Professional Documents

Culture Documents

FB 6 (English)

FB 6 (English)

Uploaded by

Ngo Ngoc Tu0 ratings0% found this document useful (0 votes)

83 views46 pagesOriginal Title

FB-6(English)

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

83 views46 pagesFB 6 (English)

FB 6 (English)

Uploaded by

Ngo Ngoc TuCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 46

DETAILED GUIDANCE

BATTERY-POWERED

FORKLIFT TRUCKS

CONTENTS

1. MAJOR ELECTRIC PARTS AND CHECKING PROCEDURES 1~31

2. PROCEDURES FOR OVERHAULING THE MOTORS/METER PANEL -----~ 32~41

3. TROUBLE SHOOTING -

ATTACHED :

1 42~ 75

FB-6 CHECK POINTS 1/2~2/2

FRB-6 CHECK POINTS 1/2~2/2

CIRCUIT DIAGRAM FOR COUNTER BALANCE TYPE

CIRCUIT DIAGRAM FOR REACH TYPE

1. MAJOR ELECTRIC PARTS AND CHECKING PROCEDURES

+ PARKING BRAKE SWITCH

« CHARGING SWITCH

« CHARGING. CONNECTOR

+ DRIVE WOTOR

+ SPEED SENSOR

+ HORN

+ STOP LAP SH TOH

POMP MOTOR

4 POTENTIOMETER FOR LIFTING

“F/R SWITCH CONTROL VALVE SHITOHES

«KEY SWITCH a ‘

* LIGHTING SWITCH

« TURN SIGNAL SWITCH

+ HORN SWITCH

~ ACCELERATOR

BACK BUZZER

~ TRANSFERIER

“ EPS. CONTROLLER

“MAGNET SWITCH

PS CONTAGTON

LOCATION FOR ELECTR! GA .

L courovent «FS COTA

ll

WETER PANEL

KEY SWITCH

LIGHTING SWITCH

HORN SWITCH

BATTERY LOCK SWITCH

= BATTERY SWITCH

* CHARGING SWITCH

PU BOARD VTW UNIT

F/R CONTACTOR

DIODE FOR CHARGING &

(COMMUTATION

RB CONTACTOR

BP. P, PB CONTACTOR CURRENT DETECTOR

D.C CHOPPER UNIT (FB)

THERMISTOR ASS’

DIODE FOR CHARGING &

‘COMMUTATION

F/R CONTACTOR ‘CURRENT DETECTOR

RB CONTACTOR

BP. P. PB CONTACTOR

D.C. CHOPPER UNIT (FRB)

1GBT

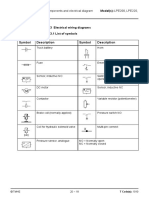

= CIRCUIT SYMBOL

2K GC & E ARE INDICATED ON IGBT BODY.

Gc, EUs Riek 645%)

~ EXPLANATION

1GBT STANDS FOR | (INSULATED), G(GATE), B(BIPOLAR), T (TRANS! STOR)

IT 1S MAIN ELEMENT FOR MOTOR DRIVING CIRCUIT AND TO CONTROL THE CURRENT PASSING RATE FOR

wor 7779 9 Me $45), 77 BAF a2h0-0 FZ

om heh

PARTS NO. TYPE APPLICABLE MODEL

177H2-62201 | iMBi600NN-060| FEiO~30

17862-62081 |MGsoou1uss1 F820725. FRO10~25. FROL

17862-62041 | CM450HA-5F FRBIA/15716

1732-62071 | CMOOOHA-6F 20725. FRBIA7 15718

“INSPECTION FOR_1GBT

wis

RESISTANCE RANGE x19 BETWEEN E AND C 447th pret

(SET ZERO(0) POSITION BEFORE USE) MEASURING POSITION | TESTER BAR] CORRECT VALUE

04z BRU 145 e BLACK | APPROX. 402

c RED

Cc | BAX =

E RED CNFINITY)

RESISTANCES ON OTHERS BETAFFN F AND 6, G AND O ARF

ALL INFINITY (co). (THERE ARE 4K1NDS)

19fe E-G , G-CR) Osta £7 00 (48)

5

MAIN DIODE

~ CIRCUIT SYMBOL

gieK Pitsh,

ANODE KATHODE

(A) (Kk)

3% A AND K ARE INDICATED ON THE BODY.

AK eaet f REBES’)

~ EXPLANATION

|T 1S USED FOR FLYWHEEL, PLUGGING AND REGENERATIVE CIRCUIT.

EFAS TAR | 15TH REW EATS HRA

PARTS NO. TYPE

‘APPLICABLE MODEL

1782-62061 | FRS300BA50

FB10~80, FRB10~25, FRBL

171H2-62381 | FRSSO0CASO

Fe20726790

tee Tha 7%

THON FOR MAIN DIODE

thw

RESISTANOE RANGE x1.

(SET ZERO(0) POSITION BEFORE USE) (MEASURING POSITION | TESTER BAR

VEER L 65

CORRECT VALUE

A BLACK 5~10Q

K RED

K BLACK °°

A RED (INFINITY)

reRK HAS

DIODE FOR CHARGING & COMMUTATION

CIRCUIT SYMBOL

Aca.

3 SYMBOL MARKS ARE INDICATED ON THE BODY.

Rea Mie AES)

~ EXPLANATION

IT 1S USED FOR COMMUTATION IN THE CHARGING CIRCUIT.

REDM) SRW

PARTS NO. TYPE APPLICABLE MODEL

1772-62211 | PTisose FB10718, FRBZO725

177P2-62401 | PT2008a

FB207256730

17@M2—62051 | PT1018

FRE10~18. FRBL

FOR THE DIODES

RESISTANCE RANGE x19

(SET ZERO (0) POSITION BEFORE USE)

MEASURING POSITION | TESTER BAR| CORREOT VALUE

= Back =| 60+20Q

Ee RED

£ BLACK’ ~

= RED CINFINITY)

44- tao

DIODE FOR SURGE-KILLER

= CIRCUIT SYMBOL

2% A & K ARE INDICATED ON THE BODY.

Ack dEI~114 ALBA’)

~ EXPLANATION

IT 1S USED TO COMBINE WITH CONDENSER OR RESISTOR FOR SURGE-KILLER CIRCUIT OF BOTH

DRIVING AND LOADING | 6B.

26 RGR LOBT 9 4-747- DM FHI, UIZ2I Ue BROT EQ

PARTS NO. TYPE. APPLICABLE MODEL

17 1A2-62071 | FRGZ5AA60 FB10~S0, FRB10~25, FRBL

= INSPECTION FOR THE DIODE

RESISTANCE RANGE x 19

(SET ZERO(O) POSITION BEFORE USE) [NEASURING POSITION] TESTER BAR] CORRECT VALUE

A BLACK 13+2Q

K RED

K BLAGK Es

Boe a RED (INFINITY)

ARS it OES H,

CONDENSER FOR SURGE-KILLER

* CIRCUIT SYMBOL

9 () 1S INDICATED ON THE BoDY.

C)eaete MERE S)

* EXPLANATION

IT 1S USED TO COMBINE WITH DIODE OR RESISTOR FOR SURGE-KILLER CIRCUIT OF BOTH DRIVING

AND LOADING ISBT. 545 BAW IoBT 9 7A THK 297 BPR ER

PARTS NO. CAPACITY RATED VOLTAGE APPLICABLE MODEL

171A2—62561 | 350v0C 680uF | FBIO~30

171A2—62571 | 850v0C 470uF | FB10~30

173A2—62111 | 160V0C 1000uF| F830, FRB10~25.FRBL |

~ INSPECTION FOR THE CONDENSER

(b) Ce)

1. CHECKING FOR BROKEN WIRES

CHECK THE TERMINALS BY RESISTANCE RANGE x 509 (SET ZERO(0) POSITION BEFORE USE)

IT 1S NORMAL TO MOVE THE NEEDLE IN oo — APPROX. 1002 — co ORDER WHEN TESTER.

BARS(RED - BLACK) ARE TOUCHED TO THE TERMINALS IN A MOMENT.

CIN ORDER AS PHOTO (a) — (b) — (c) — (@)]

PROVIDED THAT THE TESTER’ S NEEDLE MOVES ONLY ONE TIME AT THE SAME POLARITY (BLACK TO

+, RED TO - AND SO ON)

2. CHECKING FOR SHORT-CIRCUI TED

IT 1S NORMAL IF IN THE TERMINALS IS NOT INDICATED WITH SHORT-CIRCUITED (0)

F/R CONTACTOR

* CIRCUIT SYMBOL

F ee oo. R

nal Noo

ae © CONTACT

* EXPLANATION

IT HAS 2 CONTACTORS FOR F(FORNARD) AND FOR R (REVERSE)

IT 1S TO SHIFT THE ROTATING DERECTION OF THE MOTOR BY SHIFTING MOTOR CURRENT FLOW FOR

Fe con, = KT EIR Auk sve ANZ SAT ya

79D RIM TERT

PARTS. NO. TPE ‘APPLICABLE MODEL

271A2—621281 | CTTAISS4FRI42XN | FBIO71S, FREZO/25

271F2-62121 | CTTAGOSFRIG2XN | FB207E5

17772-62121 | sweoe-27 Fao

[yreme-e2te1 | oceee-aest FRB10~18, FROL

= INSPECTION FOR F/R CONTACTOR

ain dhth 2

WEASURING COIL RESISTANCE

(BY _WEANS OF DIGI TALTESTER)

PARTS NO. COIL RESISTANCE

271A2-62121 29250

271F2-62121 20250

17772-62101 | 1802109

178M2—62011 55252

10

F/R CONTACTOR

+ COMPOSED PARTS FOR F/R CONTACTOR

BP, P AND PB CONTACTOR

CIRCUIT SYMBOL

e*)

COIL

BP

a CONTACT

P, PB 3299919 25 w RIS

2% THE SYWBOL_IS DIFFERENT IN P_AND PB CONTACTOR,

> EXPLANATION

BP:BYPASS CONTACTOR FOR DRIVING C&O"4N'A 27779 ~ )

P :PUMP GONTACTOR FOR LOADING C#&™32999- )

PB:PUMP BYPASS CONTACTOR FOR LOADING (2 {i8) 41292999.)

PARTS NO. TYPE, ‘APPLICABLE MODEL BP] P | PB

271A2—62131 |CTTA150AH142XN [FB10715 olfolo

FReZ0725 ol[-|[-

271F2-62181 |CTTASOOAH142xKN |FB20725 Gijon | ue.

FRe20725 =[ofo

17712-02141 |sw200-018 ruse ol|elo

17@M2—62021 |Swa0-901 FRIO~18. FRBL ol[- [=

178M2-62031 |[swao-900 FRIO~18. FRBL =[efo

3 MARKED ©: APPLICATION (2P,

* INSPECTION FOR BP, P AND PB CONTACTOR

MEASURING COIL RESISTANCE (USE DIGITAL TESTER)

PARTS NO. COIL RESISTANCE

E71AB 08107 2058

271F2-62131 g0280

17772-62141 1602102

17eM2—62021 osa50

178M2—62031 55250

12

BP, P AND PB GONTAGTOR

~ COMPOSED PARTS FOR BP, P AND PB CONTAGTOR

324199 4 Bh

RB CONTACTOR

* CIRCUIT SYMBOL

@ [ns

COIL b CONTACT

= EXPLANATION

RB:REGENERATIVE BRAKING,

ad BY 29> J

IT 1S THE CONTACTOR FOR THIS FUNCTION.

THIS CONTACT 1S CLOSED (N.C) ON DRIVE USUALLY. WHEN OPERATING THE REGENERATIVE BRAKING,

THE CONTACT 1S OPENED. SFA aA Cnc) WER HRY eID FI.

PARTS NO. TYPE ‘APPLICABLE NODEL

177H2—62641 | Swise—s0 Fe107165

171F2—62181 | Sw2i10-120 FB20725, FRB10~25. FRBL

17772-62111 | Sw210-182 Fe30

* INSPECTION FOR RB CONTACTOR

MEASURING COIL RESISTANCE (USE DIGITAL TESTER)

PARTS NO. COIL RESISTANCE

177H2-62641 e025a

171F2—62181 S059

17772-62111 100%109

= COMPOSED PARTS FOR RB CONTACTOR

RB CONTACTOR

C/D_ASS'Y

= CIRCUIT SYMBOL

LI

~ EXPLANATION

IT DETECTS A FLOWING CURRENT FOR DRIVE MOTOR(DM) TO BE CONVERTED VOLTAGE SIGNAL FOR

OurPUT, FT E-7 COMPO RAL SRCRHL, SECT URI ENTS

PARTS NO. OUTPUT FEATURE APPLICABLE MODCL

T77H2-60801 TO00A7aV F810~30, FRB20/25

1792-60701 BOOA7 AV FRE1O~18. FROL

INSPECTION FOR C/0 Ass’ y

Lw 61

i

C/D ASS'Y

rr

DRIVE MOTOR

FAs

LW 61 POWER Sotnte 1

W 62: ee

; ys Re,

Meu Bag. (09 Sd Pt ESI) WETI eras Ee

JUDGING TO CHECK THE VOLTAGE AT THE TERMINALS OF MPU BOARD SIDE.

4-Mo4 0H OSE ES)

MEASURING POSITION | VOLTAGE AT THE KEY SWITCH ON (CORRECT VALUE)

(2-35) — (2-36) 12+

(2-28) - (2-36) £0. 15V THAN LESS

16

4 2

THERMISTOR ASS’ Y

+ CIRCUIT SYMBOL.

= EXPLANATION

IT DETECTS A TEMPERATURE FOR FITTING FACE OF THE DRIVING GBT DETECTING CONTROLLER’ s

TEMPERATURE) EW ZOD] $044 Hh 9 SRA FEHENS (2210-5 EMS)

PRATS NO. THERNISTOR TYPE. ‘APPLICABLE MODEL

18502-62021 | S02AT-2 FB10~90. FRB10~25, FRBL

~ INSPECTION FOR THERWISTOR ASS’ Y

AREDE

WEASURING RESISTANCE (USE DIGITAL TESTER)

322kQ AT A NORMAL TEMPERATURE (CORRECT VALUE)

3 (24®)

(re Sg #e% >

RESISTOR ASS’ Y (FOR VOLTAGE ON FB30)

* CIRCUIT SYMBOL

RW 11

18KQ

470Q

YB 18

+ EXPLANATION

IT 1S LOCATED AT A PART OF INPUT TERMINAL FOR DETECTING LOW VOLTAGE OF THE MPU BOARD,

TO LOWER BATTERY VOLTAGE 72V TO 48V LEVEL FOR USING MICRO-COMPUTER CONTROL.

FB 30m HPUA-F OO GEERHM rd HEPES) qv TISE t oev vv

FHT TAD OPTI RY MSZ,

PARTS NO. RESISTANCE VALUE ‘APPLICABLE MODEL

17772-62071 | 18K +4702 FBs0

~ INSPECTION FOR RESISTOR ASS" Y

bik) ze

FB90 D.C CHOPPER UNIT MEASURING RESISTANCE (USE DIGITAL TESTER)

D.¢ fart ae7b 18.5 + 0.9kS (CORRECT VALUE)

18

gev-4

ACCELERATOR (FB)

= CIROUIT SYMBOL

(tv 3)

x. B (POWER SOURCE 5¥)

(774 $8)

S (ACCELERATOR VOLTAGE)

2KQ -<—1

sh)

(R) LR (GND)

& fb

* EXPLANATION

IT 1S FOR CONTROL OF DRIVING SPEED, AND OUTPUT THE SIGNAL IN PROPORTION TO PRESSING

ANGLE OF THE ACCELERATOR PEDAL. 452° 9 J>ha-W MT, PICK ATI hy

reR EL RNID.

POTENTIOMETER PARTS No. | TYPE APPLICABLE MODEL

271A2-62101 | ScFKSz008 FB10~30

~ INSPECTION FOR ACCELERATOR

MEASURING RESISTANCE (USE DIGITAL TESTER)

MEASURING POSITION (IN COUPLER) CORRECT VALUE

®) — (LR) 1.9 +01kQ

CONDITION OF THE ACCELERATOR PEDAL S72 RE

a - aR AT FREE 01£0.1kQ

AT PRESSING 1 kQ AND OVER

23K FOR ADJUSTING THE PRESSING VOLUME, IN APPLYING VOLTAGE OF 5 = 0.01V INTO (B) ~ (LR)

AT FULL PRESSING IT, ADJUST THE STOPPER BOLT TO BECOME 2.7 + 0, 2V IN (LY) ~ (LR)

HrorFo Ny. )- (MO Mr stocivg BEE G1 FIEMATIL t-#e Boreakel

(BR) - HA) Ro Oe 272 0. 2y we ET ie Zh yn TIE PZ

19

ACCELERATOR (FRB)

* CIRCUIT SYMBOL

a romn ¢ Soe 8 5Y)

8

lk gi TICS )

(ACCELERATOR VOLTAGE)

5KQ << — LW)

FRO)

B(GND)

~ EXPLANATION

IT 18 FOR BOTH CONTROLS OF DRIVING SPEED AND DIRECTION, AND OUTPUT THE SIGNAL IN

PROPORTION TO TILTING ANGLE OF THE ACCELERATOR LEVER.

EG AETF SEW Fay 9M 1G SHO 7 THOU TTI UNA DAL RS Oe

REL URIS,

POTENT IONETER PARTS NO. TYPE ‘APPLICABLE MODEL ]

29502-62251 SCFKS200E FRE10~25. FRBL

~ INSPECTION FOR ACCELERATOR

wd Ae

(FURMAKD) (NEUTRAL) (REVERSE)

MEASURING RESISTANCE (USE DIGITAL TESTER)

rome POSITION(IN COUPLER) GORRECT VALUE ]

ap - @ 4.70. KQ

i (FORWARD) 3. 0KQ AND OVER |

“n- ® (NEUTRAL) 25:40. 2k

a = (REVERSE) 2. 0KQ THAN LESS

23K FOR ADJUSTING THE NEUTRAL, IN APPLYING VOLTAGE OF 5::0.O1V INTO (LR)-(B), ADJUST

THE POTENTIOETER’ S SCREW TO BECOME 2.5-0.1V IN (LY)-@).

SEMA AA) - Ms Stool v 9€E eit Ge (HR) - (2) OSE oD

2G f0dV CO3TF et ey ert ee

F/R SWITCH

+ CIROUIT SYMBOL.

= EXPLANATION

IT 1S TO CONTROL THE DRIVING DIRECTION OF THE TRUCK.

2 MICRO SWITCHES FOR F (FORWARD) AND R(REVERSE) ARE PROVIDED WITH THIS SWITCH

FHI2OK3H tee ZI.

F: FORWARD ()@) Ri REVERSE (it) 02792472 AMF F MyRIN WS,

PARTS NO. SPECIFICATION APPLICABLE MODEL

2772-60401 | STANDARD SPEC. (R.H) | Fe10~90

2772-60411 | LOL SPEC. (LH) |

dee eh hy Pea ey

MF OE Ln te 6G A)

NEASURING POSITION | LEVER OPERATION | CONDUCTION

‘AT FORWARD Yes 4

Gr) - &Y) AAT NEUTRAL No =

AT REVERSE NO =

‘AT FORWARD Noe

© - en AT NEUTRAL NO te

AT REVERSE Yes 4

3 IN CASE OF THE ABOVE RESULT 1S NOT OBTAINED. MAKF AN ADJUSTMENT OR

REPLACEMENT OF THE MICRO SWITCH.

Lt Hey WIE ny > ME sae DHT TFT

21

LIFTING POTENTIOMETER

~ CIRCUIT SYMBOL

z crv ER)

Br (POWER SOURCE 5V)

Cok @e >

(LIFTING VOLTAGE)

SK ey

8

R (GND)

a

* EXPLANATION

IT 1S TO CONTROL LIFTING SPEED, AND OUTPUT THE SIGNAL IN PROPORTION TO OPERATING

ANGLE OF THE LIFT LEVER.

THE METER 1S PROVIDED IN LIFT SECTION OF THE HYDRAULIC CONTROL VALVE.

DIRE Qazbew Aa, VIRVIN- BUR RAR ESE HROIT,

Dew WRT OIE IL MESS,

PARTS NO. TYPE. APPLICABLE MODEL

27742-62701 | EWT AIX R30 €53| FB10~90, FRB10~25. FRBL

iE

* INSPECTION FOR LIFTING POTENTIONETER

(HYDRAULIC CONTROL VALVE)

MEASURING RESISTANCE (USE DIGITAL TESTER)

MEASURING POSITION (IN COUPLER) CORRECT VALUE

% 60 = Ms 4.7 + 0.3 ko

a aey SHAFT CONDITION 2-07} ERE

m - ® AT PUSHING 0.3 + 0. 3k

® & AT FREE 4.7 + 0.3kQ

me

a2

LIMIT SWITCH

)

No

I

@

= CIRCUIT SYMBOL.

()

= EXPLANATION

DEADWAN BRAKE, VALVE LEVER AND BATTERY).

EMER ESD CT, EAT MTU, 97) OUR yet- 217 ORME

IT 1 FOR DETECTING EACH CONDITION STATE OF THE POSITION ANO LOOK FOR THE. PAK

PARTS NO, TYPE PART OF USE ‘APPLICABLE MODEL | WIRINGUUE IST)

PARKING BRAKE | Fo 10~90 ©

VALVE Fe10~30 @

27142-64002 | zc- TILT, ATT, REACH | FRe10~25. FRBL

wazss | BATTERY LOOK FRB10~25. FRBL @

BATTERY 1 @

BRAKE (DEADNAN) 1 @

~ INSPECTION FOR LIMIT SWITCH

NEASURING POSITION [PLUNGER | CONDUCTION

(Com = (NO) | AT FREECT@)&) NOR

AT PUSHINGUFiG) YES

[ony 0) | AT FREE CBR) YES 4

l AT PUSHING Noe

CHLREFY

23

STOP LAMP SWITCH (FB)

CIRCUIT SYMBOL

RG 102

Nc

w 110

“EXPLANATION 7yb-7v-4 % WO ALES Zo G7 7° ER USC ee,

HOGL CAS. 2499 OGG BHM Uc) TSIM, PETE EMO ME ZF

" EAE T RAT TNT oF W902

WHEN PRESSING THE ‘oot BRAKE, IT INDICATES TO STOP THE TRUCK WITH STOP LAMP GOES ON

‘AS WELL AS TRANSMITS THE CONTROLLER.

THE SWITCH IS WITH b CONTACT(N.C), IT IS INSTALLED TO PUSH THE SWITCH WHEN NO PRESSING

THE FOOT BRAKE(IN STATE OF N.0).

PRATS NO. TYPE APPLICABLE MODEL

27262-42101 | 118141 0001 FB10~s0

~ INSPECTION FOR STOP LAMP SWITCH

$a

PART OF SWITCH] CONDUCTION

AT FREE Pi Yes % |

‘AT PUSHING Noe

Tet

RESISTANCE RANGE = 1 kQ

(SET ZERO(0) POSITION BEFORE USE)

24

MAGNETIC SWITCH

* CIRCUIT SYMBOL.

cas |

1@ matatatt |

EPUMTION GA Osho AR Hy SLAY AN BRAT PNR MPU IO

BPE Rs Bay 33

IT IS FOR CONTROLLING CHARGE. 3 PHASE A.C FLONS IN CHARGE, AND CUT OFF THE POWER

SOURCEFOR CONTROL CIRCUIT OF MPU BOARD AND E.1.C TO OPEN THE b CONTACT. USUALLY, IT IS

OPENED WITH 3 PHASE A.C CONTACT NOT TO FLOW THE CHARGING CURRENT.

PARTS NO. TYP ‘APPLICABLE MODEL

27912-62513 | SD-N21 FB10~25, FRB20725

27292-62213 | SD-N35 FB25BAH, FESO

27022-63103 | SD-N12 FRB10~18. FREL

~ INSPECTION FOR MAGNET SWITCH

+ COIL RESISTANCE

(USE DIGITAL TESTER)

NORMAL VALUE 0. 2~0. 3KQ

CHARGER CONTROL PANEL (FB)

“CONDUCTION IN b CONTACT

VT 1S NORWAL IF THERE

1S NOT A CONDUCTION IN

PUSH OF THE CENTRAL

BUTTON.

1939 BR TS) TRO

RPAUMCIN GA

reynr ey

CHARGER & PS PANEL

25

SPEED SENSOR

= CIRCUIT SYMBOL

= EXPLANATION

IT IS INSTALLED AT THE PART OF DRIVE UNIT TO DETECT THE DRIVING SPEED.

KAT 22h Be BIA £1 RUE EK TT

PARTS NO. TPE ‘APPLICABLE MODEL

278A2-62431 | x809-0308-0 F810~90. FRB10~25. FRBL

~ INSPECTION FOR SPEED SENSOR

IN EITHER CASE OF THE FOLLOMINGS 1S ABNORMAL,

|. TERMINALS OF THE SENSOR 1S SHORT-CIRCUITED. (02)

2.A NEEDLE OF THE TESTER 1S NOT NOVED WHEN PUTTING)

DETECTOR OF THE SENSOR TO THE STEEL PLATE, THEN

TAKE IT APART IN A MOMENT.

€2F- OSIM 2 9-1 (02) FH Coy

FERS AB ST. BGP THD 0)

De N DNS BE

9KUSE ANALOGUE TESTER WITH SMALLER DC. V RANGE. :

Prey FAILS Bb DCVO-Bdta Les

26

MPU BOARD

“EXPLANATION MPUAS HE Peek Uy aes-9 EME AL LEME R)

MPU BOARD PROVIDES WITH 8 BITS MICRO COMPUTER TO CONTROL THE SYSTEM(DRIVING & LOADING) WITHOUT

(CHARGING.

( of 2 |

ve | eae | ied | 0. cHOPPER

chassis eee eae CIRCUIT | UNIT

4 crm (a)

© Thi G CABT MOP 5

| ea gl ae DRIVING GET CONTROL |

SENSO 4oyt + k—8)

©- aan Lh ee | wy e)

a a OR

i— an Tete aie ‘CONTROL i 7

RELAY FOR Sea \ ls |

CRS wae a |

SIMPLIFIED CIRCUIT LOCATION ON MPU BOARD

27

MPU BOARD

It | 110} 1-9} 1-8] 1-7] 1-6] 1-8 J 4] sia] ia

1-22} 1-21 | 1-20 | 1-19 | 1-18 | 1-17 1-16 1-15] 1-14] 1-13] 112

+ VIEW FROM COUPLER ¢

‘SPEED SENSOR GND ‘SPEED SENSOR GND

Br_131_ [DRIVING LOI PRONBITIVE SrIToH WUT

P 169 [P/E SWITCH INPUT

BY 250%) | (DW PM THERMO SENSOR INPUT)

P/E SWITCH INPUT

(G1) | (OM THERWO SENSOR INPUT)

1-5 [0 168 [SPEED LIMITING SWITCH INPUT 0 168 [SPEED LINITING SWITCH INPUT

1-6 |" Br 13 _|F SwiTOH INPUT

1-7 Ye 21__ [ATT 1 SWITCH INPUT Wo 22 [AIT 1, 2 SWITCH INPUT

1-8 [| 8 199 |EPS SPEED SIGNAL GND

1-0 [We 67 [EPS SPEED SIGNAL 2 OUTPUT BW 136 | (SSC POTENTIONETER INPUT)

110 [YR 94 | LIFTING POTENTIONETER INPUT a

LY 93 [ACCELERATOR INPUT

Wer 69 | SPEED SENSOR INPUT

BY 25 [SWITCH GND

(2) | (PW THERWO SENSOR INPUT)

LY 93 [ACCELERATOR INPUT

Wer 89 | SPEED SENSOR INPUT

BY 25 | SWITCH GND

G 132 _ | REACH RELEASE SWITCH INPUT

116 [RL 24 | (SCAT SWITOH INPUT)

ie [4 [TR SWITCH INPUT

17 [22 [AT 2 SwiTon INPUT Ye 21 [REACH SWITCH INPUT

1-18 [YB 20 [TILTING SWITOH INPUT YB 20 | TILTING SWITCH INPUT

Ce Wa 135 [LIFTING SSC SWITCH INPUT)

1-20 [BG 96 [LIFTING POTFNTIONETER GND BG 96 | LIFTING POTENTIONETER GND

1-21 [BG 96 [ACCELERATOR GND BG96 [ACCELERATOR GND

1-22 [UW 95 [ACCELERATOR, LIFT 25V UW 95 [ACCELERATOR LIFT +5v

1-28 | 1-27) 1-26 | 1-25] 1-24] 1-23

1-84 | 1-33] 1-92 | 1-31 | 1-30] 1-29

+ VIEW FROM COUPLER D

FS

FORWARD CHIME OUTPUT)

AIT | PONER SOURCE FOR ACCESSORY

W110 [BRAKE SWITCH INPUT

BY 41 [WAIN GND

TT ORA)_| WATN POWER SOURCE +48

RH 11 | CoMTACTOR COIL PoNER Samra mT

WS 97 _ [BACK BUZZER OUTPUT

Gy 15 | PARKING SWITCH INPUT (OSCILLATION STOPS)

BY 41 [WAIN GND

11 0X6) [LOW VOLTAGE DETECT INPUT

019 | Pine SHTGH WPUT oz ci roe RD

CONTAGTOR COTL PONER SOURCE m=

W110 [BRAKE SWITCH INPUT

BY 41 [WAIN GND

RW TT [WAIN POWER SOURCE +48

RW_TT | CONTAGTOR COTL POWER SOUROE wna Frere

WB 97__|BACK BUZZER OUTPUT

BY 41 [WAIN GND

RW 11 [LOW VOLTAGE DETECT INPUT

RW Ti [CONTACTOR COIL POWER SOURGE (FRC)

RIL TT [CONTACTOR COIL POWER SOURCE ewe revo

28

MPU BOARD

+FB10/15

+FB20725

+ VIEN FROM COUPLER A

~ ELECTRIC SEALED (CUSTOMERIZED SPEC.) : 3 WR 17

+3 TON SERIES: %4 RB 10,%5 YB 18

2-8 | 2-7] 2-6] 2-5

2-4 | 2-3 | 2-2] 2-1

2-16] 2-15 | 2-14 2-12

2-12| 2-11 [2-10] 2-9

wo

[TERMINAL TRE COLOR

no [ie

RW 128

FB, FRE IN COMMON

PU F6,_FRB_1W COMMON

CONTACTOR COIL POWER SOURCE wp.)

JURE NO. TERIINAL NAME

CONTACTOR COIL. PORER SOURCE WF 8. F 70)

2-2 _| Br 129_[F CONTACTOR COIL OUTPUT ‘GONTACTOR COTL POWER SOURCE (R/C)

23 | 0 125 _[R CONTACTOR COIL OUTPUT ‘BP CONTACTOR COIL OUTPUT

2-4 | 6 126 [RB CONTACTOR COIL OUTPUT

25 | W122 _[P CONTACTOR COIL OUTPUT PB CONTACTOR COIL OUTPUT

26 | BY 41_[WAIN GND MAIN GND

2=T_| GW BT | presen cna Sm CxT TOTS) TRANSMISSION (TXD)

2-8 | GR 82_ [RECEPTION RXD) CORMUNTCATION. GND

+ VIEW FROM COUPLER B

2-29 2-28] 2-27]2-26

2-25 | 2-24 | 2-23 | 2-22 | 2-21 | 2-20| 2-19| 2-18 | 2-17

2-42 | 2-41 | 7-40 | 2-20

2-38 | 2-37 | 2-36 | 2-25 | 2-34 | 2-93 | 2-22 | 2-21 | 2-20

PU FB,_FRE_IN COMMON FB._FRB_IN COMMON

ie TERWINAL NARE ‘a Peete TERMINAL NAME

TOADING TGBT COLLECTOR LOADING T6BT EITTER(TS)

216 | GR 72 | LOADING 1GBT GATE (TS) ‘231_| GB 7 [LOADING (GBT ENITTER(T#D (FOR 2TON)

219 | GW 73 [LoADina vast GATE a) Fon 27 | 2-32 | YW 64 | LOADING SHUNT (>)

220 | YL 65 | LOADING SHUNT (-) 2-33 [We 46 [DRIVING 1e6T EMITTER)

221 | Wa 44 | DRIVING 1GBT GATE CTI) 234

re 2-35 | Wet [C/D +12v

2m | Wel | CD INPUT 296 | BY 62 | C/D GND

224 | P49 | THERWISTOR INPUT 237 | BW 50 _| THERWISTOR GND

2-25 | WR 43 [DRIVING 1GBT COLLECTOR 236

2-26 | R39 [DRIVING MOTOR DA 230 | ¥40_| DRIVE WOTOR AA

227 | G37 [initia excireo waneric resisron nif 2-40 | G37 __| WITIA BLCITED wimETiC RESISTOR mT

2-28 | Y40[IWiTiAL ExciTED waqieric outpuT [2-41 | ¥ 40 | INITIAL EXCITED MAGNETIC OUTPUT

229 | Br 36 | iwiviat excireo wie wesiston na [2-42 | Br 36 | WIVIA EXCITED waneTIC RESISTOR A

MPU BOARD

+ FB WITH STANDARD SPECIFICATION

PARTS. NO, i ae Paid WET tenes ir aia

17742-60301 ~ 00201 i

-eowoe | rei0vis | ooz02 ~ orzie i aE usTOR THEO LOGIC

60303 o1219 ~ ERINTED BOARD TW CORON WITH FR

177P2-60301 ~ 00150 w | oD

60302 raons | St > ote : A. GWE NTE TWO LTE

60312 00341 ~ 00854 ies — WITH 2 coe oe ‘SPEC.

60313 0855 ~ re RENTED BOARD 18 COMMON WITH FRB

17772-60301 a3 ~ 00209 t inh

60302 00210 ~ pee BOARD IN COMMON WITH FRB

(WOTE) NO INTERCHANGEABLE MPU BOARD

1. IN CASE OF THE WPU BOARD P/NO. 177H2-60301 1S INSTALLED ONTO THE TRUCKS SERIAL NO. 00202 AND

AFTER. IN ANOTHER CASE OF THE MPU BOARD P/NO. 177P2-60301, P/NO. 177P2-60312 OR

P/NO. 177P2-60313 1S INSTALLED ONTO THE TRUCK SERIAL NO. 00151 THRU 00340,

= GUT OUT THE WIRES FOR EACH 1-4 AND 1-14 TERWINALS OF THE MPU BOARD.

2. IN GASE OF THE MPU BOARDS P/NO. 17H2-60302 OR P/NO. 177H2-60303 IS INSTALLED ONTO THE TRUCKS

SERIAL NO.00201 AND BEFORE. IN ANOTHER CASE OF THE NPU BOARD P/NO. 177P2-60302 1S INSTALLED

ONTO THE TRUCKS SERIAL NO. 00150 AND BEFORE OR SERIAL NO. 00341 AND AFTER.

— WAKE SHORT-CIRCUITED BY WIRES FOR EACH 1~4 AND 1-14 TERMINALS TO GND OF THE MPU BOARD.

52. THE EFFECTIVE SERIAL NOS. APPLY CORRESPONDINGLY

FB WITH(EO SPECIFICATIONS 10 THE TRUCKS WITH ST SPECIFICATION.

PARTS NO. FOR Exe speo, | PARTS NO. FOR EXE SPEC. T] joy toy e | INTERCHAN

(VIM LESS + WITH SEAT GEABILTY REMARKS

(VIM LESS) mies WoDEL ao

177H2-60321 177H2-60331

FB10/15, f=

PRINTED BOARD IN COMMON

—60322 -60332 WITH FRB MODEL.

177P2-60321 177P2-60331

F820/25 $8

PRINTED BOARD IN COMMON

60322 —60332 ae

17772-60321 |177T2~-60331

Yes

io i PRINTED BOARD 1W COMMON

60322 60332 WITH FRB MODEL

30

MPU BOARD

‘FAB WITH STANDARD SPECIFICATION

APPLICABLE TNTERGHAN

PARTS NO. ee EFFECTIVE SERIAL wo. | Ta REMARKS

178A2-60301 x

FRei0/19 —f—

60302 © (ABILITY uP

178M2-60301 x

FRBI4~18 +f

—60302 © fasiuity

178R2-60301 x

FRB20/726 an

-60302 © [ABILITY uP

178w2-60301 FRBL

31

eee ie

2. PROCEDURES FOR OVERHAULING THE MOTORS/METER PANEL

WORK ORDER POINT

[2.1 OVERHAUL OF THE DRIVE MOTOR

(1) REMOVE SNAP RING SECURING THE FAN

FROM ARMATURE SHAFT.

(2) USING 2 BOLTS AS THE PICTURE,

REMOVE THE FAN FROM ARMATURE

SHAFT.

IN THIS WORK, SCREW THE BOLT

ALTERNATIVELY IN EVEN TO SEPARATE

THE FAN FROM IT,

(3) TAKE BRUSH COVER UT AFTER

RELEASING ITS LATCH.

\ (4) LIFT BRUSH SPRING HALF THE WAY | DO NOT STRETCH

FROM BRUSH HOLDER TOP BY USING [BRUSH WIRE BY

BRUSH SPRING PULLER(AS BENT STEEL |FORCE.

WIRE) AND ATTACH BRUSH SPRING TO

BRUSH SIDE FACE AND LOCK.

32

WORK ORDER POINT

(5) PUT MOTOR UPRIGHT WITH BRACKET (F)

UPWARD, AND REMOVE 6 BOLTS

SECURING BRACKET (F) TO YOKE,

(6) SEPARATE BRACKET (F) FROM YOKE

BEFORE THAT.

REMEMBER THE MARK POSITION NOT TO|

SHIFT THE BRACKET (F) IN ASSEMBLY,

AND WRAP VINYL TAPE AROUND

ARMATURE SHAFT SPLINE FOR

PREVENTING DAMAGE.

(7) SEPARATE ARMATURE FROM YOKE, PAY ATTENTION

CAREFULLY. INOT TO HIT

JARMATURE TO

FIELD COIL.

(8) PRIOR TO SEPARATING BRACKET (R)

FROM YOKE, TAKE SCREWS OUT FROM

PART OF BRUSH HOLDER TO SECURE THE

PIG TAIL (LEAD WIRE) OF BRUSH WITH

FIELD COIL.

33

WORK ORDER

POINT

(9) REMOVE 4 BOLTS, AND SEPARATE

BRACKET (R) FROM YOKE, IF IT 1S TOO

TIGHT TO SEPARATE THEM, GENTLY HIT

BRACKET (R) AT THE INNER SIDE OF

‘SURROUNDING WITH A WOODEN HANMER

OR THE LIKE. AT THIS TIME, DO NOT

HIT THE PIGTAIL OF THE BRUSH.

(10) SEPARATE BRUSH HOLDER FRON

BRACKET (R) (4 SECURING BOLTS)

CUDRENOVAL OF BEARING SHOULD BE

PERFORMED ONLY WHEN ABNORMAL NOISE

(OR JAMMING OF BEARING 1S NOTICED.

FOR THIS PURPOSE, USE A SMALL

PULLEY PULLER, AND APPLY A FORCE

TO THE INNER RACE OF THE BEARING,

IF YOUR NAIL 1S DIFFICULT TO

CATCH THE INNER RACE, APPLY A

FORCE ON THE OUTER RACE. DO NOT

RE-USE THE REARING ONCE RENOVED.

(12) IN CASE OF REMAINING KEY AT THE

SHAFT, TAKE IT OUT, THEN REMOVE

THE BEARING,

WHEN ASSEMBLING

IT, TEMPORARILY

JCLAMP CABLES OF

ITHE BRUSH HOLDER.

34

WORK ORDER POINT

(13) COMPOSED PARTS FOR DRIVE MOTOR.

REASSEMBLE DRIVE MOTOR IN THE

IREVERSE SEQUENCE OF DISASSEMBLY,

JUSING CAUTION FOR THE FOLLOWING.

(14) WHEN INSTALLING A NEW BEARING ON | BE SURE TO

‘ARMATURE SHAFT, USE A CYLINDRICAL |ROTATE IT

JIG AND APPLY A FORCE TO THE INNER [SMOOTHLY AFTER

RACE OF THE BEARING. INSTALLING,

35

WORK ORDER.

POINT

2.2 OVERHAUL OF THE PUNP NOTOR

(1) TAKE BRUSH COVER OUT AFTER

RELEASING ITS LATCH.

(2) LIFT BRUSH SPRING HALF THE WAY

FROM BRUSH HOLDER TOP BY USING

BRUSH SPRING PULLER (AS BENT STEEL

WIRE) AND ATTACH BRUSH SPRING TO

BRUSH SIDE AND LOCK.

(3) PUT MOTOR UPRIGHT WITH BRACKET (F)

UPWARD, AND REMOVE 4 BOLTS

SECURING BRACKET (F) TO YOKE.

(4) SEPARATE BRACKET (F) FROM YOKE.

BEFORE THAT, REMEMBER THE MARK

POSITION NOT TO SHIFT THE BRACKET

(F) IN ASSEMBLY.

DO NOT STRETCH

BRUSH WIRE BY

FORCE.

36

WORK ORDER POINT

(5) SEPARATE ARMATURE FROM YOKE PAY ATTENTION

CAREFULLY. INoT To HIT

JARMATURE TO

FIELD COIL,

(6) PRIOR TO SEPARATING BRACKET (R)

FROM YOKE, TAKE SCREWS OUT FROM

PART OF BRUSH HOLDER TO SECURE THE

PIG TAIL(LEAD WIRE) OF BRUSH WITH

FIELD COIL,

(7) REMOVE 4 BOLTS, AND SEPARATE

BRACKET (R) FRON YOKE GENTLY TO HIT

BRACKET (R) AT THE INNER SIDE OF

SURROUNDING WITH A WOODEN HAMMER

OR THE LIKE. AT THIS TIME, DO NOT

HIT THE PIG TAIL OF THE BRUSH.

(8) SEPARATE BRUSH HOLDER FROM

BRACKET (R) (4 SECURING BOLTS)

37

POINT

(9) ONLY IN THE EVENT OF ABNORMAL

NOISE OR JAWMING OF BALL BEARING,

REPLACE IT WITH NEW ONE.

WHEN REMOVING, USE A SMALL

PULLER, AND APPLY A FORCE TO THE

INNER RACE OF BEARING,

DO NOT RE-USE THE BEARING ONCE

REMOVED.

(10) COMPOSED PARTS FOR

REASSEWBIF PUMP MOTOR IN THE REVERSE

|SEQUENCE OF DISASSEMBLY, USING

JCAUTION FOR THE FOLLOWING,

(TI)NHEN INSTALLING A NEW BEARING ON

ARMATURE SHAFT, USE A CYLINDRICAL

JIG AND APPLY A FORCE TO THE INNER

RACE OF THE BEARING.

BE SURE TO

ROTATE. IT

[SMOOTHLY AFTER

INSTALL ING

WORK ORDER.

POINT

2.3 OVERHAUL OF THE METER PANEL.

LOOSEN NUT SECURING HANDLE WHEEL.

(D0 NOT SEPARATE IT YET)

(2) AS SHOWN IN PHOTO, LIGHTLY HIT BY

HAND FOR PUSHING UP THE HANDLE

WHEEL AT BOTH END TO LOOSEN IT,

THEN REMOVE IT WITH NUT.

(3) REMOVE 8 SCRENS THE SEPARATE

COVER(A) FROM HANDLE COLUMN.

(4) REMOVE 4 BOLTS THEN SEPARATE

METER PANEL FROM HANDLE COLUMN,

(1) REMOVE CAP OF THE HORN SWITCH AND}

39

WORK ORDER

POINT

(5) FALL METER PANEL DOWN SIDEWAYS

WITH CARE OF THE HARNESS,

(6) DISCONNECT COUPLER CONNECTING

WITH LoD BOARD.

(1) REMOVE 4 SCREWS (RIGHT AND LEFT

EACH 2) AS POINTED IN PHOTO.

(8) SEPARATE COVER(C) FROW COVER (B)

40

WORK ORDER

POINT

(9) SEPARATE METER PANEL ASS’ Y FROM

COVER(B) TO REMOVE 5 SCREMS.

(10) REMOVE ALUMINUM PLATE (WITH 2

‘SOREWS) AT THE BACK SIDE OF THE

WETER PANEL ASS'Y, THEN SEPARATE

LOD BOARD FROM IT(WITH 6 SCREWS)

(11) REASSEMBLE IN THE REVERSE

PROCEDURE OF DISASSEMBLY.

41

vT™M

MP US

HEE

1

pele

eee rey

Pe] 8 121 8 Lee

FB10~25 - 6

73

vT™

MP Ud&4R MPU BOARD

@

Pena

aT PET or YU eet cleat

a

©

74

FB30 - 6

BuBE-—6cog

feeue wees

SABES

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- LSV Service ManualDocument242 pagesLSV Service ManualNgo Ngoc Tu88% (16)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- SPE Service ManualDocument170 pagesSPE Service ManualNgo Ngoc Tu81% (16)

- SPE Service ManualDocument170 pagesSPE Service ManualNgo Ngoc Tu81% (16)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Service Manual LWE130Document92 pagesService Manual LWE130Ngo Ngoc Tu67% (3)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Structure Description: Repair Manual: Troubleshooting Model(s) : LPE200, LPE220, LPE250Document72 pagesStructure Description: Repair Manual: Troubleshooting Model(s) : LPE200, LPE220, LPE250Ngo Ngoc Tu77% (13)

- Structure Description: Repair Manual: Troubleshooting Model(s) : LPE200, LPE220, LPE250Document72 pagesStructure Description: Repair Manual: Troubleshooting Model(s) : LPE200, LPE220, LPE250Ngo Ngoc Tu77% (13)

- Truckcom TE ManualDocument44 pagesTruckcom TE ManualNgo Ngoc Tu100% (9)

- Truckcom TE ManualDocument44 pagesTruckcom TE ManualNgo Ngoc Tu100% (9)

- Service Manual En: LWE180, LWE200, LPE200-6/8Document142 pagesService Manual En: LWE180, LWE200, LPE200-6/8ник100% (5)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- LPE 240 Service ManualDocument164 pagesLPE 240 Service ManualNgo Ngoc Tu100% (5)

- S10-S12 - EXEL Service ManualDocument106 pagesS10-S12 - EXEL Service ManualNgo Ngoc Tu50% (4)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Your Request Has Been Sent: Size (Bytes) Items in Your Download PackageDocument4 pagesYour Request Has Been Sent: Size (Bytes) Items in Your Download PackageNgo Ngoc TuNo ratings yet

- Steering System For Electric Lift Trucks: MaintenanceDocument28 pagesSteering System For Electric Lift Trucks: MaintenanceNgo Ngoc Tu100% (1)

- 005 - Electrical Wiring DiagramsDocument20 pages005 - Electrical Wiring DiagramsNgo Ngoc TuNo ratings yet

- We Reserve The Right To Change The Design of Our Products Without Incurring An Obligation To Modify Previously Manufactured ProductsDocument1 pageWe Reserve The Right To Change The Design of Our Products Without Incurring An Obligation To Modify Previously Manufactured ProductsNgo Ngoc TuNo ratings yet

- We Reserve The Right To Change The Design of Our Products Without Incurring An Obligation To Modify Previously Manufactured ProductsDocument2 pagesWe Reserve The Right To Change The Design of Our Products Without Incurring An Obligation To Modify Previously Manufactured ProductsNgo Ngoc TuNo ratings yet

- LA00001R03YDocument3 pagesLA00001R03YNgo Ngoc TuNo ratings yet

- Service Bulletin: HA00023R01YDocument1 pageService Bulletin: HA00023R01YNgo Ngoc TuNo ratings yet

- Service Manual GB: Valid From Serial Number: 364690AADocument98 pagesService Manual GB: Valid From Serial Number: 364690AANgo Ngoc Tu100% (1)

- 6huylfh XLGH %: Valid From Serial Number: 364690AADocument68 pages6huylfh XLGH %: Valid From Serial Number: 364690AANgo Ngoc Tu100% (1)