Stuck Pipe in CTD OperationsDocument5 pagesStuck Pipe in CTD OperationsAdel Ahmed AlkhaligyNo ratings yet

- Example BHA Tally Directional Drilling 8.5 SectionDocument2 pagesExample BHA Tally Directional Drilling 8.5 Sectionfauzanhaq1602No ratings yet

- Drilling Fluid FunctionsDocument28 pagesDrilling Fluid FunctionsChristian Olascoaga MoriNo ratings yet

- Drilling Fluids Guide for Well ConstructionDocument21 pagesDrilling Fluids Guide for Well ConstructionFernando AybarNo ratings yet

- SHS-113D Diagrama Actual WO 02Document1 pageSHS-113D Diagrama Actual WO 02Jaime Calderón C.No ratings yet

- UL G 9-46 Unit #2H WBD PDFDocument7 pagesUL G 9-46 Unit #2H WBD PDFMilad Ebrahimi DastgerdiNo ratings yet

- 8-Csg Running Practices-GTs-Aug 2011Document33 pages8-Csg Running Practices-GTs-Aug 2011Smita kuliNo ratings yet

- Plugback Sidetracks - Off Cement PlugsDocument4 pagesPlugback Sidetracks - Off Cement PlugsAdel Ahmed AlkhaligyNo ratings yet

- WELL: 112-147: Directional, Dev. (W.I.)Document15 pagesWELL: 112-147: Directional, Dev. (W.I.)Mostafa KorttamNo ratings yet

- Cementing Job - 5 Inch Liner Al Raja 37Document2 pagesCementing Job - 5 Inch Liner Al Raja 37Doni KurniawanNo ratings yet

- IPM Flow Chart TempDocument1 pageIPM Flow Chart TempAnonymous U5t9NYzhLWNo ratings yet

- Field Fluids QaqcDocument38 pagesField Fluids QaqcscrbdgharaviNo ratings yet

- Mud Report 1Document65 pagesMud Report 1Brahim LetaiefNo ratings yet

- Bn67 Completion Schematic - Final 4 Apr 16Document1 pageBn67 Completion Schematic - Final 4 Apr 16sharil 9228No ratings yet

- Asamera (South Sumatra) LTD Mechanical Status Production Engineering Department RB-22aDocument13 pagesAsamera (South Sumatra) LTD Mechanical Status Production Engineering Department RB-22afauzan kartiyasaNo ratings yet

- Gas MigrationDocument42 pagesGas Migrationmoussa mrzg100% (1)

- OKW 61 (De Comp.) TimelineDocument6 pagesOKW 61 (De Comp.) TimelineVibhu GuptaNo ratings yet

- Well Data Summary ProgramDocument13 pagesWell Data Summary ProgramTemitope BelloNo ratings yet

- Surge - Swab ProgramDocument1 pageSurge - Swab ProgramHenry BritoNo ratings yet

- AC-0049 Well Design RulesDocument5 pagesAC-0049 Well Design RulesairlinemembershipNo ratings yet

- As Built Abandonment SchematicDocument1 pageAs Built Abandonment SchematicMarkus LandingtonNo ratings yet

- Alaska Drilling and Wells Recommended Practice: CTD Drilling FluidDocument4 pagesAlaska Drilling and Wells Recommended Practice: CTD Drilling FluidAdel Ahmed AlkhaligyNo ratings yet

- Daily drilling fluid report provides operational detailsDocument1 pageDaily drilling fluid report provides operational detailsLenis CeronNo ratings yet

- Rotary Bottom Hole Assembly: at The End of This Lecture, YOU Should Be Able ToDocument19 pagesRotary Bottom Hole Assembly: at The End of This Lecture, YOU Should Be Able Toburak kamaliNo ratings yet

- Fishing Operations Checklist - Basic StepsDocument1 pageFishing Operations Checklist - Basic StepsaungwinnaingNo ratings yet

- Off-Bottom Drilling PracticesDocument3 pagesOff-Bottom Drilling PracticesAdel Ahmed AlkhaligyNo ratings yet

- Drill String 1 DISDocument1 pageDrill String 1 DISpiies85No ratings yet

- Optimizing ROP with Schlumberger TechniquesDocument14 pagesOptimizing ROP with Schlumberger TechniquesMaría MarquinaNo ratings yet

- Final Diagram Fanny 18b-164 Wo1Document8 pagesFinal Diagram Fanny 18b-164 Wo1MANUEL ASTUDILLONo ratings yet

- Manzalai-07 Daily Mud Report (10!7!20)Document1 pageManzalai-07 Daily Mud Report (10!7!20)Sharjeel AhmedNo ratings yet

- Hole Cleaning: Downhole Motors in Deviated WellsDocument13 pagesHole Cleaning: Downhole Motors in Deviated WellsJairo CortesNo ratings yet

- Chapter 05 Spacers PDFDocument14 pagesChapter 05 Spacers PDFLeonardo Barrios CarreraNo ratings yet

- Cementing Proposal Programs TFT-473 - TP-211 PDFDocument25 pagesCementing Proposal Programs TFT-473 - TP-211 PDFAmine MimoNo ratings yet

- CementingDocument27 pagesCementingrezaNo ratings yet

- Well Control Data Sheet: Vertical WellsDocument2 pagesWell Control Data Sheet: Vertical WellsscrbdgharaviNo ratings yet

- Velocity String Helps To Revive A Standing Gas Well in Saudi ArabiaDocument14 pagesVelocity String Helps To Revive A Standing Gas Well in Saudi Arabiaerdal aydin100% (1)

- 1ST2 - Etapa 17.5in - BHA#03 - PDC Bit+PD-X6+MWDDocument1 page1ST2 - Etapa 17.5in - BHA#03 - PDC Bit+PD-X6+MWDAntonio Hdez JmnzNo ratings yet

- Master of Petroleum Well Engineering - Casing DesignDocument92 pagesMaster of Petroleum Well Engineering - Casing DesignGFarizNo ratings yet

- Wellbore Skematic DrawingsDocument74 pagesWellbore Skematic DrawingsMino MinoNo ratings yet

- Primary Cementing Lenin DiazDocument24 pagesPrimary Cementing Lenin DiazGonzalo GabrielNo ratings yet

- SDU Ver142beta1 - Demo Print 1 PDFDocument12 pagesSDU Ver142beta1 - Demo Print 1 PDFreza khNo ratings yet

- Primary Cementing OperationsDocument43 pagesPrimary Cementing OperationsMax SinghNo ratings yet

- Lab Test - AM - 17.5 - 01Document1 pageLab Test - AM - 17.5 - 01tungxuanbrNo ratings yet

- Warning Signs When CirculatingDocument7 pagesWarning Signs When CirculatingDidin DelgadoNo ratings yet

- U6 - Economic Optimization of Unconventional ReservoirsDocument92 pagesU6 - Economic Optimization of Unconventional ReservoirsWoodoo OodoowNo ratings yet

- 11-5000 BOP stack diagramDocument1 page11-5000 BOP stack diagramBram MartinezNo ratings yet

- Kill Sheet: Prerecorded Infromation Pump Strokes RequiredDocument17 pagesKill Sheet: Prerecorded Infromation Pump Strokes RequiredscrbdgharaviNo ratings yet

- Schematic Compeletion - AzhDocument15 pagesSchematic Compeletion - AzhHamid Reza BabaeiNo ratings yet

- Stimulation 4Document27 pagesStimulation 4DVScherbakovNo ratings yet

- AM DRLG Report 19-12-2017Document336 pagesAM DRLG Report 19-12-2017Islam AtifNo ratings yet

- CT Fatigue ModificDocument24 pagesCT Fatigue Modificfrank vNo ratings yet

- Mud Training SchoolDocument78 pagesMud Training School叶芊No ratings yet

- PIPE Tally Sheet 7'' Liner kB2Document10 pagesPIPE Tally Sheet 7'' Liner kB2nabiNo ratings yet

- Drilling Fluid Rheology ExplainedDocument22 pagesDrilling Fluid Rheology ExplainedLazharNo ratings yet

- Badhra-06 Wellbore Cleanout ProgramDocument52 pagesBadhra-06 Wellbore Cleanout ProgramsalmanNo ratings yet

- Method Statement For Lifting WorksDocument12 pagesMethod Statement For Lifting WorksBeomHee Lee100% (1)

- Lifting Procedure Rev 4Document48 pagesLifting Procedure Rev 4Morad M SwidNo ratings yet

- Completion OperationDocument17 pagesCompletion OperationsalmanNo ratings yet

- Mostafa Yakoot Well Intervention Completion Equipment 1Document12 pagesMostafa Yakoot Well Intervention Completion Equipment 1Yunus JawedNo ratings yet

- FulltextDocument100 pagesFulltextsalmanNo ratings yet

- 11 Jarle Haga Management SystemDocument17 pages11 Jarle Haga Management SystemsalmanNo ratings yet

- Samuel 2013Document11 pagesSamuel 2013salmanNo ratings yet

- Application For Api6av1 Validation Test Form 022 FDDocument1 pageApplication For Api6av1 Validation Test Form 022 FDsalmanNo ratings yet

- BSEE Test ProcedureDocument35 pagesBSEE Test ProcedureNatraji100% (2)

- Tubing StressanalysisDocument63 pagesTubing StressanalysissalmanNo ratings yet

- Badhra-06 Wellbore Cleanout ProgramDocument52 pagesBadhra-06 Wellbore Cleanout ProgramsalmanNo ratings yet

- Application For Api14a Validation Test Form 021 FDDocument2 pagesApplication For Api14a Validation Test Form 021 FDsalmanNo ratings yet

- CamScanner 05-12-2022 12.52Document1 pageCamScanner 05-12-2022 12.52salmanNo ratings yet

- Asme Code Sec Ix Ma Appe 2004Document3 pagesAsme Code Sec Ix Ma Appe 2004Guillermo CamachoNo ratings yet

- Ship Construction IonsDocument25 pagesShip Construction Ionsanon-49038083% (6)

- 456/1 Mathematics Paper 1 June /july 2012 HoursDocument4 pages456/1 Mathematics Paper 1 June /july 2012 HoursBaguma MichaelNo ratings yet

- Performance Analysis of Cooling TowerDocument7 pagesPerformance Analysis of Cooling TowerIbrahim Al-MutazNo ratings yet

- 3 Uscg BWM VRPDocument30 pages3 Uscg BWM VRPdivinusdivinusNo ratings yet

- 3D Bioprinting From The Micrometer To Millimete 2017 Current Opinion in BiomDocument7 pages3D Bioprinting From The Micrometer To Millimete 2017 Current Opinion in Biomrrm77No ratings yet

- MAGA Training ReportDocument56 pagesMAGA Training ReportChaturanga WagaArachchige67% (3)

- Physical Education Week 1 ActivitiesDocument4 pagesPhysical Education Week 1 ActivitiesTummys TummieNo ratings yet

- NEDO's Role in International Technical Cooperation ProjectsDocument45 pagesNEDO's Role in International Technical Cooperation Projectsamitsh20072458No ratings yet

- Unit 1 Unit 2 Unit 3 DIFFERENTIAL CALCULUS 1 2 3 PDFDocument124 pagesUnit 1 Unit 2 Unit 3 DIFFERENTIAL CALCULUS 1 2 3 PDFjayaram prakash kNo ratings yet

- Cats Meow Edition 3 PDFDocument320 pagesCats Meow Edition 3 PDFbrunokfouriNo ratings yet

- 22nd Annual Report 2021-22Document155 pages22nd Annual Report 2021-22Karthic Selvam KandavelNo ratings yet

- Wall Mounted Wireless Air ConditionersDocument2 pagesWall Mounted Wireless Air ConditionerspenavicbNo ratings yet

- In Re Winslow 1966 - Scope & Content of Prior ArtDocument5 pagesIn Re Winslow 1966 - Scope & Content of Prior ArtJorel Andrew FlautaNo ratings yet

- 2.seismic Coefficient CalculationDocument14 pages2.seismic Coefficient CalculationVenkat PalliNo ratings yet

- Manual: KFD2-UT-E 1Document20 pagesManual: KFD2-UT-E 1Kyrie AbayaNo ratings yet

- Brazed Tool ArDocument5 pagesBrazed Tool ArRoni MustafiqNo ratings yet

- 8-Input Multiplexer Selects One of Eight InputsDocument3 pages8-Input Multiplexer Selects One of Eight InputsKang RoyNo ratings yet

- The Mini Percutaneous Nephrolithotomy (Mini-PCNL) and Percutaneous Nephrolithotomy (PCNL) in Pediatric PatientsDocument4 pagesThe Mini Percutaneous Nephrolithotomy (Mini-PCNL) and Percutaneous Nephrolithotomy (PCNL) in Pediatric PatientsMarius DanilaNo ratings yet

- JAOP Progress ReportDocument36 pagesJAOP Progress ReportnidhisasidharanNo ratings yet

- Feed Water Heater ModellingDocument64 pagesFeed Water Heater ModellingSIVA KAVYANo ratings yet

- Phases of Clinical Trials: OverlapDocument3 pagesPhases of Clinical Trials: OverlapMohammed El-GezeiryNo ratings yet

- Hydro-, Balneo-, and Spa Treatment in Pain Management PDFDocument5 pagesHydro-, Balneo-, and Spa Treatment in Pain Management PDFfriend717100% (1)

- MTD Big Bore Engines 78 277cc 83 357cc 90 420cc Repair Manual PDFDocument136 pagesMTD Big Bore Engines 78 277cc 83 357cc 90 420cc Repair Manual PDFGiedrius MalinauskasNo ratings yet

- Chapter 17Document48 pagesChapter 17MahmoudKhedrNo ratings yet

- The Spring, Energy Accumulator A Mechanical WatchDocument5 pagesThe Spring, Energy Accumulator A Mechanical WatchismbllNo ratings yet

- Architecture in The AnthropoceneDocument265 pagesArchitecture in The Anthropoceneziyad fauziNo ratings yet

- All ProblemsDocument107 pagesAll ProblemsjoshiabhijeetNo ratings yet

- Cancer EssayDocument4 pagesCancer EssayCamille Joy BaliliNo ratings yet

- Usg Iom PDFDocument56 pagesUsg Iom PDFAnonymous 7xHNgoKE6eNo ratings yet