Professional Documents

Culture Documents

Development and Promotion of The Reversible Airflo

Uploaded by

Johann TagadanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Development and Promotion of The Reversible Airflo

Uploaded by

Johann TagadanCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/334394913

Development and Promotion of the Reversible Airflow

Flatbed Dryer in the Philippines

Article · September 2015

DOI: 10.32945/atr3717.2015

CITATIONS READS

5 13,561

6 authors, including:

Caesar Joventino Tado John Eric Ortiz Abon

Philippine Rice Research Institute Philippine Rice Research Institute

6 PUBLICATIONS 49 CITATIONS 9 PUBLICATIONS 23 CITATIONS

SEE PROFILE SEE PROFILE

Some of the authors of this publication are also working on these related projects:

rice straw research View project

All content following this page was uploaded by Caesar Joventino Tado on 01 April 2020.

The user has requested enhancement of the downloaded file.

Annals of Tropical Research 37[1]:97-109(2015)

© VSU, Leyte, Philippines

Development and Promotion of the Reversible

Airflow Flatbed Dryer in the Philippines

1 1 1

Caesar Joventino M. Tado , Dexter P. Ona , John Eric O. Abon ,

1 2 2

Eden C. Gagelonia , Nguyen Thanh Nghi , and Le Quang Vinh

1

Rice Engineering and Mechanization Division, Philippine Rice Research Institute,

Maligaya, Science City of Muñoz, Nueva Ecija, Philippines.

2

Nong Lam University, Ho Chi Minh City, Vietnam

ABSTRACT

A flatbed dryer with a reversible airflow was introduced in the Philippines

through a collaborative project between Nong Lam University of Vietnam and the

Philippine Rice Research Institute (PhilRice). In this design, airflow is reversed at

some point during the drying period to achieve uniform drying without mixing the

grain.

An 8-ton capacity dryer was constructed at PhilRice Central Experiment Station

in Nueva Ecija to evaluate its performance and adaptability under Philippine

conditions. Appropriate and locally available materials were used in the construction

of the pilot unit. Nine (9) additional dryers were then constructed at PhilRice stations

(Nueva Ecija, Isabela, Negros, Agusan, Central Mindanao University, and Midsayap)

that served as pilot units for technology promotion in their respective areas of

coverage. Performance of the dryer was evaluated in terms of the following

parameters: (1) drying; (2) quality of dried grains; and (3) economic analysis of using

the dryer. The performance evaluation was conducted in three drying batches of newly

harvested rice seeds.

Paddy dried with the reversible airflow flatbed dryer at full load capacity has a

uniform moisture content with one percent (1%) moisture gradient at different layers

of the grain mass along the depth and across the drying bin. The drying rate was 1%

moisture reduction per hour.

The drying cost of using the reversible dryer is PhP0.74 per kg which is lower than

the prevailing mechanical drying cost of PhP1.13 per kg. It has a payback period of 2.5

years and break-even point of 53.0 batches/year. To date, eight (8) privately-owned

units have already been constructed and fully operational in the provinces of Nueva

Ecija, Quirino, and Bukidnon, with PhilRice receiving inquiries from interested

individuals here and abroad regarding the technology.

Keywords: reversible airflow flatbed dryer, drying rate, moisture gradient

Correspondence: C.J.M. Tado Address: Rice Engineering and Mechanization Division, Philippine Rice

Research Institute, Maligaya, Science City of Muñoz, Nueva Ecija, Philippines. Telephone: (044)456-0285

E-mail: cjmtado@yahoo.com.

DOI: 10.32945/atr3717.2015

98

Tado et al.

INTRODUCTION

The recent spike in world rice prices showed the vulnerability of

countries such as the Philippines which depend on imports for its food

security, to the volatility of the world rice market. In many countries of Asia,

increase in rice production has been traditionally attained by increasing

the area devoted to rice. In the Philippines, however, we can no longer

afford this luxury, as the physical area planted to rice has already reached

its upper limit. The country's quest for self sufficiency in rice should

therefore be done in a two-pronged approach: increasing productivity of

our ricelands, and reducing postharvest losses. Approximately 15% of our

rice production is lost in postharvest handling and processing. Thirty

percent of the total postharvest losses is lost in drying (BPRE, 2003, as cited

by PCARRD, 2009). Since the rice grain quality starts to deteriorate 24

hours after harvest if left undried, farmers need ready access to dryers.

Given the above scenario, the introduction of mechanical dryers in the

Philippines is a must. Many recirculating mechanical dryers were put up in

the country as part of the government's intervention to the prevalent

postharvest problem in the countryside. However, many of these units are

now idle due to very high operating costs and lack of technical expertise on

the parts of the farmers/cooperatives to maintain these postharvest

facilities. The Department of Agriculture, through the Philippine Center for

Postharvest Development and Mechanization (PhilMech) has also

embarked on distributing the 6-ton flatbed dryers to selected cooperatives

and irrigators' associations, as one of the interventions in reducing

postharvest losses of paddy (Gagelonia, et al., 2013). However, issues like

difficulty in mixing during drying are always raised by the users. Mixing can

be eliminated by reversing the direction of the drying air at some point

during the drying period. A reversible airflow grain dryer was developed in

Leyte, Philippines in the 1990s (Kuizon, 1995). The air is blown at the

center into the plenum chamber underneath the drying bin, thus

increasing the bed height level, and making it more difficult for manual

loading.

The reversible airflow flatbed dryer (e.i. reversible dryer) which is now

being extensively used in the Mekong Delta of Vietnam is a dryer which also

uses farm biomass such as rice hull for fuel (Hien, 2010). In this

configuration, the air is blown at the side duct of the drying bin, so that the

bed height level remains low.As the direction of the drying front is reversed

at some point during dying, mixing of the grains in the drying bin is now

99

Development and Promotion of the Reversible Airflow Flatbed Dryer

eliminated. This type of dryer therefore presents a bright potential of being

adopted in the country. Thus, this study wasconducted in order to

introduce and promote the technology in the Philippines.

OBJECTIVES

The general objective was to introduce the Vietnamese reversible

drying technology to the Philippines and adapt it to local conditions.

Specific objectives were as follows:

1. To build the reversible dryer and evaluate its performance;

2. To modify the design based on the results of evaluation to suit local

field conditions; and

3. To promote the technology in the major rice producing provinces

of the country.

METHODOLOGY

Observation Tour

As an initial activity, an observation tour by key officials of the

Department of Agriculture, PhilRice, and PhilMech to observe the

reversible dryer in operation in Vietnam was organized. The main

objective of the tour was for tour participants to familiarize themselves

with the technology and to determine its possibility of being adopted in the

Philippines. Travel expenses of the tour participants were shouldered by

the International Rice Research Institute (IRRI).

Dispatch of Vietnamese Experts to PhilRice

The transfer of the reversible drying technology from Vietnam to the

Philippines included the dispatch of two (2) Vietnamese experts to

PhilRice to provide technical assistance to the PhilRice team in

constructing the dryer as well as in the technical evaluation of the dryer.

The plan was to invite one (1) PhD student and one (MS) student who

would take their graduate studies at a reputable higher education

institution in the country. The cost of their stay in the Philippines was

borne by PhilRice.

100

Tado et al.

Description of the Reversible Airflow Flatbed Dryer

The reversible dryer (Figure 1) adopted in the Philippines is the

product of the collaborative project on transferring the reversible drying

technology of Nong Lam University to PhilRice. It has three main

components, namely: the furnace, the blower assembly, and the drying bin.

The dryer has a capacity of 8 tons of paddy per batch. The fan used is an

axial-flow type having a diameter of 900 mm (Figure 2). This is powered by

a 22-25 hp diesel engine or an 11 kW electric motor. The rice hull furnace

is the second generation furnace which has incorporated a cylindrical

combustion chamber for better separation of the fly ash. The drying bin is a

flatbed-type with side-duct plenum and perforated screen flooring.

During the reversal of the airflow, the top of the drying bin is covered, the

trap door of the air-reversal device is opened to allow the air to flow from

the top of the drying bin in the downward direction, ultimately exiting at

the side of the plenum below. The dryer was constructed at the Central

Experiment Station of PhilRice (PhilRice CES) by PhilRice engineers, in

collaboration with the technical experts from Vietnam.

Figure 1. The reversible airflow flatbed dryer.

Figure 2. Two-stage axial flow fan used in the reversible dryer.

101

Development and Promotion of the Reversible Airflow Flatbed Dryer

Principle of Operation

Drying material is manually loaded into the drying bin with a depth of

50 to 60cm. Heated air is produced by the furnace and sucked by the dryer

fan. The drying air blown into the drying bin is a mixture of the hot air from

the furnace and ambient air. The drying air temperatures of 40 to 43oC are

used for drying of seed grains. Grains for milling purposes can be dried at

higher temperatures. During the drying process, rice husk and ashes are

manually fed and discharged, respectively. The drying process involves two

periods, namely:

The upward drying period. In this period (Figure 3a), the fan blows the

heated air into the air-reversal chamber which is connected to the lower

side-plenum chamber, and then to the plenum chamber under the floor.

The air then goes through layers of grain mass, bringing moisture

vaporized from grains, and exits on top of the grain mass. This phase

continues until the moisture content of the second layer of the 3-layer grain

mass is around 2.5-4.0 % higher than desired moisture level, which is

about two-thirds (2/3) of total drying time of the batch (Hien et al., 2003).

The downward drying period. During this period (Figure 3b), the cover

sheet is used to cover the whole drying bin and must be tightly fastened.

The air-reversal chamber is then set so that the heated air enters the upper

side-plenum chamber, turns toward the space between the cover sheet and

top of grain mass, goes through upper and lower layers of grain mass, and

exits at openings on the side of the lower side-plenum chamber. Drying is

then continued until the desired moisture content is reached.

Figure 3. Principle of operation of the reversible dryer.

102

Tado et al.

Technical Evaluation

After constructing the dryer, the unit was subjected to a series of

laboratory tests to determine its critical operating parameters and to fine-

tune the unit. Afterwards, a series of actual drying tests at full capacity was

conducted to determine its field performance. Aspects of the laboratory

and field evaluation were used by the Vietnamese counterparts as their

research topics for their graduate studies at the nearby Central Luzon State

University (CLSU).

The dryer was tested based on the Philippine Agricultural Engineering

Standards (PAES 202:2000). Right after loading the grain sample, checking

the initial distribution of air (Figure 4) and installing the different

instruments were carried out, after which, the drying operation was

started. In these experiments, temperature and relative humidity of

ambient, drying, and exhaust air were measured with an interval of 30

minutes during the drying process. Since the drying bed area of the dryer

was rather large, it was necessary to collect data of sample moisture

content (MC) and air velocity at several points in the drying bed. From the

second drying period onwards (after covering the canvas sheet to reverse

direction of the drying airflow), grain MC was only taken when the drying

process was finished, because unfastening and reinstalling of cover sheet

as well as getting samples would take much time. Drying operation was

terminated when the desired final MC of grain was reached. At the end of

the drying process, the fan was allowed to run for 30-45 minutes for proper

tempering of the paddy and prevent grain fissures. Milling operations

were done on the following day.

Figure 4. Checking the air distribution.

103

Development and Promotion of the Reversible Airflow Flatbed Dryer

Economic Analysis

An economic analyis of the reversible dryer was conducted in

collaboration with the Socio-economics Division of PhilRice to guide the

adoptors of the technology on the profitability of its operation.In

estimating the cost of drying, the maximum drying capacity of the dryer

was used to calculate related parameters. Estimation of the drying cost

needs general assumptions which were based on actual drying operations

at the PhilRice CES. Economic indicators were payback period and internal

rate of return (IRR). The payback period in years is the time required to

recoup the investment and the IRR is the interest rate that makes the net

present value of all cash flow equal to zero.

Technology Promotion Strategies

Additional 12 units of reversible dryers were constructed in 6 PhilRice

stations. These units serve as demonstration units for all those who are

interested in the technology. The dryer is also included among the

technologies being showcased during the regular field days conducted by

the PhilRice stations in collaboration with the Department of Agriculture

(DA) and LGU personnel. Technical assistance were provided by PhilRice to

those who are interested in constructing the dryer. Furthermore, the dryer

was included among the postharvest technologies being promoted by IRRI

and PhilRice through a collaborative project “Addressing the Pre- and

Postharvest Challenges in the Rice Supply Chain.”

Training and Technical Assistance to Technology Adaptors

Farmers and other stakeholders who were interested on the reversible

dryer technology were provided hands-on training on the operation and

maintenance of the dryer. In addition, several batches of similar training

courses were conducted for agricultural extension workers in Bohol,

Agusan and Bicol through the collaborative postharvest project with IRRI.

Several operators and owners of the conventional flatbed dryer also

benefited from the above training courses.

104

Tado et al.

RESULTS AND DISCUSSION

Performance Test of Blower

Performance test of the blower was conducted at the Rice Engineering

and Mechanization Division of PhilRice using a locally-fabricated fan test

duct (Figures 5 and 6). The aim was to measure fan parameters such as air

rate, power consumption, and fan efficiency. The performance of the

blower is shown in Table 1.

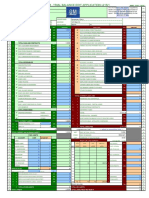

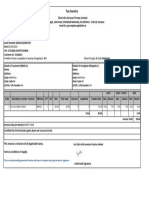

Table 1. Performance of the reversible dryer blower.

STATIC AIR STATIC OVERALL MOTOR MOTOR STATIC AIR MOTOR MOTOR

PRESS., VOLUME AIR Eff., Eff., POWER, POWER, PRESS., VOLUME, POWER, POWER,

mm H2O m3/s % % kW hp mmH2O m3/s kW hp

64.60 10.65 53.64 67.45 13.77 18.46 36.40 7.99 5.82 7.80

54.40 10.90 47.64 62.91 13.39 17.95 30.60 8.18 5.66 7.59

38.60 10.68 35.77 51.30 12.49 16.74 21.70 8.02 5.28 7.08

26.10 10.72 25.72 42.34 11.85 15.88 14.70 8.04 5.01 6.72

19.30 10.51 18.27 33.57 12.10 16.22 10.90 7.89 5.12 6.86

Fan-shaft speed, n = 1,332 rpm * Converted to: n' = 1,000 rpm

*

The mean speed of blower shaft measured when testing.

Figure 5. Static pressure measurement using an inclined manometer.

105

Development and Promotion of the Reversible Airflow Flatbed Dryer

Figure 6. Measurement of power consumption of the blower using a power meter.

The blower was able to produce enough required air volume even as

the speed was converted to 1,000 rpm. An air flow rate of about 8.0 m3/s at

a static pressure of 36 mmH2O was produced by the blower, which met the

requirements for air volume in the dryer.

Performance Test of Dryer

Dryer performance was evaluated by drying wet paddy at full-load

capacity to determine the drying rate, air velocity, moisture content

gradient, fuel/power consumption, and rice hull consumption. Test results

are shown in Table 2.

Table 2. Performance test results of the reversible dryer

Parameters Values

Mean Drying Rate (%/h) 0.88

Mean MC Gradient (%) 1.03

Drying Efficiency (%) 44.01

Cracked Grains (%) 0.53

Head Rice Recovery (%) 60.34

Germination Rate (%) 91.53

Drying Cost (PhP/kg) 0.74

Payback Period (yr) at 120 batches/yr 2.42

106

Tado et al.

Based on the data gathered, the reversible dryer had a mean drying

efficiency of 44.01%. The drying curve and the linear regression equation

of the dryer were derived and are shown in Figure 7. The drying rate was

not so fast and is deemed suitable for drying seeds. There was no observed

soot or blackening of the grains, indicating that the cylindrical combustion

chamber with fly ash separator has performed very well.

Figure 7. Drying curve of the reversible dryer.

Economic analysis

The cost of drying is dependent on investment cost and annual drying

capacity. With an annual use of 120 drying batches/yr, the drying cost of

the reversible dryer was PhP0.735/kg of dried paddy which was cheaper

than the prevailing mechanical drying cost of PhP1.13/kg of dried paddy in

the Philippines (Vinh, 2011).

Payback period for the reversible dryer was computed to be 2.42 years,

with break-even point of 53.0 batches/yr (Figure 8). It has an internal rate

of return of 33.14%.

107

Development and Promotion of the Reversible Airflow Flatbed Dryer

Figure 8. Determining the break-even point of using the reversible dryer.

Technology Promotion and Knowledge Sharing

As a result of the information campaign conducted on the technology, a

number of private individuals and farmers' groups have already adopted

the technology, as shown in Table 3. After the dryer was installed, operators

were trained about its operation, maintenance, and troubleshooting.

During the training, the operators and the dryer owners were provided

with operator's manuals (Figures 9 and 10).

Furthermore, the reversible drying technology is being promoted to

farmers, traders, and cooperatives through conferences, workshops,field

days, and training courses held at the PhilRice stations.Knowledge sharing

madethe stakeholders realize the importance of mechanical drying

technology.

Figure 9. Grain loading training. Figure 10. Operator’s manual.

108

Tado et al.

Table 3. Reversible airflow flatbed dryers installed in the Philippines.

No. of

Location Capacity, ton per batch

Units

Philrice station

CES 2 10 and 8

Isabela 1 8

Los Baños 1 4

Negros 2 8

Agusan 2 8

Midsayap 2 8

CMU 3 8

Privately owned

Diffun, Quirino 1 8

Cabarroguis, Quirino 1 8

Gapan, Nueva Ecija 1 8

San Antonio, Nueva 1 8

Ecija 1 8

Bongabon, Nueva Ecija

Community owned

Impasugong, Bukidnon 2 4

Malaybalay, Bukidnon 1 4

CONCLUSIONS AND RECOMMENDATIONS

The reversible drying technology makes it possible to achieve uniform

drying at double the drying depth of the conventional flatbed dryer:

thereby eliminating mixing of the grains. The 1% moisture gradient

obtained at a drying depth of 60 cm was well below the 2% maximum limit

set by PAES standards (PAES 201:2000).

The cylindrical combustion chamber with fly ash separator eliminated

the problem of soot or blackening of the grains, as observed in the

conventional flatbed dryers.

Economic analysis and experiences of initial adoptors of the

technology indicate that even with the high investment cost of the

reversible dryer, it is a viable option for custom drying with a break-even

point of 53 drying batches per year, with a payback period of less than 3

years.

Further research is needed to simplify and optimize some components

such as the blower in order to reduce power requirement.

Linkage with manufacturers and the private sector is a must in order to

speed up diffusion of the technology to the countryside.

109

Development and Promotion of the Reversible Airflow Flatbed Dryer

REFERENCES

GAGELONIA, E.C., MARTINEZ, R., and D. ALOJADO. 2013. Mechanized

drying of paddy: an industry concern. Paper presented during the Asia

Rice Foundation Annual Rice Forum. Bureau of Soils and Water

Management Bldg., Quezon City, 22 November 2013.

HIEN, P.H. 2010. Harvesting and drying of rice in Vietnam. In: Bong BB, Bo

NV, Buu BC (eds) Vietnam Fifty Years of Research and Development.

Agriculture Publishing House, Hanoi. pp. 361-380.

HIEN, P.H., TAM, N.H. and N.V. XUAN. 2003. Study on the reversal timing for

the SRA reversible dryer. Paper presented at the Seminar on

“Agricultural Engineering and Agro-products Processing Towards

Mechanization and Modernization in Rural Areas”. Nong-Lam

University, Ho Chi Minh City. 11-12 December 2003.

KUIZON, P. 1995. Rice husk furnace and reversible airflow grain dryer. In:

Champ BR, Highley E, Johnson GI (eds) Grain Drying in Asia. ACIAR

Proceedings No. 71. pp. 356-359.

PAES 201:2000. Agricultural Machinery - Heated-Air Mechanical Grain

Dryer - Specifications. Philippine Agricultural Engineering Standards,

Vol. 1. pp. B-1 - B-8.

PAES 202:2000. Agricultural Machinery - Heated-Air Mechanical Grain

Dryer - Methods of Test. Philippine Agricultural Engineering Standards,

Vol. 1. pp. B-12 - B-36.

PCARRD. 2009. Agricultural Mechanization in the Philippines. PCARRD

Book Series No. 179/2009.

VINH, L. Q. 2011. Comparative Study of the Performance of the Reversible

Airflow Dryer and the Conventional Flatbed Dryer. (MSc thesis), Cental

Luzon State University, Nueva Ecija, Philippines.

View publication stats

You might also like

- Hydroponics ManualDocument22 pagesHydroponics ManualAbdullah Talib100% (1)

- PILI NUT CRACKING MACHINE - An Innovative StudyDocument86 pagesPILI NUT CRACKING MACHINE - An Innovative StudyEmmanuel Cristo83% (6)

- Li Report CraunDocument21 pagesLi Report CraunHamizah MokhtarNo ratings yet

- Teff Harvesting Machine DesignDocument12 pagesTeff Harvesting Machine DesignAbdu Mohammed100% (5)

- Conservation Agriculture: Training Guide for Extension Agents and Farmers in Eastern Europe and Central AsiaFrom EverandConservation Agriculture: Training Guide for Extension Agents and Farmers in Eastern Europe and Central AsiaNo ratings yet

- Test Bank For Principles of Macroeconomics 5th Edition N Gregory MankiwDocument3 pagesTest Bank For Principles of Macroeconomics 5th Edition N Gregory MankiwMarlys Campbell100% (29)

- Management and Operation Practices of Philmech's Fluidized Bed Dryer: Examining The Challenges, Efficiency, and Impact On BeneficiariesDocument5 pagesManagement and Operation Practices of Philmech's Fluidized Bed Dryer: Examining The Challenges, Efficiency, and Impact On BeneficiariesPoonam KilaniyaNo ratings yet

- Mechanical DryerDocument11 pagesMechanical DryerCharlyn Flores100% (1)

- Seedling Propagation and Hydroponic Farming 1Document5 pagesSeedling Propagation and Hydroponic Farming 1NGANJANI WALTERNo ratings yet

- SACLOBDocument10 pagesSACLOBRicardo OrgeNo ratings yet

- Improved Drying of High Moisture Grains: ACIAR Projects PHT/1983/008, PHT/1986/008 and PHT/1990/008Document35 pagesImproved Drying of High Moisture Grains: ACIAR Projects PHT/1983/008, PHT/1986/008 and PHT/1990/008Leon LinNo ratings yet

- Rationale For Corn CobDocument4 pagesRationale For Corn CobDemie Jay DanabarNo ratings yet

- SOLAR DRYER v1Document43 pagesSOLAR DRYER v1Maria Angelica Borillo100% (1)

- Chapter IDocument74 pagesChapter Ihoney mae100% (1)

- Reviewed Proposal January 4, 2022Document22 pagesReviewed Proposal January 4, 2022Kamil GuillerganNo ratings yet

- Performance of Cassava Peeling Machines in Nigeria: A Review of LiteratureDocument18 pagesPerformance of Cassava Peeling Machines in Nigeria: A Review of LiteratureKPONSIHOIN RenéNo ratings yet

- AEN 4 Laboratory Exercise 8Document3 pagesAEN 4 Laboratory Exercise 8Jonel JacoboNo ratings yet

- Murray Birch Jagmohan IsaacDocument12 pagesMurray Birch Jagmohan IsaacAebel Joseph PrinceNo ratings yet

- An Economic Evaluation of Post-Harvest Technology: The Case of Rice and Corn Drying in The PhilippinesDocument13 pagesAn Economic Evaluation of Post-Harvest Technology: The Case of Rice and Corn Drying in The PhilippinesVince LagumbayNo ratings yet

- Drying Facilities Concept PaperDocument5 pagesDrying Facilities Concept PaperRoselyn de JesusNo ratings yet

- AGRO199 SeminarDocument86 pagesAGRO199 SeminarJosephine Tino100% (1)

- Design of Paddy Collecting MachineDocument7 pagesDesign of Paddy Collecting MachineMelchor PadillaNo ratings yet

- ClayemitterpublishedpaperDocument9 pagesClayemitterpublishedpaperHani AdelNo ratings yet

- LRB Project Proposal Multi Crop Juice Flour 07 Jun 2020Document13 pagesLRB Project Proposal Multi Crop Juice Flour 07 Jun 2020Andru VelaNo ratings yet

- Manual On Potato Seed Tuber Production Through AeroponicsDocument46 pagesManual On Potato Seed Tuber Production Through AeroponicssahooajitNo ratings yet

- Introduction-V1 5Document10 pagesIntroduction-V1 5kriza balNo ratings yet

- Increasing The Impact of Engineering in Agricultural and Rural DevelopmentDocument116 pagesIncreasing The Impact of Engineering in Agricultural and Rural DevelopmentIRRI_resourcesNo ratings yet

- Chapter 1 (Intro Rice)Document6 pagesChapter 1 (Intro Rice)Ash Njelic HamolNo ratings yet

- NIAEASABAConference 2022Document8 pagesNIAEASABAConference 2022Aimé IkoyobNo ratings yet

- grp2 Research ProposalDocument67 pagesgrp2 Research ProposalChristian V. SagaoNo ratings yet

- Aeroponics Thesis - Docx 2Document83 pagesAeroponics Thesis - Docx 2Kobe YambiNo ratings yet

- Research About FarmingDocument47 pagesResearch About FarmingAcer LaptopNo ratings yet

- PS1 Chapter 123 FinalDocument30 pagesPS1 Chapter 123 FinalDrw ArcyNo ratings yet

- 11 2015 029philippines Vietnam 03091Document11 pages11 2015 029philippines Vietnam 03091Jesus Gabriel Polo CardozoNo ratings yet

- Research Paper HydroponicsDocument5 pagesResearch Paper Hydroponicsc9rvcwhf100% (1)

- RT Vol. 3, No. 2 NewsDocument4 pagesRT Vol. 3, No. 2 NewsRice TodayNo ratings yet

- Greenhouse Economics: January 1990Document12 pagesGreenhouse Economics: January 1990Vincent John RigorNo ratings yet

- Some Physical and Mechanical PropertiesDocument2 pagesSome Physical and Mechanical PropertiesJaymel ZamoraNo ratings yet

- The Use of Plug Transplants in KoreaDocument9 pagesThe Use of Plug Transplants in KoreaBrij Mohan SinghNo ratings yet

- Economic Studies On The Production of Fruit Juice From A Locally Sourced Fruit African Star AppleDocument9 pagesEconomic Studies On The Production of Fruit Juice From A Locally Sourced Fruit African Star AppleercanefeogluNo ratings yet

- SIP ENGG401 Final Project Concept Development FormDocument6 pagesSIP ENGG401 Final Project Concept Development FormSam AlerozaNo ratings yet

- Battery Operated Paddy Dryer With Humidity Level SensorsDocument10 pagesBattery Operated Paddy Dryer With Humidity Level SensorsEm MendozaNo ratings yet

- Potato Storage Technology and Store Design AspectsDocument19 pagesPotato Storage Technology and Store Design AspectsEbrahim ElhawamNo ratings yet

- RITA Temporary Immersion SystemDocument3 pagesRITA Temporary Immersion Systemelgibin100% (1)

- Design Grain DryerDocument101 pagesDesign Grain DryerDavid Lambert100% (1)

- Saeri 2023 IOP Conf. Ser. Earth Environ. Sci. 1253 012080Document9 pagesSaeri 2023 IOP Conf. Ser. Earth Environ. Sci. 1253 012080zainurihanifNo ratings yet

- Development of A Fruit WashingmachineDocument9 pagesDevelopment of A Fruit WashingmachinerassNo ratings yet

- Chapter 1-5Document34 pagesChapter 1-5Acer LaptopNo ratings yet

- I-1a FarmMech 1-11Document12 pagesI-1a FarmMech 1-11SannyBombeoJomocNo ratings yet

- Agricultural Processing CHP 1Document5 pagesAgricultural Processing CHP 1Moiz Khan YousufzaiNo ratings yet

- Use of Aeroponics Technique For Potato (Solanum Tuberosum) Minitubers Production in KenyaDocument6 pagesUse of Aeroponics Technique For Potato (Solanum Tuberosum) Minitubers Production in KenyaDanu Prasetyo AjiNo ratings yet

- Production Operations Management of Broom Reed Industry in The PhilippinesDocument10 pagesProduction Operations Management of Broom Reed Industry in The PhilippinesIjaems JournalNo ratings yet

- A Review On Sweet Potato Postharvest Processing and Preservation TechnologyDocument15 pagesA Review On Sweet Potato Postharvest Processing and Preservation TechnologyPhương TăngNo ratings yet

- Detail Design AnalysisDocument16 pagesDetail Design AnalysisFisseha BirhaneNo ratings yet

- Nutritional Composition of Processed and Unprocessed Samples of Unripe PlantainDocument7 pagesNutritional Composition of Processed and Unprocessed Samples of Unripe PlantainRemi OsanyinlusiNo ratings yet

- Soybean - Applications and TechnologyDocument412 pagesSoybean - Applications and TechnologyJosé RamírezNo ratings yet

- Crop Production and Soil Management Techniques for the TropicsFrom EverandCrop Production and Soil Management Techniques for the TropicsNo ratings yet

- Restoration in Action against Desertification: A Manual for Large-Scale Restoration to Support Rural Communities’ Resilience in the Great Green Wall ProgrammeFrom EverandRestoration in Action against Desertification: A Manual for Large-Scale Restoration to Support Rural Communities’ Resilience in the Great Green Wall ProgrammeNo ratings yet

- Field Guide to Improve Water Use Efficiency in Small-Scale Agriculture: The Case of Burkina Faso, Morocco and UgandaFrom EverandField Guide to Improve Water Use Efficiency in Small-Scale Agriculture: The Case of Burkina Faso, Morocco and UgandaNo ratings yet

- Environmental Degradation and Dryland Agro-Technologies in Northwest ChinaFrom EverandEnvironmental Degradation and Dryland Agro-Technologies in Northwest ChinaNo ratings yet

- Innovation Processes in Agro-Ecological Transitions in Developing CountriesFrom EverandInnovation Processes in Agro-Ecological Transitions in Developing CountriesLudovic TempleNo ratings yet

- Building Economics For Architecture PPT (F)Document54 pagesBuilding Economics For Architecture PPT (F)vaidehi vakil100% (2)

- Pipistrel Alpha Trainer e Learning 2020Document185 pagesPipistrel Alpha Trainer e Learning 2020Kostas RossidisNo ratings yet

- $Ffhvvwr6Dih:Dwhu: Charting The Progress of PopulationsDocument5 pages$Ffhvvwr6Dih:Dwhu: Charting The Progress of PopulationskatoNo ratings yet

- Chapter 01 Ten Principles of EconomicsDocument30 pagesChapter 01 Ten Principles of EconomicsTasfia Rahman Riva100% (1)

- Manta Aji Coroko Sungsang ASLIDocument1 pageManta Aji Coroko Sungsang ASLIFarhan HumamNo ratings yet

- Evaluasi Penerapan Perlakuan Akuntansi Psak 24 Pada PT Gudang Garam TBKDocument9 pagesEvaluasi Penerapan Perlakuan Akuntansi Psak 24 Pada PT Gudang Garam TBKphoechoexNo ratings yet

- Indraneel N M.com SBKDocument3 pagesIndraneel N M.com SBKJared MartinNo ratings yet

- PHM PCH EnglishDocument9 pagesPHM PCH Englishlalit823187No ratings yet

- Guide To Buying A Wooden SunglassesDocument2 pagesGuide To Buying A Wooden SunglassesBrendan LuoNo ratings yet

- The Entry and Exit of Political Economy ArrangementsDocument13 pagesThe Entry and Exit of Political Economy ArrangementsMARIANNE JANE ZARANo ratings yet

- Interpretation Nadeem SirDocument2 pagesInterpretation Nadeem SirDENZYL D'COUTHONo ratings yet

- B2B Marketing - MRFDocument13 pagesB2B Marketing - MRFMohit JainNo ratings yet

- Jason White Resume 2019 v2Document1 pageJason White Resume 2019 v2api-355115412No ratings yet

- Export Invoice: Item Description: Qty: UOM: Curr Unit PriceDocument4 pagesExport Invoice: Item Description: Qty: UOM: Curr Unit PriceAdam GreenNo ratings yet

- 115 - Yam v. CA DigestDocument2 pages115 - Yam v. CA DigestStephieIgnacioNo ratings yet

- Indian Economic Development: DAV Fertilizer Public School, BabralaDocument96 pagesIndian Economic Development: DAV Fertilizer Public School, Babralakavin sNo ratings yet

- Financial and Physical Performance Report FORMATDocument9 pagesFinancial and Physical Performance Report FORMATJeremiah TrinidadNo ratings yet

- A Final Board Packet August 7, 2013 - 0.... 5Document199 pagesA Final Board Packet August 7, 2013 - 0.... 5نيرمين احمدNo ratings yet

- GM OEM Financials Dgi9ja-2Document1 pageGM OEM Financials Dgi9ja-2Dananjaya GokhaleNo ratings yet

- Indias Top 50 Best ItDocument14 pagesIndias Top 50 Best ItAnonymous Nl41INVNo ratings yet

- Oceangoing Ships 2007 PDFDocument102 pagesOceangoing Ships 2007 PDFaleventNo ratings yet

- Understanding ManagementDocument35 pagesUnderstanding ManagementXian-liNo ratings yet

- Watcho Masti - Mar 02, 2023 - 1677944911Document1 pageWatcho Masti - Mar 02, 2023 - 1677944911Rajesh KumarNo ratings yet

- EcoTourism Unit 8Document20 pagesEcoTourism Unit 8Mark Angelo PanisNo ratings yet

- Gender Wise Classification of RespondentsDocument34 pagesGender Wise Classification of Respondentspavith ranNo ratings yet

- SsDocument8 pagesSsAnonymous cPS4htyNo ratings yet

- Rallis India AR 2014-15 Page 25Document168 pagesRallis India AR 2014-15 Page 25bhomikjainNo ratings yet

- Neo-Liberal Theory and Practice For Eastern Europe - Peter GowanDocument58 pagesNeo-Liberal Theory and Practice For Eastern Europe - Peter GowanpeterVoterNo ratings yet

- Japan CurrencyDocument13 pagesJapan CurrencymelisaNo ratings yet