0% found this document useful (0 votes)

265 views152 pagesCleanroom HVAC Performance Qualification

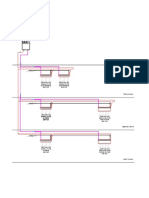

This document provides a performance qualification protocol for cleaning HVAC systems in clean rooms. It outlines test procedures for measuring air velocity, calculating air changes per hour, testing HEPA filter integrity, evaluating air flow patterns, measuring non-viable particulate counts, conducting recovery studies, testing differential pressure, temperature, humidity, light intensity and noise levels. The protocol is intended to validate that the HVAC system is meeting predetermined specifications and performing effectively and reproducibly.

Uploaded by

Mr. AliCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

265 views152 pagesCleanroom HVAC Performance Qualification

This document provides a performance qualification protocol for cleaning HVAC systems in clean rooms. It outlines test procedures for measuring air velocity, calculating air changes per hour, testing HEPA filter integrity, evaluating air flow patterns, measuring non-viable particulate counts, conducting recovery studies, testing differential pressure, temperature, humidity, light intensity and noise levels. The protocol is intended to validate that the HVAC system is meeting predetermined specifications and performing effectively and reproducibly.

Uploaded by

Mr. AliCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd