0% found this document useful (0 votes)

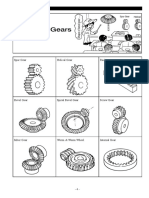

194 views9 pagesInternal Gear Applications and Types

Internal gears are used to transmit power between two parallel shafts. They have teeth on the inner periphery which makes the drive very compact. Internal gears are useful for high load, high speed applications with high reduction ratios, and can be found in automobile automatic transmissions and cement mill reduction gearboxes.

Uploaded by

Goutam AcharjeeCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

194 views9 pagesInternal Gear Applications and Types

Internal gears are used to transmit power between two parallel shafts. They have teeth on the inner periphery which makes the drive very compact. Internal gears are useful for high load, high speed applications with high reduction ratios, and can be found in automobile automatic transmissions and cement mill reduction gearboxes.

Uploaded by

Goutam AcharjeeCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd