Professional Documents

Culture Documents

Earthing Table

Earthing Table

Uploaded by

Karthick NatarajanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Earthing Table

Earthing Table

Uploaded by

Karthick NatarajanCopyright:

Available Formats

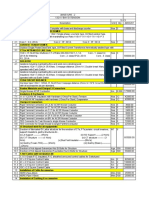

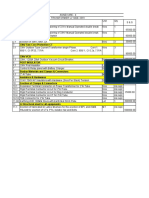

SR.

DESCRIPTION / EARTH CONDUCTOR MATERIAL SIZE, NO OF RUN

NO. APPLICATION MOC /

EARTHING CONDUCTOR (GI) BURIED

1 PLANT MAIN EARTH GRID 75 MM X 10 MM, STEEL CONDUCTOR (GI)

AROUND THE BUIDINGS

2 NOS. (I.E. 1 RUN AT EACH END OF PANEL) OF

2 HV SWITCHGEAR (6.6KV) 75 MM X 10 MM, STEEL CONDUCTOR (GI)

RUNS FOR EACH EQUIPMENT

CONNECTING CABLE TRAY

2 NOS. (I.E. 1 RUN AT EACH END OF PANEL) OF

3 THROUGH PIPE RACK / 75 MM X 10 MM, STEEL CONDUCTOR (GI)

RUNS FOR EACH EQUIPMENT

PLANT TO PLANT

CONNECTION

LT DISTRIBUTION TRANSFORMER NEUTRAL IS CONNECTED TO

4 1CX630 MM2 AL CABLE/ 75X10 GI STRIP

TRANSFORMER NEUTRAL TWO (2 NO'S) INDEPENDENT EARTH PIT

5 TRANSFORMER BODY 75 MM X 10 MM, STEEL CONDUCTOR (GI) 2 NOS. OF RUNS EACH FOR NEUTRAL AND BODY

EARTHING

2 NOS. (I.E. 1 RUN AT EACH END OF PANEL) OF

6 TRANSFORMER 25 MM X 6 MM, STEEL CONDUCTOR (GI)

RUNS FOR EACH EQUIPMENT

MARSHELLING BOX

7 LIGHTING TRANSFORMER 25 MM X 6 MM, STEEL CONDUCTOR (GI) 2 NOS. OF RUNS EACH FOR NEUTRAL AND BODY

(50KVA) EARTHING

PCC, MCC, MLDB, APFC 2 NOS. (I.E. 1 RUN AT EACH END OF PANEL) OF

8 75 Mm X 10 Mm, Steel Conductor (Gi)

PANEL RUNS FOR EACH EQUIPMENT

AND LV AUX DB, VFD PANELS

1 RUN ALONG THE CABLE TRAY. ALL

9 HT CABLE TRAY , LT CABLE 50 X 6MM, STEEL CONDUCTOR (GI) INSTALLED CABLE TRAYS IN TIERS SHALL BE

TRAY INTERCONNECTED EVERY 30 MTR INTERVAL

1 RUN ALONG THE CABLE TRAY, LOOOPING AT

10 LIGHTING CABLE TRAY 25 MM X 6 MM, STEEL CONDUCTOR (GI)

COUPLER PLATE

2 Nos. OF RUNS FOR BODY EARTHING

11 HT MOTORS 50 MM X 6 MM, STEEL CONDUCTOR (GI)

CONNECTED TO NEAREST LOCATED GI STRIP

RUNNING ALONG CABLE TRAY.

2 Nos. OF RUNS FOR BODY EARTHING

12 LT MOTOR & PJB (>90 KW) 50 X 6MM, STEEL CONDUCTOR (GI) CONNECTED TO NEAREST LOCATED GI STRIP

RUNNING ALONG LADDER CABLE TRAY.

2 Nos. OF RUNS FOR BODY EARTHING

LT MOTOR & PJB (>15 KW

13 25 MM X 6 MM, STEEL CONDUCTOR (GI) CONNECTED TO NEAREST LOCATED GI Strip

TO 90 KW

Running Along Ladder Cable Tray.

2 Nos. OF RUNS FOR BODY EARTHING

14 LT MOTORS - UPTO (15 KW) 8 SWG GI WIRE CONNECTED TO NEAREST LOCATED GI STRIP

RUNNING ALONG LADDER CABLE TRAY.

2 Nos. OF RUNS FOR BODY EARTHING

15 LDB, CRANE PANEL 25 MM X 6 MM, STEEL CONDUCTOR (GI) CONNECTED TO NEAREST LOCATED GI STRIP

RUNNING ALONG LADDER CABLE TRAY.

2 Nos. Of runs for body earthing connected

16 LCS, CJB OTHER CONTROL 8 SWG GI Wire to nearest located GI strip running along

PANELS ladder cable tray.

LIGHTING FIXTURES AND 3rd cable core to be used for Lighting

17 3rd core of power cable

LIGHTING JB fixture earthing

1 Nos. Of runs for body earthing connected

RAILS, HANDRAILING,

18 25 mm X 6 mm, steel Conductor (GI) to nearest located GI strip running along

FENCING, METTALIC

ladder cable tray.

SUPPORTS ETC.

2 Nos. Of runs for earthing connected to

Electronic earth pit (EEP) located at

INSTRUMENTATION /

19 16 mm2 insulated copper cable Substation/El. Room. Instrument cable shield

ELECTRONIC EARTHING

to be earth at Panel end (at Substation/El.

Room) instrument Earth and further connected

to EEP.

A) 75 mm X 10 mm, steel Conductor (GI)-

1 Run along the ladder cable tray. All installed

for along the HT cable tray b)

20 BELT CONVEYOR GALLERY cable trays in tiers shall be interconnected

50 mm X 6 mm, steel Conductor (GI)-for

every 30 Mtr interval

Along LT cable tray

You might also like

- Auto-Transformer Design - A Practical Handbook for Manufacturers, Contractors and WiremenFrom EverandAuto-Transformer Design - A Practical Handbook for Manufacturers, Contractors and WiremenRating: 4 out of 5 stars4/5 (2)

- Diode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesFrom EverandDiode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesRating: 4.5 out of 5 stars4.5/5 (7)

- Indian Diet Plan For Pregnancy FullDocument125 pagesIndian Diet Plan For Pregnancy FullKarthick NatarajanNo ratings yet

- Howard Fine Suggested Female Audition Pieces 2013Document21 pagesHoward Fine Suggested Female Audition Pieces 2013CatherineEmilyLangleyNo ratings yet

- Price ScheduleDocument12 pagesPrice ScheduleAkd DeshmukhNo ratings yet

- Conductor ParametersDocument34 pagesConductor ParametersDHARMENDRANo ratings yet

- Rules For Reading The Dasamsa ChartDocument7 pagesRules For Reading The Dasamsa ChartV Narayan Rao60% (5)

- 3.BOQ - The GambiaDocument43 pages3.BOQ - The Gambiamanish100% (1)

- Ele. Supply Boq For Taqa NeyveliDocument1 pageEle. Supply Boq For Taqa NeyvelitechbhaskarNo ratings yet

- Ohe IDocument41 pagesOhe IMandar GorheNo ratings yet

- 10012020-50MW-220-33KV PSS BoqDocument4 pages10012020-50MW-220-33KV PSS BoqHari HaranNo ratings yet

- 33kv WTG Switchyard BOMDocument4 pages33kv WTG Switchyard BOMManohar Potnuru100% (1)

- Volkswagen Golf: Jump To Navigation Jump To SearchDocument23 pagesVolkswagen Golf: Jump To Navigation Jump To SearchKhaled FatnassiNo ratings yet

- Annexure 2Document2 pagesAnnexure 2Anoop DamodaranNo ratings yet

- Boq For Lig & Ews FlatsDocument42 pagesBoq For Lig & Ews FlatsHiteshNo ratings yet

- Sr. No. Item Description UOM QTYDocument1 pageSr. No. Item Description UOM QTYVenkat KrishnanNo ratings yet

- Suppliers & Project For Diff KVDocument79 pagesSuppliers & Project For Diff KVapi-25885200No ratings yet

- JMR Ksba20Document2 pagesJMR Ksba20Ashok KumarNo ratings yet

- Price Bid For Lattice StructureDocument16 pagesPrice Bid For Lattice Structuresouvikbesu89No ratings yet

- To, Vasu Bangalore 9845098450Document9 pagesTo, Vasu Bangalore 9845098450Arka EnergyNo ratings yet

- Supply Erection & CommissioningDocument5 pagesSupply Erection & CommissioningChethan GowdaNo ratings yet

- 3311 KV (1x5MVA) Sub-Staion - Tender BoQDocument10 pages3311 KV (1x5MVA) Sub-Staion - Tender BoQRicky ChangNo ratings yet

- BHDL19 JMRDocument2 pagesBHDL19 JMRAshok KumarNo ratings yet

- Rate List-3Document7 pagesRate List-3Bittudubey officialNo ratings yet

- Vellur INdustrial FielderDocument38 pagesVellur INdustrial FielderparameswarikumarNo ratings yet

- LightingsDocument17 pagesLightingsYuvan PrakashNo ratings yet

- As Per Exccution Qty 6 7 8 Rate Per in Rs - Ps Amount in RsDocument9 pagesAs Per Exccution Qty 6 7 8 Rate Per in Rs - Ps Amount in RspudurbhaskarNo ratings yet

- Covection Section Tube FIN Tube Size Material QTY THK MM Height MM FPM Type Materiallength (MM)Document3 pagesCovection Section Tube FIN Tube Size Material QTY THK MM Height MM FPM Type Materiallength (MM)Nilesh PatelNo ratings yet

- 30 KWP - Grid Roof Top Solar Power Project of Ghrce at Nagpur, MaharashtraDocument2 pages30 KWP - Grid Roof Top Solar Power Project of Ghrce at Nagpur, MaharashtraSandeep SinghNo ratings yet

- 33 KV Pooling Station & Metering YardDocument12 pages33 KV Pooling Station & Metering YardMadhukar PadipallyNo ratings yet

- New Microsoft Excel WorksheetDocument6 pagesNew Microsoft Excel WorksheetAtluri Naga Sai Saran KumarNo ratings yet

- Cost Estimate XANTHENG V3Document15 pagesCost Estimate XANTHENG V3Andy ArenasNo ratings yet

- Item Decription Unit SL NoDocument4 pagesItem Decription Unit SL NoPrashant TrivediNo ratings yet

- List Material ME Dan GroundingDocument2 pagesList Material ME Dan GroundingsandyNo ratings yet

- Name of Company/Firm: National Highways Authority of IndiaDocument2 pagesName of Company/Firm: National Highways Authority of IndiapiuhyderabadNo ratings yet

- 1 Exe.E.I For P.S To Ampani P.S - 0 - Pole - Mounted - Spec - MTODocument7 pages1 Exe.E.I For P.S To Ampani P.S - 0 - Pole - Mounted - Spec - MTOAlexey PyatinNo ratings yet

- Price ScheduleDocument14 pagesPrice ScheduleAkd DeshmukhNo ratings yet

- SL - No. Description Unit Quantity A Cable: BERKHEDA: (33/6.6 KV)Document5 pagesSL - No. Description Unit Quantity A Cable: BERKHEDA: (33/6.6 KV)Anand Mohan PandeyNo ratings yet

- Annexure 4Document1 pageAnnexure 4Anoop DamodaranNo ratings yet

- Cahtodic Protection SystemDocument31 pagesCahtodic Protection SystemPhan Cao An TruongNo ratings yet

- For INDENT TransformerDocument2 pagesFor INDENT TransformerPRASHANT KUMAR SINGHNo ratings yet

- BOQ JonelDocument3 pagesBOQ JonelJonel TorresNo ratings yet

- Electrical BOQ - 21027 R1 PDFDocument1 pageElectrical BOQ - 21027 R1 PDFnavtej singhNo ratings yet

- Transmission Line Item BoqDocument1 pageTransmission Line Item BoqkarthickNo ratings yet

- Boerstn Quotation (Schneider) Fadel-2Document1 pageBoerstn Quotation (Schneider) Fadel-2Mtvc LbNo ratings yet

- Electrical MTO: Sr. No. Item Description Qty-A Unit RemarksDocument2 pagesElectrical MTO: Sr. No. Item Description Qty-A Unit RemarksadilsiddiqueNo ratings yet

- SL No. Item Decription Unit QtyDocument1 pageSL No. Item Decription Unit QtyPrashant TrivediNo ratings yet

- DMRDocument8 pagesDMRaks2205No ratings yet

- 1 X 600 MW KWPCL Raigarh Project Sizing Calculation For Power Station Earthing SystemDocument1 page1 X 600 MW KWPCL Raigarh Project Sizing Calculation For Power Station Earthing Systemsimu84No ratings yet

- Sub Station Earthing Mat DesignDocument6 pagesSub Station Earthing Mat DesignmaninderpreetNo ratings yet

- Design & Optimization of Power Transformers With Source CodesDocument75 pagesDesign & Optimization of Power Transformers With Source CodesN. T. DadlaniNo ratings yet

- E1Document1 pageE1JohnSerranoNo ratings yet

- Cable CalculationDocument1 pageCable CalculationAbhishek SinhaNo ratings yet

- Works FormatDocument12 pagesWorks FormatnikithayagantiNo ratings yet

- Cross Belt Magnetic Separator (CBMS)Document2 pagesCross Belt Magnetic Separator (CBMS)mkbhat17kNo ratings yet

- Exide New BoqDocument7 pagesExide New Boqkishor veheleNo ratings yet

- 315kVA 11kV 400V SampleDocument1 page315kVA 11kV 400V SampleJohn Nash TunNo ratings yet

- 1 KM of 33 KV LineDocument3 pages1 KM of 33 KV LineAkram Elhadi100% (1)

- 1 ACSR380/50mm2 (NA)Document3 pages1 ACSR380/50mm2 (NA)bassamwael6689No ratings yet

- Unserved Legacy PR (Filtered)Document2 pagesUnserved Legacy PR (Filtered)Francis DedumoNo ratings yet

- Robby TestDocument16 pagesRobby TestvsigalinggingNo ratings yet

- Stainless SteelDocument1 pageStainless SteelSadashiva sahoo100% (1)

- INSTRUMENT TYPICAL dwgDocument55 pagesINSTRUMENT TYPICAL dwgKarthick NatarajanNo ratings yet

- VFD SLD Inputs To KarthiDocument1 pageVFD SLD Inputs To KarthiKarthick NatarajanNo ratings yet

- AhtaliDocument1 pageAhtaliKarthick NatarajanNo ratings yet

- Emergency Power Supply of Control Rod For RDEDocument9 pagesEmergency Power Supply of Control Rod For RDEKarthick NatarajanNo ratings yet

- Comments Resolution Sheet 2676 KRAN 7025 - REV BDocument1 pageComments Resolution Sheet 2676 KRAN 7025 - REV BKarthick NatarajanNo ratings yet

- Abb DB CatlogueDocument18 pagesAbb DB CatlogueSelva KumarNo ratings yet

- Unturned Pages of My HeartDocument47 pagesUnturned Pages of My HeartSomya TiwariNo ratings yet

- Process Based WritingDocument10 pagesProcess Based WritingMacarena OhseNo ratings yet

- OGDCL Trainee Test 2018 NTSDocument1 pageOGDCL Trainee Test 2018 NTSBilal AhmadNo ratings yet

- NIOS 8.5.4 ReleaseNotesDocument70 pagesNIOS 8.5.4 ReleaseNoteskarolkarol1No ratings yet

- Bmec Final ExamDocument1 pageBmec Final ExamnovyNo ratings yet

- Final Proposal Presentation ME Project1Document12 pagesFinal Proposal Presentation ME Project1Miguel Paolo LademoraNo ratings yet

- ProvisionsDocument5 pagesProvisionsAngelshine LacanlaleNo ratings yet

- AsiaYo Final-Report - Team - 1Document8 pagesAsiaYo Final-Report - Team - 1Rabianur KalemNo ratings yet

- Bronchodilator & Other Drugs Used in AsthmaDocument15 pagesBronchodilator & Other Drugs Used in AsthmaGenta JagadNo ratings yet

- Neeraj Kumar: Nokia Siemens Networks (Global SDC Chennai)Document4 pagesNeeraj Kumar: Nokia Siemens Networks (Global SDC Chennai)Kuldeep SharmaNo ratings yet

- The Dark Heart of Uukrul Manual DOS enDocument36 pagesThe Dark Heart of Uukrul Manual DOS enqcrw5No ratings yet

- IIT Madras Thesis Synopsis Template 3Document31 pagesIIT Madras Thesis Synopsis Template 3SAGAR RATHEENo ratings yet

- Asystasia Coromandeliana, Nees Justicia Gangetica, LDocument2 pagesAsystasia Coromandeliana, Nees Justicia Gangetica, LRaihono HAUMANINo ratings yet

- CH 9 Ethics and Information TechnologyDocument16 pagesCH 9 Ethics and Information Technologyfatima zaheerNo ratings yet

- 06 TheCPUAndMemoryDocument34 pages06 TheCPUAndMemoryAkbar BadhushaNo ratings yet

- IEA Bioenergy 2009 Annual ReportDocument136 pagesIEA Bioenergy 2009 Annual ReportAkhilesh GuptaNo ratings yet

- 2021 Corporate ProfileDocument21 pages2021 Corporate Profilekanikak97No ratings yet

- Special Running ConditionsDocument3 pagesSpecial Running ConditionsGeorgios PapakostasNo ratings yet

- Bissell Powerforce Bagless Turbo ManualDocument16 pagesBissell Powerforce Bagless Turbo ManualdennisborcherNo ratings yet

- Construction and Behavior of Drilled ShaftsDocument12 pagesConstruction and Behavior of Drilled ShaftsapapadiaNo ratings yet

- English Multimodal Presentation ScriptDocument2 pagesEnglish Multimodal Presentation ScriptPaul PanizaNo ratings yet

- RFCM - Compassionate Pastor Dec-2011Document44 pagesRFCM - Compassionate Pastor Dec-2011pacesoft321No ratings yet

- Etsi DMR ProtocoloDocument177 pagesEtsi DMR ProtocoloIvan Flores MelchorNo ratings yet

- Plant Kingdom: Class I - ChlorophyceaeDocument8 pagesPlant Kingdom: Class I - ChlorophyceaeLawrence StokesNo ratings yet

- Cornell University, School of Industrial & Labor RelationsDocument3 pagesCornell University, School of Industrial & Labor RelationsZana S. NajmaddinNo ratings yet

- Biography of Srila PrabhupadaDocument2 pagesBiography of Srila Prabhupadamapl2891No ratings yet

- List of Experiments: Exp. No. Name of The Experiments Page NoDocument76 pagesList of Experiments: Exp. No. Name of The Experiments Page NoPushpavalli MohanNo ratings yet