Professional Documents

Culture Documents

Rev.D-3

Rev.D-3

Uploaded by

BW Mechanical0 ratings0% found this document useful (0 votes)

1 views1 pageOriginal Title

75181 Rev.D-3

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

1 views1 pageRev.D-3

Rev.D-3

Uploaded by

BW MechanicalCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

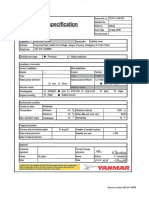

10, HOSE WALL THICKNESS-The hose wall thickness for hose i sted below. Its important

tacheck the hose wall hickness fo make sure that te crimp wil be leak es,

(CRIMP DIAMETER AND HOSE WALL CHART

HOSE ‘CRIN. HOSE WALL

SIZE DIAMETER | _ THICKNESS

‘WESTIE 1D. Recuoad Dameter | 556° s.012- | 128" 018"

05.5116" |.0.2-Braid Diameter | —655"s.012" [214° 029"

#08: 13132" 1D. Reduced Dame ‘s5".012 | 128° 018"

#08-13132" 1D. 2-Braid Diameter | 830" .012" | 24a" 025"

10-112" 1D. Reduced Osameter | 742" .012" [128° 020"

10-112" —10.2-Braig Diameter | 807" 2.012" | —2as"= 028"

12-516" 1D. Reduced Dameter | 697"2012" | 148"= 020"

2-518" —1.-2-Braid Diameter | 1.015 4.012" | 246" 025"

OPERATION

WARNING! Atways wear eye protection when operating this crimper.

1. Mount the erimper as described previously unless itis necessary to crimp on the vehicle.

2. Solect the proper size des. Check all segments to make sure that al ofthe segments have

the same numbers an te back. Each segment willbe marked identifying the hose size and

‘timp dameter. Example: 5/76 ID hose witha 556 diameter crimp wil be marked "BR 556"

(Refer to Fig 4, Pg. 6).

3. Lubricate all parts indicated on page 7 with the Teton groase provided (tom "A" Pg. 7) or

ccauivalent.

4. Refer to DIE CHANGE for proper assembly ofthe dis into the crimper.

‘5. Inset the hose into the fiting making sue thatthe hose appears in the small inspection hole

ton the side or en ofthe fete.

CAUTION! {tthe hose does not appear in he inspection hole, a poor crimp may result

6. Postion the fag (item 7, Pg, 7) 0 the ferrule ofthe iting bumps it when inserted into the

crimper (Refer t Fg. 8, PQ. 6)

CAUTION! Do not locate from the bead on the iting. This wil result inthe wrong crimp

rosation,

WARNING! Keep hands clear ofthe crimp jaws. This machine develops up to 7000

‘pounds of force and can inflict serious personal injury f not used properly.

ATCO Prods, 3 et na ms

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Rev.D-2Document1 pageRev.D-2BW MechanicalNo ratings yet

- Rev.D-1Document1 pageRev.D-1BW MechanicalNo ratings yet

- - - - Movie Data Starter Project (Final) -н ХуулбарDocument85 pages- - - Movie Data Starter Project (Final) -н ХуулбарBW MechanicalNo ratings yet

- Rev.DDocument1 pageRev.DBW MechanicalNo ratings yet

- Tonly TL885 Dump Truck Specs PDFDocument4 pagesTonly TL885 Dump Truck Specs PDFBW MechanicalNo ratings yet

- Panasonic YC-400TX3Document21 pagesPanasonic YC-400TX3BW MechanicalNo ratings yet

- Rev.D-4Document1 pageRev.D-4BW MechanicalNo ratings yet

- Water Pump PumpDocument3 pagesWater Pump PumpBW Mechanical100% (1)

- Water Pump PumpDocument3 pagesWater Pump PumpBW MechanicalNo ratings yet

- Engine Data Sheet As4006 m5 3tnm72 GHFCLDocument15 pagesEngine Data Sheet As4006 m5 3tnm72 GHFCLBW MechanicalNo ratings yet

- GR3005T3平地机操作手册 - 英文20210125Document154 pagesGR3005T3平地机操作手册 - 英文20210125BW MechanicalNo ratings yet

- Kubota Seal Kit Part No ListDocument2 pagesKubota Seal Kit Part No ListBW Mechanical0% (1)

- Liebherr Seal Kit Part No ListDocument6 pagesLiebherr Seal Kit Part No ListBW MechanicalNo ratings yet

- Wiring HarnessDocument2 pagesWiring HarnessBW MechanicalNo ratings yet

- Cam Follower CoverDocument3 pagesCam Follower CoverBW MechanicalNo ratings yet

- Camshaft Cam FollowerDocument3 pagesCamshaft Cam FollowerBW MechanicalNo ratings yet

- Hitachi Seal Kit Part No ListDocument7 pagesHitachi Seal Kit Part No ListBW MechanicalNo ratings yet

- Disc Brake Pads, Caliper Spares & Brake DiscsDocument13 pagesDisc Brake Pads, Caliper Spares & Brake DiscsBW MechanicalNo ratings yet

- Kato Seal Kit Part No ListDocument4 pagesKato Seal Kit Part No ListBW MechanicalNo ratings yet

- Kobelco Seal Kit Part No ListDocument4 pagesKobelco Seal Kit Part No ListBW MechanicalNo ratings yet

- Samsung Seal Kit Part No ListDocument2 pagesSamsung Seal Kit Part No ListBW Mechanical0% (1)

- Mitsubishi Seal Kit Part No ListDocument2 pagesMitsubishi Seal Kit Part No ListBW MechanicalNo ratings yet

- MANN FILTER'S ХарьцуулалтDocument4 pagesMANN FILTER'S ХарьцуулалтBW MechanicalNo ratings yet