Professional Documents

Culture Documents

The Effect of Silicone Coating Emulsion On Polycarbonate Helmet Glass

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Effect of Silicone Coating Emulsion On Polycarbonate Helmet Glass

Copyright:

Available Formats

Volume 8, Issue 6, June – 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Mechanical Engineering Study Program

Faculty of Engineering

Tarumanagara University

Jakarta

The Effect of Silicone Coating

Emulsion on Polycarbonate Helmet Glass

Ayra Diputera Hardjo1, Erwin Siahaan2, Abrar Riza3

Fakultas Teknik, Program Studi Teknik Mesin

(515190042)1

Abstract:- Coating is a method or technique to cover the I. INTRODUCTION

surface of the substrate with the aim of protection,

decorative and other purposes. coating is a more general Coating is a method or technique to cover the surface

term for a variety of materials that can be applied as a of the substrate with the aim of protection, decorative and

thin layer to a surface. Paint is traditionally described as other purposes. Coating is a more general term for any

a material having a color pigment used to coat a surface, material that can be applied as a thin layer to a surface. Paint

the coating may be either a liquid or a solid material. has traditionally been described as a material having colored

coatings are known and used since ancient times and to pigments used to coat a surface; coatings can be either liquid

protect various kinds of objects and buildings. or solid materials. Coatings are known and used since

Emulsified silicone is a term generally used to describe a ancient times and to protect various kinds of objects and

group of hydrophobic polymeric and monomer buildings. Coatings can be colored or not, and can be a

compounds composed of silicon-oxygen bonds and given transparent solid layer. Coating is more synonymous with

the name organosiloxane, because of their viscosity and coatings used in the industrial world, and paint refers more

ability to repel water, they are referred to as oils. to coatings used on objects related to architecture, such as

Polycarbonate helmet visors are the material used today. houses, walls and ceilings, roofs, fences and others. The

Plastic Helmet Glass (Polycarbonate) has advantages coating is in the form of liquid silica oxide which can harden

and disadvantages, the first advantage of plastic helmet or crystallize so that it looks like a thin acrylic layer when it

glass is that it is flexible. The flexibility it has makes it dries. This layer will keep the paint from scratching easily.

more resistant to receiving impact impacts when

incidents occur. Polycarbonate can withstand impacts 30 The process of applying this coating can be applied to

times better than glass, that's why most helmets now use the visor/helmet glass made of polycarbonate using an

this material. However, the drawback of plastic visors is applicator pad, one of the methods to prevent scratches on

that they are not scratch resistant. To resist scratches on the visor is by coating. Coating functions as a protective

this polycarbonate helmet glass, it must be covered with layer for any material and can be used in the automotive

a coating. industry. Coating also has many advantages, namely having

high resistance so that the color and luster of a specimen can

Keywords:- Coating, Emulsified Silicone, Polycarbonate, last longer than not using coating, has high durability, is

Helmet Visor. anti-dust, and is also resistant to scratches. Coating

application requires skilled workers and special equipment.

If it is not done properly or professionally, the appearance

can look bad and its function is reduced, the application

takes quite a long time because it needs perfect drying in

IJISRT23JUN2535 www.ijisrt.com 3493

Volume 8, Issue 6, June – 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

order to produce good coating results. material or coating The research started from preparing specimens of

material is quite high. polycarbonate material that had been coated & which were

not coated because the differences between each specimen

Silicone emulsion is a term generally used to describe would be seen and the impact force would be tested using a

a group of hydrophobic polymeric and monomer compounds charpy impact testing machine.

composed of silicon-oxygen bonds and given the name

organosiloxane, because of their viscosity and ability to Material

repel water, they are referred to as oils. The work material used in this study is a glass

specimen sample made from polycarbonate material which

The purpose of this study was to determine the is the same as a helmet glass material, the work material

characteristics of the coating on the helmet visor made of uses polycarbonate glass which has not gone through a

polycarbonate which is used as one of the helmet protectors, coating process and which has undergone a coating process

and to determine the value of the impact force on the using a base material consisting of Silicone. Oil, Glycerin,

polycarbonate material which is coated with a coating using Sodium Silicate, Aqua Distillation are the main ingredients

a charpy impact test tool so that it is able to provide scratch for making the liquid coating. Meanwhile, after mixing

resistance to the helmet glass. these materials, they can be directly used as a coating for

helmet visors made of polycarbonate material.

The benefits obtained from conducting research in the

form of testing in this experiment are being able to provide a Polycarbonate Glass

reference to helmet glass manufacturers so that they are able

to utilize the coating on their helmet glass so that they are of

higher quality and more safety optimally, as well as

providing a reference to Tarumanagara University in

operating the impact testing machine according to with

indicators of impact testing in automotive companies.

II. RESEARCH METHODS

The flowchart of the research process so that the

implementation of this researchruns smoothly is as follows :

Fig 2 Polycarbonate Glass

Silicone Oil

Fig 1 Diagram Fig 3 Silicone Oil

IJISRT23JUN2535 www.ijisrt.com 3494

Volume 8, Issue 6, June – 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Glycerin Aqua Destilation

Fig 4 Glycerin

Fig 6 Aqua Destilasi

Natrium Silikat

Tools

Equipment used in research, namely :

Impact Tools Test

The charpy impact test tool is used to test material

hardness, the purpose of impact testing is to determine the

resistance of a material to shock loads. The magnitude of the

impact value indicates the material's ability to withstand

loading. This test is carried out on a testing machine

designed to have a pendulum of a certain weight swinging

from a height to apply a shock load.

Fig 5 Natrium Silikat

Fig 7 Impact Charpy Tools Test

IJISRT23JUN2535 www.ijisrt.com 3495

Volume 8, Issue 6, June – 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Another Support Tools Test

Supporting tools were used for the needs of the

research, consisting of measuring cups, cutters, wooden

chopsticks, microfiber cloths.

.

Fig 9 Impact Test Graph

Fig 8 Supporting Tools Test

III. RESULTS AND DISCUSSION

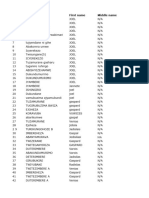

Impact Test Results on Helmet Visors

The graph of the impact test results on the

polycarbonate helmet glass material with a height of 1.5

meters shows that the magnitude of the force is different, as

shown in Figure 9

Fig 10 Impact Test

Table 1 Impact Test Results on a Polycarbonate Helmet Visor with a Height of 1.5 Meters.

No. Sample Luas area Gaya Pengujian F (N) Tegangan yang terjadi Explanation

impak A (mm2) α (MPa)

1 350 203 0,933 Scratch

2 350 295 1,172 Scratch

3 350 253 0,981 Scratch

Average 350 244,33 1,029

IV. CONCLUSION REFERENCES

Based on the data from the experimental process that [1]. MINISTER OF MANPOWER. (2016). SKKNI 2016-

has been collected, it can be concluded that the results of 091 COATING.

this study are : [2]. Josep, V. K. (1995). Paint and Coating Testing

Manual. Astm.

The results of the analysis of the impact test on the https://doi.org/10.1002/col.5080200415.

helmet visor made of polycarbonate found that sample 1, [3]. Husnur Rosyidah Aulia. (2021, Januari 26). ”Apa Itu

2, 3 were different due to the fact that the helmet visor Coating?” [Online]. Available:

had been coated and not coated, making the level of each https://wira.co.id/coating-adalah/.

stroke unequal. [4]. Barca, F., Caporossi, T., Rizzo, S. (2014). “Silicone

Based on the results of the stress that occurs, it can be Oil: Different Physical Proprieties and Clinical

concluded that aftermarket coatings and self-coating are Applications.” Hindawi Publishing Corporation, Via

different, this is due to several differences in the mixture Paradisa 2, 56124 Pisa, Italy.

of materials in the self-coating manufacturing process. [5]. Pal, R., Bhattacharya, S.N. and Rhodes, E.Flow

behaviour of oil-in-water emulsions.Can. J. Chem.

Eng.64,3–10 (1986).

[6]. Mehta, S.C., Somasundarana, P. and Kulk-arni, R.

Variation in emulsion stabilization behavior of hybrid

silicone polymers withchange in molecular structure:

phase dia-gram study.J. Colloid Interface Sci.333,635–

640 (2009).

IJISRT23JUN2535 www.ijisrt.com 3496

You might also like

- Microstructure and Hardness Analysis of Silicon Emulsion & Graphene Oxide Coating Material For Helmet VisorsDocument5 pagesMicrostructure and Hardness Analysis of Silicon Emulsion & Graphene Oxide Coating Material For Helmet VisorsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Mechanical Properties of Polycarbonate: Experiment and Modeling for Aeronautical and Aerospace ApplicationsFrom EverandMechanical Properties of Polycarbonate: Experiment and Modeling for Aeronautical and Aerospace ApplicationsNo ratings yet

- Self-Cleaning Materials and Surfaces: A Nanotechnology ApproachFrom EverandSelf-Cleaning Materials and Surfaces: A Nanotechnology ApproachWalid A. DaoudRating: 5 out of 5 stars5/5 (1)

- Tribology of Graphene: Simulation Methods, Preparation Methods, and Their ApplicationsFrom EverandTribology of Graphene: Simulation Methods, Preparation Methods, and Their ApplicationsRating: 5 out of 5 stars5/5 (1)

- Scope of Maxillofacial Prosthesis Materials: From Past To Future-A Literature ReviewDocument4 pagesScope of Maxillofacial Prosthesis Materials: From Past To Future-A Literature ReviewNishanthini AnnamalaiNo ratings yet

- Informe Materiales 2.011Document17 pagesInforme Materiales 2.011Juan Sebastian Lozada PeñaNo ratings yet

- A Review Article On Acrylic PMMA: Eshwar PawarDocument4 pagesA Review Article On Acrylic PMMA: Eshwar PawarIOSRjournalNo ratings yet

- Performance and Properties of Glass Fiber and Its Utilization in Concrete - A ReviewDocument12 pagesPerformance and Properties of Glass Fiber and Its Utilization in Concrete - A ReviewWidya Puspita SariNo ratings yet

- Inometa Protek Coatings en LowDocument16 pagesInometa Protek Coatings en LowsakthivelNo ratings yet

- What Is A Polymer CoatingDocument14 pagesWhat Is A Polymer CoatingGvsr SunnyNo ratings yet

- Journal of Industrial Textiles: A New Generation of Silicone Elastomers For Airbag CoatingsDocument13 pagesJournal of Industrial Textiles: A New Generation of Silicone Elastomers For Airbag CoatingshaddanNo ratings yet

- Proceedings of the 42nd International Conference on Advanced Ceramics and Composites, Ceramic Engineering and Science Proceedings, Issue 3From EverandProceedings of the 42nd International Conference on Advanced Ceramics and Composites, Ceramic Engineering and Science Proceedings, Issue 3Jingyang WangNo ratings yet

- A Review Tribological Analysis of Cast Iron by Advanced CoatingDocument6 pagesA Review Tribological Analysis of Cast Iron by Advanced CoatingEditor IJTSRDNo ratings yet

- ARTICLE SUMMARIES NimiDocument4 pagesARTICLE SUMMARIES NimiNameeraNo ratings yet

- (N.D.) - Retrieved From: Uniqueness and Advantages of The MaterialDocument4 pages(N.D.) - Retrieved From: Uniqueness and Advantages of The Materialashna latheefNo ratings yet

- Atlas Coatings Durability White Paper 2015Document40 pagesAtlas Coatings Durability White Paper 2015gowtham50% (2)

- Engineering Encyclopedia: Protective Coating ApplicationDocument24 pagesEngineering Encyclopedia: Protective Coating ApplicationAnonymous S9qBDVkyNo ratings yet

- Theoretical Explanation On Nitrile Latex and FilmDocument5 pagesTheoretical Explanation On Nitrile Latex and FilmAik Hwee EngNo ratings yet

- Functional Glasses and Glass-Ceramics: Processing, Properties and ApplicationsFrom EverandFunctional Glasses and Glass-Ceramics: Processing, Properties and ApplicationsNo ratings yet

- Lastic 450 I 120427Document4 pagesLastic 450 I 120427Mohiuddin MuhinNo ratings yet

- Review On Automotive Body Coating ProcessDocument4 pagesReview On Automotive Body Coating ProcessIJEMR JournalNo ratings yet

- Review On Automotive Body Coating ProcessDocument4 pagesReview On Automotive Body Coating ProcessIJEMR JournalNo ratings yet

- Paint and Protective Coating Failure AnalysisDocument17 pagesPaint and Protective Coating Failure AnalysisAnonymous S9qBDVky100% (2)

- Ceramic Coating Industry and Market OverviewDocument37 pagesCeramic Coating Industry and Market OverviewSreehari RavindranNo ratings yet

- Evaluation of Peel Bond Strength Between Self Cure Acrylic Resin Material and Two Different Commercially Avaliable Maxillofacial Silicone Material Using A Primer - An in Vitro StudyDocument11 pagesEvaluation of Peel Bond Strength Between Self Cure Acrylic Resin Material and Two Different Commercially Avaliable Maxillofacial Silicone Material Using A Primer - An in Vitro StudyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Mechanical Properties and Performance of Engineering Ceramics and Composites VIIIFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites VIIIDileep SinghNo ratings yet

- Map Project MbaDocument58 pagesMap Project Mbaankit PadhyaNo ratings yet

- Device Turns Air Pollution Into InkDocument2 pagesDevice Turns Air Pollution Into InkAnonymous izrFWiQNo ratings yet

- Rust Preventative Spray Varnish Verification and Nozzle DevelopmeDocument72 pagesRust Preventative Spray Varnish Verification and Nozzle DevelopmesdchorgheNo ratings yet

- Pew 105.04 (P)Document174 pagesPew 105.04 (P)Raj BindasNo ratings yet

- RP 4Document7 pagesRP 4AKSHAT BENIWALNo ratings yet

- The Comparison of Different Type Reflector Materials Using With SmallDocument18 pagesThe Comparison of Different Type Reflector Materials Using With SmallDaniela LaraNo ratings yet

- High-Performance Silicones For: Transmission and DistributionDocument54 pagesHigh-Performance Silicones For: Transmission and DistributionHerry KurniawanNo ratings yet

- Coatings Application 2Document54 pagesCoatings Application 2Namta GeorgeNo ratings yet

- Thermal Arc Spray Overview: IOP Conference Series Materials Science and Engineering June 2013Document12 pagesThermal Arc Spray Overview: IOP Conference Series Materials Science and Engineering June 2013novernandoNo ratings yet

- A Comparative Study Zinc Phosphate-Soapcoatingversus Polymer Based Coati..Document6 pagesA Comparative Study Zinc Phosphate-Soapcoatingversus Polymer Based Coati..mirosekNo ratings yet

- Peelable Coating To Protect New Construction Coating SystemsDocument10 pagesPeelable Coating To Protect New Construction Coating SystemsDinh Quoc HungNo ratings yet

- Nano-Glass Ceramics: Processing, Properties and ApplicationsFrom EverandNano-Glass Ceramics: Processing, Properties and ApplicationsNo ratings yet

- Abhi Seminar ReportDocument25 pagesAbhi Seminar ReportÃmit ŘajgadkarNo ratings yet

- Coatings: Wear Characterization of Chromium PVD Coatings On Polymeric Substrate For Automotive Optical ComponentsDocument20 pagesCoatings: Wear Characterization of Chromium PVD Coatings On Polymeric Substrate For Automotive Optical ComponentsVũ Nguyễn TuấnNo ratings yet

- Fibre GlassDocument7 pagesFibre GlassFirly Rajabi SoeratinoyoNo ratings yet

- Polyurethane PDFDocument2 pagesPolyurethane PDFvtbk0% (1)

- Study of Transparent Plastics for Aircraft WindshieldsDocument56 pagesStudy of Transparent Plastics for Aircraft Windshieldspokemon AkunNo ratings yet

- MS - SikaWrap-231 C (Structural Strenghtening) (v.01.2018)Document5 pagesMS - SikaWrap-231 C (Structural Strenghtening) (v.01.2018)abdillah mursyidNo ratings yet

- Capstone 2 (2)Document23 pagesCapstone 2 (2)dongiaponrashelle355No ratings yet

- Vacuum Coating of Plastic OpticsDocument15 pagesVacuum Coating of Plastic OpticsSasiKumar PetchiappanNo ratings yet

- A Report On A In-Plant TrainingDocument11 pagesA Report On A In-Plant TrainingTony StarkNo ratings yet

- Choosing The Right Conformal Coating The Facts & MythsDocument4 pagesChoosing The Right Conformal Coating The Facts & Mythssdfdfs7253No ratings yet

- Coating As An Ideal Prevention For Corrosion in Manufacture and Infrastructure IndustryDocument43 pagesCoating As An Ideal Prevention For Corrosion in Manufacture and Infrastructure IndustryLarasanto LarasantoNo ratings yet

- Pds CPD Sikadur301 UsDocument2 pagesPds CPD Sikadur301 UsGabriel MazariegosNo ratings yet

- UV-Cured Functional CoatingsDocument13 pagesUV-Cured Functional CoatingsAshwary Sheel Wali Research Scholar, Dept of Mech Engg., IIT (BHU)No ratings yet

- 2022 The Effect of Additions of Anticorrosive Pigments On The Dela Wear AlvarezDocument12 pages2022 The Effect of Additions of Anticorrosive Pigments On The Dela Wear AlvarezJakub GrzelkaNo ratings yet

- Effect of Plastic Optical Fibers On Properties ofDocument17 pagesEffect of Plastic Optical Fibers On Properties ofRamesh BabuNo ratings yet

- Bio-Glasses: An IntroductionFrom EverandBio-Glasses: An IntroductionJulian JonesNo ratings yet

- Chemically Strengthened GlassDocument4 pagesChemically Strengthened GlassMarwa SamierNo ratings yet

- Release LinersDocument1 pageRelease LinersGhost_suolNo ratings yet

- Polylacticacidfiber AnoverviewDocument29 pagesPolylacticacidfiber Anoverviewanirudh sharmaNo ratings yet

- Degradation of Scrath Resistance of Clear Coating by Outdoor WeatheringDocument8 pagesDegradation of Scrath Resistance of Clear Coating by Outdoor WeatheringAndy Z del PieroNo ratings yet

- An Analysis on Mental Health Issues among IndividualsDocument6 pagesAn Analysis on Mental Health Issues among IndividualsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Harnessing Open Innovation for Translating Global Languages into Indian LanuagesDocument7 pagesHarnessing Open Innovation for Translating Global Languages into Indian LanuagesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Diabetic Retinopathy Stage Detection Using CNN and Inception V3Document9 pagesDiabetic Retinopathy Stage Detection Using CNN and Inception V3International Journal of Innovative Science and Research TechnologyNo ratings yet

- Investigating Factors Influencing Employee Absenteeism: A Case Study of Secondary Schools in MuscatDocument16 pagesInvestigating Factors Influencing Employee Absenteeism: A Case Study of Secondary Schools in MuscatInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Exploring the Molecular Docking Interactions between the Polyherbal Formulation Ibadhychooranam and Human Aldose Reductase Enzyme as a Novel Approach for Investigating its Potential Efficacy in Management of CataractDocument7 pagesExploring the Molecular Docking Interactions between the Polyherbal Formulation Ibadhychooranam and Human Aldose Reductase Enzyme as a Novel Approach for Investigating its Potential Efficacy in Management of CataractInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Making of Object Recognition Eyeglasses for the Visually Impaired using Image AIDocument6 pagesThe Making of Object Recognition Eyeglasses for the Visually Impaired using Image AIInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Relationship between Teacher Reflective Practice and Students Engagement in the Public Elementary SchoolDocument31 pagesThe Relationship between Teacher Reflective Practice and Students Engagement in the Public Elementary SchoolInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Dense Wavelength Division Multiplexing (DWDM) in IT Networks: A Leap Beyond Synchronous Digital Hierarchy (SDH)Document2 pagesDense Wavelength Division Multiplexing (DWDM) in IT Networks: A Leap Beyond Synchronous Digital Hierarchy (SDH)International Journal of Innovative Science and Research TechnologyNo ratings yet

- Comparatively Design and Analyze Elevated Rectangular Water Reservoir with and without Bracing for Different Stagging HeightDocument4 pagesComparatively Design and Analyze Elevated Rectangular Water Reservoir with and without Bracing for Different Stagging HeightInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Impact of Digital Marketing Dimensions on Customer SatisfactionDocument6 pagesThe Impact of Digital Marketing Dimensions on Customer SatisfactionInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Electro-Optics Properties of Intact Cocoa Beans based on Near Infrared TechnologyDocument7 pagesElectro-Optics Properties of Intact Cocoa Beans based on Near Infrared TechnologyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Formulation and Evaluation of Poly Herbal Body ScrubDocument6 pagesFormulation and Evaluation of Poly Herbal Body ScrubInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Advancing Healthcare Predictions: Harnessing Machine Learning for Accurate Health Index PrognosisDocument8 pagesAdvancing Healthcare Predictions: Harnessing Machine Learning for Accurate Health Index PrognosisInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Utilization of Date Palm (Phoenix dactylifera) Leaf Fiber as a Main Component in Making an Improvised Water FilterDocument11 pagesThe Utilization of Date Palm (Phoenix dactylifera) Leaf Fiber as a Main Component in Making an Improvised Water FilterInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Cyberbullying: Legal and Ethical Implications, Challenges and Opportunities for Policy DevelopmentDocument7 pagesCyberbullying: Legal and Ethical Implications, Challenges and Opportunities for Policy DevelopmentInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Auto Encoder Driven Hybrid Pipelines for Image Deblurring using NAFNETDocument6 pagesAuto Encoder Driven Hybrid Pipelines for Image Deblurring using NAFNETInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Terracing as an Old-Style Scheme of Soil Water Preservation in Djingliya-Mandara Mountains- CameroonDocument14 pagesTerracing as an Old-Style Scheme of Soil Water Preservation in Djingliya-Mandara Mountains- CameroonInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- A Survey of the Plastic Waste used in Paving BlocksDocument4 pagesA Survey of the Plastic Waste used in Paving BlocksInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Hepatic Portovenous Gas in a Young MaleDocument2 pagesHepatic Portovenous Gas in a Young MaleInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Design, Development and Evaluation of Methi-Shikakai Herbal ShampooDocument8 pagesDesign, Development and Evaluation of Methi-Shikakai Herbal ShampooInternational Journal of Innovative Science and Research Technology100% (3)

- Explorning the Role of Machine Learning in Enhancing Cloud SecurityDocument5 pagesExplorning the Role of Machine Learning in Enhancing Cloud SecurityInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- A Review: Pink Eye Outbreak in IndiaDocument3 pagesA Review: Pink Eye Outbreak in IndiaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Automatic Power Factor ControllerDocument4 pagesAutomatic Power Factor ControllerInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Review of Biomechanics in Footwear Design and Development: An Exploration of Key Concepts and InnovationsDocument5 pagesReview of Biomechanics in Footwear Design and Development: An Exploration of Key Concepts and InnovationsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Mobile Distractions among Adolescents: Impact on Learning in the Aftermath of COVID-19 in IndiaDocument2 pagesMobile Distractions among Adolescents: Impact on Learning in the Aftermath of COVID-19 in IndiaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Studying the Situation and Proposing Some Basic Solutions to Improve Psychological Harmony Between Managerial Staff and Students of Medical Universities in Hanoi AreaDocument5 pagesStudying the Situation and Proposing Some Basic Solutions to Improve Psychological Harmony Between Managerial Staff and Students of Medical Universities in Hanoi AreaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Navigating Digitalization: AHP Insights for SMEs' Strategic TransformationDocument11 pagesNavigating Digitalization: AHP Insights for SMEs' Strategic TransformationInternational Journal of Innovative Science and Research Technology100% (1)

- Drug Dosage Control System Using Reinforcement LearningDocument8 pagesDrug Dosage Control System Using Reinforcement LearningInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Effect of Time Variables as Predictors of Senior Secondary School Students' Mathematical Performance Department of Mathematics Education Freetown PolytechnicDocument7 pagesThe Effect of Time Variables as Predictors of Senior Secondary School Students' Mathematical Performance Department of Mathematics Education Freetown PolytechnicInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Formation of New Technology in Automated Highway System in Peripheral HighwayDocument6 pagesFormation of New Technology in Automated Highway System in Peripheral HighwayInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- 15-5240 enDocument14 pages15-5240 enRafa Lopez PuigdollersNo ratings yet

- Employment and Skill MismatchDocument20 pagesEmployment and Skill MismatchFarah LimNo ratings yet

- Topic 1 Being A 21st Century LearnerDocument17 pagesTopic 1 Being A 21st Century LearnerNAZATUL EZETY BINTI AHMAD STUDENTNo ratings yet

- Oromia Pension FormDocument3 pagesOromia Pension FormAboma Mekonnen86% (7)

- Cause and Effects of Social MediaDocument54 pagesCause and Effects of Social MediaAidan Leonard SeminianoNo ratings yet

- Tell The World of His LoveDocument1 pageTell The World of His LoveLucky Valera DayondonNo ratings yet

- Love Letters Reveal Deep EmotionsDocument21 pagesLove Letters Reveal Deep EmotionsChima NnosimikeNo ratings yet

- Parallel Worlds ChessDocument2 pagesParallel Worlds ChessRobert BonisoloNo ratings yet

- Data Compilation TemplateDocument257 pagesData Compilation TemplateemelyseuwaseNo ratings yet

- Madbarz Routines Plan: Strength - AdvancedDocument18 pagesMadbarz Routines Plan: Strength - AdvancedJuan Sebastian AnguloNo ratings yet

- Test Bank For Behavior Modification Principles and Procedures 6th EditionDocument36 pagesTest Bank For Behavior Modification Principles and Procedures 6th Editionempericetagragyj6f8100% (31)

- Lesson Plan For PortfolioDocument6 pagesLesson Plan For Portfolioapi-282640896No ratings yet

- Shadow On The Mountain Reading GuideDocument2 pagesShadow On The Mountain Reading GuideAbrams BooksNo ratings yet

- Public High School Teachers' Strategies for Addressing Challenges in Conducting Action ResearchDocument75 pagesPublic High School Teachers' Strategies for Addressing Challenges in Conducting Action ResearchMilbert Loyloy SalmasanNo ratings yet

- E Thesis Uas DharwadDocument5 pagesE Thesis Uas DharwadLori Head100% (1)

- Manticore Search Case-Study Layout-InternationalDocument1 pageManticore Search Case-Study Layout-Internationalnilasoft2009No ratings yet

- Business Profile (JAO-REN)Document15 pagesBusiness Profile (JAO-REN)Michael T. SebullenNo ratings yet

- Descarga de ScribdDocument4 pagesDescarga de ScribdYoel MartínezNo ratings yet

- OS Fundamentals: Memory, Processes, KernelsDocument36 pagesOS Fundamentals: Memory, Processes, KernelsSparkerz S Vijay100% (1)

- Daemon Prince Character Sheet: P D D DDocument2 pagesDaemon Prince Character Sheet: P D D Dshamshir7307858No ratings yet

- Bcom MADocument21 pagesBcom MAAbl SasankNo ratings yet

- Capstone PosterDocument1 pageCapstone Posterapi-538849894No ratings yet

- Understand Quran 50 Percent Course Workbook Solution (UNDERSTAND AL-QUR'AAN ACADEMY)Document25 pagesUnderstand Quran 50 Percent Course Workbook Solution (UNDERSTAND AL-QUR'AAN ACADEMY)Al Huda75% (4)

- Freebie The Great Composerslapbookseries ChopinDocument24 pagesFreebie The Great Composerslapbookseries ChopinAnonymous EzNMLt0K4C100% (1)

- g10 Ntot Physics em SpectrumDocument50 pagesg10 Ntot Physics em Spectrumapi-283862617100% (5)

- UPSA - Ethics of Project Management-3Document42 pagesUPSA - Ethics of Project Management-3JSN1790% (1)

- Scaffold Inspection Checklist FINALDocument2 pagesScaffold Inspection Checklist FINALRhannie GarciaNo ratings yet

- Cases in OBLIGATIONS AND CONTRACTSDocument17 pagesCases in OBLIGATIONS AND CONTRACTSRommell Esteban ConcepcionNo ratings yet

- HCL TechDocument4 pagesHCL Techdm.sgstechNo ratings yet

- AYUDA Multi-Words VerbsDocument6 pagesAYUDA Multi-Words VerbsGabriel RodriguezNo ratings yet