Professional Documents

Culture Documents

Hydraulic Seals-Fcs

Uploaded by

ABRAHAM EBEN ANDREWSOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydraulic Seals-Fcs

Uploaded by

ABRAHAM EBEN ANDREWSCopyright:

Available Formats

FCS FLUORO CARBON SEALS PVT LTD

(an ISO 9001:2008 Certified Company)

Quality, Reliability & Customers’ Satisfaction

HYDRAULIC SEALS

Manufacturers of

PTFE, VICTREX® PEEK, PCTFE, PVDF & PFA Components

WIPERS

Pressure Surface speed

Type Standardmaterial Temp. (°C)

(bar) (m/sec)

PU -30 to 105

FCS-WR01 - 4

NBR -25 to 100

PU -30 to 105

FCS-WR01A - 4

NBR -25 to 100

PU -30 to 105

FCS-WR02 - 4

NBR -25 to 100

PU -30 to 105

FCS-WR02A - 4

NBR -25 to 100

PU -30 to 105

FCS-WR02B - 4

NBR -25 to 100

PU -30 to 105

FCS-WR02C - 4

NBR -25 to 100

PU

FCS-WR02D - -30 to 105 4

PU-D57

PU/POM * -30 to105

FCS-WR03 - 4

NBR/POM * -25 to100

PU -30 to 105

FCS-WR04 - 4

NBR -25 to 100

POM -50 to 80

FCS-WR07 PA - -50 to 80 1

PU-D57 -30 to 105

POM -50 to 80

FCS-WR08 PA - -50 to 80 1

PU-D57 -30 to 105

PU -30 to 105

FCS-WR11 - 4

NBR -25 to 100

PU -30 to 105

FCS-WR12 - 4

NBR -25 to 100

FCS-WR13 PTFE/NBR 15 -25 to 100 10

FCS-WR13_E2 PTFE/NBR 15 -25 to100 10

FCS-WR14 PTFE/NBR 15 -25 to 100 10

FCS-WR15 PTFE/NBR 15 -25 to100 10

PU -30 to 105

FCS-WR17 - 4

NBR -25 to 100

PU -30 to 105

FCS-WR18 - 4

NBR -25 to 100

* For technical reasons POM should be used up to a maximum temperature of 80° C only. For higher temperature we recommend Aluminum/Steel.

Butterfly Soft Seat

ROD SEALS

Pressure Surface speed

Type Standardmaterial Temp. (°C)

(bar) (m/sec)

PU 400 -30 to 105

FCS-RS01 NBR 160 -25 to 100 0,5

FPM 160 -20 to 210

PU 300 -30 to 105

FCS-RS01A NBR 160 -25 to 100 0,5

FPM 160 -20 to 210

PU 400 -30 to 105

FCS-RS01B NBR 160 -25 to 100 0,5

FPM 160 -20 to 210

NBR 160 -25 to 100

FCS-RS01C 1

FPM 160 -20 to 210

PU/POM 700 -30 to 100

FCS-RS02 NBR/POM 250 -25 to 100 0,5

FPM/PTFE 250 -20 to 210

PU/POM 700 -30 to 100

FCS-RS02A NBR/POM 250 -25 to 100 0,5

FPM/PTFE 250 -20 to 210

FCS-RS02B PU/PTFE 700 -30 to 105 0,5

FCS-RS02C PU/POM 400 -25 to 100 5

FCS-RS03 PU/NBR 400 -25 to 100 0,5

FCS-RS04 PU/NBR/POM 700 -25 to 100 0,5

PU -30 to 105

FCS-RS05 25 1

NBR -25 to 100

PU 400 -30 to 105

FCS-RS08 0,3

NBR 160 -25 to 100

PU-D57/NBR 5

FCS-RS09 600 -25 to 100

PTFE/NBR 10

PU-D57/NBR 5

FCS-RS09A 600 -25 to 100

PTFE/NBR 10

PU-D57/NBR 5

FCS-RS09B 600 -25 to 100

PTFE/NBR 10

PU-D57/NBR 5

FCS-RS91 600 -25 to 100

PTFE/NBR 10

PU-D57/NBR 5

FCS-RS91B 600 -25 to 100

PTFE/NBR 10

PU -30 to 105

FCS-RS16 160 0,5

NBR -25 to 100

PU 400 -30 to 105

FCS-RS17 0,5

NBR 160 -25 to 100

FCS-RS17A PU/POM 700 -30 to 100 0,5

Butterfly Soft Seat

ROD SEALS

Pressure Surface speed

Type Standardmaterial Temp. (°C)

(bar) (m/sec)

FCS-RS17B PU/NBR 400 -25 to 100 0,5

FCS-RS17C PU/NBR/POM 700 -25 to 100 0,5

FCS-RS17D PU 400 -30 to 105

0,3

NBR 160 -25 to 100

FCS-RS17E PU/POM 700 -30 to 100 0,3

FCS-RS19 PTFE-virgin / V-spring 200

-200 to 260 15

PTFE-Filled / V-spring 400

FCS-RS19A PTFE/V-spring 150 -200 to 260 2

FCS-RS20 NBR/POM 700 -25 to 100 0,5

FCS-RS31-33 PU/POM 500 -30 to 100 0,5

FCS-RS35 PU 400 -30 to 105 0,4

PISTON SEALS

Pressure Surface speed

Type Standardmaterial Temp. (°C)

(bar) (m/sec)

PU 400 -30 to 105

FCS-PS01 NBR 160 -25 to 100 0,5

FPM 160 -20 to 210

PU 300 -30 to 105

FCS-PS01A NBR 160 -25 to 100 0,5

FPM 160 -20 to 210

PU 400 -30 to 105

FCS-PS01B NBR 160 -25 to 100 0,5

FPM 160 -20 to 210

NBR 160 -25 to 100

FCS-PS01C 1

FPM 160 -20 to 210

PU/POM 700 -30 to 100

FCS-PS02 NBR/POM 250 -25 to 100 0,5

FPM/PTFE 250 -20 to 210

PU/POM 700 -30 to 100

FCS-PS02A NBR/POM 250 -25 to 100 0,5

FPM/PTFE 250 -20 to 210

FCS-PS03 PU/NBR 400 -25 to 100 0,5

FCS-PS04 PU/NBR/POM 700 -25 to 100 0,5

PU -30 to 105

FCS-PS05 25 1

NBR

Butterfly Soft Seat

PISTON SEALS

Pressure Surface speed

Type Standardmaterial Temp. (°C)

(bar) (m/sec)

PU-D57/NBR 5

FCS-PS08 600 -25 bis 100

PTFE/NBR 15

PU/NDR 250 1

FCS-PS08A PU-D57/NBR 400 -25 to 100 5

PTFE/NBR 400 15

PU-D57/NBR 5

FCS-PS08B 600 -25 to 100

PTFE/NBR 10

FCS-PS08C PTFE/NBR 400 -25 to 100 2

FCS-PS08D PTFE/NBR 400 -25 to 100 3

PU-D57/NBR 5

FCS-PS08E 600 -25 to 100

PTFE/NBR 10

PU-D57/NBR 400 5

FCS-PS08F -25 to 100

PU/NBR 250 1

PU-D57/NBR 5

FCS-PS81 600 -25 to 100

PTFE/NBR 10

PU-D57/NBR 5

FCS-PS81B 600 -25 to 100

PTFE/NBR 10

FCS-PS09 PU/NBR/POM 400 -25 to 100 0,5

FCS-PS09A PTFE/NBR/POM 400 -25 to 100 1

PU -30 to 105

FCS-PS16 160 0,5

NBR -25 to 100

PU -30 to 105

FCS-PS16A 160 0,5

NBR -25 to 100

PU/POM 400

FCS-PS17 -25 to 100 0,5

NBR/POM 250

PU/POM 400

FCS-PS17A -25 to 100 0,5

NBR/POM 250

PU/POM 400

FCS-PS17B -25 to 100 0,5

NBR/POM 250

PTFE-virgin / V-spring 200

FCS-PS19 -200 to 260 15

PTFE-Filled / V-spring 400

PTFE-virgin / V-spring 200

FCS-PS19A -200 to 260 2

PTFE-Filled / V-spring 400

FCS-PS20 NBR/POM 700 -25 to 100 0,5

FCS-PS23 PU/NBR/POM 400 -25 to 100 0,5

FCS-PS35 PU 400 -30 to 105 0,4

Butterfly Soft Seat

SYMMETRICAL SEALS

Pressure Surface speed

Type Standardmaterial Temp. (°C)

(bar) (m/sec)

PU 400 -30 to 105

FCS-PRS06 0,5

NBR 160 -25 to 100

PU 300 -30 to 105

FCS-PRS06A 0,5

NBR 160 -25 to 100

PU 400 -30 to 105

FCS-PRS06B 0,5

NBR 160 -25 to 100

PU 400 -30 to 105

FCS-PRS06C 0,3

NBR 160 -25 to 100

PU 400 -30 to 105

FCS-PRS06D 0,5

NBR 160 -25 to 100

PU 400 -30 to 105

FCS-PRS06E 0,5

NBR 160 -25 to 100

FCS-PRS07 PU/NBR 400 -25 to 100 0,5

PU -30 to 105

FCS-PRS10SP FPM - -20 to 210 -

POM -60 to 100

PU/POM 500 -30 to 100

FCS-PRS10-12 0,5

NBR/POM 250 -25 to 100

PU/POM 500 -30 to 100

FCS-PRS13-15 0,5

NBR/POM 250 -25 to 100

FCS-PRS18 PU/NBR 400 -25 to 100 0,5

PTFE-virgin / V-spring 200

FCS-PRS19 -200 to 260 15

PTFE-Filled / V-spring 400

PTFE-virgin / Helicoil Spring 200

FCS-PRS19B PTFE-Filled / Helicoil Spring

-200 to 260 5

400

PTFE-virgin / Helicoil Spring 200

FCS-PRS19C PTFE-Filled / Helicoil Spring

-200 to 260 5

400

PTFE-virgin / Helicoil Spring 200

FCS-PRS19D PTFE-Filled / Helicoil Spring

-200 to 260 5

400

PU/POM 400 -30 to 100

FCS-PRS22 NBR/POM 160 -25 to 100 0,5

FPM/PTFE 160 -20 to 210

PTFE-virgin

FCS-PRS25-27 100 -200 to 260 1,5

PTFE-illed

PU 400 -30 to 105

FCS-PRS99 NBR 160 -25 to 100 0,5

FPM 160

Butterfly Soft Seat

BACK-UP RINGS

Pressure Surface speed

Type Standardmaterial Temp. (°C)

(bar) (m/sec)

POM -60 to 100

FCS-BUR08 - -

PTFE -200 to 260

POM -60 to 100

FCS-BUR09 - -

PTFE -200 to 260

POM -60 to 100

FCS-BUR10 - -

PTFE -200 to 260

POM -60 to 100

FCS-BUR11 - -

PTFE -200 to 260

POM -60 to 100

FCS-BUR12 - -

PTFE -200 to 260

POM -60 to 100

FCS-BUR13 - -

PTFE

GUIDE RINGS

Pressure Surface speed

Type Standardmaterial Temp. (°C)

(bar) (m/sec)

POM -60 to 100

FCS-BWR01 PTFE - -200 to 260 4

Polyester-fabric* -40 to 130

POM -60 to 100

FCS-BWR01A - 4

PTFE -200 to 260

POM -60 to 100

FCS-BWR03 - 4

PTFE -200 to 260

POM -60 to 100

FCS-BWR04 - 4

PTFE -200 to 260

POM -60 to 100

FCS-BWR05 - 4

PTFE -200 to 260

POM -60 to 100

FCS-BWR06 - 4

PTFE -200 to 260

POM -60 to 100

FCS-BWR07 - 4

PTFE -200 to 260

POM -60 to 100

FCS-BWR08 - 4

PTFE -200 to 260

FCS-BWR09 - - -

*

Various dimensions available in reels.

Butterfly Soft Seat

ROTARY SEALS

Pressure Surface speed

Type Standardmaterial Temp. (°C)

(bar) (m/sec)

PU/POM* 0,5 -30 to 100 5

FCS-OS01 NBR/POM* 0,5 -25 to 100 10

FPM/PTFE 0,5 -20 to 210 15

PU/POM* 0,5 -30 to 100 5

FCS-OS02 NBR/POM* 0,5 -25 to 100 10

FPM/PTFE 0,5 -20 to 210 15

PU 0,5 -30 to 100 5

FCS-OS03 NBR 0,5 -25 to 100 10

FPM 0,5 -20 to 210 15

PU -30 to 105 5

FCS-OS08 -

NBR -25 to 100 10

PU -30 to 105 5

FCS-OS08A -

NBR -25 to 100 10

PU/POM 400 -30 to 100 0,2

FCS-R03 NBR/POM 250 -25 to 100 0,2

PU 160 -30 to 105 0,2

FCS-R04 NBR 100 -25 to 100 0,2

PU 160 -30 to 105 0,2

FCS-R04A NBR 100 -25 to 100 0,2

PU 160 -30 to 105 0,2

FCS-R05 NBR 100 -25 to 100 0,2

PU 160 -30 to 105 0,2

FCS-R05A NBR 100 -25 to 100 0,2

FCS-VR06 NBR - -25 to 100 25

FCS-VR07 NBR - -25 to 100 25

FCS-R08 PTFE/NBR 350 -25 to 100 0,4

FCS-R08D PTFE/NBR 350 -25 to 100 0,4

FCS-R09 PTFE/NBR 350 -25 to 100 0,4

FCS-R09A PTFE/NBR 350 -25 to 100 0,4

FCS-R10 PTFE/NBR 350 -25 to 100 0,4

FCS-R10A PTFE/NBR 350 -25 to 100 0,4

FCS-R11 PTFE/NBR 350 -25 to 100 0,4

FCS-R11D PTFE/NBR 350 -25 to 100 0,4

* For technical reasons POM should be used up to a maximum temperature of 80° C only. For higher temperature we recommend Aluminum/Steel.

Butterfly Soft Seat

STATIC SEALS & O - RINGS

Pressure Surface speed

Type Standardmaterial Temp. (°C)

(bar) (m/sec)

PU 400 -30 to 105

FCS-FL01A FPM 250 -20 to 210 -

EPDM 250 -50 to 130

PU 400 -30 to 105

FCS-FL02B FPM 250 -20 to 210 -

EPDM 250 -50 to 130

PU 600 -30 to 105

FCS-FL03 NBR 250 -25 to 100 -

FPM 250 -20 to 210

FCS-FL06 PTFE-virgin / Helicoil Spring 200

PTFE-Filled / Helicoil Spring -60 to 200 0,1

400

FCS-FL07 PTFE-virgin / Helicoil Spring 200

PTFE-Filled / Helicoil Spring -60 to 200 0,1

400

PU 600 -30 to 105

FCS-OR NBR 160 -25 to 100 -

FPM 160 -20 to 210

PU 600 -30 to 105

FCS-ORH NBR 160 -25 to 100 -

FPM 160 -20 to 210

PU 600 -30 to 105

FCS-ORV NBR 160 -25 to 100 -

FPM 160 -20 to 210

PU 600 -30 to 105

FCS-QR01 NBR 160 -25 to 100 -

FPM 160 -20 to 210

PU 600 -30 to 105

FCS-QR02 NBR FCS- 160 -25 to 100 -

FPM 160 -20 to 210

PU 600 -30 to 105

FCS-SS01 NBR 250 -25 to 100 -

FPM 250 -20 to 210

CUSTOMIZED SEALS & MACHINED PARTS

Butterfly Soft Seat

MINING SEALS

Pressure Surface speed

Type Standardmaterial Temp. (°C)

(bar) (m/sec)

400 dyn. 0,5

FCS-P50 PU/POM -30 to 100

1500 stat.** 0,2

400 dyn. 0,5

FCS-P50A PU/POM -30 to 100

1500 stat.** 0,2

400 dyn. 0,5

FCS-P51 PU/NBR/POM -25 to 100

1500 stat.** 0,2

400 dyn. 0,5

FCS-P51A PU/NBR/POM -25 to 100

1500 stat.** 0,2

400 dyn. 0,5

FCS-P51G PU/NBR/POM -25 to 100

1500 stat.** 0,2

700 dyn. 0,5

FCS-P52 PU/POM -30 to 100

1500 stat.** 0,2

700 dyn. 0,5

FCS-P53 PU/NBR/POM -25 to 100

1500 stat.** 0,2

400 dyn. 0,5

FCS-P54 PU/NBR/POM -25 to 100

1500 stat.** 0,2

400 dyn. 0,5

FCS-P54A PU/NBR/POM -25 to 100

1500 stat.** 0,2

PU/POM 700 dyn./1500 stat.** 0,5/0,2

FCS-P55 -25 to 100

NBR/POM 400 dyn./1500 stat.** 0,5/0,2

FCS-R50 PU/NBR/POM 700 -25 to 100 0,5

FCS-R50A PU/NBR/POM 700 -25 to 100 0,5

FCS-R51 PU/NBR 400 -25 to 100 0,5

FCS-R52 PU/POM 700 -30 to 100 0,5

FCS-R53 PU 400 -30 to 105 0,5

FCS-W50 PU - -30 to 105 2

FCS-W51 PU - -30 to 105 2

FCS-W53 PU/POM* - -30 to 80 2

FCS-W54 PU - -30 to 105 2

POM -60 to 100

FCS-BWR01-P - 4

PTFE -200 to 260

POM -60 to 100

FCS-BWR01-R - 4

PTFE -200 to 260

FCS-P58 PU 400 -30 to 105 0,3

* For technical reasons POM should be used up to a maximum temperature of 80° C only. For higher temperature we recommend Aluminum/Steel.

Butterfly Soft Seat

TABLE OF MATERIALS

Application

Description Color Hardn. at 20°C Main application

temp.

PU Lip seals, wiper rings, vee packings and other seal elements

U500-R95 -30 to +125°C Shore A 95 +/-2 Mineral oils, HFA, HFB Fluids, water, sea water, dilute acids and alkaline solutions

red improved chemical and thermal resistance excellent wear and friction properties

PU Lip seals, wiper rings, vee packings and other seal elements

* all Polyurethane grades resistant to hydrolysis

U510-G88 -30 to +115°C Shore A 90 +/-2 Mineral oils, HFA, HFB Fluids, water, sea water, dilute acids and alkaline solutions

light green Application for pneumatic and low pressure

PU Lip seals, wiper rings, vee packings and other seal elements

U520-OR95-HT -30 to +135°C Shore A 96 +/-2 Mineral oils, HFA, HFB Fluids, water, sea water, dilute acids and alkaline solutions

orange Applications at high temperature

PU Lip seals, wiper rings, vee packings and other seal elements

U530-B95-LT -50 to +105°C Shore A 95 +/-2 Mineral oils, HFA, HFB Fluids, water, sea water

light blue Applications at low temperature

PU Lip seals, wiper rings, vee packings and other seal elements

Mineral oils, HFA, HFB FFluids, water, sea water

U540-VI95-CR -30 to +115°C Shore A 95 +/-2 Improved chemical resistance, suitable for CIP processes

violet Applicable for contact with foodstuff

PU

Lip seals, wiper rings, vee packings and other seal elements

U550-GM95

-30 to +125°C Shore A 95 +/-2 Mineral oils, HFA, HFB Fluids, water, sea water

dark red Improved wear and friction properties for waterhydraulics and heavy duty applications

with low lubrication

POLYURETHANE

PU Lip seals, wiper rings, vee packings and other seal elements

U570-D57 -30 to +125°C Shore D 57 +/-3 Mineral oils, HFA, HFB Fluids, water, sea water

blue High pressure and extrusion resistance

PU Back-up rings or composite seals with preload element

Mineral oils, HFA, HFB Fluids, water, sea water

U580-D57G -30 to +125°C Shore D 57 +/-3 High pressure and extrusion resistance

grey Improved wear and friction properties

PU

Lip seals, wiper rings, vee packings and other seal elements

U203-G95 -30 to +105°C Shore A 95 +/-2 Mineral oils, HFA, HFB Fluids, water, sea water

green

NBR

Lip seals, wiper rings, vee packings and other seal elements

N107-B85 -25 to +100°C Shore A 85 +/-5 Mineral oils, HFA, HFB, HFC Fluids, cold water

black

NBR 95

Lip seals, wiper rings, vee packings and other seal elements

NBR

N109-B95 -25 to +100°C Shore A 95 +/-5 Mineral oils, HFA, HFB, HFC Fluids, cold water

black

NBR FDA Lip seals, wiper rings, vee packings and other seal elements

N111-W85 -22 to +100°C Shore A 85 +/-3 Mineral oils, HFA, HFB, HFC Fluids, cold water

white Applicable for contact with foodstuff

H-NBR Lip seals, wiper rings, vee packings and other seal elements

HN112-B85 -25 to +150°C Shore A 85 +/-5 Mineral oils, HFA, HFB, HFC Fluids at high temperature

black Aliphatic hydrocarbons, dilute acids and bases

H-NBR RGD Lip seals, wiper rings, vee packings and other seal elements

Mineral oils, HFA, HFB, HFC Fluids at high temperature

H-NBR

HN900-B85-RGD -20 to +150°C Shore A 85 +/-5 Aliphatic hydrocarbons, dilute acids and bases

black RGD (ED) optimized for use in Oil & Gas Industry

Lip seals, wiper rings, vee packings and other seal elements

H-NBR RGD LT Mineral oils, HFA, HFB, HFC Fluids at high temperature

HN901-B85-RGD -40 to +150°C Shore A 85 +/-5 Aliphatic hydrocarbons, dilute acids and bases

black RGD (ED) optimized for low temperature use in Oil & Gas Industry

Meets the NORSOK M-710 requirements

FPM Lip seals, wiper rings, vee packings, oil seals at high speed and other seal elements

F109-BR85 -20 to +210°C Shore A 85 +/-5 Mineral oils, HFD Fluids at high temperature | Very good chemical resistance such as

brown phosphates and chlorinated hydrocarbons, crude and sour gas

FPM FDA Mineral oils, HFD Fluids at high temperature

F110-BR85 -25 to +210°C Shore A 85 +/-5 Very good chemical resistance such as phosphates and chlorinated hydrocarbons, crude

brown and sour gas | Applicable for contact with foodstuff

FPM

FPM Lip seals, wiper rings, vee packings, oil seals at high speed and other seal elements

F111-B85 -25 to +210°C Shore A 85 +/-5 Mineral oils, HFD Fluids at high temperature | Very good chemical resistance such as

black phosphates and chlorinated hydrocarbons, crude and sour gas

FPM-RGD Lip seals, wiper rings, vee packings and other seal elements

Mineral oils, HFD Fluids at high temperature | Very good chemical resistance such as

F800-B85-RGD -30 to +210°C Shore A 85 +/-5 phosphates and chlorinated hydrocarbons, crude and sour gas | RGD (ED) optimized for

black use in Oil & Gas Industry | Meets the NORSOK M-710 requirements

Butterfly Soft Seat

TABLE OF MATERIALS

Application

Description Color Hardn. at 20°C Main application

temp.

EPDM Lip seals, vee packings and other seal elements

E131-B85 -50 to +130°C Shore A 85 +/-5 Hot water and steam, ozone, dilute acids and alkaline solutions.

black EPDM is NOT resistant against mineral oils

EPDM FDA Lip seals, vee packings and other seal elements

EPDM

Hot water and steam, ozone, dilute acids and alkaline solutions.

E132-W85 -50 to +100°C Shore A 85 +/-3 EPDM is NOT resistant against mineral oil

white Applicable for contact with foodstuff

EPDM KTW Lip seals, vee packings and other seal elements

Hot water and steam, dilute acids and alkaline solutions.

E133-W270 -45 to +120°C Shore A 85 +/-5 EPDM is NOT resistant against mineral oil

black Applicable for use in drinking water

Silicone FDA Flange seals, gaskets and other static seals

Mineral oils, HFA, HFB, HFC, HFD Fluids, ozone

S102-R85 -55 to +210°C Shore A 85 +/-5

SILICONE

Not recommended for dynamic applications

red Applicable for contact with foodstuff

Silicone FDA Flange seals, gaskets and other static seals

Mineral oils, HFA, HFB, HFC, HFD Fluids, ozone

S103-BL85 -55 to +180°C Shore A 85 +/-3 Not recommended for dynamic applications

blue Applicable for contact with foodstuff

AFLAS

TFE/P

Lip seals, vee packings and other seal elements

AF101-B85 -15 to +210°C Shore A 85 +/-5 Mineral oils, HFA, HFB, HFC, HFD Fluids

black Hot water and steam, ozone, dilute acids and alkaline solutions, Sour oil and gas, amines

PTFE-P FDA Composite seals with elastomer preload elements, spring loaded

seals, Back-up and guide rings

T101-W -200 to +260°C Shore D 51 - 60 Resistance to almost all common chemicals and Fluids except molten alkaline metals.

white Applicable for contact with foodstuff

PTFE-F Composite seals with elastomer preaload elements

Spring loaded seals, back-up and guide rings

T105-G -200 to +260°C Shore D 55 - 64 Resistance to almost all common chemicals and Fluids except molten alkaline metals.

grey Glass ibre / MoS2 reinforced for improved wear and extrusion resistance

PTFE

PTFE-40% Composite seals with elastomer preaload elements

T110-BR40 -200 to +260°C Shore D 62 - 67 Resistance to almost all common chemicals except molten alkaline metals.

bronze brown Filled with 40% bronze for improved wear, pressure and extrusion resistance

PTFE-25% Composite seals with elastomer preaload elements

Spring loaded seals, back-up and guide rings, rotary seals

T125-C25 -200 to +260°C Shore D 62 - 67 Resistance to almost all common chemicals except molten alkaline metals.

carbon grey 25% carbon powder friction properties and increased extrusion resistance

POM FDA Back-up and guide rings, machined parts with tight tolerances

P101-WE -50 to +100°C - Mineral oils, HFA, HFB, HFC Fluids

white Minor absorption of water, applicable for contact with foodstuff

PA FDA Back-up and guide rings, machined parts

A112-WC -40 to +90°C - Mineral oils, acids and dilute alkaline solutions

PLASTICS

natural Applicable for contact with foodstuff

PEEK natural Composite seals with elastomer preload elements,

Back-up and guide rings high prescision parts

PK100-CN

-50 to +250°C Shore D 90 Excellent wear, friction and extrusion properties

beige Resistance to almost all common chemicals

Applicable for contact with foodstuff

UHMW - PE Back-up and guide rings, spring loaded seals

Mineral oils, HFC, HFD Fluids, acids and dilute alkaline solutions, Sour oil and gas

PE1000-HD -200 to +80°C Shore D 60 - 65 Very low water absorption, excellent friction and wear properties

white Applicable for contact with foodstuff

The indicated minimum application temperatures are thought as a general guideline, because a seal‘s function

at low temperatures is dependent on the kind of the seal, the general application conditions, and on the kind of

the surrounding metal parts the seal is in touch with. The indicated upper temperature limits may be exceeded,

but this reduces the service life. Other materials available on request.

In case of doubt you are always welcome to contact our application engineers.

Butterfly Soft Seat

(an ISO 9001:2008 Certified company)

3/178, Old Mahabalipuram Road,

Thuraipakkam, Chennai - 600 097. India

Tel: 91-044-2458 0666, 2458 0888 Telefax: 91-044-2458 0707.

e-Mail: fcs@fluorocarbonseals.net, info@fluorocarbonseals.net

Web: www.fluorocarbonseals.com

Manufacturers of

PTFE, Victrex ® PEEK, PCTFE(Kel-F), PFA, PVDF, VESPAL, NYLON MOS2, ACETAL, DEVLON ,

UHMWPE, FFKM, FKM, HNBR, EPDM and other Engineering Polymer Components.

FCS - 2016

You might also like

- Mass Effect 5e - The HomebreweryDocument253 pagesMass Effect 5e - The HomebreweryRony Do CarmoNo ratings yet

- Big Shot Underground Piercing ToolsDocument2 pagesBig Shot Underground Piercing ToolsFootage Tools IncNo ratings yet

- Solution Manual For A Friendly Introduction To Numerical Analysis Brian BradieDocument14 pagesSolution Manual For A Friendly Introduction To Numerical Analysis Brian BradieAlma Petrillo100% (43)

- Annexure 3 Courtesy Car AgreementDocument3 pagesAnnexure 3 Courtesy Car AgreementManishNo ratings yet

- Chloroprene Rubber CR Selection Guide The Chloroprene Rubber (CR) Used in General Industrial Rubber ProductsDocument2 pagesChloroprene Rubber CR Selection Guide The Chloroprene Rubber (CR) Used in General Industrial Rubber ProductsPhuong The Nguyen100% (1)

- Kastas NewProductsCatalogue enDocument86 pagesKastas NewProductsCatalogue enjohnysonycum0% (2)

- Catalogo HerculesDocument15 pagesCatalogo HerculesjhhvgNo ratings yet

- High Pressure - Valves Ball Valve BKH BSP/NPT: Material: Seals: Working Temp.Document5 pagesHigh Pressure - Valves Ball Valve BKH BSP/NPT: Material: Seals: Working Temp.tadilakshmikiranNo ratings yet

- Anexo 5 - Válvula de BolaDocument23 pagesAnexo 5 - Válvula de BolaclulloaNo ratings yet

- World Class Sealing: FASS Dichtungen Private LimitedDocument2 pagesWorld Class Sealing: FASS Dichtungen Private LimitedPratik MoreNo ratings yet

- PF Series Tech FlyerDocument2 pagesPF Series Tech FlyerEduardo PNo ratings yet

- Large Diameter Optical Fiber CleaverDocument2 pagesLarge Diameter Optical Fiber CleaverTourchianNo ratings yet

- Fcs Fluoro Carbon Seals PVT LTD: O-RingsDocument36 pagesFcs Fluoro Carbon Seals PVT LTD: O-Ringsvikram velayuthamNo ratings yet

- Manguera C-Inc. Poliester Acop. Br. de 30MTS 150psi 5 Elem Certf - FMDocument1 pageManguera C-Inc. Poliester Acop. Br. de 30MTS 150psi 5 Elem Certf - FMEdgar YauriNo ratings yet

- Blue-White Pool Brochure 2020b CA-1Document6 pagesBlue-White Pool Brochure 2020b CA-1Quang SinhNo ratings yet

- HANGER FULL SET Drawings Roof PurlinDocument2 pagesHANGER FULL SET Drawings Roof PurlinReem KhaledNo ratings yet

- Brass Ball Valve B 300TDocument2 pagesBrass Ball Valve B 300TMateusz BiskupNo ratings yet

- 5elem Lona - 250psi - Listada PDFDocument1 page5elem Lona - 250psi - Listada PDFChristian Ricra100% (1)

- 1 & 2 Ball Valve BONDVALVESDocument2 pages1 & 2 Ball Valve BONDVALVESHA TRADINGSNo ratings yet

- 201 PU Conveyor BeltDocument3 pages201 PU Conveyor BeltDavid ChinNo ratings yet

- Counterpart Products List PODAX WAXDocument1 pageCounterpart Products List PODAX WAXhuy.dicNo ratings yet

- Item: Aux Boiler Vendor: PT. Maxitherm Boilers Indonesia Discipline: Structure & PlatformDocument19 pagesItem: Aux Boiler Vendor: PT. Maxitherm Boilers Indonesia Discipline: Structure & PlatformPratama Eka Putra SijabatNo ratings yet

- Replanteo PTFEIN23-106 - 21072023Document1 pageReplanteo PTFEIN23-106 - 21072023Martin ZegarraNo ratings yet

- Univeral WPS For Pipe To Plate Fillet Welding (6800009)Document1 pageUniveral WPS For Pipe To Plate Fillet Welding (6800009)Ibrahim shaikNo ratings yet

- P&ID 5000 LPH Softener Plant R0Document1 pageP&ID 5000 LPH Softener Plant R0Sameer WareNo ratings yet

- MH15000 20160913 CertificateofComplianceDocument2 pagesMH15000 20160913 CertificateofCompliancelou janeNo ratings yet

- Reciprocating CompressorsDocument1 pageReciprocating CompressorsSh.nasirpurNo ratings yet

- 50 NB Ms-Inlet: Sumitomo Chemical India Ltd. Tag. NoDocument1 page50 NB Ms-Inlet: Sumitomo Chemical India Ltd. Tag. NoPrathmesh GujaratiNo ratings yet

- Ghibson ButterflyDoubleEccentric BrochureDocument9 pagesGhibson ButterflyDoubleEccentric Brochurejhon jairo arangoNo ratings yet

- Consumable Parts List UNIX-DFDocument2 pagesConsumable Parts List UNIX-DFBenji BananaNo ratings yet

- Zaptivni Elementi PDFDocument100 pagesZaptivni Elementi PDFBranko Dimitric Dime100% (1)

- Coordinacion 294-FAN-004MDocument1 pageCoordinacion 294-FAN-004MBoris Yeltsein Jove CaceresNo ratings yet

- Discharge Hose FH-50HC - Rv05Document1 pageDischarge Hose FH-50HC - Rv05cham hoiNo ratings yet

- C1a-1Document9 pagesC1a-1Darwin CornejoNo ratings yet

- P200 Plastic EOM - WIL 11070 E ULTUMO PDFDocument1 pageP200 Plastic EOM - WIL 11070 E ULTUMO PDFAlex SanzNo ratings yet

- 11 TFS Toyofood-S EngDocument2 pages11 TFS Toyofood-S EngHalimNo ratings yet

- SFL GAU 300 3.5 Mánometro SecoDocument1 pageSFL GAU 300 3.5 Mánometro Secoadministración camelotNo ratings yet

- SFL-GAU-300-3.5 - Mánometro SecoDocument1 pageSFL-GAU-300-3.5 - Mánometro SecoJimmy FernándezNo ratings yet

- Tube Fitting Stainless SUS304 SeriesDocument12 pagesTube Fitting Stainless SUS304 SeriessunanNo ratings yet

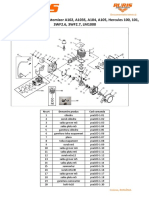

- Documentatie Tehnica Atomizor A102, A103, A103s, Hercules 100,3wf 2.6,3wf 2.7Document6 pagesDocumentatie Tehnica Atomizor A102, A103, A103s, Hercules 100,3wf 2.6,3wf 2.7razvan.pintilieNo ratings yet

- Merkel U-Ring N 100, AUN 100: MaterialDocument7 pagesMerkel U-Ring N 100, AUN 100: MaterialEloy Colque ANo ratings yet

- Pcs 100 eDocument2 pagesPcs 100 eWilson Yecit OrtizNo ratings yet

- Documentatie Tehnica Atomizor A102, A103, A103S, Hercules 100,3WF 2.6,3WF 2.7Document6 pagesDocumentatie Tehnica Atomizor A102, A103, A103S, Hercules 100,3WF 2.6,3WF 2.7Ionuț CojocariuNo ratings yet

- m1100 s06 v1.1f en - Engineered - PlasticsDocument18 pagesm1100 s06 v1.1f en - Engineered - Plasticsdzul fiqarNo ratings yet

- High Density Polyethylene Pipe Hdpe Pe 100 Page 22 23Document2 pagesHigh Density Polyethylene Pipe Hdpe Pe 100 Page 22 23Tony JamesNo ratings yet

- Data Sheet: Cello HR 290/O Cello HR 290/71Document2 pagesData Sheet: Cello HR 290/O Cello HR 290/71FWEFWEFWNo ratings yet

- Base Support On Elbow 2" - 68" NPS: Pipe Standard SupportsDocument2 pagesBase Support On Elbow 2" - 68" NPS: Pipe Standard SupportsMainuddin AliNo ratings yet

- Datasheet 1011 HSLAS-FDocument1 pageDatasheet 1011 HSLAS-FDaniel Moreno JassoNo ratings yet

- Eriks - Hose Guide PDFDocument2 pagesEriks - Hose Guide PDFArdian20No ratings yet

- The UL Certificate of The Gate Valve-JINAN MEIDEDocument5 pagesThe UL Certificate of The Gate Valve-JINAN MEIDEIRENENo ratings yet

- PT-059 TG-6 Uwc 2019-05Document1 pagePT-059 TG-6 Uwc 2019-05Sylvie CatalanNo ratings yet

- Support On Funnel For Pipes " - 4" NPS: Pipe Standard SupportsDocument2 pagesSupport On Funnel For Pipes " - 4" NPS: Pipe Standard SupportsMainuddin Ali100% (1)

- GEFA-Flanged Ball Valve - Advantages For The User: Processtechnik GMBHDocument4 pagesGEFA-Flanged Ball Valve - Advantages For The User: Processtechnik GMBHjorgeNo ratings yet

- Line No. Fluid Code Type Short Description Pipe Spec Size (In.) Item Code QTY UOMDocument18 pagesLine No. Fluid Code Type Short Description Pipe Spec Size (In.) Item Code QTY UOMRona Flor ArguellesNo ratings yet

- USQT.S309 - Extinguishing System AttachmentsDocument3 pagesUSQT.S309 - Extinguishing System AttachmentsMd.ShahabuddinNo ratings yet

- Fire Hose: Single Jacket All Synthetic Polyurethane Lined 500Lb. Test - Rack HoseDocument1 pageFire Hose: Single Jacket All Synthetic Polyurethane Lined 500Lb. Test - Rack HoseCHOMCRPANo ratings yet

- VW - BV (Series 50)Document2 pagesVW - BV (Series 50)Mazwan Che MansorNo ratings yet

- Castrol Product Training: It'S More Than Just Oil. It'S Liquid EngineeringDocument106 pagesCastrol Product Training: It'S More Than Just Oil. It'S Liquid EngineeringFerry Marketing SekafuNo ratings yet

- A101747A Item 03 Foam InductorDocument7 pagesA101747A Item 03 Foam InductorВячеслав ГоряшинNo ratings yet

- Base Support For Horizontal Pipes 2" - 68" NPS: Pipe Standard SupportsDocument2 pagesBase Support For Horizontal Pipes 2" - 68" NPS: Pipe Standard SupportsMainuddin AliNo ratings yet

- Nozzles For Fixed Fire Suppression: Manual No. 104.FFDocument6 pagesNozzles For Fixed Fire Suppression: Manual No. 104.FFManuelMartinezNo ratings yet

- Reclaiming of Amine-Based Absorption Liquids Used in Post-Combustion CaptureDocument14 pagesReclaiming of Amine-Based Absorption Liquids Used in Post-Combustion CaptureABRAHAM EBEN ANDREWSNo ratings yet

- ME Gate 2020 - Section 1 Question PaperDocument48 pagesME Gate 2020 - Section 1 Question PaperABRAHAM EBEN ANDREWSNo ratings yet

- ME Gate 2020 - Section 2 Question PaperDocument49 pagesME Gate 2020 - Section 2 Question PaperABRAHAM EBEN ANDREWSNo ratings yet

- Effect of Chemical Treatment On Alpaca Fleece Reinforced Polymer CompositesDocument4 pagesEffect of Chemical Treatment On Alpaca Fleece Reinforced Polymer CompositesABRAHAM EBEN ANDREWSNo ratings yet

- Effect of Silane Treated and UN - Treated Jute and Glass Hybrid Polymer Composites PDFDocument5 pagesEffect of Silane Treated and UN - Treated Jute and Glass Hybrid Polymer Composites PDFABRAHAM EBEN ANDREWSNo ratings yet

- Effect of Silane Treated and UN - Treated Jute and Glass Hybrid Polymer Composites PDFDocument5 pagesEffect of Silane Treated and UN - Treated Jute and Glass Hybrid Polymer Composites PDFABRAHAM EBEN ANDREWSNo ratings yet

- 09120110155668 (1)Document49 pages09120110155668 (1)Upul NishanthaNo ratings yet

- Performance Online - Classic Car Parts CatalogDocument168 pagesPerformance Online - Classic Car Parts CatalogPerformance OnlineNo ratings yet

- Pythonbiogeme: A Short Introduction: Michel Bierlaire July 6, 2016Document19 pagesPythonbiogeme: A Short Introduction: Michel Bierlaire July 6, 2016asasdasdNo ratings yet

- Bugreport Fog - in SKQ1.211103.001 2023 04 10 19 23 21 Dumpstate - Log 9097Document32 pagesBugreport Fog - in SKQ1.211103.001 2023 04 10 19 23 21 Dumpstate - Log 9097chandrakanth reddyNo ratings yet

- 1a. Create Your Yosemite Zone USB DriveDocument9 pages1a. Create Your Yosemite Zone USB DriveSimon MeierNo ratings yet

- Week 7 Module 7 TAX2 - Business and Transfer Taxation - PADAYHAGDocument23 pagesWeek 7 Module 7 TAX2 - Business and Transfer Taxation - PADAYHAGfernan opeliñaNo ratings yet

- Bilal CVDocument3 pagesBilal CVShergul KhanNo ratings yet

- Valentine Carol Ann Duffy EssayDocument8 pagesValentine Carol Ann Duffy Essayafibybflnwowtr100% (1)

- BBBB - View ReservationDocument2 pagesBBBB - View ReservationBashir Ahmad BashirNo ratings yet

- NHW Beg 4E Unit Tests - 3a PDFDocument2 pagesNHW Beg 4E Unit Tests - 3a PDFabeer24No ratings yet

- FDI and FIIDocument17 pagesFDI and FIIsharathNo ratings yet

- Sciencedirect Sciencedirect SciencedirectDocument7 pagesSciencedirect Sciencedirect SciencedirectMiguel AngelNo ratings yet

- New Champlain Bridge: Final Report Summary (English)Document82 pagesNew Champlain Bridge: Final Report Summary (English)andyrigaNo ratings yet

- Istqb Agile Tester Learning Objectives SingleDocument3 pagesIstqb Agile Tester Learning Objectives SingleSundarNo ratings yet

- BUSINESS PROPOSAL-dönüştürüldü-2Document15 pagesBUSINESS PROPOSAL-dönüştürüldü-2Fatah Imdul UmasugiNo ratings yet

- Color Coding - 2018Document28 pagesColor Coding - 2018Aris MunandarNo ratings yet

- SKF BeyondZero White Paper 12761ENDocument12 pagesSKF BeyondZero White Paper 12761ENdiosmio111No ratings yet

- Bureau of Indian Standards Conformity Assessment Scheme For Milk and Milk ProductsDocument51 pagesBureau of Indian Standards Conformity Assessment Scheme For Milk and Milk Productsatvenu16160No ratings yet

- CBD20LDocument1 pageCBD20LFelix StancioiuNo ratings yet

- Chem 111a - Activity No. 2Document5 pagesChem 111a - Activity No. 2MARY KATE FATIMA BAUTISTANo ratings yet

- Micro Link Information Technology Business College: Department of Software EngineeringDocument34 pagesMicro Link Information Technology Business College: Department of Software Engineeringbeki4No ratings yet

- 1LG4253-4AA60 Datasheet enDocument1 page1LG4253-4AA60 Datasheet enanm bNo ratings yet

- Gas Agency Management SystemDocument78 pagesGas Agency Management SystemManish Sharma100% (2)

- ALLOY 7150-T7751 PLATE AND 7150-T77511 EXTRUSIONS: Alcoa Mill ProductsDocument4 pagesALLOY 7150-T7751 PLATE AND 7150-T77511 EXTRUSIONS: Alcoa Mill Productshitesh_tilalaNo ratings yet

- Sick - Photoelectric 4-180 MM v2Document7 pagesSick - Photoelectric 4-180 MM v2Muhammad SumeetNo ratings yet

- Project DescriptionDocument5 pagesProject DescriptionM ShahidNo ratings yet

- Writing NuocRut Ver02Document118 pagesWriting NuocRut Ver02thuy linhNo ratings yet