Professional Documents

Culture Documents

Division 5

Uploaded by

hari banggaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Division 5

Uploaded by

hari banggaCopyright:

Available Formats

STRUCTURAL STEEL 05120-1

SECTION 05120

STRUCTURAL STEEL

PART 1: GENERAL

1.01 DESCRIPTION:

A. This Section includes specifications for manufacturing structural steel canopy

as indicated on the contract documents.

B. Related Work Specified Elsewhere:

1. Section 03300 – Cast in Place Concrete.

2. Section 05500 – Metal Fabrications.

3. Section 09900 – Painting.

1.02 QUALITY CONTROL:

A. Installer Qualifications: A qualified installer who participates in the AISC

Quality Certification Program and is designated an AISC-Certified Erector,

Category CASE CSE.

B. Fabricator Qualifications: A qualified fabricator who participates in the

AISC Quality Certification Program and is designated an AISC-Certified

Plant, Category Cbd Sbd.

C. Welding: Qualify procedures and personnel according to AWS D1.1,

"Structural Welding Code--Steel."

D. Qualifications of Welders: In accordance with the American Welding

Society Standards.

E. Owner may engage an independent testing and inspecting agency to perform

shop tests and inspections and prepare test reports. Provide testing agency

with access to places where structural-steel work is being fabricated or

produced to perform tests and inspections. Correct deficiencies in Work that

test reports and inspections indicate does not comply with the Contract

Documents.

F. Welded Connections: In addition to visual inspection, shop-welded

connections will be tested at the Contractor’s expense and inspected

according to AWS D1.1 and the following inspection procedures, at testing

agency's option: Testing agency shall directly provide Engineer with test

VRE Burke Centre Station -1-

Platform Extension

STRUCTURAL STEEL 05120-2

reports upon completion of testing such as: Magnetic Particle Inspection:

ASTM E 709; performed on root pass and on finished weld. Ultrasonic

Inspection: ASTM E 164. Radiographic Inspection: ASTM E 94.

G. Comply with applicable provisions of the following specifications and

documents:

1. AISC's "Code of Standard Practice for Steel Buildings and Bridges."

2. AISC's "Specification for Structural Steel Buildings--Allowable Stress

Design and Plastic Design."

3. AISC's "Specification for the Design of Steel Hollow Structural

Sections."

4. AISC's "Specification for Allowable Stress Design of Single-Angle

Members."

5. RCSC's "Specification for Structural Joints Using ASTM A 325 or A

490 Bolts."

6. AWS D1.1 Structural Welding Code - Steel.

7. ASTM Specifications.

1.03 SUBMITTALS:

A. In accordance with Section 01300, submit the following:

1. Product Data: For each type of product indicated.

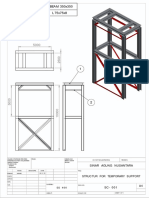

2. Shop Drawings: Show fabrication of structural-steel components.

Include details of cuts, connections, holes, and other pertinent data.

Indicate type, size, and length of bolts, distinguishing between shop and

field bolts. Identify pretensioned and slip-critical high-strength bolted

connections.

3. Mill Test Reports: Signed by manufacturers certifying that the

following products comply with requirements: Structural steel

including chemical and physical properties. Bolts, nuts, and washers

including mechanical properties and chemical analysis. Direct-tension

indicators. Tension-control, high-strength bolt-nut-washer assemblies.

Shop primers and paints.

VRE Burke Centre Station -2-

Platform Extension

STRUCTURAL STEEL 05120-3

4. Source quality-control test reports.

5. Loading diagrams and supporting calculations for open-web steel joists

stamped and sealed by a Professional Engineer.

PART 2 - PRODUCTS

2.01 MATERIALS

A. Structural Steel:

1. W-Shapes: ASTM A 992/A 992M, Grade 50.

2. Channels, Angles: ASTM A 572/A 572M, Grade 50.

3. Plate and Bar: ASTM A 36/A 36M.

4. Steel Pipe: ASTM A 53/A 53M, Type E, Grade B.

B. Bolts, Connectors and Anchors:

1. High-Strength Bolts, Nuts, and Washers: ASTM A 325, Type 1, heavy

hex steel structural bolts; ASTM A 563 heavy hex carbon-steel nuts;

and ASTM F 436 hardened carbon-steel washers.

2. Direct-Tension Indicators: ASTM F 959, Type 325 compressible-

washer type.

3. Finish: Mechanically deposited zinc coating, ASTM B 695, Class 50.

4. Threaded Rods: ASTM A 193/A 193M.

5. Nuts: ASTM A 563 heavy hex carbon steel.

6. Washers: ASTM A 36/A 36M carbon steel.

7. Finish: Hot-dip zinc coating, ASTM A 153/A 153M, Class C.

C. Primer and Paint:

1.

Shop prime steel surfaces and finish paint according to Section 09900

“Painting”.

2.02 FABRICATION

VRE Burke Centre Station -3-

Platform Extension

STRUCTURAL STEEL 05120-4

A. Structural Steel: Fabricate and assemble in shop to greatest extent possible.

Fabricate according to AISC's "Code of Standard Practice for Steel Buildings

and Bridges" and AISC's "Specification for Structural Steel Buildings--

Allowable Stress Design and Plastic Design."

B. Camber structural-steel members where indicated.

C. Identify high-strength structural steel according to ASTM A 6/ A 6M and

maintain markings until structural steel has been erected.

D. Mark and match-mark materials for field assembly...

E. Thermal Cutting: Perform thermal cutting by machine to greatest extent

possible.

F. Plane thermally cut edges to be welded to comply with requirements in AWS

D1.1.

G. Bolt Holes: Drill or punch standard bolt holes perpendicular to metal

surfaces.

H. Cleaning: Clean and prepare steel surfaces that are to remain unpainted

according to SSPC-SP 1, "Solvent Cleaning."

I. Holes: Provide holes required for securing other work to structural steel and

for passage of other work through steel framing members.

J. Cut, drill, or punch holes perpendicular to steel surfaces. Do not thermally

cut bolt holes or enlarge holes by burning.

K. High-Strength Bolts: Shop install high-strength bolts according to RCSC's

"Specification for Structural Joints Using ASTM A 325 or A 490 Bolts" for

type of bolt and type of joint specified.

L. Shop weld connections as indicated on plans.

M. Shop prime steel surfaces except the following: Surfaces embedded in

concrete or mortar. Extend priming of partially embedded members to a

depth of 2 inches. Surfaces to be field welded. Surfaces to be high-strength

bolted with slip-critical connections. Surfaces to receive sprayed fire-resistive

materials. Galvanized surfaces.

N. Surface Preparation: Clean surfaces to be painted in accordance with Section

09900, “Painting”.

O. Priming: Immediately after surface preparation, apply primer according to

VRE Burke Centre Station -4-

Platform Extension

STRUCTURAL STEEL 05120-5

manufacturer's written instructions and at rate recommended by SSPC to

provide a dry film thickness of not less than 1.5 mils. Use priming methods

that result in full coverage of joints, corners, edges, and exposed surfaces.

P. Apply two coats of shop paint to inaccessible surfaces after assembly or

erection.

Q. Painting: Apply a 1-coat, nonasphaltic primer complying with SSPC-PS

Guide 7.00, "Painting System Guide 7.00: Guide for Selecting One-Coat

Shop Painting Systems," to provide a dry film thickness of not less than 1.5

mils.

PART 3 – EXECUTION

3.01 PRODUCT DELIVERY AND STORAGE

A. Store materials to permit easy access for inspection and identification. Keep

steel members off ground and spaced by using pallets, dunnage, or other

supports and spacers. Protect steel members and packaged materials from

erosion and deterioration.

B. Store fasteners in a protected place. Clean and relubricate bolts and nuts that

become dry or rusty before use.

C. Do not store materials on structure in a manner that might cause distortion,

damage, or overload to members or supporting structures. Repair or replace

damaged materials or structures as directed.

3.02 ERECTION

A. The General Contractor shall be responsible for providing suitable access to

the site, proper drainage and firm level bearing, for the hauling and erection

equipment to operate under their own power.

B. Provide temporary shores, guys, braces, and other supports during erection to

keep structural steel secure, plumb, and in alignment against temporary

construction loads and loads equal in intensity to design loads. Remove

temporary supports when permanent structural steel, connections, and bracing

are in place, unless otherwise indicated.

C. Set structural steel accurately in locations and to elevations indicated and

according to AISC's "Code of Standard Practice for Steel Buildings and

Bridges" and "Specification for Structural Steel Buildings--Allowable Stress

Design and Plastic Design."

VRE Burke Centre Station -5-

Platform Extension

STRUCTURAL STEEL 05120-6

D. Maintain erection tolerances of structural steel and architecturally exposed

structural steel within AISC's "Code of Standard Practice for Steel Buildings

and Bridges."

E. Align and adjust various members forming part of complete frame or structure

before permanently fastening. Before assembly, clean bearing surfaces and

other surfaces that will be in permanent contact with members. Perform

necessary adjustments to compensate for discrepancies in elevations and

alignment.

F. Level and plumb individual members of structure.

G. Make allowances for difference between temperature at time of erection and

mean temperature when structure is completed and in service.

H. Splice members only where indicated.

I. Remove erection bolts on welded, architecturally exposed structural steel; fill

holes with plug welds; and grind smooth at exposed surfaces.

J. Do not use thermal cutting during erection.

K. Field welding shall be performed by a certified welder.

L. Do not enlarge unfair holes in members by burning or using drift pins. Ream

holes that must be enlarged to admit bolts.

3.03 REPAIRS AND PROTECTION

A. Repair damaged galvanized coatings on galvanized items with galvanized

repair paint according to ASTM A 780 and manufacturer's written

instructions.

B. Touchup Painting: After installation, promptly clean, prepare, and prime or

reprime field connections, rust spots, and abraded surfaces of prime-painted

joists and accessories and abutting structural steel.

C. Clean and prepare surfaces by SSPC-SP 2 hand-tool cleaning or SSPC-SP 3

power-tool cleaning.

D. Apply a compatible primer of same type as shop primer used on adjacent

surfaces.

E. Touchup Painting: Cleaning and touchup painting are specified in Section

09900.

END OF SECTION

VRE Burke Centre Station -6-

Platform Extension

STEEL DECK 05310-1

SECTION 05310

STEEL DECK

PART 1: GENERAL

1.01 DESCRIPTION:

A. This Section includes specifications for manufacturing steel canopy roofing

as indicated on the contract documents.

B. Related Work Specified Elsewhere:

1. Section 05120 – Structural Steel.

2. Section 05500 – Metal Fabrications.

1.02 QUALITY CONTROL:

A. Testing Agency Qualifications: An independent agency qualified according

to ASTM E 329 for testing indicated.

B. Welding: Qualified procedures and personnel according to AWS D1.3,

"Structural Welding Code - Sheet Steel."

C. AISI Specifications: Comply with calculated structural characteristics of

steel deck according to AISI's "North American Specification for the Design

of Cold-Formed Steel Structural Members."

D. Qualifications of Welders: In accordance with the American Welding

Society Standards.

E. Owner may engage an independent testing and inspecting agency to perform

shop tests and inspections and prepare test reports. Provide testing agency

with access.

F. FMG Listing: Provide steel roof deck evaluated by FMG and listed in its

"Approval Guide, Building Materials" for Class 1 fire rating and Class 1-90

windstorm ratings.

G. Comply with applicable provisions of the following specifications and

documents:

1. AISC's "Code of Standard Practice for Steel Buildings and Bridges."

2. AISC's "Specification for Structural Steel Buildings--Allowable Stress

VRE Burke Centre Station -1-

Platform Extension

STEEL DECK 05310-2

Design and Plastic Design."

3. AISC's "Specification for the Design of Steel Hollow Structural

Sections."

4. AISC's "Specification for Allowable Stress Design of Single-Angle

Members."

5. RCSC's "Specification for Structural Joints Using ASTM A 325 or A

490 Bolts."

6. AWS D1.1 Structural Welding Code - Steel.

7. AISI’s “American Iron and Steel Institute, Specifications For the Design

of Cold-Formed Steel Structural Members”, latest edition.

8. ASTM Specifications.

1.03 SUBMITTALS:

A. In accordance with Section 01300, submit the following:

1. Product Data: For each type of deck, accessory, and product indicated.

2. Shop Drawings: Show layout and types of deck panels, anchorage

details, reinforcing channels, pans, cut deck openings, special jointing,

accessories, and attachments to other construction.

3. Product Certificates: For each type of steel deck, signed by product

manufacturer.

4. Welding certificates.

5. Field quality-control test and inspection reports.

6. Product Test Reports: Based on evaluation of comprehensive tests

performed by a qualified testing agency, indicating that each of the

following complies with requirements: Power-actuated mechanical

fasteners, and Roof deck.

7. Research/Evaluation Reports: For steel deck.

8. Certification of the calculations, connections and or drawings by a

registered Professional Engineer in the State of Virginia.

VRE Burke Centre Station -2-

Platform Extension

STEEL DECK 05310-3

PART 2 - PRODUCTS

2.01 MATERIALS

A. Available Manufacturers: Subject to compliance with requirements,

manufacturers offering products that may be incorporated into the Work

include, but are not limited to, the following:

1) MBCI Metal Roofing and Wall Systems, 18” wide by 3” deep

22 gauge Double-Lok ® Panel

B. Deck:

1. Galvanized Steel Sheet: ASTM A 792, Structural Steel (SS), Grade 22,

aluminum-zinc alloy coating.

2. Profile Depth: 3 inch high rib x 18 inch wide panel.

3. Design Uncoated-Steel Thickness: As indicated.

4. Span Condition: As indicated.

5. Side Laps: Overlapped or interlocking seam at Contractor's to match

the existing where applicable

C. Accessories:

1. General: Provide manufacturer's standard accessory materials for deck

that comply with requirements indicated.

2. Mechanical Fasteners: Corrosion-resistant, low-velocity, power-

actuated or pneumatically driven carbon-steel fasteners; or self-drilling,

self-threading screws.

3. Flexible Closure Strips: Vulcanized, closed-cell, synthetic rubber.

4. Miscellaneous Sheet Metal Deck Accessories: Galvalume ® Steel

sheet, minimum yield strength of 50,000 psi, not less than 0.0359-inch

design uncoated thickness, of same material and finish as deck; and of

profile indicated or required for application.

5. Galvanizing Repair Paint: ASTM A 780.

6. Repair Paint: Manufacturer's standard rust-inhibitive primer of same

color as primer.

VRE Burke Centre Station -3-

Platform Extension

STEEL DECK 05310-4

PART 3 – EXECUTION

3.01 INSTALLATION

A. Install deck panels and accessories according to applicable specifications and

commentary in SDI Publication No. 30, manufacturer's written instructions,

and requirements in this Section.

B. Install temporary shoring before placing deck panels, if required to meet

deflection limitations.

C. Locate deck bundles to prevent overloading of supporting members.

D. Place deck panels on supporting frame and adjust to final position with ends

accurately aligned and bearing on supporting frame before being permanently

fastened. Do not stretch or contract side-lap interlocks.

E. Place deck panels flat and square and fasten to supporting frame without warp

or deflection.

F. Cut and neatly fit deck panels and accessories around openings and other work

projecting through or adjacent to deck.

G. Provide additional reinforcement and closure pieces at openings as required

for strength, continuity of deck, and support of other work, designed by a

professional engineer registered in the state of Virginia.

H. Comply with AWS requirements and procedures for manual shielded metal

arc welding, appearance and quality of welds, and methods used for correcting

welding work.

I. Mechanical fasteners may be used in lieu of welding to fasten deck. Locate

mechanical fasteners and install according to deck manufacturer's written

instructions.

J. Fasten roof-deck panels to steel supporting members using mechanical

fasteners.

K. Side-Lap and Perimeter Edge Fastening: Fasten side laps and perimeter edges

of panels between supports, at intervals specified on the plans and not

exceeding the lesser of 1/2 of the span or 18 inches, and as follows:

Mechanically fasten with self-drilling, No. 10 diameter or larger, carbon-steel

screws. Mechanically clinch or button punch.

L. End Bearing: Install deck ends over supporting frame with a minimum end

bearing of 1-1/2 inches.

M. Miscellaneous Roof-Deck Accessories: Install ridge and valley plates, finish

VRE Burke Centre Station -4-

Platform Extension

STEEL DECK 05310-5

strips, end closures, and reinforcing channels according to deck manufacturer's

written instructions. Mechanically fasten to substrate to provide a complete

deck installation.

N. Galvanizing Repairs: Prepare and repair damaged galvanized coatings on

both surfaces of deck with galvanized repair paint according to ASTM A 780

and manufacturer's written instructions.

O. Provide final protection and maintain conditions to ensure that steel deck is

without damage or deterioration at time of Substantial Completion.

END OF SECTION

VRE Burke Centre Station -5-

Platform Extension

METAL FABRICATIONS 05500-1

SECTION 05500

METAL FABRICATIONS

PART 1: GENERAL

1.01 DESCRIPTION:

A. This Section includes specifications for manufacturing the steel canopy as

indicated on the contract documents.

B. Related Work Specified Elsewhere:

1. Section 05120 – Structural Steel.

1.02 QUALITY CONTROL:

A. Qualifications of Welders: In accordance with the American Welding

Society Standards.

B. Comply with applicable provisions of the following specifications and

documents:

1. Steel Structures Painting Council (SSPC): Painting Manual.

2. AISC-02: Manual of Steel Construction Allowable Stress Design.

3. AISC S303: Code of Standard Practice for Steel Buildings and Bridges.

4. AISC S329: Allowable Stress Design Specification for Structural Joints

Using ASTM A325 or ASTM A490 Bolts."

5. AISC S335: Specification for Structural Steel Buildings - Allowable

Stress Design and Plastic Design."

6. American Welding Society (AWS): D1.1 Structural Welding Code -

Steel.

7. National Association of Architectural Metal Manufacturers (NAAMM):

Standards.

8. ASTM Specifications.

VRE Burke Centre Station -1-

Platform Extension

METAL FABRICATIONS 05500-2

1.03 SUBMITTALS:

A. In accordance with Section 01300, submit the following:

1. Product Data: For each type of deck, accessory, and product indicated.

2. Shop Drawings: Show layout and types of deck panels, anchorage

details, reinforcing channels, pans, cut deck openings, special jointing,

accessories, and attachments to other construction.

PART 2 - PRODUCTS

2.01 MATERIALS

1. Steel Plates, Shapes and Bars: ASTM A 36.

2. Rolled Steel Floor Plates: ASTM A 786.

3. Steel Tubing: ASTM A 500 or A 501.

4. Uncoated Structural Steel Sheet: ASTM A 611 or A 570.

5. Uncoated Steel Sheet: ASTM A 366 or A 569.

6. Galvanized Steel Sheet, Structural Quality: ASTM A 446, Grade A,

G90.

7. Galvanized Steel Sheet, Commercial Quality: ASTM A 526, G90.

8. Steel Pipe, Black Finish: ASTM A 53.

9. Steel Pipe, Galvanized Finish: ASTM A 53.

10. Gray Iron Castings: ASTM A 48, Class 30.

11. Malleable Iron Castings: ASTM A 47, Grade 32510.

12. Reinforcing Bars: ASTM A 615, Grade 60.

13. Brackets, Flanges, and Anchors: Cast or formed metal.

14. Concrete Inserts: Threaded or wedge type.

15. Welding Rods and Bare Electrodes: AWS specifications.

VRE Burke Centre Station -2-

Platform Extension

METAL FABRICATIONS 05500-3

16. Zinc-Coating: Hot-dip galvanized coating for materials in exterior

assemblies or exterior walls

PART 3 – EXECUTION

3.01 FABRICATION

A. General: Shop assemble work in largest practical sections; minimize field

connections. Grind smooth parts exposed to view; remove weld marks and

leave free of fabrication marks. Miter corners and edges unless otherwise

shown. Make members true to length so assembling may be done without

fillers. Bends, twists, open joints in finished members, or projecting edges or

corners at connections will not be permitted. Miter, cope, and block carefully

to produce tight hairline joints. Provide lugs, clips, connections, bolts, and

fastenings necessary to complete fabrication.

B. Treat all areas burned off or damaged during fabrication with specified repair

compound.

C. Reinforcement: Provide proper reinforcement for hardware, and other

fabricated metal work, as required.

D. Welding: Use sequence welding to minimize distortion and heat stresses.

Weld by shielded electric arc process per AWS. Use continuous welding

along entire area of contact, except where spot welding is permitted. Grind all

welds smooth on exposed surfaces. Spot welding not permitted on exposed

surfaces.

E. Surface Preparation For Paint: Clean surfaces of loose mill scale, dirt, rust,

and other foreign matter by use of suitable tools per SSPC SP-6. Remove oil

and grease with suitable volatile solvents per SSPC SP-1.

F. General: Apply paint in accordance with manufacturer’s recommendations.

Product: Carboline 859 Organic Zinc, 3-5 Mils thickness, or approved equal.

Shop Coat: Apply to steel surfaces. Do not shop coat surfaces and edges

requiring field welding; keep shop coat at least 2 inches away.

G. Workmanship: Set work plumb and true; properly assemble and erect in a

rigid and workmanlike manner. Do cutting, punching, drilling and tapping for

attachment of other work coming into contact with fabricated metal work

where indicated or as directed. Do necessary cutting, drilling, and fitting for

installation of fabricated metal work. Execute drilling, cutting, and fitting

carefully; when required, fit work at job before finishing. No burning in field

permitted. Replace, or repair parts damaged or injured during erection in an

acceptable manner. Drill holes for fasteners to exact diameter as

VRE Burke Centre Station -3-

Platform Extension

METAL FABRICATIONS 05500-4

recommended by fastener manufacturer. Oversized holes or holes not

properly located that produce misalignment of fastener will be rejected.

H. Field Touch-up: Touch-up damaged surfaces and field welds of steel,

scheduled to be painted, per SSPC standards.

END OF SECTION

VRE Burke Centre Station -4-

Platform Extension

You might also like

- Design of Steel Structures: Materials, Connections, and ComponentsFrom EverandDesign of Steel Structures: Materials, Connections, and ComponentsNo ratings yet

- FL - Ta1056Document10 pagesFL - Ta1056ery achjariNo ratings yet

- Section 05120 Structural Steel Part 1Document43 pagesSection 05120 Structural Steel Part 1jacksondcplNo ratings yet

- Structural SteelDocument4 pagesStructural Steelrize1159No ratings yet

- 05 40 00ssbDocument12 pages05 40 00ssbJerico NamucoNo ratings yet

- Section 05500 Metal FabricationsDocument7 pagesSection 05500 Metal FabricationsMØhãmmed ØwięsNo ratings yet

- SECTION 05 12 00 Structural Steel FramingDocument6 pagesSECTION 05 12 00 Structural Steel FramingmiteshsuneriyaNo ratings yet

- ITCC in Riyadh Residential Complex J10-13300 05120-1 Structural SteelDocument6 pagesITCC in Riyadh Residential Complex J10-13300 05120-1 Structural SteeluddinnadeemNo ratings yet

- Civil - Technical SpecificationsDocument28 pagesCivil - Technical SpecificationskhalidNo ratings yet

- FL - Ta1056Document4 pagesFL - Ta1056ery achjariNo ratings yet

- 05120-Structural SteelDocument10 pages05120-Structural SteelHusen ZahranNo ratings yet

- Section051200 StructuralsteelDocument5 pagesSection051200 StructuralsteelZeljko VasicNo ratings yet

- Pipe and Tube Railing SystemsDocument8 pagesPipe and Tube Railing Systemsery achjariNo ratings yet

- COLD-FORMED METAL FRAMING Rev.1Document7 pagesCOLD-FORMED METAL FRAMING Rev.1mohdNo ratings yet

- Steel Joist Specification for Libyan Infrastructure ProjectDocument7 pagesSteel Joist Specification for Libyan Infrastructure Projectwafikmh4No ratings yet

- King Abdullah Bin Abdulaziz Project Mataf Extension - DesignDocument14 pagesKing Abdullah Bin Abdulaziz Project Mataf Extension - DesignshoebNo ratings yet

- NU - Division 05 - MetalsDocument18 pagesNU - Division 05 - Metalsyamanta_rajNo ratings yet

- Steel Stairs, Ladders and Platforms - MSTDocument13 pagesSteel Stairs, Ladders and Platforms - MSTwafikmh4No ratings yet

- Structural Steel Framing SpecificationDocument9 pagesStructural Steel Framing SpecificationJuanPaoloYbañezNo ratings yet

- 31 63 29 Drilled Concrete PiersDocument13 pages31 63 29 Drilled Concrete PierssbunNo ratings yet

- Sec 05520 - Handrails and RailingsDocument5 pagesSec 05520 - Handrails and Railingstiju2005hereNo ratings yet

- Uniform General Conditions For Construction Contracts, State of Texas, 2010 (UGC) - ConstructionDocument13 pagesUniform General Conditions For Construction Contracts, State of Texas, 2010 (UGC) - ConstructionTaher AmmarNo ratings yet

- Metal StairsDocument5 pagesMetal Stairsshivayogi asundiNo ratings yet

- Handrail & PlatformDocument58 pagesHandrail & Platformvhung TranNo ratings yet

- 09 22 16.13mbaDocument11 pages09 22 16.13mbaHanamanthNo ratings yet

- GratingsDocument6 pagesGratingsHusen ZahranNo ratings yet

- Glass-Fiber Reinforced Precast Concrete Panel SpecificationDocument11 pagesGlass-Fiber Reinforced Precast Concrete Panel SpecificationMhmd AbdoNo ratings yet

- Section 05120 Structural SteelDocument9 pagesSection 05120 Structural SteelMØhãmmed ØwięsNo ratings yet

- FL - Ta1056Document14 pagesFL - Ta1056ery achjariNo ratings yet

- CompositeJoistStandardSpecifications PDFDocument8 pagesCompositeJoistStandardSpecifications PDFcorrokokoNo ratings yet

- FL - Ta1056Document7 pagesFL - Ta1056ery achjariNo ratings yet

- Building No. SC#Document7 pagesBuilding No. SC#ephremNo ratings yet

- Open Web Steel Joists InstallationDocument5 pagesOpen Web Steel Joists Installationjack.simpson.changNo ratings yet

- AESS Framing DesignDocument7 pagesAESS Framing Designery achjariNo ratings yet

- STEEL JOISTS FOR NON-UNIFORM LOADINGDocument7 pagesSTEEL JOISTS FOR NON-UNIFORM LOADINGuddinnadeemNo ratings yet

- Early Works Package - Specification B (Section 317210) - Tunnel Primary Support - Ground ReinforcementDocument3 pagesEarly Works Package - Specification B (Section 317210) - Tunnel Primary Support - Ground ReinforcementZain AbidiNo ratings yet

- 1.5 Sample BRB Specification - bw2sDocument7 pages1.5 Sample BRB Specification - bw2sKen SuNo ratings yet

- Structural Steel Framing Specs - AISCDocument5 pagesStructural Steel Framing Specs - AISCSteve HuppertNo ratings yet

- Uniform General Conditions For Construction Contracts, State of Texas, 2010 (UGC) - ConstructionDocument10 pagesUniform General Conditions For Construction Contracts, State of Texas, 2010 (UGC) - ConstructionsbunNo ratings yet

- Metal Gratings TA1056 - MBI Sampang Agung Factory Extension 1Document6 pagesMetal Gratings TA1056 - MBI Sampang Agung Factory Extension 1ery achjariNo ratings yet

- Spiral Stairs For QuotationDocument4 pagesSpiral Stairs For QuotationsuperpiojooNo ratings yet

- 055100Document5 pages055100Abdul basithNo ratings yet

- Technical Specifications for Metal Stairs and LaddersDocument7 pagesTechnical Specifications for Metal Stairs and Laddersrizkboss8312No ratings yet

- ACS Specs GFRC1Document10 pagesACS Specs GFRC1Chrill DsilvaNo ratings yet

- FL Cold Formed Metal FramingDocument10 pagesFL Cold Formed Metal FramingTaher AmmarNo ratings yet

- SharonStairsSpecs PDFDocument7 pagesSharonStairsSpecs PDFJohn TreffNo ratings yet

- Table Metal StairDocument6 pagesTable Metal StairJohneey DeepNo ratings yet

- Structural Steel Spec. and ConstructionDocument12 pagesStructural Steel Spec. and ConstructionAshwani DograNo ratings yet

- Guide Specifications For NUTRUSS Cold-Formed Steel FramingDocument6 pagesGuide Specifications For NUTRUSS Cold-Formed Steel FramingKeysha ApriliaNo ratings yet

- PCI Hollowcore Specifications 4-8-11Document8 pagesPCI Hollowcore Specifications 4-8-11Roberto Pérez LeónNo ratings yet

- ITCC in Riyadh Residential Complex J10-13300 10200-1 Louvers and VentsDocument6 pagesITCC in Riyadh Residential Complex J10-13300 10200-1 Louvers and VentsuddinnadeemNo ratings yet

- Concrete Reinforcing SpecsDocument3 pagesConcrete Reinforcing Specsطه حلمىNo ratings yet

- MINISTRY HOUSING METAL RAILINGSDocument4 pagesMINISTRY HOUSING METAL RAILINGSmasoodaeNo ratings yet

- Metal Fabrications: Materials and ReferencesDocument21 pagesMetal Fabrications: Materials and ReferencesuddinnadeemNo ratings yet

- 09 22 16ssbDocument7 pages09 22 16ssbHanamanthNo ratings yet

- Alamein Downtown Towers Metal FabricationsDocument15 pagesAlamein Downtown Towers Metal FabricationsWENDING HUNo ratings yet

- 03 49 00 Glass Fiber Reinforced Concrete PanelsDocument15 pages03 49 00 Glass Fiber Reinforced Concrete PanelsSourav BasakNo ratings yet

- Architecturally Exposed Structural Steel PDFDocument8 pagesArchitecturally Exposed Structural Steel PDFJagatheesh RadhakrishnanNo ratings yet

- Bt4 Midterm OmañaDocument14 pagesBt4 Midterm OmañaDerick John RoselNo ratings yet

- Inspection & Test Plan Mechanical (ITP)Document6 pagesInspection & Test Plan Mechanical (ITP)hari banggaNo ratings yet

- Switchgear Pre-Commissioning ChecklistDocument2 pagesSwitchgear Pre-Commissioning Checklisthari banggaNo ratings yet

- Radial Spherical Plain Bearings Requiring Maintenance, Steel-On-Steel, UnsealedDocument1 pageRadial Spherical Plain Bearings Requiring Maintenance, Steel-On-Steel, Unsealedhari banggaNo ratings yet

- Pt. Indonesia Power Up Suralaya: Time Sheet Temuan Pekerjaan Diluar ScopeDocument1 pagePt. Indonesia Power Up Suralaya: Time Sheet Temuan Pekerjaan Diluar Scopehari banggaNo ratings yet

- 1 H BEAM 350x350 2 L 75x75x8: Sinar Agung NusantaraDocument1 page1 H BEAM 350x350 2 L 75x75x8: Sinar Agung Nusantarahari banggaNo ratings yet

- Oiles Bearing:: - Oil - Free - Maintenance - Free - High Performance - High QualityDocument1 pageOiles Bearing:: - Oil - Free - Maintenance - Free - High Performance - High Qualityhari banggaNo ratings yet

- Detail Schedule PabrikasiDocument1 pageDetail Schedule Pabrikasihari banggaNo ratings yet

- Infrastructure Finance Project Design and Appraisal: Professor Robert B.H. Hauswald Kogod School of Business, AUDocument2 pagesInfrastructure Finance Project Design and Appraisal: Professor Robert B.H. Hauswald Kogod School of Business, AUAida0% (1)

- Samples For Loanshyd-1Document3 pagesSamples For Loanshyd-1dpkraja100% (1)

- Detailed Lesson Plan in TechnologyDocument11 pagesDetailed Lesson Plan in TechnologyReshiela OrtizNo ratings yet

- Configuration Management and ISO 9001Document7 pagesConfiguration Management and ISO 9001Simone MeschinoNo ratings yet

- DMG48480F021 01WN DataSheetDocument16 pagesDMG48480F021 01WN DataSheeteminkiranNo ratings yet

- Hele 4 PPT - 2nd QT - Week 1Document47 pagesHele 4 PPT - 2nd QT - Week 1jerico juarezNo ratings yet

- Electrical Experimenter 1915-08Document1 pageElectrical Experimenter 1915-08GNo ratings yet

- Lesson Plan in ESPDocument4 pagesLesson Plan in ESPkaren daculaNo ratings yet

- Consumer Behaviour of Titan WatchesDocument57 pagesConsumer Behaviour of Titan Watchesmanu100% (1)

- Power Fresh 16Document3 pagesPower Fresh 16M. Ardi PrediyanaNo ratings yet

- Asian Paint FMVRDocument20 pagesAsian Paint FMVRdeepaksg787No ratings yet

- Day3 PESTLE AnalysisDocument13 pagesDay3 PESTLE AnalysisAmit AgrawalNo ratings yet

- Samsung (UH5003-SEA) BN68-06750E-01ENG-0812Document2 pagesSamsung (UH5003-SEA) BN68-06750E-01ENG-0812asohas77No ratings yet

- Abbadvant 800 XaDocument9 pagesAbbadvant 800 XaAlexNo ratings yet

- Arnica The Miracle Remedy - Case RecordsDocument4 pagesArnica The Miracle Remedy - Case Recordskaravi schiniasNo ratings yet

- "Network Security": Alagappa UniversityDocument1 page"Network Security": Alagappa UniversityPRADEEPRAJANo ratings yet

- Luxand FaceSDK DocumentationDocument117 pagesLuxand FaceSDK DocumentationrdhartzNo ratings yet

- Performance Evaluation of Root Crop HarvestersDocument15 pagesPerformance Evaluation of Root Crop HarvestersIJERDNo ratings yet

- Netutils ToturialDocument35 pagesNetutils ToturialLuis SanchoNo ratings yet

- Pertanyaan Dan Jawaban Interview Dengan Bahasa InggrisDocument2 pagesPertanyaan Dan Jawaban Interview Dengan Bahasa Inggrissan_idrus_sip99No ratings yet

- 4 Types and Methods of Speech DeliveryDocument2 pages4 Types and Methods of Speech DeliveryKylie EralinoNo ratings yet

- Hercules Segers - Painter EtchterDocument4 pagesHercules Segers - Painter EtchterArtdataNo ratings yet

- Astm D 4417Document4 pagesAstm D 4417Javier Celada0% (1)

- Examen TSMDocument4 pagesExamen TSMKaryna VeraNo ratings yet

- SW - Simulation - Product MatrixDocument2 pagesSW - Simulation - Product Matrixsamar2011No ratings yet

- Indigo Vision CatalogDocument117 pagesIndigo Vision CatalogWAEL50% (2)

- The History of Coins and Banknotes in Mexico: September 2012Document35 pagesThe History of Coins and Banknotes in Mexico: September 2012Mladen VidovicNo ratings yet

- Teaching English as a Second Language in Four PhasesDocument18 pagesTeaching English as a Second Language in Four PhasesVia Johnson100% (1)

- Engine Rear Oil Seal PDFDocument3 pagesEngine Rear Oil Seal PDFDIEGONo ratings yet

- WhatsoldDocument141 pagesWhatsoldLuciana KarajalloNo ratings yet