Professional Documents

Culture Documents

Np-Hip-Whd-052 - Road Works & Repair

Np-Hip-Whd-052 - Road Works & Repair

Uploaded by

Rene Heba0 ratings0% found this document useful (0 votes)

4 views6 pagesOriginal Title

NP-HIP-WHD-052- ROAD WORKS & REPAIR

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views6 pagesNp-Hip-Whd-052 - Road Works & Repair

Np-Hip-Whd-052 - Road Works & Repair

Uploaded by

Rene HebaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 6

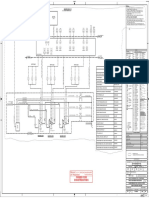

HAZARD IDENTIFICATION PLAN

WATER HANDLING DESOTTLENECKING PROJECT Soeamaigiste cad

‘Saudi Arum

CONTRACT CONTRACTOR — | BUDGET ITEM# Tme HP Rev# | TOTALPAGES

6500044281 | NESMA&PARTNERS | 10-0217 HIP FOR ROAD WORKS & REPAIR | NP-HIP-WHD-052 00 10f6

‘Job Descriptions 3 Aaphalt Worl Primer & Tack Goat Application

1. Loading and unloading of sandsso8 Asphalt Laying

2. Compaction 7. Shoveling & Raking

NESMA NESMIA NESMA PMT Safety PMT SPE

HSE Supervisor HSE Manager Project Manager

Name: Noell Bereso Name: Ralph F Mocled Name See atin 5 4 Name: Dhar

Date. S NOV, 2023 Date: 15NOv, 2021 Date: Nov | 26/26" Date

lof 6

‘ssificaion | Saudi Aramco —

‘© Over speeding duringvehicle

of sand / soil movernent around the job site

ROAD WORKS & REPAIR

party certificate and Saudi Aramco approval.

* Follow SAG traffic regulations and SA traffic requirements at allthe

times in allocation.

‘+ Not exceed the posted speed limit at any time.

‘© Use mobile phone, eating or drinking while driving is st

prohibited.

© The use or being under the influence of intoxicants or

‘medications which cause impairment to judgment while

operating vehicle is prohibited

‘+ Reduce vehicle speed under hazardous weather or road

conditions.

+ Safe route shall be identified and clearly marked,

+ Observe system of traffic flow.

Keep a close watch for people and traffic

* Only approved route shall be used for access and to egress fromthe

site,

‘+ Provide safe walkway to sidewalks in the job site for workers

protection against all moving vehicles & equipments.

‘Road shall be properly maintained for the convenience to all

commuters.

locate trained flagman/banks man. Operator must follow

I given by flagman / banks man and keep distance of

minimum & meters away from the equipment.

‘+ Back up alarm shall be installed and properly working prior to

use

Rotating beacon light must be on whilst in operation,

* Struck of personnel and other ‘© Back up alarm shall be installed and properly working prior to

‘equipmentduring reverse to use.

load/unload soi '* Operators shall sound the horn 3 times and walt S seconds

before reversing if vision is restricted, or get a spotter.

‘* Work area shall be barricaded properly with warning signs to

keep personnel in a safe distance from the activity

‘© Trained flagman shall be present in the workplace at all the

time with high visibility vest and green, red flag or light

illuminated baton and minimum distance & meters away from

the equipment.

* _ Rotating beacon light must be on whilst in operation.

P

Classification | Saudi Aramco eens

‘© Dust /Sandstorm

All involved personnel in the activity shall use rated dust mask.

Dust control- spraying water on top soil shall be implemented

regularly

Stop park the equipment when visi

obstructed.

gets poor or

© Slipand Trip

Clear walkways, work areas of equipment, tools, construction

2 Compaction

= Struck By

have valid Saudi Government License, 3rd

party certificate and Saudi Aramco approval.

Back up alarm shall be installed and properly working prior to

use

Operators shall sound the horn 3 times and wait 5 seconds

before reversing if vision is restricted, or get a spotter.

Work area shall be barricaded properly with warning signs to

keep personnel ina safe distance from the activity.

Trained flagman shall be present in the workplace at all the

time with high visi ht

luminated baton

All equipment should have PWAS installed

Never cover operator's window such as: card board, curtain or

any sun shade or protector.

Keep cut of the danger zone of operating equipment area.

‘© Noise above 85db. Generated by

equipment

Provide earplug/earmufs to all workers involved in the a

ity

= Dust

involved personnel in the activity shall use rated dust mask

‘ol spraying water on top soil shall be implemented

3. Base courselaying

‘© Manual handling ofbase course

Brief all workers on hazards of manual handling of base course

Ensure the area is clear from slip & trip hazard before handling

the materials,

Use mechanical means whenever possible.

“Take regular breaks or rotation of workers

‘© into paver machine

Heavy equipment shall be check prior to starting the activity

Back up alarm and rotating flashing beacon light shall be on,

hile operating & ensure PWAS system shall be operational.

Never put cover on operator window such as: card board,

‘curtain or any sun shade or protect

PWAS checklist shall be filled up by driver/operator & verify by

Classification | Saudi Aramco

Page 3 of 6

supervisor, foreman & area safety officer.

No personnel permitted in front of paver machine when the

truck is reversing.

Drivers /operators should follow the flagman given signal

‘Moving Parts / Entanglement

pavermachine

Do not clear hopper with shovel whilst slat conveyor

the hopper wings without first checking for

the presence of workers.

Flagman required ensuring the vehicle movement whilst crew

members clean the front of paver machine,

Wear appropriate PPE’s for the particular activity.

Dust

All involved personnel in the activity shall use rated dust mask.

Dust control- spraying water on top soil shall be implemented

regularly

Field DensityTest (FDT)

Personnel exposureto radioactive

hazards

‘Arrange separate

Radioactive materials shall be kept from public places and barricade

the area by 5 meters radius while conducting test.

Only trained and certified technician with approval from radiation

safety officer is authorized to handle radioactive materials/gauges.

Only the author conduct FOT test.

‘the FDT

jation which may arise and same

endorsed in the PTW, workers and supervisor.

Only the authorized technician shall transfer the nuclear gauge from

one point to other point on site.

Manual Handling

Verify the area is clear and safe before transferring the materials,

Rotation of workers when multiple lifts are required,

Handle with care to avoid falling and tilting of container.

Park the vehicles carrying radioactive material in a safe place that

cannot obstruct the access or road area,

Asphalt Works Primer &

‘Tack Coat Application

Chemical exposureduring spraying

Closed monitoring of construction supervisor & HSE representative

uring the task.

‘Assess the adjacent obstructions, parked vehicles, traffic etc. for risk of

contamination and remove obstruction or contral measure to mitigate

Follow safe work practices and specific trainings on how to work safely

ch the MSDS requirements.

Avoid skin contact; wear chemical-resistant gloves, boots, coveralls,

eyewear and other clothing as recommended in MSDS.

know in advance where the closest eyewash kit is located and how to

use it

Classification | Saudi Aramco

Page 4 of 6

h water for at least 15 minutes in

immediately for

Flush contaminated eyes or skit

case of accidental contact and c:

medical assistance.

Chemical burns

Chemical spills

Eye/skin damage

(Only competent personnel will carry out chemical handling.

Ensure to provide a proper supervision,

Use chemically resistant PPE including face shields, respirators, and

chemical suits when required.

Ground Personnel

Isolate the area through barricade and provide warning sign.

Sound horn twice before commencing the spraying act

Nobody shall be allowed to work close to the equipment while

equipments are moving.

Provide eye wash kit in the working area.

Ensure s lable on the trucks always.

Don’t spray ifs likely to rain.

Do not overspray or allow emulsion to pool in areas.

isa

Noise above 85 decibels

Generated by equipment

Provide earplug or ear muffs to all workers involved in the activity

6. Asphalt Laying

‘Manual Handling

Conduct TET multilanguage regarding hazards of asp

Brief all the workers on hazards of manual handling.

Ensure the area is clear from slip & trip hazard before handling the

materials,

Use mechanical means whenever possible.

Take regular breaks or rotation of workers.

ed rear visiontipping,

asphalt into paver machine

Al drivers should have valid SAG license and Aramco approved

certification or 3rd party certification

All trucks should have safety induction prior to enter the working area

Heavy equipment shall be checked prior to starting the activity,

Back up alarm and rotating flashing beacon light shall be on while

operating.

Never cover operator’s window such as: card board, curtain or any sun

shade or protector.

No personnel permitted behind paver machine when the truck is

reversing.

Drivers operators should follow the flagman given signal

‘Working with hot mix (manual

laying if required.)

Long sleeve clothing and protective footwear.

Handle the hot mix with shovel or mechanical aid.

jot mix use appropriate hand gloves.

‘Moving parts ofpaver machine

t clear hopper with shovel whilst slat conveyor is operational

Don't raise or lower the hopper wings without first checking for the

presence of workers,

Flagman required ensuring the vehicle movement whilst crew

members clean the front of paver machine.

Classification | Saudi Aramco

Page 5 of 6

Hot Surface

f the paver which may be hot,

contact with hot surfaces

7. Shoveling &Raking

Manual Handling

Use mechanical means whenever possible.

‘Take regular breaks or rotation of workers.

Utilize skid loader to di

Ensure shovel and rakes are in good con

Always place feet apart and assure adequate footing,

Proper body mechanics shall be maintained by bending legs. Keep back

straight during handling any materials.

Hold the shovel close to the body & shift feet when load.

Do not overload the shovel beyond your physical capacity.

Keep shovel and rake lubricated with release ag

Use the shovel to spread large amount of asphalt pri

‘not push large amounts of asphalt with rake.

raking, do

© Hot Asphalt '* Wear long sleeves and pants, safety shoes, leather gloves, & safety

goggles.

‘= Take extra precaution when laying asphalt on the ground.

‘+ Don’t touch the hot asphalt with bear hands.

& Emergencies ‘© Accidents / bodily injuries ° Fire Extinguishers, and other emergency kits shall be

ble in the working areas.

Everybody must know the Emergency Response procedure and Saudi

‘Aramco Emergency Numbers.

Proper emergency communication equipment & contact numbers shall

be provided to all workers.

Ambulance and Nurse shall be on site at

‘9, Housekeeping

Untidy and Messy workplaces

Keep floors clean and debris free mop up s

keep object of floors- put in correct storage areas.

Always look where you are going ~ do not assume there is a clear

path,

Keep scrap lumber with protruding nails separate from other debris;

Bend nails over or remove from lumber.

Keep all waste debris in neat piles and away from the immediate

work area.

Remove debris from the job on a regular basis:

Store materials only in their designated areas

Classification | Saudi Aramco.

Page 6 of 6

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- R901085036P00Document1 pageR901085036P00Rene HebaNo ratings yet

- 4 Ow 2651 1leouDocument4 pages4 Ow 2651 1leouRene HebaNo ratings yet

- R901084002P00Document1 pageR901084002P00Rene HebaNo ratings yet

- R901085037P00Document1 pageR901085037P00Rene HebaNo ratings yet

- R901084003P00Document1 pageR901084003P00Rene HebaNo ratings yet

- R901085038P00Document1 pageR901085038P00Rene HebaNo ratings yet

- Ta193115 002Document1 pageTa193115 002Rene HebaNo ratings yet

- TB 135483 001Document1 pageTB 135483 001Rene HebaNo ratings yet

- TB135483 005Document1 pageTB135483 005Rene HebaNo ratings yet

- TB 135483 006Document1 pageTB 135483 006Rene HebaNo ratings yet

- PAC Items U-8 W Remarks (4OCT2022)Document3 pagesPAC Items U-8 W Remarks (4OCT2022)Rene HebaNo ratings yet

- Np-Jsa-Whd-061-Equipment Opening and Line Breaking & Tie in WorksDocument9 pagesNp-Jsa-Whd-061-Equipment Opening and Line Breaking & Tie in WorksRene HebaNo ratings yet

- NP-JSA-WHD-003-General Excavation Works (R-5)Document9 pagesNP-JSA-WHD-003-General Excavation Works (R-5)Rene HebaNo ratings yet

- PAC Items U-8 - Updating - PIPING MECHANICALDocument1 pagePAC Items U-8 - Updating - PIPING MECHANICALRene HebaNo ratings yet

- Np-Jsa-Whd-038 - Fabrication & Erection of Piping Rev. 03Document10 pagesNp-Jsa-Whd-038 - Fabrication & Erection of Piping Rev. 03Rene HebaNo ratings yet