Professional Documents

Culture Documents

Annexure-I DSP-Weight Breakup of Crane 25T DG EOT Crane X 11.28 MTR Span

Annexure-I DSP-Weight Breakup of Crane 25T DG EOT Crane X 11.28 MTR Span

Uploaded by

MUBASHSHIR HELAL0 ratings0% found this document useful (0 votes)

6 views1 pageThis document provides a weight breakdown of a 25T DG EOT crane with an 11.28 meter span. It lists the following key details:

1. The total weight of the crane without electrics is 51 tons, including 34 tons of structural weight and 17 tons of mechanical weight.

2. An additional 17 tons is included for mechanical components like alloy steel forgings, heat treated pinions and gears, and steel castings and fasteners.

3. The weight of the long travel rail and end stoppers is 10 tons. Motors and brakes for the main hoist, cross travel, and long travel are also specified.

Original Description:

Original Title

11

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides a weight breakdown of a 25T DG EOT crane with an 11.28 meter span. It lists the following key details:

1. The total weight of the crane without electrics is 51 tons, including 34 tons of structural weight and 17 tons of mechanical weight.

2. An additional 17 tons is included for mechanical components like alloy steel forgings, heat treated pinions and gears, and steel castings and fasteners.

3. The weight of the long travel rail and end stoppers is 10 tons. Motors and brakes for the main hoist, cross travel, and long travel are also specified.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views1 pageAnnexure-I DSP-Weight Breakup of Crane 25T DG EOT Crane X 11.28 MTR Span

Annexure-I DSP-Weight Breakup of Crane 25T DG EOT Crane X 11.28 MTR Span

Uploaded by

MUBASHSHIR HELALThis document provides a weight breakdown of a 25T DG EOT crane with an 11.28 meter span. It lists the following key details:

1. The total weight of the crane without electrics is 51 tons, including 34 tons of structural weight and 17 tons of mechanical weight.

2. An additional 17 tons is included for mechanical components like alloy steel forgings, heat treated pinions and gears, and steel castings and fasteners.

3. The weight of the long travel rail and end stoppers is 10 tons. Motors and brakes for the main hoist, cross travel, and long travel are also specified.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

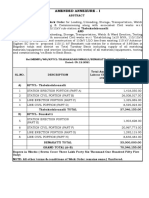

Annexure-I

DSP-Weight breakup of Crane File No.:-Steel/MKTG/F2/1.0447

25T DG EOT Crane x 11.28 mtr span Qty 1

Weight

(Duty Class M8, IS:3177, IS:807)

(in Tones)

Customer DSP

1 Wt. of crane without Electrics per crane 51.00 Special Features

Structural 34.00 1.Spring Buffer for CT & LT shall be

Mechanical 17.00 provided

2. Operation through Pendant+RRC

Mechanical wt. includes 3. MH- 01 no. single shank Hook with safety latch

Alloy steel forging and

3.00

heat treated pinions & gears 4. Ambient temperature=55ºC

Steel Forging 3.50 5. Laser type anti collision device.

Steel casting 3.00 6. Manual CGL system.

Crain rail for CT (CR80) 2.00 7. Festoon cable system for cross travel.

Fastnesrs 1.00 8. Parking Brake for LT Motion

Bearings 1.20 9. Tools and Tackles, Mandatory spares,

Wire ropes 0.50 2 yrs operational spares to be considered by

Lubricants 0.80 marketing.

Lubrication system 0.50 10. Data given in TS are converted into metric unit.

Hydraulic Jack 0.50 11. Marketing to consider scope of dismentling of

AC for E-room , Capacity:12KW, 2 no( 1 W +1 SB) 1.00 existing underslung crane.

12. Geared Coupling and Reduction Gear boxes shall

be of HEC make

Total 17.00 13. LT rail for entire bay shall be changed as it may be

old and worn out.

2 Weight of LT rail+ End stopper 10.00 T

3 Motors and brakes

Main hoist Cross Travel long Tarvel Note:

Motor

21.09 0.88 6.98

(Mech Kw) 1. Power supply to LT is considered through DSL,

No. of Motors 1 1 2 complete with all accessories.

RPM 750 750 750 2. VVVF drives shall be provided

Brakes size(mm) 300 160 200 3. Design, supply,erection of DSL under HEC's scope.

Type DCEM DCEM DCEM 4.E-room for panel

No. of Brakes 1 1 2 5. EDB to refer TS for electrics detail

Mech. KW = MV/6.120E for Hoists

Mech. KW = MV*(F + 1100 x a / 981x E) / 6117 T (For CT & LT)

Satish Kumar

DM/Crane

You might also like

- Typical HT & LT Power Cable Sizing CalculationDocument13 pagesTypical HT & LT Power Cable Sizing CalculationSamant Saurav100% (1)

- Mec 113 Basic Workshop Technology 1Document52 pagesMec 113 Basic Workshop Technology 1VietHungCao90% (21)

- Service Manual BELL Drop BoxDocument70 pagesService Manual BELL Drop BoxWere WolfNo ratings yet

- Vibrating Screen ManualDocument36 pagesVibrating Screen ManualJUNIOR ANDERSON TINOCO FALERONo ratings yet

- Typical HT and LT Power Cable Sizing PDFDocument26 pagesTypical HT and LT Power Cable Sizing PDF1382ace100% (2)

- Bus-bar-Sizing-Calculation For 5000 ADocument12 pagesBus-bar-Sizing-Calculation For 5000 Aanandpurushothaman100% (1)

- GA 132-180 VSD Part List (AIF 079019 Den)Document78 pagesGA 132-180 VSD Part List (AIF 079019 Den)Sales AydinkayaNo ratings yet

- BOQVIEWONLYDocument14 pagesBOQVIEWONLYVinay KumarNo ratings yet

- CalculationDocument33 pagesCalculationSwagat Pradhan100% (1)

- Document No. 6544-00-HH-DS-004, Rev. A Data Sheet Eot CraneDocument7 pagesDocument No. 6544-00-HH-DS-004, Rev. A Data Sheet Eot CraneSachin5586No ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- Cost Data 132 KVDocument14 pagesCost Data 132 KVJojolasNo ratings yet

- Manual RadioShack For PRO 2017Document32 pagesManual RadioShack For PRO 2017Benjamin Dover0% (1)

- VT Sizing Calculation For 132 KV Cable Feeder: Page 1 of 8Document8 pagesVT Sizing Calculation For 132 KV Cable Feeder: Page 1 of 8Chilukuri Jithendra100% (1)

- Solar Cable GTP 2.5 TO 50 SQ - MM - XLPE 1 1Document1 pageSolar Cable GTP 2.5 TO 50 SQ - MM - XLPE 1 1Koushik KarmakarNo ratings yet

- Material - Tech - High Impedance Differential Protection - 757208 - ENaDocument22 pagesMaterial - Tech - High Impedance Differential Protection - 757208 - ENaThet ThetNo ratings yet

- Data Sheet: Induction Motor Champion Series Motor Type: 1SE0 319-2NC80-Z SDocument1 pageData Sheet: Induction Motor Champion Series Motor Type: 1SE0 319-2NC80-Z SudayaNo ratings yet

- 16 Samss 503Document43 pages16 Samss 503Florante Nobleza100% (2)

- Fuzhou Tianyu Electric Co., LTD.: KYN31-12 Armored Metal-Enclosed Switch CabinetDocument26 pagesFuzhou Tianyu Electric Co., LTD.: KYN31-12 Armored Metal-Enclosed Switch CabinetRusman LumbantoruanNo ratings yet

- MP-6 Sonixs 800x600 2020 Rev ADocument184 pagesMP-6 Sonixs 800x600 2020 Rev Agoretty cantonNo ratings yet

- 19-02-2024 BSCPL Tdi JasolaDocument11 pages19-02-2024 BSCPL Tdi JasolaDarshit VyasNo ratings yet

- Assembly Data Symbol Units Value: Lo-Cog DC Servo GearmotorDocument2 pagesAssembly Data Symbol Units Value: Lo-Cog DC Servo GearmotorJuan De los PalotesNo ratings yet

- Unit Qty. Description of Work Sl. No.: Name & Address of The FirmDocument3 pagesUnit Qty. Description of Work Sl. No.: Name & Address of The Firmganeswar SahooNo ratings yet

- Motor Data Sheet 18. KW 4 PoleDocument1 pageMotor Data Sheet 18. KW 4 Poledeepak kumarNo ratings yet

- 0830AT54A2200 - LTE Multi-Band Ceramic Antenna - JohansonDocument10 pages0830AT54A2200 - LTE Multi-Band Ceramic Antenna - JohansonalexNo ratings yet

- GTP - Imb145Document1 pageGTP - Imb145Melvin Enoc Chavarría ZelayaNo ratings yet

- Amended Annexure - I: Ref:Mempl/Wo/Kptcl-Thabakadahonnalli/Benakatti/2021-22/071A Dated: 05.12.2021Document19 pagesAmended Annexure - I: Ref:Mempl/Wo/Kptcl-Thabakadahonnalli/Benakatti/2021-22/071A Dated: 05.12.2021PRADEEP basannavarNo ratings yet

- System Specifications: CompatibilityDocument2 pagesSystem Specifications: CompatibilityLuis PaizNo ratings yet

- 2KJ3514-7KN38-9AR1-Z B33+C46+D11+K01+K06+L02+L75+M10+M59+N1S+P92 Datasheet enDocument2 pages2KJ3514-7KN38-9AR1-Z B33+C46+D11+K01+K06+L02+L75+M10+M59+N1S+P92 Datasheet encaukhoeoNo ratings yet

- Techtop 7.5 HP PDFDocument4 pagesTechtop 7.5 HP PDFJOKO WIKARNANo ratings yet

- Maintenance Work Quotation For Mawlamyaing (MON 00236) : Core Site Power System Inspection and Maintenance ProjectDocument22 pagesMaintenance Work Quotation For Mawlamyaing (MON 00236) : Core Site Power System Inspection and Maintenance ProjectAung Thein OoNo ratings yet

- crouzetSW MS SS 83141 ENDocument4 pagescrouzetSW MS SS 83141 ENugucua.01No ratings yet

- Assembly Data Symbol Units Value: Lo-Cog DC GearmotorDocument2 pagesAssembly Data Symbol Units Value: Lo-Cog DC GearmotornickNo ratings yet

- 1 3500 1183a 02 PDFDocument3 pages1 3500 1183a 02 PDFTolias EgwNo ratings yet

- Part 5Document4 pagesPart 5Ashirvad RathNo ratings yet

- Website Revision Of: 10/100 Base-T Ethernet Isolation Transformer P/N: Ts21C HF Data SheetDocument2 pagesWebsite Revision Of: 10/100 Base-T Ethernet Isolation Transformer P/N: Ts21C HF Data Sheet8ctanoNo ratings yet

- Tana Wonjeta Fekerte Irrigation PumpDocument70 pagesTana Wonjeta Fekerte Irrigation PumpAda AntenehNo ratings yet

- Approved - 4977-AVBOT-Approval For Procurement of ATMSHTMS Accessories - NE-1Document3 pagesApproved - 4977-AVBOT-Approval For Procurement of ATMSHTMS Accessories - NE-1Rajesh DeyNo ratings yet

- BMT1B 01 05 00 A1Document10 pagesBMT1B 01 05 00 A1bemltc3rsdm 2022No ratings yet

- S4030 600F111001FVDocument290 pagesS4030 600F111001FVШибко ЯрикNo ratings yet

- TQC v2.2.2Document1 pageTQC v2.2.2IratiNo ratings yet

- HT Cable ScheduleDocument11 pagesHT Cable ScheduleVivek ThakurNo ratings yet

- 1LE1003 0DA21 7AB4 Datasheet enDocument1 page1LE1003 0DA21 7AB4 Datasheet enkamal_arbabNo ratings yet

- 1305 DriveDocument8 pages1305 DriveHdez AhfNo ratings yet

- 6029Gt Sales Gas Compressor Turbine Lube Oil Cooler Fan Motors Motor Tags - Xm11 & Xm33Document4 pages6029Gt Sales Gas Compressor Turbine Lube Oil Cooler Fan Motors Motor Tags - Xm11 & Xm33yenni aldanaNo ratings yet

- Email Ke Pak Budi - Electrical Work DM1W+B R2 Final 1Document6 pagesEmail Ke Pak Budi - Electrical Work DM1W+B R2 Final 1Serdadu LebahNo ratings yet

- BHEl Reply For TA & TM With Details - 01.09.2023Document8 pagesBHEl Reply For TA & TM With Details - 01.09.2023dycdemechirsmeNo ratings yet

- Resistance Heating Wire Iron-Chrome-Aluminum (Fe-Cr-Al) Alloy - KAFDocument2 pagesResistance Heating Wire Iron-Chrome-Aluminum (Fe-Cr-Al) Alloy - KAFAndruNo ratings yet

- DS Linear Motors P10-70x320U-BD-SSCDocument21 pagesDS Linear Motors P10-70x320U-BD-SSCArturo GomezNo ratings yet

- Item Wise Details of Mboa Proposed For Re - 2018-19Document24 pagesItem Wise Details of Mboa Proposed For Re - 2018-19venkateshbitraNo ratings yet

- KSG GranitesDocument3 pagesKSG Granitesshivakumar hiremathNo ratings yet

- 1LE2321-3CB11-2AA3 Datasheet en PDFDocument1 page1LE2321-3CB11-2AA3 Datasheet en PDFJolito RamosNo ratings yet

- 100kva DG Set - 100kva Koel GensetDocument3 pages100kva DG Set - 100kva Koel GensetMothilalNo ratings yet

- ComboTank Illustrated Parts ListDocument12 pagesComboTank Illustrated Parts ListsonotiumNo ratings yet

- ThyristorDocument13 pagesThyristorallhmfwk81No ratings yet

- CM7 User ManualDocument27 pagesCM7 User ManualMyllerNo ratings yet

- PNP Silicon Surface Mount Transistor With Monolithic Bias Resistor NetworkDocument10 pagesPNP Silicon Surface Mount Transistor With Monolithic Bias Resistor Networkyesid velasco ninaNo ratings yet

- MMR For Oct '10Document1 pageMMR For Oct '10karna_1999No ratings yet

- Am144fxvafr2aa Submittal 230V+HR 03182019Document2 pagesAm144fxvafr2aa Submittal 230V+HR 03182019Gene Williams Jr.No ratings yet

- Cost Data - Merged DocumentDocument135 pagesCost Data - Merged DocumentjaktomsNo ratings yet

- L1-CHE-SPE-060 Transmission Wire Hard-Drawn Copper 72.0 22mm 2Document7 pagesL1-CHE-SPE-060 Transmission Wire Hard-Drawn Copper 72.0 22mm 2CK TangNo ratings yet

- Purchase Requisition::Maintenance Sub Div 400kv Nirmal::1200004678/03.02.2022:ZserDocument2 pagesPurchase Requisition::Maintenance Sub Div 400kv Nirmal::1200004678/03.02.2022:ZserBoddu ThirupathiNo ratings yet

- Repsol Yard 3 and Jetty Rev2 (Blank BOQ With IT)Document8 pagesRepsol Yard 3 and Jetty Rev2 (Blank BOQ With IT)Bagas Lesta CoratiesNo ratings yet

- Resistance Heating Wire Nickel-Chromium Alloy 80% Nickel / 20% Chromium - N8Document2 pagesResistance Heating Wire Nickel-Chromium Alloy 80% Nickel / 20% Chromium - N8Idan FriedbergNo ratings yet

- LT Cable Datasheet and Type Test - NTPC-ELE-LT-036 - R2Document34 pagesLT Cable Datasheet and Type Test - NTPC-ELE-LT-036 - R2dilipnayak101406No ratings yet

- GAC-12-VX-RMH-LAH-006 - Rev 1 - GSUTDocument4 pagesGAC-12-VX-RMH-LAH-006 - Rev 1 - GSUTDipayan DasNo ratings yet

- Tir Lens Guide-Web PDFDocument8 pagesTir Lens Guide-Web PDFFilozófus ÖnjelöltNo ratings yet

- Aoc Auo Inverter Rework SopDocument13 pagesAoc Auo Inverter Rework SopVinicius MarcosNo ratings yet

- 8BK20 Operation enDocument24 pages8BK20 Operation enMufasa 7762No ratings yet

- Group 4 Connectors: 1. Connector DestinationDocument23 pagesGroup 4 Connectors: 1. Connector DestinationАлексейNo ratings yet

- Di6001 00 - en Us PDFDocument3 pagesDi6001 00 - en Us PDFTony IbraNo ratings yet

- Activity 4 Section BDocument3 pagesActivity 4 Section BSahil BijarniaNo ratings yet

- Datasheet 7X7 Galvanised Wire Strand CoreDocument1 pageDatasheet 7X7 Galvanised Wire Strand CoreAnonymous I8nZsDqlmhNo ratings yet

- 8570 NEC Plugs - ReceptaclesDocument6 pages8570 NEC Plugs - ReceptaclesleokoreaNo ratings yet

- TABLE (1) Single-Core PVC Insulated Cables, Non-Armoured, With or Without Sheath (COPPER CONDUCTORS)Document16 pagesTABLE (1) Single-Core PVC Insulated Cables, Non-Armoured, With or Without Sheath (COPPER CONDUCTORS)RubbenNo ratings yet

- 95 8723 U5015Document20 pages95 8723 U5015Jorge Isaac Lara RamosNo ratings yet

- SR03-01NMEA To Synchro Converter User Manual (REPEATER) PDFDocument45 pagesSR03-01NMEA To Synchro Converter User Manual (REPEATER) PDFTheodoreNo ratings yet

- MPR RitikDocument20 pagesMPR RitikRavan bhoyeNo ratings yet

- TM 11-617 1945 An - TRC-7Document194 pagesTM 11-617 1945 An - TRC-7Advocate100% (1)

- IMT G5 Suspended Plate MagnetsDocument2 pagesIMT G5 Suspended Plate Magnetssusmita.sivasankaranNo ratings yet

- Slide Film Developing E6Document2 pagesSlide Film Developing E6Coopers Photo ImagingNo ratings yet

- Infrared Camera - Thermal Imager - IR Camera - Thermal ImagingDocument7 pagesInfrared Camera - Thermal Imager - IR Camera - Thermal ImagingborescopeNo ratings yet

- Navin PhysicsDocument9 pagesNavin PhysicsNavin RaiNo ratings yet

- HameedDocument45 pagesHameedHassan JavaidNo ratings yet

- DIY Monitor HoodDocument1 pageDIY Monitor HoodNIkola VelkovNo ratings yet

- ESPA Interface Module BSL-333Document2 pagesESPA Interface Module BSL-333Prasetyo FatahNo ratings yet

- Elvs Offer For Ghana ProjectDocument1 pageElvs Offer For Ghana ProjectOsei Collins SnrNo ratings yet

- Pertemuan 7. Unit Protection (T. DAVIES) Protection of Industrial Power SystemsDocument24 pagesPertemuan 7. Unit Protection (T. DAVIES) Protection of Industrial Power Systemswijayaroni363No ratings yet

- Sony Ericsson K510i Service ManualDocument46 pagesSony Ericsson K510i Service ManualpiotreNo ratings yet