Professional Documents

Culture Documents

Chlorine - Dosing Specs - 1

Chlorine - Dosing Specs - 1

Uploaded by

SANRAJ TECHNOOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chlorine - Dosing Specs - 1

Chlorine - Dosing Specs - 1

Uploaded by

SANRAJ TECHNOCopyright:

Available Formats

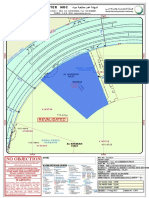

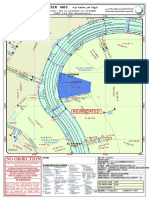

ISLAND PARK I & II

PLOT No. A-026 & A-027

DUBAI CREEK HARBOUR DEVELOPMENT, DUBAI, UAE

Volume 5, Part-E

the variable speed mode. A solid red indicator light shall signal this condition and a message shall be

displayed on the operator interface of the pump logic controller indicating the failure.

In the event of a system differential pressure failure, due to an AFD fault, the pump logic controller

shall automatically initiate a timed sequence of operation to start the selected pump across the line. A

solid red indicator light shall signal this condition and message shall be displayed on the operator

interface of the pump logic controller indicating the failure.

A subsequent overload trip or duty pump failure shall automatically start a timed sequence of

operation to start the standby pump across the line.

When in the “bypass” mode and the pump selector on “Pump No.1”, Pump No. 1 shall operate across

the line at constant speed with motor overload and ground fault protection. A solid red indicator light

shall signal this condition. The standby pump shall be locked out.

22.3.9 In the event of an overload fault while in the “bypass” mode, the backup pump shall be locked out.

In the event of the failure of a zone sensor / transmitter, its process variable signal shall be removed

from the scan / compare program. Alternative zone sensor / transmitters, if available, shall remain in

the scan / compare program for control.

22.3.10 The zone number corresponding to the failed sensor / transmitter shall be displayed on the operator

interface of the pump logic controller.

22.3.11 In the event of failure to receive all zone process variable signals, the AFD shall maintain 100% speed,

reset shall be automatic upon correction of the zone failure.

22.3.12 Pump, AFD, overload fault shall be continuously scrolled through the display on the operator interface

of pump logic controller until the fault has been corrected and the pump logic controller has been

manually reset.

22.3.13 The Packaged booster pump set shall have 2 years’ warranty.

23.0 PACKAGED WATER FILTERATION & SOFTENING UNIT (Where Applicable)

23.1 Pre Chlorination

The raw water supplied by the Municipality shall be chlorinated by means of Sodium hypochlorite

solution. The Sodium Hypochlorite Dosing set shall comprise of dosing tank (PVC), Electronic

metering pump (PP).

DATA SHEET FOR THE CHLORINATION DOSING SYSTEM

Description Data Chlorination Details

Type of Chemical Sodium Hypochlorite solution

Dosing tank details

Number 1

Type Vertical, Circular

Material of tank Polyethylene

Capacity As per the design requirements

Number As per the design requirements

Type Electronic Metering

Section 04 - PLUMBING WORKS Page 21 of 30 Rev. 00 – Dec.2022

Tender Addendum Submission

ISLAND PARK I & II

PLOT No. A-026 & A-027

DUBAI CREEK HARBOUR DEVELOPMENT, DUBAI, UAE

Volume 5, Part-E

Material of pump PVC

Capacity 0 – 20Lph

23.2 AUTO MULTIMEDIA FILTRATION UNIT

Type of Treatment for Removal of Suspended impurities

23.2.1 Vessel:

The filter vessels shall be fabricated from high grade steel and internally lined with epoxy paint. The

External surface of the vessels shall be protected with a primer undercoat and Epoxy paint.

The vessel shall be designed for 100PSI working pressure and tested to 150PSI. The vessel shall be

supplied internally coated with Zinc Epoxy and externally painted.

23.2.2 Valves:

Automatic Solenoid driven Hydro / Pneumatic Diaphragm / Butterfly valve to control the operating

steps. The valves shall be made of Carbon Steel. The water treatment equipment supplier as per the

requirement shall arrange necessary compressed airline.

23.2.3 Frontal Piping

The frontal piping of the filter unit shall be uPVC surface protected with U.V. resistant paint.

23.2.4 Media

The Multimedia Sand Filter bed shall consist of a top layer of a uniformly graded granular form of

anthracite. The intermediate layer shall consist of three grades of Silica sand. The under bed shall

consist of a layer of gravel, which is a granular material of extra ordinary density available in graded

sizes for fine filtration.

Charge of carefully graded filtering Sand and Anthracite Media complete with supporting gravel

underbed.

23.2.5 Pressure Gauge

Inlet / Outlet gauge shall be fitted to give indication of pressure drop through filter.

23.2.6 Controls

The filters shall be provided with Specialized PLC Controllers with timer mechanism to enable to

program the backwash cycle of the filter at any time of the day. The PLC Controller shall complete

with Soft Keyboard and LCD display and shall give signals to the Solenoid driven hydro / Pneumatic

Butterfly valves.

23.3 DUPLEX SOFTENER

23.3.1 The unit shall consist of softener vessels for continuous supply of the softened water. The plant shall

be capable of producing zero temporary hardness at the rate as scheduled.

23.3.2 The Duplex softener should consist of two tanks in Polyester Fibre Glass with suitable coating internal

and external of the construction. Pressure rating of the tanks is 10bars.

Section 04 - PLUMBING WORKS Page 22 of 30 Rev. 00 – Dec.2022

Tender Addendum Submission

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Water Meter Room Regulations From DEWADocument34 pagesWater Meter Room Regulations From DEWASANRAJ TECHNONo ratings yet

- Dchip1&2 FC PL Mas 0008, Rev 00 (Wha)Document4 pagesDchip1&2 FC PL Mas 0008, Rev 00 (Wha)SANRAJ TECHNONo ratings yet

- Chlorine - Dosing Specs - 2Document2 pagesChlorine - Dosing Specs - 2SANRAJ TECHNONo ratings yet

- Polyfab Fabication CatalogueDocument12 pagesPolyfab Fabication CatalogueSANRAJ TECHNONo ratings yet

- Service Guide enDocument35 pagesService Guide enSANRAJ TECHNONo ratings yet

- NO Objection: Water Noc هﺎ ـ ﯿﻣ ﺔـ ـ ﻌﻧﺎ ﻤﻣ مﺪﻋ ةدﺎ ﮭـ ﺷDocument25 pagesNO Objection: Water Noc هﺎ ـ ﯿﻣ ﺔـ ـ ﻌﻧﺎ ﻤﻣ مﺪﻋ ةدﺎ ﮭـ ﺷSANRAJ TECHNONo ratings yet