Professional Documents

Culture Documents

ACTIV ATED SLUDGE PLANTS W. Eckenfelder

Uploaded by

Daniel BravoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ACTIV ATED SLUDGE PLANTS W. Eckenfelder

Uploaded by

Daniel BravoCopyright:

Available Formats

� Pergamon Wal. Sci. Tech. Vol.29, No.9, pp.79-88, 1994.

Copyright © 1994 IAWQ

Printed in Great Britain. All rights reserved.

0273-1223194 $7'00 + 0'00

0273-1223(94)00237-1

TREATMENT AND PRETREATMENT

REQUIREMENTS FOR INDUSTRIAL

WASTEWATERS IN MUNICIPAL

ACTIVATED SLUDGE PLANTS

W. Wesley Eckenfelder, Jr and John L. Musterman

Eckenfelder & Binnie Ltd., Grosvenor House, 69 London Road, Redhill,

Surrey RHl lLQ, UK

ABSTRACT

Industrial wastewaters may have a significant impact on municipal activated sludge plants. Depending on the

degradability of the wastewater, the overall reaction coefficient, K, may be increased or decreased. Readily

degradable wastewaters will render the process more susceptible to filamentous bulking. Increasing the

soluble BOD fraction will increase the temperature effect. Sludge dewaterability may be decreased with

readily degradable soluble wastewaters or increased with pulp and paper mill wastewaters containing pulp and

fibre. Volatile organics which do not biodegrade require source treatment. Effluent toxicity should be

controlled by industrial pretreatment where possible. In some cases, PAC will eliminate toxicity in the

activated sludge process.

KEYWORDS

Industrial wastewater pretreatment; effect ofindustrial wastes on municipal systems; activated sludge

BACKGROUND

There are several reasons for pretreatment of industrial wastewaters prior to discharge to a Publicly Owned

Treatment Works (POTW). In addition to control of conventional pollutants (BOD, TSS and NH3) which

may affect effluent or sludge quality in the POTW, pretreatment may be required for removal ofinhibitory or

biotoxic compounds which would interfere with the operation or performance of the plant or cause effluent

toxicity as defined by a bioassay; removal of priority pollutants which do not degrade in the POTW and would

therefore violate effluent discharge criteria; control of volatile organic compounds (VOC) entering the plant;

and removal of heavy metals which would concentrate in the sludge, and create sludge disposal problems.

A fundamental factor which must be considered in evaluating pretreatment requirements is the chemical

nature of the BOD being treated, i.e. its degradability and its potential to cause filamentous sludge bulking.

The BOD in domestic sewage is generally composed of three fractions; suspended, colloidal, and soluble. In

most sewages, the soluble fraction varies from 20 to 30 percent of the total. By contrast, many industrial

wastewaters contain close to 100 percent soluble organics. In the activated sludge process, the suspended

and colloidal organics are rapidly removed by bio-coagulation with the soluble organics being removed more

slowly by biooxidation. In the case of industrial wastewaters, rapid biosorption will occur in the case of

readily degradable wastewaters, while little or no biosorption occurs in the case of poorly degradable

wastewaters. The importance of this phenomenon will be discussed later.

79

Downloaded from https://iwaponline.com/wst/article-pdf/29/9/79/23847/79.pdf

by UNIVERSITY OF MELBOURNE user

80 W. W. ECKENFELDER, JR and J. L. MUSTERMAN

BOD REMOVAL KINETICS

Only the soluble BOD affects the organic removal kinetics in the activated sludge process. The removal

kinetics can be estimated from the relationship developed by Grau (1975) and Adams et aI. (1975) for multi

component substrates in a complete mix system.

(1)

in which

So = influent soluble BOD

Se = effluent soluble BOD

Xv= MLVSS

t aeration basin detention time

K = composite rate coefficient

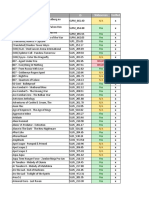

The composite rate coefficient, K, has been determined for a variety of industrial wastewaters as shown in

Table 1.

TABLE 1 COMPOSITE RATE COEFFICIENT FOR INDUSTRIAL WASTEWATERS

Wastewater Characteristics K200 days -l

Readily Degradable 16-30

(food process, brewery)

Moderately Degradable 8-15

(petroleum, pulp and paper)

Poorly Degradable 2-6

(chemical, textile)

The soluble fraction of domestic sewage has been observed to have a rate coefficient (K20) of 8.0/day by

McCauley (1974). This falls under the moderately degradable category. It is apparent from Equation (1) that

the introduction of a poorly degradable wastewater will reduce the overall K value and require either a longer

hydraulic detention period or a higher MLVSS to achieve the same effluent quality. Therefore, in considering

pretreatment requirements for an industrial wastewater discharge to an existing POTW, a higher degree of

pretreatment will be required for poorly degradable wastewater than for a readily degradable wastewater. An

approach to calculate the pretreatment requirements is to mathematically average rate coefficients of the

sewage and the industrial wastewater in proportion to their individual BOD mass loading rates. This

approach is shown in Example 1.

Effect of Rate Coefficient

Example 1. A 20,000 m3/d municipal activated sludge plant is presently operating at a FIM of 0.3/day and

producing an effluent soluble BOD (Se) of 10 mg/L. A chemical complex has requested to discharge

4,500 m37d of wastewater with a BOD of1,500 mg/L to the plant. What level of pretreatment is required at

the chemical complex in order for the POTW to maintain an effluent solubility of 10 mg/L assuming the

following conditions?

Municipal Sewage Characteristics

Flow 20,000 m3/d

Influent Total BOD 200 mg/L

Influent Soluble BOD 50 mg/L

Downloaded from https://iwaponline.com/wst/article-pdf/29/9/79/23847/79.pdf

by UNIVERSITY OF MELBOURNE user

Municipal activated sludge plants 81

FIM 0.3/day

MLVSS 2,5oo mgIL

Eflluent Soluble BOD 10 mgIL

K20 8/day

t 0.27 day

Industrial Wastewater

Flow 4,500 m3/day

BOD 1,500 mgIL

K20 2.2/day

If the chemical wastewater were added without pretreatment the BOD load weighted average would be

reaction rate. Introduction of the chemical wastewater will be:

.

[(20, 000 ·8· SO) + (4, 500 . 2. 2 . 1, 500)]

K 20 = = 2. 95 / day

(20, 000 SO) + (4, 500 . 1, 500)

and the new hydraulic detention time in the existing aeration basins would be:

t = 0. 27 ( 20,000 )

20,000 + 4, 500

= 0. 22 day

The required influent soluble BOD (So) to the POTW needed to maintain the current eflluent soluble BOD

concentration of 10 mgIL can be calculated by rearranging Equation (1) and assuming that K20 2.95/day, =

t 0.22 day and MLVSS 2,500 mgIL.

= =

(So)PI =

{to + [( 10)2 + (4·2.95·2,500·0.22·10)0. 5]} /2

132 mgIL

=

The concentration of BOD required in the pretreated industrial wastewater can then be calculated by writing a

material balance for soluble BOD in the combined influent to the POTW. The balance for the existing influent

wastewater to the POTW (designed as IIPII) and the pretreated industrial wastewater (designed as " I") can be

determined from Equation (2).

Qp(So)p + QI(So)I (Qp + QI)(So)PI

= (2)

(20,000· SO) + (4,500)(So)1 (20,000 + 4,500)(132)

=

(So)1 500 mgIL =

Pretreatment is therefore required to reduce approximately 67 percent of the soluble BOD in the industrial

wastewater.

EFFECT OF INDUSTRIAL WASTEWATERS ON MIXED LIQUOR

SETTLEABILITY

It has long been known that the introduction of a readily degradable wastewater to a POTW that treats

primarily domestic wastewater frequently results in filamentous bulking. This phenomenon has been attributed

to insufficient mixed liquor dissolved oxygen, nutrients, or mode of operation of the process resulting in a

BOD limitation for the biological floc.

The oxygen limitation can be related to the oxygen uptake rate or more simply the organic loading rate (FIM)

of the process. The phenomenon is shown in Figure 1 for the introduction of a pulp mill wastewater to an

activated sludge plant. The implication of Figure 1 is that increasing the FIM by addition of a readily

degradable industrial wastewater will require an increased dissolved oxygen level in the mixed liquor in order

Downloaded from https://iwaponline.com/wst/article-pdf/29/9/79/23847/79.pdf

by UNIVERSITY OF MELBOURNE user

82 W. W. ECKENFELDER, JR and J. L. MUSTERMAN

to maintain a low SVI. The available oxygenation capacity may limit the operating dissolved oxygen

concentration, which, in tum, would restrict the quantity of industrial wastewater added to the plant. This

phenomenon is illustrated in Example 2.

'i

a

68

l1li

�

"

0

'tI

� 2

1

.!l

Q Numbers Indicate SV]

1

0 0.2 0.4 0.6 0.8 1

l

FIM. day-

Fig. I. Relationship Between FIM and Dissolved Oxygen Relative to Sludge Bulking

Example 2. Oxygen Limitations - The municipal treatment plant in Example I is planning on accepting

1,900 m3/d ofa brewery wastewater with a soluble BOD of 2,200 mg/L. Determine what changes need to be

made to avoid filamentous bulking.

The projected total BOD load is:

BOD Load [(20,000·200) + (1,900· 1,200)]/1,000

6,280 kg/d

287 mg/L

The new hydraulic detention time is:

( 20, 000 ) . 0.27 = 0.245 days

2 1, 900

Ifthe MLVSS is increased to 3,000 mg/L, the FIM will be,

287

F /M = ----- . 0.245 = 0.39 / day

(3,000 . 0.245)

The present oxygen requirements can be calculated from Equation (3) assuming a'=0.55, b'=0.15/day and

Xd=0.60.

02/day= 0.55 Sr + 0. 15 Xd Xv (3)

02/day = [(0.55· 190) + (0.15·0.60·2,500·0.270)] (20,000/103)

= 3,300 kg/d

Downloaded from https://iwaponline.com/wst/article-pdf/29/9/79/23847/79.pdf

by UNIVERSITY OF MELBOURNE user

Municipal activated sludge plants 83

At the present FIM (0.3/day), a minimum mixed liquor dissolved oxygen concentration of 1.6 mg/L (Figure 1)

is required to provide complete oxygen transfer into the biological floc. At the increased FIM of 0.39/day, the

dissolved oxygen must be raised to at least 2.6 mg/L. The present aeration equipment is transferring 0.7 kg

021HP-HR at a 1.6 mg/L D.O. and the present aeration power level is 200 HP. The new oxygen requirements

are:

02/day = [(0.55 277)

• + (0. 15 0.6.3,000.0.245)](21,9001103)

•

= 4,785 kg/d

The oxygenation rate of the equipment must be corrected to the new dissolved oxygen concentration,

assuming a mixed liquor saturation concentration of 8.6 mg/L.

(0.7) . [ 8.6 - 2.6

8.6 _ l.6

] = 0.58 kg 0 2 /lIP-HR

The required power for oxygenation must be increased to:

. 4,785

lIP required = = 343

24 . 0.58

An additional 150 lIP will therefore be required to maintain an adequate mixed liquor dissolved oxygen level.

Flow modifications, such as multi-stage or plug flow can also be considered.

Filamentous bulking due to nutrient limitations have also been observed in some POTWs that receive

industrial wastewaters. For example, alum sludge was periodically discharged to a POTW. This resulted in

precipitation of the available phosphorus and the onset of filamentous bulking. Discontinuance of the alum

sludge discharge restored the sludge quality.

It has been observed by several investigators that filamentous bulking occurs in completely mixed basins at

low F1M levels in the presence of readily degradable wastewaters. This can be attributed to a food limitation

in the biological floc in a manner similar to the oxygen limitation previously discussed. The solution to this

problem is to employ a plug flow regime in the aeration basin or to use a selector to increase the FIM in the

early stages of the process. The oxygen distribution would also have to be changed in this case.

TEMPERATURE CONSIDERAnONS

Temperature affects all biological reactions and can be estimated over the range of 4°C to 31 °C by the

relationship.

Kt K o(T-20) (4)

200C

=

In the case of soluble industrial wastewaters, the coefficient, 9, has been found to vary from 1 .03 to 1 . 1 0. A

typical value is 1.065. In the case of domestic sewage, however, a major portion of the BOD is removed by

bio-coagulation which is relatively insensitive to temperature. In these wastewaters, the overall coefficient

has been observed to have a value of 1.01 5. The implication of this is that the introduction of large quantities

of soluble industrial wastewaters will increase the coefficient 9, frequently resulting in poorer effluent quality

during the winter.

The temperature effects on an activated sludge plant are i1Justrated in Example 3.

Example 3 Temperature Effects. Determine the change in MLVSS from 2,500 mg/L which will be required

-

when the temperature coefficient (9) increases from 1.01 5 to 1.04 due to an increase in soluble industrial

wastewater BOD. The seasonal temperature change is from 20°C to lOoC.

Downloaded from https://iwaponline.com/wst/article-pdf/29/9/79/23847/79.pdf

by UNIVERSITY OF MELBOURNE user

84 W. W. ECKENFELDER, JR and J. L. MUSTERMAN

The ratio ofK values for the municipal sewage is:

K20 = (1.015)10 =

1.16

KIO

and for the mixture of municipal sewage and industrial wastewater is:

K20 = (1.04)10 = 1.48

KIO

The increase in MLVSS required can be calculated.

1.48 .

2,500 mg I L = 3,110 mg I L

1.16

High temperature in the aeration basin will also have a deleterious affect on mixed liquor settling

characteristics and biofloc quality. Temperatures above 96°F have been shown to result in a loss of protozoa

and a dispersed floc, with an increase in filaments. Results from one plant are shown in Figure 2. The

implication of a reduced mixed liquor zone settling velocity is that for a given final clarifier size, a lower

MLSS must be maintained in the aeration basin to prevent excessive solids loading on the clarifier.

VOLATILE ORGANIC CARBON (VOC)

New air pollution regulations in the United States severely restrict the emission of volatile organics (VOC)

from wastewater treatment plants. The biodegradability of the volatile compound depends on the number of

chlorine atoms associated with the molecule as shown in Table 2. In addition, at a constant SRT both the

power level in the aeration basin and the type of aeration equipment affect the amount of a compound that

will strip. This is shown in Figure 3. In order to avoid covering the aeration basins and providing treatment

of the off-gas, non-degradable VOCs should be removed by pretreatment and degradable VOCs restricted to

influent levels that will biodegrade in the actual sludge process.

o +-------�--�--_r--�

" wo W5 IW

AERATION BASIN TEMPERATURE, OF

Fig. 2. Zone settling velocity as a function of temperature at a MLSS concentration of 5,000 Mg/I

Downloaded from https://iwaponline.com/wst/article-pdf/29/9/79/23847/79.pdf

by UNIVERSITY OF MELBOURNE user

Municipal activated sludge plants 85

TABLE 2 FATE OF TOXIC ORGANICS IN ACCLIMATED ACTIVATED SLUDGE BIOREACTORS

OPERATED AT A 6-DAY SRT UNDER STEADY-STATE CONDITIONS (Weber et aI., 1983)

EfIluent Percent of Influent

Compound Off-Gas Biosorbed Biodegraded

Nitrobenzene 2 <1 0 98

Benzene <1 16 0 84

Toluene <1 17 0 83

Ethylbenzene <1 22 0 78

o-Xylene <1 25 0 75

Chlorobenzene <1 20 0 80

1,2-Dichlorobenzene 6 59 0 35

1,2,4-Trichlorobenzene 10 90 <1 0

40

...

1:1

� 30 Surface Aeration

8-

-g

g: 20

�

�

N 10 L--�..--- Diffused Aeration

o +-------�--_+--�

80 100 150 200

Power Level - HPIMG

Fig. 3 . Stripping of benzene in the activated sludge process as related to power level

EFFLUENT TOXICITY

Aquatic toxicity as defined by a bioassay is now being applied to all industrial and municipal wastewater

treatment plants in the United States . Toxicity can be caused by the introduction ofinorganics (e.g.. metals),

non-biodegradable organics or by the generation ofsoluble microbial products (SMP) in the activated sludge

process itself A rapid bio-oxidation test using the Fed Batch Reactor (Watkin et al. 1989) or other

respirometric technique should identitY whether the wastewater is biodegradable and/or exhibits aquatic

toxicity. If the wastewater is nondegradable and toxic, it should be pretreated at the source. Available

technologies are shown in Figure 4.

Downloaded from https://iwaponline.com/wst/article-pdf/29/9/79/23847/79.pdf

by UNIVERSITY OF MELBOURNE user

86 W. W. ECKENFELDER. JR and J. L. MUSTERMAN

TO DISCHARGE

RECYCLE OR

TREA'lMENT

VOLATB..E

PROCESS HEAVY ORGANIC ORGANICS

WASTEWATER METALS CHEMICALS AMMONIA

Fig. 4. Applicable technologies for treatment of toxic wastewaters

If effiuent toxicity is the result of microbial by-products (SMP), however, pretreatment may not solve the

problem. In this case, the introduction of powdered activated carbon (PAC) to the aeration basin has proven

to be effective. The carbon effectively adsorbs the toxic molecules. The effect of PAC dosage on reducing

effiuent toxicity is shown in Figure 5.

10

:!

;:l

6

.ll

Ie

,.

'il 4

�

I<l

2

0 100 200 300 400 1100

PAC Do •• ge (mg/L)

Fig. 5. Typical toxicity reduction through the PACT® system (Lankford et aI., 1988)

Downloaded from https://iwaponline.com/wst/article-pdf/29/9/79/23847/79.pdf

by UNIVERSITY OF MELBOURNE user

Municipal activated sludge plants 87

It has also been shown that inhibition of nitrifiers closely parallels toxicity to many aquatic species. In this

case,nitrification can be maintained by increasing the sludge age or by the addition of PAC. In one case, the

introduction of a chemical plant effluent increased the required sludge age for nitrification from 4 days at

20°C to 25 days. Introduction of PAC effectively reduced the required sludge age to noninhibitory levels. In

such a case economics would dictate the mode of operation.

PRIORITY POLLUTANTS

There is an increasing restriction on the discharge of specific organic and inorganic pollutants from

wastewater treatment plants. Depending on the organic in question and the required effluent level, a greatly

increased sludge age may be required. In the same manner as with VOCs, increasing the number of

substituted chlorine atoms reduces the biooxidation rate and hence increases the required sludge age as shown

in Table 3. For example, in one case, a sludge age of 21 days was required to meet an effluent BOD of

15 mgIL. In order to meet an effluent requirement of 0.02 mgIL of 2,4 dichlorophenol, the sludge age would

have to be increased to 39 days.

TABLE 3 EFFECT OF CHLORINE SUBSTITUTION ON DEGRADATION

RATE OF PHENOLICS (PITTER AND CHUDOBA, 1 990)

Maximum Degradation Rate

Compound g COD/g VSS-day

Phenol 1 .92

2-Chlorophenol 0.6

2,4-Dichlorophenol 0.25

Temperature also plays an important role in the removal of priority pollutants. It would require a sludge age

of 11 days to reduce phenol to 15 IlgIL at 20°C. If the temperature was reduced to 1 0°C, the required sludge

age would increase to 47 days.

SLUDGE HANDLING

The impact of introducing industrial wastewaters to a POTW on sludge handling operations must also be

considered. In most cases, introduction of a soluble industrial wastewater will result in an increase in waste

activated sludge production. An increase in SVI due to filamentous bulking will severely affect both the

thickening and dewatering of the waste sludge. For example, sludge with an SVI of 1 00 mL/g thickened to 4

to 5 percent in a DAF, while sludge with an SVI of 300 mL/g only thickened to 1 .8 percent. These

conditions will have a detrimental effect on thickening and dewatering operations and usually result in an

increased usage of dewatering chemicals and a reduced cake solids. One exception to this was observed when

a pulp and paper mill reduced their discharge of primary suspended solids to a POTW. Since the fiber from

the pulp mill served as a filter aid in the vacuum filters at the POTW a marked reduction in sludge filtration

rate was observed following reduction of the pulp mill discharge.

OTHER CONSIDERATIONS

It is apparent that significant industrial discharges to a municipal activated sludge plant can markedly affect

effluent quality,sludge quality and sludge handling. It is suggested that a laboratory activated sludge study be

conducted to determine these effects and provide the basis for pretreatment requirements. The primary

factors to be evaluated include reaction kinetics and temperature effects, dissolved oxygen requirements,

effluent toxicity,and sludge characteristics.

Downloaded from https://iwaponline.com/wst/article-pdf/29/9/79/23847/79.pdf

by UNIVERSITY OF MELBOURNE user

88 W. W. ECKENFELDER, JR and J. L. MUS1ERMAN

CONCLUSIONS

When industrial effluents are introduced into municipal plants, there are a number of factors which must be

considered. Readily degradable wastewaters will enhance filamentous bulking so that a plug flow

configuration or the use of a selector needs to be considered. Refractory wastewaters will usually require an

increased sludge age in order to meet effluent limitations. In general, increasing the soluble fraction of the

BOD will increase the temperature effect, frequently requiring longer sludge ages during winter operation.

Recent legislation in the United States limits volatile emissions from wastewater treatment plants, restricts

aquatic toxicity, and places limits on specific organics such as phenol. In most cases, industrial pretreatment

is required to meet these limitations. Depending on the characteristics of the industrial effluent, sludge

handling and disposal may require modificatIon.

REFERENCES

Adams,C. E.,Eckenfelder,W. W.,and Hovious,1., 1975. A Kinetic Model for Design of Completely Mixed

Activated Sludge, Water Research, 2, 37.

Chudoba, 1., et aI., 1 973. Control of Activated Sludge Filamentous Bulking, Water Research, 1, 1380.

Grau, P., 1 975. Kinetics of Multi-component Substrate Removal by Activated Sludge, Water Research, 2,

637.

Lankford, P. W., Eckenfelder, W. W., and Torrens, K. D., 1 988. Reducing Wastewater Toxicity, Chemical

Engineering, � 1 6.

McCauley,D.C., 1 974. Union Carbide Research Report.

Palm, 1. D., Jenkins, D., and Parker, P.S., 1 980. Relationship Between Organic Loading Dissolved Oxygen

and Sludge Settleability in the Complete Mix Activated Sludge Process, Journal Water Pollution

Control Federation, 51, 2,484.

Pitter, P. and Chudoba, J., 1 990. Biodegradability of Organic Substances in the Aquatic Environment. CRC

Press, Boca Raton,Florida.

Watkin, A. and Eckenfelder, W. W., 1989. A Technique to Determine Non-Steady State Inhibition in the

Activated Sludge Process, Water Science Technology, 2 1 (617),593-602.

Weber, W. J. and Jones, B., 1 983. Toxic Substances Removal in Activated Sludge and PAC Treatment

Systems. USEPA NTIS No. PB-86-1 8242J/AS.

Downloaded from https://iwaponline.com/wst/article-pdf/29/9/79/23847/79.pdf

by UNIVERSITY OF MELBOURNE user

You might also like

- Treatment of Industrial WastewaterDocument17 pagesTreatment of Industrial WastewaterOmar DoskyNo ratings yet

- Lime Hemp and Rice Husk-Based Concretes for Building EnvelopesFrom EverandLime Hemp and Rice Husk-Based Concretes for Building EnvelopesNo ratings yet

- Introduction To WWTPs DesignDocument55 pagesIntroduction To WWTPs Designalvaro.roldan1No ratings yet

- 116CH0120 RP ReportDocument12 pages116CH0120 RP ReportAscender ZeusNo ratings yet

- Difference Between Industrial Wastewater and Municipal WastewaterDocument11 pagesDifference Between Industrial Wastewater and Municipal WastewaterSupatmono NAINo ratings yet

- How Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisFrom EverandHow Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisRating: 5 out of 5 stars5/5 (1)

- Sept AgeDocument7 pagesSept AgeMalek Abou HarbNo ratings yet

- MBR - Industrial WW AE 02Document12 pagesMBR - Industrial WW AE 02transilvanpopNo ratings yet

- Nitrification and Denitrification in the Activated Sludge ProcessFrom EverandNitrification and Denitrification in the Activated Sludge ProcessNo ratings yet

- Waste Water Stabilisation PondsDocument24 pagesWaste Water Stabilisation PondsRyeanKRumanoNo ratings yet

- UKLA PERA Best Practice Guide For The Disposal of Water Mix Metalworking FluidsDocument11 pagesUKLA PERA Best Practice Guide For The Disposal of Water Mix Metalworking FluidsLiliNo ratings yet

- Membrane BioreactorsDocument9 pagesMembrane Bioreactorsสิริลักษณ์ ประเสริฐกุลศักดิ์No ratings yet

- Best Practices & Design Considerations For Wastewater Treatment With MBBR Technology.Document4 pagesBest Practices & Design Considerations For Wastewater Treatment With MBBR Technology.Ravishankar ANo ratings yet

- IRP 166SingareJEnvChemEngiDocument12 pagesIRP 166SingareJEnvChemEngimaaahiiNo ratings yet

- Wastewater 12Document27 pagesWastewater 12egorceacovaNo ratings yet

- Case Study For Soap Waste WaterDocument6 pagesCase Study For Soap Waste WaterKari ConwayNo ratings yet

- Icoest LFG 2017Document16 pagesIcoest LFG 2017Cevat YamanNo ratings yet

- Replacement of Fine Aggregate Using Sludge in ConcreteDocument5 pagesReplacement of Fine Aggregate Using Sludge in ConcretehghgheeeeNo ratings yet

- Assignment Submitted By: Name: Mustafizur Rahman Roll: ASH 1809MS134MDocument15 pagesAssignment Submitted By: Name: Mustafizur Rahman Roll: ASH 1809MS134MMustafizur RahmanNo ratings yet

- Chemistry Journal Chjv06i11p0989Document8 pagesChemistry Journal Chjv06i11p0989Ana HernándezNo ratings yet

- Chapter 2 Principle of Industrial Waste Water TreatmentDocument11 pagesChapter 2 Principle of Industrial Waste Water Treatmentmazlina85100% (6)

- Indicative GuidelinesDocument29 pagesIndicative GuidelinesSameer HussainNo ratings yet

- Sewage Treatement PlantDocument42 pagesSewage Treatement PlantSunil A. Bakoliya100% (2)

- Membrane Bioreactors For Industrial Wastewater Treatment: Applicability and Selection of Optimal System ConfigurationDocument16 pagesMembrane Bioreactors For Industrial Wastewater Treatment: Applicability and Selection of Optimal System Configurationvk100No ratings yet

- Analysis of Treatment Plant For Dyeing IDocument9 pagesAnalysis of Treatment Plant For Dyeing ISaravanaKumarNo ratings yet

- Landfill Leachate Treatment 2Document7 pagesLandfill Leachate Treatment 2Christian Mihai GNo ratings yet

- Study of Textile Wastewater Characteristics For Raymond Textile and Design of Uasb ReactorDocument2 pagesStudy of Textile Wastewater Characteristics For Raymond Textile and Design of Uasb ReactorInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Sustainability 12 07501Document24 pagesSustainability 12 07501Carlos CubillaNo ratings yet

- Kobya 20061Document11 pagesKobya 20061Violeta GarciaNo ratings yet

- Anaerobic Treatment of Recycled Paper Mill EffluenDocument6 pagesAnaerobic Treatment of Recycled Paper Mill EffluenBaying SASNo ratings yet

- Quality Assurance RDFDocument10 pagesQuality Assurance RDFANo ratings yet

- Guidelines Textile Industry Draft PDFDocument36 pagesGuidelines Textile Industry Draft PDFRohan LadNo ratings yet

- Good One Chaube ZLD Techno Economic AnalysisDocument5 pagesGood One Chaube ZLD Techno Economic AnalysisAmitNo ratings yet

- Sewage TreatmentDocument57 pagesSewage Treatmentimrozkhan150% (2)

- Influence of Compaction On Copper SlagDocument82 pagesInfluence of Compaction On Copper SlagakashNo ratings yet

- EnviroChemie Modern Wastewater Treatment Solutions in A State-Of-The-Art Pharmaceutical Production EnvironmentDocument14 pagesEnviroChemie Modern Wastewater Treatment Solutions in A State-Of-The-Art Pharmaceutical Production EnvironmentKhang TrầnNo ratings yet

- Membranes-12-00223-V2 - 2023-01-25T123624.248Document11 pagesMembranes-12-00223-V2 - 2023-01-25T123624.248sarfa aslamNo ratings yet

- Landfill Disposal of Alum Water Treatment Residues: Some Pertinent Geoengineering PropertiesDocument19 pagesLandfill Disposal of Alum Water Treatment Residues: Some Pertinent Geoengineering Propertiesdmvaldes21No ratings yet

- WKS R 10Document38 pagesWKS R 10raushanm8434No ratings yet

- Textile Industry Wastewater Treatment UsDocument4 pagesTextile Industry Wastewater Treatment UsShamimNo ratings yet

- Design of Reverse Osmosis System For Reuse of Waste Water From Common Effluent Treatment PlantDocument9 pagesDesign of Reverse Osmosis System For Reuse of Waste Water From Common Effluent Treatment PlantSrini VasanNo ratings yet

- Biosolids Technology Fact Sheet - In-Vessel CompostingDocument9 pagesBiosolids Technology Fact Sheet - In-Vessel CompostingfrtklauNo ratings yet

- Membranes 12 00864Document30 pagesMembranes 12 00864gerson.santillanNo ratings yet

- Photo EODocument8 pagesPhoto EOJorge VecinoNo ratings yet

- Diva Envitec CHD-OxDocument5 pagesDiva Envitec CHD-OxThe Sur StudioNo ratings yet

- PARMAR 2022 - Co-Processing Lignocellulosic Biomass and Sewage Digestate by Hydrothermal Carbonisation, Influence of Blending On Product QualityDocument21 pagesPARMAR 2022 - Co-Processing Lignocellulosic Biomass and Sewage Digestate by Hydrothermal Carbonisation, Influence of Blending On Product QualityKiran R R ParmarNo ratings yet

- Water Quality Standards: Envis Centre, Ministry of Environment & Forest, Govt. of IndiaDocument6 pagesWater Quality Standards: Envis Centre, Ministry of Environment & Forest, Govt. of IndiaPraveen KumarNo ratings yet

- SBR (Ingeniería Ambiental)Document5 pagesSBR (Ingeniería Ambiental)Alvaro HueteNo ratings yet

- Operation AND Maintenance ManualDocument62 pagesOperation AND Maintenance ManualMohan BabuNo ratings yet

- Application of The Combined Ultrafiltration and Reverse Osmosis For Refinery Wastewater Reuse in Sinopec Yanshan PlantDocument11 pagesApplication of The Combined Ultrafiltration and Reverse Osmosis For Refinery Wastewater Reuse in Sinopec Yanshan PlanteducacionNo ratings yet

- Treatment of Industrial Wastewater by Membrane BioreactorsDocument10 pagesTreatment of Industrial Wastewater by Membrane BioreactorsEnrique MartinezNo ratings yet

- Application of High Power in Water TreatmentDocument42 pagesApplication of High Power in Water TreatmentDuc Nguyen HuuNo ratings yet

- Extended Aeration Activated Sludge Proce PDFDocument4 pagesExtended Aeration Activated Sludge Proce PDFEnrique MartinezNo ratings yet

- Jean-Wash WaterDocument7 pagesJean-Wash WaterSchaelCooperNo ratings yet

- Ppt-Me ProjectDocument26 pagesPpt-Me ProjectPatel RonakNo ratings yet

- Final ZLD (Draft) 1Document25 pagesFinal ZLD (Draft) 1raghavendran raghuNo ratings yet

- Data Validation OutputDocument14 pagesData Validation OutputDaniel BravoNo ratings yet

- Dairy Industry-Anaerobic DigestorDocument16 pagesDairy Industry-Anaerobic Digestorneeraj sharmaNo ratings yet

- Ebook Energy and Environment NowadaysDocument272 pagesEbook Energy and Environment NowadaysBudihardjo Sarwo SastrosudiroNo ratings yet

- Lecture 2.2Document14 pagesLecture 2.2Daniel BravoNo ratings yet

- Vent-O-Mat Catt Program: Begin Distance: 0.000 M End Distance: 857.840 M New Pipeline Analyses Performed: Burst and DrainDocument1 pageVent-O-Mat Catt Program: Begin Distance: 0.000 M End Distance: 857.840 M New Pipeline Analyses Performed: Burst and DrainDaniel BravoNo ratings yet

- Ebar #1 - SMRDocument1 pageEbar #1 - SMRDaniel BravoNo ratings yet

- Manual HAMMER V8i - Guia Del Usuario (Ingles) PDFDocument1,062 pagesManual HAMMER V8i - Guia Del Usuario (Ingles) PDFsebasfarsaNo ratings yet

- H61M VG3Document69 pagesH61M VG3Adina BubulinaNo ratings yet

- ATV900 Getting Started Annex NHA61583 01Document2 pagesATV900 Getting Started Annex NHA61583 01Daniel BravoNo ratings yet

- H61M VG3Document69 pagesH61M VG3Adina BubulinaNo ratings yet

- Topcon Link Ref ManDocument148 pagesTopcon Link Ref ManDaniel BravoNo ratings yet

- CFD Algorithms For Hydraulic EngineDocument0 pagesCFD Algorithms For Hydraulic EnginelgroscheNo ratings yet

- Books & PeriodicalsDocument1 pageBooks & PeriodicalsDebabrat MishraNo ratings yet

- Motion in One Dimension QuestionDocument6 pagesMotion in One Dimension Questionabh_omega33% (3)

- Himachal Pradesh Staff Selection Commission Hamirpur - 177001Document2 pagesHimachal Pradesh Staff Selection Commission Hamirpur - 177001Verma JagdeepNo ratings yet

- TM 9-1425-429-12-HR - Stinger - Training - Set - 1983 PDFDocument34 pagesTM 9-1425-429-12-HR - Stinger - Training - Set - 1983 PDFWurzel1946No ratings yet

- Theory 2 - The Demand of The Society From The Teacher As A Professional (PPST)Document6 pagesTheory 2 - The Demand of The Society From The Teacher As A Professional (PPST)Angel RodriguezNo ratings yet

- 2022 Cement Lime Manufacturing Ehs Guidelines enDocument39 pages2022 Cement Lime Manufacturing Ehs Guidelines enSamiNo ratings yet

- Fiitjee All India Test Series: Concept Recapitulation Test - Iv JEE (Advanced) - 2019Document13 pagesFiitjee All India Test Series: Concept Recapitulation Test - Iv JEE (Advanced) - 2019Raj KumarNo ratings yet

- A C Engines and Jet Propulsion1Document16 pagesA C Engines and Jet Propulsion1Mukesh KumarNo ratings yet

- Electromechanical Instruments: Permanent-Magnet Moving-Coil InstrumentsDocument13 pagesElectromechanical Instruments: Permanent-Magnet Moving-Coil InstrumentsTaimur ShahzadNo ratings yet

- Application Bright Ideas Education Grant Program For TeachersDocument6 pagesApplication Bright Ideas Education Grant Program For Teachersapi-320983699No ratings yet

- FINAL ReportDocument48 pagesFINAL ReportMythri RangaswamyNo ratings yet

- Introduction To Rhetorical Analysis: Week 1Document16 pagesIntroduction To Rhetorical Analysis: Week 1Will KurlinkusNo ratings yet

- 20160323110112-Sae 1215Document1 page20160323110112-Sae 1215awesome_600No ratings yet

- Compressor-Less: Historical ApplicationsDocument70 pagesCompressor-Less: Historical Applicationssuryakantshrotriya100% (1)

- UntitledDocument37 pagesUntitledUnknown UserNo ratings yet

- Module 14-Area ComputationsDocument5 pagesModule 14-Area ComputationsGerovic Parinas50% (2)

- Sem06 Gca InsoDocument2 pagesSem06 Gca InsoBogdan PistolNo ratings yet

- Chapter 1 MPLS OAM Configuration Commands ...................................................................... 1-1Document27 pagesChapter 1 MPLS OAM Configuration Commands ...................................................................... 1-1Randy DookheranNo ratings yet

- Chapter 01 Fundamental and Derived QuantitiesDocument7 pagesChapter 01 Fundamental and Derived QuantitiesAlicia WilliamsNo ratings yet

- Ultraviolet Flame Detector: Omniguard Model 660Document2 pagesUltraviolet Flame Detector: Omniguard Model 660carlosNo ratings yet

- Chapter 2 Ag - EconDocument7 pagesChapter 2 Ag - EconJay Kenneth Bajar Cernal100% (1)

- Studi Tentang Pelayanan Terhadap Kapal Perikanan Di Pelabuhan Perikanan Pantai (PPP) Tumumpa Kota ManadoDocument9 pagesStudi Tentang Pelayanan Terhadap Kapal Perikanan Di Pelabuhan Perikanan Pantai (PPP) Tumumpa Kota ManadoAri WibowoNo ratings yet

- Barriers of CommunicationDocument5 pagesBarriers of CommunicationIVY YBAÑEZNo ratings yet

- Sap Retail Two Step PricingDocument4 pagesSap Retail Two Step PricingShams TabrezNo ratings yet

- Engine Torque Settings and Spec's 3.0L V6 SCDocument4 pagesEngine Torque Settings and Spec's 3.0L V6 SCMario MaravillaNo ratings yet

- WideScreen Code For PS2 GamesDocument78 pagesWideScreen Code For PS2 Gamesmarcus viniciusNo ratings yet

- Is There Any Way To Download The Whole Package of Asphalt 8 Airborne So That I Can Install It On Any Android Device Without An Internet Connection - QuoraDocument4 pagesIs There Any Way To Download The Whole Package of Asphalt 8 Airborne So That I Can Install It On Any Android Device Without An Internet Connection - QuoraMounir2105No ratings yet

- Pile Capacity - An Overview - ScienceDirect TopicsDocument15 pagesPile Capacity - An Overview - ScienceDirect TopicssurNo ratings yet

- Template 3 - MATH 3-REGULAR-DIAGNOSTICDocument2 pagesTemplate 3 - MATH 3-REGULAR-DIAGNOSTIClailanie CervantesNo ratings yet

- The Everything Aquarium Book: All You Need to Build the Acquarium of Your DreamsFrom EverandThe Everything Aquarium Book: All You Need to Build the Acquarium of Your DreamsRating: 5 out of 5 stars5/5 (1)

- The Dragon Behind the Glass: A True Story of Power, Obsession, and the World's Most Coveted FishFrom EverandThe Dragon Behind the Glass: A True Story of Power, Obsession, and the World's Most Coveted FishRating: 4 out of 5 stars4/5 (35)

- Biofloc Fish Farming for Dummies: The Beginner's Guide to Setting Up FarmFrom EverandBiofloc Fish Farming for Dummies: The Beginner's Guide to Setting Up FarmNo ratings yet

- Livebearers: Understanding Guppies, Mollies, Swordtails and OthersFrom EverandLivebearers: Understanding Guppies, Mollies, Swordtails and OthersNo ratings yet

- Eye to Eye with Big Bass: “Let Her Go! She Is Just Another Big Fish!”From EverandEye to Eye with Big Bass: “Let Her Go! She Is Just Another Big Fish!”No ratings yet

- Freshwater Aquariums: Basic Aquarium Setup and MaintenanceFrom EverandFreshwater Aquariums: Basic Aquarium Setup and MaintenanceRating: 3 out of 5 stars3/5 (1)

- Axolotl for beginners: 1x1 guide for species-appropriate keeping, care and feeding in the aquarium incl. interesting factsFrom EverandAxolotl for beginners: 1x1 guide for species-appropriate keeping, care and feeding in the aquarium incl. interesting factsNo ratings yet

- The New Saltwater Aquarium Guide: How to Care for and Keep Marine Fish and CoralsFrom EverandThe New Saltwater Aquarium Guide: How to Care for and Keep Marine Fish and CoralsRating: 5 out of 5 stars5/5 (2)

- The Big Book Of Sea Monsters (Scary Looking Sea Animals): Animal Encyclopedia for KidsFrom EverandThe Big Book Of Sea Monsters (Scary Looking Sea Animals): Animal Encyclopedia for KidsNo ratings yet

- Sharks: 101 Super Fun Facts And Amazing Pictures (Featuring The World's Top 10 Sharks With Coloring Pages)From EverandSharks: 101 Super Fun Facts And Amazing Pictures (Featuring The World's Top 10 Sharks With Coloring Pages)Rating: 3 out of 5 stars3/5 (3)

- Aquascaping: A Step-by-Step Guide to Planting, Styling, and Maintaining Beautiful AquariumsFrom EverandAquascaping: A Step-by-Step Guide to Planting, Styling, and Maintaining Beautiful AquariumsRating: 5 out of 5 stars5/5 (4)

- Profitable Fish Farming From Scratch: Where To Begin, How To BeginFrom EverandProfitable Fish Farming From Scratch: Where To Begin, How To BeginNo ratings yet

- Dolphins: 101 Fun Facts & Amazing Pictures (Featuring The World's 6 Top Dolphins)From EverandDolphins: 101 Fun Facts & Amazing Pictures (Featuring The World's 6 Top Dolphins)Rating: 4 out of 5 stars4/5 (2)

- How To Make A Million Dollars With Fish: The Ultimate Guide To Profitable Fish FarmingFrom EverandHow To Make A Million Dollars With Fish: The Ultimate Guide To Profitable Fish FarmingNo ratings yet

- Sharks: 101 Super Fun Facts And Amazing Pictures (Featuring The World's Top 10 Sharks)From EverandSharks: 101 Super Fun Facts And Amazing Pictures (Featuring The World's Top 10 Sharks)Rating: 3.5 out of 5 stars3.5/5 (7)

- Understanding Life Below the Beautiful Sea | Children's Fish & Marine LifeFrom EverandUnderstanding Life Below the Beautiful Sea | Children's Fish & Marine LifeNo ratings yet

- The Everything Fishing Book: Grab Your Tackle Box and Get Hooked on America's Favorite Outdoor SportFrom EverandThe Everything Fishing Book: Grab Your Tackle Box and Get Hooked on America's Favorite Outdoor SportNo ratings yet

- Avoid the 5 Most Common Saltwater Aquarium MistakesFrom EverandAvoid the 5 Most Common Saltwater Aquarium MistakesRating: 5 out of 5 stars5/5 (1)

- Essential Tropical Fish Species Guide: The simplified guide to identifying, selecting and caring for your tropical fishFrom EverandEssential Tropical Fish Species Guide: The simplified guide to identifying, selecting and caring for your tropical fishNo ratings yet

- Arowana: The Complete Owner’s Guide for the Most Expensive Fish in the World - Arowana Fish Tank, Types, Care, Food, Habitat, Breeding, Mythology – Includes Silver, Platinum, Red, Jardini, Black, Golden, GreenFrom EverandArowana: The Complete Owner’s Guide for the Most Expensive Fish in the World - Arowana Fish Tank, Types, Care, Food, Habitat, Breeding, Mythology – Includes Silver, Platinum, Red, Jardini, Black, Golden, GreenNo ratings yet